Abstract

An algorithm for determining the thickness of the olivine layer cut when determining charges of galactic nuclei from meteorites is presented. The calculation results related to the intersection points of nuclei trajectory projections on the crystal surface at different stages are presented. It is shown that the mechanism is valid to control cut operations when searching for traces of galactic nuclei in olivines from meteorites with good accuracy.

Similar content being viewed by others

In the Laboratory of Elementary Particles of the Lebedev Physical Institute, within the OLYMPIA project, tracks of superheavy nuclei in olivine crystals from meteorites are studied [1]. Individual crystal fragments are removed from a meteorite and are packed into an epoxy pellet. One such pellet 2 × 1 × 0.5 cm3 in size contains from several to twenty crystals. Figure 1 shows the micrograph of one such pellet. The processing procedure includes several stages including etching, the search for and processing tracks under a microscope, followed by cutting a 50–100-μm olivine layer. Then the procedure is repeated. The objective of the study is to construct the charge distribution of galactic superheavy elements (Z > 50) [1].

During processing, it becomes necessary to correct the cut layer thickness. This quantity is involved in the algorithm for calculating the track length and finally affects the nucleus charge estimate [2]. The full thickness of the cut layer consists of two parts. The first cut is associated with the necessity of removing the network on the etched crystal surface, consisting of many short tracks of iron group nuclei. The length of these tracks was 10–15 μm and the density was 106–107 cm–2. Figure 2 shows the example of microscopy images of such a network. Since these tracks complicate recognition and analysis of heavy nucleus tracks, precision grinding of the crystal surface to a depth of 15–20 μm is performed. As a result, the network of iron group nuclei is removed.

The second cut is the main olivine cut after etching and microscopy processing when preparing the next stage. This cut thickness is 50–100 μm depending on the results of the previous stage.

In the stage-by-stage processing of heavy nucleus tracks, a fraction of them having a sufficiently large angle to the crystal surface and with a sufficient energy is also detected at the next stage after cutting and grinding. In this case, the determination of the full track length and corresponding nucleus requires accurate knowledge of the cut thickness. This value is controlled immediately during cutting and grinding; however, an additional control is required to test their precision, because this affects the nucleus charge determination accuracy. To implement this control, a special algorithm was developed, whose essence is as follows.

The nuclei under study have significant masses and energies; therefore, their trajectories within olivine represent straight lines; in the microscopy images, their etched channels are seen as small segments of various length and thickness, lying on this straight line, which are projections of the etched channel on the crystal surface. Figure 3 shows the microscopy images of the same crystal from the pellet in Fig. 1 after the (a) first and (b) second stages. In this crystal, three tracks were detected, which appear at both stages (denoted by numerals 1, 2, and 3). The microscope equipment makes it possible to measure coordinates X, Y, and Z of the origin and end of the etched channel with high accuracy in the microscope coordinate system.

Before measurements, the microscope coordinate origin is set on the crystal image. Since a relatively thick olivine layer is cut, on the crystals, as a rule, there are no any labels (spots, scratches, and others) which can relate microscope and crystal coordinate systems at various stages.

In going to the next processing stage, a fraction of tracks of nuclei whose penetration depths to the crystal were longer than the cut thickness appears in the next stage. New traces are on the same straight lines, but their projections are displaced in comparison with projections at the previous stage. The displacement is related to the cut thickness and the track angle to the crystal surface. This angle can be calculated by the coordinates of the track origin and end; however, the displacement should be calculated by comparing the track trace images obtained at two stages. Unfortunately, as noted above, these two images have no common coordinate system. There is also no possibility of matching them using characteristic features on the surface (spots, scratches, and others) which can be used to join images, because they disappear after cutting. However, since etched channels have relatively long lengths in comparison with widths, their axis, i.e., the track direction can be well determined. The particle trajectory is the same at the first and second stages. Therefore, track direction projections can be matched; however, absolute referencing of channel projections to each other along the track cannot be performed even in this case, because the crystal coordinate systems are not matched in crystal images in different stages. Some other elements which would lead to such track matching are required.

As such elements, fixed points on the crystal surface can be used, which preserve their coordinates X and Y in the crystal coordinate system even after cutting layers of 50 μm and larger.

Such fixed points are, e.g., the intersection points of nucleus trajectory projections on the crystal surface, since these surfaces are parallel at various stages. Thus, having found the intersection point of two trajectories appearing at different stages, we can obtain the displacement vector between crystal coordinate systems (X, Y) at different stages. In this case, a comparison of the coordinates (X, Y) of nucleus entrance points into the crystal at different stages yields an accurate track displacement. Because the angle at which the nucleus enters the crystal, is known from geometrical parameters of the track, the cut layer thickness caused such displacement can be calculated.

