Abstract

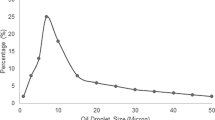

Nitrile butadiene rubber latex/graphene oxide (NBR/GO) membranes were fabricated by latex compounding and curing method. This was a new method to produce membrane, thus, the steps in the production were needed to be evaluated to optimize the performance of the membrane. Degassing is an important step in the production of polymer-based membrane through the common phase inversion method. In this research, the need to perform the degassing step in the latex compounding and curing method was confirmed through the morphology study, permeation flux, and oil rejection rate performance of the new NBR/GO membrane. Membrane without-degassing was prepared for comparison, as well. The highest oil rejection rate was found to be 95.04% with permeation flux of 438.43 Lm−2 h−1 for the membrane without-degassing, at the operating pressure of 0.3 bar for 1000 ppm of oily wastewater concentration. While for degassed membrane, the oil rejection rate and permeation flux at the same filtration conditions were found to be 91.88% and 2720.53 Lm−2 h−1, respectively. Surface morphology of the membranes showed ridges and grooves as a result of folds that provided effective surface area for filtration of oily wastewater. From these results, it could be concluded that the degassing step could be eliminated in the preparation of the membrane through the latex compounding and curing method. This decision will reduce the time, cost, and energy for producing the membranes.

Similar content being viewed by others

Code availability

The code availability is not applicable throughout this research.

References

Daud NM, Abdullah SRS, Hasan HA, Yaakob Z (2015) Production of biodiesel and its wastewater treatment technologies: a review. Process Saf Environ 94:487–508

Jamly S, Giwa A, Hasan SW (2015) Recent improvements in oily wastewater treatment: progress, challenges, and future opportunities. J Environ Sci 37:15–30

Yu L, Han M, He F (2017) A review of treating oily wastewater. Arab J Chem 10:S1913–S1922

Tanudjaja HJ, Hejase CA, Tarabara VV, Fane AG, Chen JW (2019) Membrane-based separation for oily wastewater: a practical perspective. Water Res 156:347–365

Kalla S (2021) Use of membrane distillation for oily wastewater treatment – a review. J Environ Chem Eng 9:104641

Chen ASC, Flynn JT, Cook RG, Casaday AL (1991) Removal of oil, grease, and suspended solids from produced water with ceramic crossflow microfiltration. SPE Prod Eng 6:131–136

Changmai M, Pasawan M, Purkait MK (2019) Treatment of oily wastewater from drilling site using electrocoagulation followed by microfiltration. Sep Purif Tech 210:463–472

Ahmad T, Guria C, Mandal A (2018) Optimal synthesis and operation of low-cost polyvinyl chloride/bentonite ultrafiltration membranes for the purification of oilfield produced water. J Memb Sci 564:859–877

Huang S, Ras RHA, Tian X (2018) Antifouling membranes for oily wastewater treatment: interplay between wetting and membrane fouling. Curr Opin Colloid Interface Sci 36:90–109

Park HB, Kamcev J, Robeson LM, Elimelech M, Freeman BD (2017) Maximizing the right stuff: the trade-off between membrane permeability and selectivity. Science 356:eaab0530. https://doi.org/10.1126/science.aab0530

Yang T, Ma Z-F, Yang Q-Y (2011) Formation and characterization of Kaolin/MnO2 bi-layer composite dynamic membrane for oily wastewater treatment: effect of solution conditions. Desalination 270:50–56

Ahmad T, Guria C, Mandal A (2018) Synthesis, characterization and performance studies of mixed-matrix poly(vinyl chloride)-bentonite ultrafiltration membrane for the treatment of saline oily wastewater. Process Saf Environ 116:703–717

Salahi A, Gheshlaghi A, Mohammadi T, Madaeni SS (2010) Experimental performance evaluation of polymeric membranes for treatment of an industrial oily wastewater. Desalination 262:235–242

Zavastin D, Cretescu I, Bezdadea M, Bourceanu M, Drăgan M, Lisa G, Mangalagiu I, Vasić V, Savić J (2010) Preparation, characterization and applicability of cellulose acetate–polyurethane blend membrane in separation techniques. Surf A Physiochem Eng Asp 370:120–128

Ma W, Li Y, Zhang M, Gao S, Cui J, Huang C, Fu G (2020) Biomimetic durable multifunctional self-cleaning nanofibrous membrane with outstanding oil/water separation, photodegradation of organic contaminants, and antibacterial performances. ACS Appl Mater Interfaces 12:34999–35010

Ma W, Ding Y, Zhang M, Gao S, Li Y, Huang C, Fu G (2020) Nature-inspired chemistry toward hierarchical superhydrophobic, antibacterial and biocompatible nanofibrous membranes for effective UV-shielding, self-cleaning and oil-water separation. J Hazard Mater 384:121476

Chakrabarty B, Ghoshal AK, Purkait MK (2008) Ultrafiltration of stable oil-in-water emulsion by polysulfone membrane. J Membr Sci 325:427–437

Chakrabarty B, Ghoshal AK, Purkait MK (2010) Cross-flow ultrafiltration of stable oil-in-water emulsion using polysulfone membrane. Chem Eng J 165:447–456

Kumar S, Guria C, Mandal A (2015) Synthesis, characterization and performance studies of polysulfone/bentonite nanoparticles mixed-matrix ultra-filtration membranes using oil field produced water. Sep Purif Tech 150:145–158

