Abstract

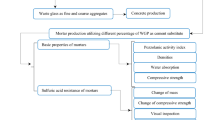

In this study, fine stone powder (FSP) generated in the process for producing crushed coarse and fine aggregate was used as a partial replacement for the fine aggregate. The durability of mortars was investigated under sulfate attack in terms of compressive strength loss, change in mass, and expansion. Cement mortars were made with the replacement rate of 0–30% of FSP for fine aggregate with two water-to-cement ratios of 48.5% and 58.5%. The prepared mortar specimens were immersed in 5% sodium and magnesium sulfate solutions for 365 days, and the changes in strength, mass, and length due to sulfate attack were estimated and compared according to ages (days). The strength loss rate of the specimen made with 15% FSP replacement immersed in sulfate solutions was less than the controlled specimen and the higher amount of FSP than 15% resulted in a significant strength loss. At the replacement level of 15% FSP, the mass loss and expansion were also less than that of the controlled specimen. The results illustrate that replacing the appropriate amount of FSP can improve the strength and sulfate resistance. In addition, it could be seen that the magnesium sulfate solution caused a more severe attack than the sodium solution.

Similar content being viewed by others

References

Ferrara L, Krelani V, Carsana M (2014) A “fracture testing” based approach to assess crack healing of concrete with and without crystalline admixtures. Constr Build Mater 68:535–551. https://doi.org/10.1016/j.conbuildmat.2014.07.008

Chan TK, Poh CK (2000) Behaviour of precast reinforced concrete pile caps. Constr Build Mater 14:73–78. https://doi.org/10.1016/S0950-0618(00)00006-4

Bengar HA, Shahmansouri AA, Sabet NKZ, Kabirifar K, Tam VWY (2020) Impact of elevated temperatures on the structural performance of recycled rubber concrete: experimental and mathematical modeling. Constr Build Mater 255:119374. https://doi.org/10.1016/j.conbuildmat.2020.119374

Skalny J, Marchand J, Older I (2003) Sulfate attack on concrete. Spon Press, Taylor & Francis e-Library. https://doi.org/10.4324/9780203301623

Bonen D (1993) A microstructural study of the effect produced by magnesium sulfate on plain and silica fume-bearing Portland cement mortars. Cem Concr Res 23(3):541–553. https://doi.org/10.1016/0008-8846(93)90004-S

Hekal EE, Kishar E, Mostafa H (2002) Magnesium sulfate attack on hardened blended cement pastes under different circumstances. Cem Concr Res 32:1421–1427. https://doi.org/10.1016/S0008-8846(02)00801-3

Turker F, Akoz F, Koral S, Yuzer N (1997) Effects of magnesium sulfate concentration on the sulfate resistance of mortars with and without silica fume. Cem Concr Res 27(2):205–214. https://doi.org/10.1016/S0008-8846(97)00009-4

Santhanam M, Cohen MD, Olek J (2003) Mechanism of sulfate attack: a fresh look—part 2. proposed mechanisms. Cem Concr Res 33:341–346. https://doi.org/10.1016/S0008-8846(02)00958-4

Neville A (2004) The confused world of sulfate attack on concrete. Cem Concr Res 34:1275–1296. https://doi.org/10.1016/j.cemconres.2004.04.004

Mehta PK (1983) Mechanism of sulfate of attack on portland cement concrete – another look. Cem Concr Res 13(3):401–406. https://doi.org/10.1016/0008-8846(83)90040-6

Najjar MF, Nehdi ML, Soliman AM, Azabi TM (2017) Damage mechanisms of two stage concrete exposed to chemical and physical sulfate attack. Constr Build Mater 137:141–152. https://doi.org/10.1016/j.conbuildmat.2017.01.112

Haynes H, O’Neill R, Neff M, Metha PK (2008) Salt weathering distress on concrete exposed to sodium sulfate environment. ACI Mater J 105(1):35–43. https://doi.org/10.14359/19205

