Abstract

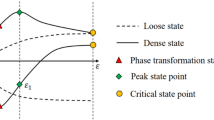

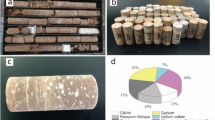

A geosynthetic liner system that consists of geomembrane (GMB) and geosynthetic clay liner (GCL) is vital for landfill stability analysis and it is essential to investigate the shear characteristics of GMB/GCL interface. This paper introduces a new direct shear apparatus for various geosynthetic interfaces with innovative designing, and using this apparatus 48 shear test sets of four GMB/GCL interface types are conducted under a normal stress level of 100–500 kPa and a shear rate of 0.1–100 mm/min. Effects of the surface roughness of GMB and the hydration condition of GCL on the shear stress–displacement relationship and shear strength of interfaces are investigated. Results show that the evolution of physical phenomena from shear deformation of GCL (denoted as shear phase) to frictional slip between GMB and GCL (denoted as friction phase) occurs at the critical state of peak shear strength where GMB/GCL interfaces provide the largest shear resistance. For GMB/hydrated GCL, shear phase can be further divided into pure shear phase and reinforced shear phase by initial peak strength. Thus, phased shear mechanism of GMB/GCL interface is revealed with explanations on physical and mechanical results. Some future prospects on GMB/GCL interfaces are also proposed.

Similar content being viewed by others

Availability of data and materials

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- GCL:

-

Geosynthetic clay liner

- UGCL:

-

Unhydrated geosynthetic clay liner

- HGCL:

-

Hydrated geosynthetic clay liner

- GMB:

-

Geomembrane

- GMBS:

-

Smooth geomembrane

- GMBX:

-

Textured geomembrane

- HDPE:

-

High-density polyethylene

- NP:

-

Needle-punched

- NW:

-

Nonwoven

References

ASTM (2017) Standard test method for determining the coefficient of soil and geosynthetic or geosynthetic and geosynthetic friction by the direct shear method. American Society for Testing and Materials, ASTM D5321/D5321M-17, West Conshohocken, Pennsylvania, USA. https://doi.org/10.1520/D5321_D5321M-17

ASTM (2013) Standard test method for determining the internal and interface shear resistance of geosynthetic clay liner by the direct shear method. American Society for Testing and Materials, ASTM D6243/D6243M-13a, West Conshohocken, Pennsylvania, USA

Bacas BM, Cañizal J, Konietzky H (2015) Shear strength behavior of geotextile/geomembrane interfaces. J Rock Mech Geotech Eng 7:638–645. https://doi.org/10.1016/j.jrmge.2015.08.001

Briançon L, Girard H, Poulain D (2002) Slope stability of lining systems-experimental modeling of friction at geosynthetic interfaces. Geotext Geomembr 20:147–172. https://doi.org/10.1016/S0266-1144(02)00009-2

Carbone L, Gourc JP, Carrubba P, Pavanello P, Moraci N (2015) Dry friction behaviour of a geosynthetic interface using inclined plane and shaking table tests. Geotext Geomembr 43:293–306. https://doi.org/10.1016/j.geotexmem.2015.05.002

Chang JY, Feng SJ, Zheng QT, Shen Y (2020) Cyclic shear behavior of GMB/GCL composite liner. Geotext Geomembr 49(3):593–603

Dickinson S, Brachman RWI (2006) Deformations of a geosynthetic clay liner beneath a geomembrane wrinkle and coarse gravel. Geotext Geomembr 24:285–298

Esterhuizen JJB, Filz GM, Duncan JM (2001) Constitutive behavior of geosynthetic interfaces. J Geotech Geoenviron Eng 127:834–840. https://doi.org/10.1061/(ASCE)1090-0241(2001)127:10(834)

Feng SJ, Chang JY, Chen HX (2018) Seismic analysis of landfill considering the effect of GM-GCL interface within liner. Soil Dyn Earthq Eng 107:152–163

Feng SJ, Chang JY, Chen HX, Zhang DM (2019) Numerical analysis of earthquake-induced deformation of liner system of typical canyon landfill. Soil Dyn Earthq Eng 116:96–106. https://doi.org/10.1016/j.soildyn.2018.10.006

Feng SJ, Lu SF (2016) Repeated shear behaviors of geotextile/geomembrane and geomembrane/clay interfaces. Environ Earth Sci 75:1–13. https://doi.org/10.1007/s12665-015-4994-2