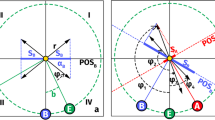

To demonstrate the capability of this procedure, tracks 1 and 2 shown in Fig. 3 were used. Figure 4 schematically shows the positions of these two tracks by arrows in the microscope coordinate system; these tracks appear at the first (vectors 11 and 21) and second (vector 12 and 22) processing stages, as well as extensions of trajectories of each track until their intersection.

Schematic image of the position of tracks 1 and 2 shown in Fig. 3, in the microscope coordinate system.

Arrow lengths correspond to lengths of measured track parts. Points A and B are the intersection points of trajectories. The dotted vector \(\vec {P}\) connecting these points is the vector of crystal coordinate system displacement at the first and second stages in the microscope coordinate system. Using this vector, we can join tracks in the common crystal coordinate system. For example, in Fig. 4 vectors 11 and 21 are displaced to positions I and II, respectively. Points of nucleus entrance into the crystal are on the crystal surface. In Fig. 4, arrow origins correspond to these points, so that points a and b are on the crystal surface at the first stage and points c and d are on the crystal surface at the second stage. Figure 4 shows the track projections onto the XY plane. The thickness of the cut layer is equal to the distance between crystal surfaces along the Z axis, i.e., in this case, to the difference between Z coordinates of track origins at the first and second stages. This quantity can be determined by formulas Zac = Lac ∙ tan(α), Zbd = Lbd ∙ tan(α), where Lij is the distance between points i and j in Fig. 4, Zij are the corresponding distances along Z, and α is the angle between the track and crystal surface.

The calculations performed for tracks 1 and 2 yield the values Zac = 48.6 μm and Zbd = 47.3 μm at a nominal thickness of 50 μm. Taking into account the third track in this crystal, as well as the tracks having extensions, we estimate the cut thickness for other crystals of this pellet as Z = 49.6 ± 0.5 μm.

Thus, the mechanism under consideration functions with good accuracy and is successfully applied to control cut operations in the search for traces of galactic nuclei in olivines from meteorites.

Along with the problem of improving the cut thickness, the procedure under consideration makes it possible to prevent errors in the cutting and grinding procedures. For example, thickness testing in one of pellets showed the result Z = 16 μm, which is not in line with the expected value of 55 μm. More comprehensive testing showed that the grinding procedure was performed whereas the principal cut was missed. Thus, it became possible to avoid overestimated nucleus charges.

One of the most significant and urgent problems of modern nuclear physics and astrophysics is the search for trans-Fermi nuclei with charges Z > 100 in nature. It is clear that each processing stage is of great importance in the complex procedure of the search for galactic cosmic ray tracks in olivine crystals from meteorites. The method for testing the cut layer thickness is described in this paper in detail for the first time and is used in the original technique for automated searching and processing tracks [3]. The method allows improving the determination accuracy of nuclei charges and acquiring unique statistics on the charge distribution of more than 21 000 nuclei of galactic cosmic rays [4].

REFERENCES

Alexeev, V., Bagulya, A., Chernyavsky, M., Gippius, A., Goncharova, L., et al., Charge spectrum of heavy and superheavy components of galactic cosmic rays: results of the OLIMPIYA experiment, Astrophys. J., 2016, vol. 829, no. 2, p. 120. https://doi.org/10.3847/0004-637X/829/2/120

Aleksandrov, A.B., Bagulya, A.V., Vladimirov, M.S., Goncharov, L.A., Ivliev, A.I., Kalinina, G.V., Kashkarov, L.L., Konovalov, N.S., Okatieva, N.M., Polukhina, N.G., Rusetskii, A.S., Starkov, N.I., and Tsarev, V.A., Technique for determining the charge of cosmic ray nuclei by tracks in olivine crystals from meteorites, Bull. Lebedev Phys. Inst., 2008, vol. 35, no. 7, pp. 205–210. https://doi.org/10.3103/S1068335608070038

Alekseev, V.A., Bagulya, A.V., Volkov, A.E., Gippius A.A., Goncharova, L.A., et al., Search for the “stability island” of superheavy nuclei using natural track detectors, Bull. Lebedev Phys. Inst., 2017, vol. 44, no. 11, pp. 336–339. https://doi.org/10.3103/S1068335617110069

Aleksandrov, A.B., Alekseev, V.A., Bagulya, A.V., Dashkina, A.B., Chernyavskiy, M.M., et al., Determination of charges of superheavy nuclei in finding them in nature, Bull. Lebedev Phys. Inst., 2019, vol. 46, no. 12, pp. 383–386. https://doi.org/10.3103/S1068335619120042

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Kazantsev

About this article

Cite this article

Soe, T.N., Polukhina, N.G. & Starkov, N.I. Algorithm for Determining the Thickness of the Cut Olivine Layer when Determining Charges of Galactic Nuclei. Bull. Lebedev Phys. Inst. 48, 131–134 (2021). https://doi.org/10.3103/S1068335621050080

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068335621050080