Suleiman AR, Soliman AM, Nehdi ML (2014) Effect of surface treatment on durability of concrete exposed to physical sulfate attack. Constr Build Mater 73:674–681. https://doi.org/10.1016/j.conbuildmat.2014.10.006

Diamond S (1996) Delayed ettringite formation—processes and problems. Cem Concr Comp 18:205–215. https://doi.org/10.1016/0958-9465(96)00017-0

Yu C, Sun W, Scrivener K (2013) Mechanism of expansion of mortars immersed in sodium sulfate solutions. Cem Concr Res 43:105–111. https://doi.org/10.1016/j.cemconres.2012.10.001

Escadeillas G, Aubert J, Segerer M, Prince W (2007) Some factors affecting delayed ettringite formation in heat-cured mortars. Cem Concr Res 37:1445–1452. https://doi.org/10.1016/j.cemconres.2007.07.004

Huang Q, Wang C, Yang C, Zhou L, Yin J (2015) Accelerated sulfate attack on mortars using electrical pulse. Constr Build Mater 95:875–881. https://doi.org/10.1016/j.conbuildmat.2015.07.034

Nie L, Xu J, Bai E (2018) Dynamic stress–strain relationship of concrete subjected to chloride and sulfate attack. Constr Build Mater 165:232–240. https://doi.org/10.1016/j.conbuildmat.2018.01.044

Bellmann F, Stark J (2007) Prevention of thaumasite formation in concrete exposed to sulphate attack. Cem Concr Res 37(8):1215–1222. https://doi.org/10.1016/j.cemconres.2007.04.007

Wang Y, He X, Su Y, Ma B, Chu J, Jiang B (2018) Effect of aluminium phases on thaumasite formation in cement slurries containing limestone powder. Mag Concr Res 70(12):610–616. https://doi.org/10.1680/jmacr.16.00521

Blanco-Varela MT, Aguilera J, Martínez-Ramírez S (2006) Effect of cement C3A content, temperature and storage medium on thaumasite formation in carbonated mortars. Cem Concr Res 36(4):707–715. https://doi.org/10.1016/j.cemconres.2005.11.010

Irassar EF (2009) Sulfate attack on cementitious materials containing limestone filler —A review. Cem Concr Res 39(3):241–254. https://doi.org/10.1016/j.cemconres.2008.11.007

Ramyar K, Inan G (2007) Sodium sulfate attack on plain and blended cements. Build Environ 42(3):1368–1372. https://doi.org/10.1016/j.buildenv.2005.11.015

Rasheeduzzafar A-A, Abduljauwad SN, Maslehuddin M (1994) Magnesium-sodium sulfate attack in plain and blended cements. J Mater Civ Eng 6(2):201–222. https://doi.org/10.1061/(ASCE)0899-1561(1994)6:2(201)

Cyr M (2013) Influence of supplementary cementitious materials (SCMs) on concrete durability. In: Pacheco-Torgal F, Jalali S, Labrincha J, John VM (eds) Eco- efficient concrete. Woodhead Publishing, Cambridge, pp 153–197

Mulenga DM, Stark J, Nobst P (2003) Thaumasite formation in concrete and mortars containing fly ash. Cem Concr Compos 25(8):907–912. https://doi.org/10.1016/S0958-9465(03)00136-7

Tiburzi NB, Garcia J, Drimalas T, Folliard KJ (2020) Sulfate resistance of portland-limestone cement concrete systems: linking laboratory and field performances. Constr Build Mater 250:118750. https://doi.org/10.1016/j.conbuildmat.2020.118750

Radlinski M, Olek J (2012) Investigation into the synergistic effects in ternary cementitious systems containing portland cement, fly ash and silica fume. Cem Concr Compos 34(4):451–459. https://doi.org/10.1016/j.cemconcomp.2011.11.014

Hossack AM, Thomas MDA (2015) Varying fly ash and slag contents in Portland limestone cement mortars exposed to external sulfates. Constr Build Mater 78:333–341. https://doi.org/10.1016/j.conbuildmat.2015.01.030