Ahmad T, Guria C, Mandal A (2020) Enhanced performance of salt-induced pluronic F127 and bentonite blended polyvinyl chloride ultrafiltration membrane for the processing of oilfield produced water. J Water Process Eng 34:101144

Zhang Z, Sun J, Lai Y, Wang Y, Liu X, Shi S, Chen X (2018) Effects of thermal aging on uniaxial ratcheting behavior of vulcanised natural rubber. Polym Test 70:102–110

Shen M, Peng X, Meng X, Zheng J, Zhu M (2016) Fretting wear behavior of acrylonitrile-butadiene rubber (NBR) for mechanical seal applications. Tribol Int 93:419–428

Zhao Y, Yu W, Li R, Xu Y, Liu Y, Sun T, Shen L, Lin H (2019) Electric field endowing the conductive polyvinylidene fluoride (PVDF)-graphene oxide (GO)-nicel (Ni) membrane with high-efficient performance for dye wastewater treatment. Appl Surf Sci 483:1006–1016

Lu J, Gu Y, Chen Y, Yan X, Guo Y, Lang W (2019) Ultrahigh permeability of graphene-based membranes by adjusting D-spacing with poly (ethylene imine) for the separation of dye wastewater. Sep Purif Technol 210:737–745

Moradi R, Karimi-Sabet J, Shariaty-Niassar M, Amini Y (2016) Air gap membrane distillation for enrichment of H218O isotopomers in natural water using poly(vinylidene fluoride) nanofibrous membrane. Chem Eng Process 100:26–36

Su C, Li Y, Cao H, Lu C, Li Y, Chang J, Duan F (2019) Novel PTFE hollow fibre membrane fabricated by emulsion electrospinning and sintering for membrane distillation. J Memb Sci 583:200–208

Bhran A, Shoaib A, Elsadeq D, El-gendi A, Abdallah H (2018) Preparation of PVC/PVP composite polymer membranes via phase inversion process for water treatment purposes. Chin J Chem Eng 26:715–722

Liu H, Liao X (2019) The effects of fluorocarbon special surfactant (FS-30) additive on the phase inversion, morphology and separation performance of poly(vinylidene fluoride) (PVDF) membranes. Sep Purif Technol 212:619–631

Korolkov IV, Gorin YG, Yeszhanov AB, Kozlovskiy AL, Zdorovets MV (2018) Preparation of PET track-etched membranes for membrane distillation by photo-induced graft polymerization. Mater Chem Phys 205:55–63

Huang Y, Huang Q, Liu H, Zhang C, You Y, Li N, Xiao C (2017) Preparation, characterization and applications of electrospun ultrafine fibrous PTFE porous membranes. J Membr Sci 523:317–326

Zaaba NI, Foo KL, Hashim U, Tan SJ, Liu W, Voon CH (2017) Synthesis of graphene oxide using modified Hummers method: solvent influence. Procedia Eng 184:467–477

Mensah B, Kim S, Arepalli S, Nah C (2014) A study of graphene oxide-reinforced rubber nanocomposite. J App Polym Sci 131:40640. https://doi.org/10.1002/app.40640

Malkin AY, Isayev AI (2012) Rheology: concepts, methods, and applications, 2nd edn. ChemTec Publishing, Toronto

Papageorgiou DG, Kinloch AI, Young RJ (2017) Mechanical properties of graphene and graphene-based nanocomposites. Prog Mater Sci 90:75–127

Perez LD, Zuluaga MA, Kyu T, Mark JE, Lopez BL (2009) Preparation, characterization, and physical properties of multiwall carbon nanotube/elastomer composites. Polym Eng Sci 49:866–874

Tummons E, Han Q, Tanudjaja HJ, Hejase CA, Chew JW, Tarabara VV (2020) Membrane fouling by emulsified oil: a review. Sep Purif Technol 248:116919

Yu L, Kanezashi M, Nagasawa H, Tsuru T (2020) Phase inversion/sintering-induced porous ceramic microsheet membranes for high-quality separation of oily wastewater. J Membr Sci 595:117477

Golshenas A, Sadeghian Z, Ashrafizadeh SN (2020) Performance evaluation of a ceramic-based photocatalytic membrane reactor for treatment of oily wastewater. J Water Process Eng 36:101186

Monash P, Pugazhenthi G (2011) Effect of TiO2 addition on the fabrication of ceramic membrane supports: a study on the separation of oil droplets and bovine serum albumin (BSA) from its solution. Desalination 279:104–114

Suresh K, Srinu T, Ghoshal AK, Pugazhenthi G (2016) Preparation and characterization of TiO2 and γ-Al2O3 composite membranes for the separation of oil-in-water emulsions. RSC Adv 6:4877–4888

Acknowledgements

Throughout the research, T-J Yong was assisted by Mr. S-J Ding under the supervision of Dr. Y. Munusamy.

Funding

This research is funded by the Centre for Environment and Green Technology (CEGT) with vote account number V26000.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest and this research has not been carried out yet.

Rights and permissions

About this article

Cite this article

Yong, TJ., Munusamy, Y., Ding, SJ. et al. Fabrication of a novel latex-based membrane for oily wastewater filtration: effect of degassing on the properties of membrane. Iran Polym J 30, 989–1000 (2021). https://doi.org/10.1007/s13726-021-00954-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00954-5