Chen F, Gao J, Qi B, Shen D (2017) Deterioration mechanism of plain and blended cement mortars partially exposed to sulfate attack. Constr Build Mater 154:849–856. https://doi.org/10.1016/j.conbuildmat.2017.08.017

Irassar EF, Maio AD, Batic OR (1996) Sulfate attack on concrete with mineral admixtures. Cem Concr Res 26(1):113–123. https://doi.org/10.1016/0008-8846(95)00195-6

Bilal H, Chen T, Ren M, Gao X, Su A (2020) Influence of silica fume, metakaolin & SBR latex on strength and durability performance of pervious concrete. Constr Build Mater 275:122124. https://doi.org/10.1016/j.conbuildmat.2020.122124

Zhang J, Chen T, Gao X (2020) Incorporation of self-ignited coal gangue in steam cured precast concrete. J Clean Produc 292:126004. https://doi.org/10.1016/j.jclepro.2021.126004

Mo Z, Gao X, Su A (2020) Mechanical performances and microstructures of metakaolin contained UHPC matrix under steam conditions. Constr Build Mater 268:121112. https://doi.org/10.1016/j.conbuildmat.2020.121112

KS F 2527 (2020) Aggregates for concrete. Korea Standards and Certifications. KS, Eumseong, Korea (in Korean)

BS EN 12620 (2013) Aggregates for concrete. British Standards Institutions, BSI, London

AS 2758 (2009) Aggregates and rock for engineering purposes. Standards Australia, Sydney, NSW, Australia

Kronlof A (1994) Effect of very fine aggregate on concrete strength. Mater Struct 27:15–25. https://doi.org/10.1007/BF02472816

Koh KT, Ryu GS, Park JJ, Lee JH (2007) Effect of the fine particles of crushed sand on concrete qualities. J Kor Soc Civ Eng 27(1A):99–105 (in Korean)

Koehler EP, Fowler DW (2008) Dust-of-fracture aggregate microfines in self-consolidating concrete. ACI Mater J 105(2):165–173

Kang ST, Seo JY (2016) The Properties of concrete incorporating stone powders as part of fine aggregates. JKISMI 20(5):116–122 (in Korean)

Song JW, Choi JJ (2013) The influence of fine particles under 0.08 mm contained in aggregate on the characteristics of concrete. JKCI 25(3):347–354 (in Korean)

Monteiro PJM (1986) Improvement of the aggregate-cement paste transition zone by grain refinement of hydration products. In: Proceedings of 8th international congress on chemistry of cement, Rio, vol 3, pp 433–437

Aköz F, Türker F, Koral S, Yüzer N (1999) Effects of raised temperature of sulfate solutions on the sulfate resistance of mortars with and without silica fume. Cem Con Res 29(4):537–544. https://doi.org/10.1016/S0008-8846(98)00251-8

Saribas I, Cakir O (2017) Short-term effects of sodium sulfate and sodium chloride solutions on the strength and durability properties of hardened mortars. Euro J Sci Techno 6(10):38–47

Irassar EF, Bonavetti VL, Gonzalez M (2003) Microstructural study of sulfate attack on ordinary and limestone Portland cements at ambient temperature. Cem Con Res 33:31–41. https://doi.org/10.1016/S0008-8846(02)00914-6

El-Hachem R, Rozière E, Grondin F, Loukili A (2012) Multi-criteria analysis of the mechanism of degradation of Portland cement based mortars exposed to external sulphate attack. Cem Con Res 42(10):1327–1335. https://doi.org/10.1016/j.cemconres.2012.06.005

Acknowledgements

This research was supported by the Daegu University Research Grant (No. 20180550).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rajagopalan, S.R., Kang, ST. Evaluation of sulfate resistance of cement mortars with the replacement of fine stone powder. J Mater Cycles Waste Manag 23, 1995–2004 (2021). https://doi.org/10.1007/s10163-021-01272-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-021-01272-x