Feng SJ, Shi JL, Shen Y, Chen HX, Chang JY, Wang HT (2020) Experimental investigation on the shear strength of GM/CCL composite liner interface due to monotonic loading. Environ Geotech. https://doi.org/10.1680/jenge.19.00014

Fox PJ, Nye CJ, Morrison TC, Hunter JG, Olsta JT (2006) Large dynamic direct shear machine for geosynthetic clay liners. Geotech Test J 29:392–400. https://doi.org/10.1520/GTJ100183

Fox PJ, Ross JD (2011) Relationship between NP GCL internal and HDPE GMX/NP GCL interface shear strengths. J Geotech Geoenviron Eng 137:743–753

Fox PJ, Ross JD, Sura JM, Thiel RS (2011) Geomembrane damage due to static and cyclic shearing over compacted gravelly sand. Geosynth Int 18:272–279

Fox PJ, Rowland MG, Scheithe JR, Davis KL, Supple MR, Crow CC (1997) Design and evaluation of a large direct shear machine for geosynthetic clay liners. Geotech Test J 20:279–288

Gilbert RB, Bryne RJ (1996) Strain-softening behavior of waste containment system interfaces. Geosynth Int 3:181–203. https://doi.org/10.1680/gein.3.0059

Hillman RP, Stark TD (2001) Shear strength characteristics of PVC geomembrane-geosynthetic interfaces. Geosynth Int 2:135–162

Jones DRV, Dixon N (1996) Shear strength properties of geomembrane/geotextile interfaces. Geosynth Int 3:181–200

Kavazanjian E, Gutierrez A (2017) Large scale centrifuge test of a geomembrane-lined landfill subject to waste settlement and seismic loading. Waste Manage 68:252–262

Kishida H, Uesugi M (1987) Tests of the interface between sand and steel in the simple shear apparatus. Géotechnique 37(1):45–52. https://doi.org/10.1680/geot.1987.37.1.45

Koerner GR, Narej D (2005) Direct shear database of Geosynthetic-to-Geosynthetic and Geosynthetic-to-Soil Interfaces. Geosynthetic Research Institute, Folsom

Li LH, Wang Q, Wang NX, Wang JP (2009) Vacuum dewatering and horizontal drainage blankets: a method for layered soil reclamation. Bull Eng Geol Environ 68:277–285. https://doi.org/10.1007/s10064-009-0200-7

McBean EA, Rovers FA (1995) Solid waste landfill engineering and design. Prentice Hall, Upper Saddle River

Narejo DB (2003) A simple tilt table device to measure index friction angle of geosynthetics. Geotext Geomembr 21:49–57. https://doi.org/10.1016/S0266-1144(02)00035-3

Navayogarajah N, Desai CS, Kiousis PD (1992) Hierarchical single-surface model for static and cyclic behavior of interfaces. J Eng Mech 118:990–1011

Pitanga HN, Gourc J, Vilar OM (2009) Interface shear strength of geosynthetics: evaluation and analysis of inclined plane tests. Geotext Geomembr 27:435–446. https://doi.org/10.1016/j.geotexmem.2009.05.003

Ross JD (2009) Static and dynamic shear strength of a geomembrane/geosynthetic clay liner interface. Master thesis, The Ohio State University

Ross JD, Fox PJ (2015) Dynamic shear strength of GMX/GCL composite liner for monotonic loading. J Geotech Geoenviron Eng 141:04015026. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001198

Rowe RK, Ewais AMR (2015) Ageing of exposed geomembranes at locations with different climatological conditions. Can Geotech J 52:326–343

Sarsby RW (2006) Geosynthetics in civil engineering. Woodhead Publishing, Cambridge

Stren AN (2009) Dynamic shear behavior of a needle-punched geosynthetic clay liner/geomenbrane interface at a high normal stress. The Ohio State University Master thesis

Thielmann SS, Fox PJ, Athanassopoulos C (2016) Shear strength of GMX/GCL composite liner under high normal stress. J Geotech Geoenviron Eng 142:04016005

Thusyanthan NI, Madabhushi SPG, Singh S (2006) Centrifuge modeling of solid waste landfill systems-Part 2: centrifuge testing of model waste. Geotech Test J 29:223–229

Triplett EJ, Fox PJ (2001) Shear strength of HDPE geomembrane/geosynthetic clay liner interfaces. J Geotech Geoenviron Eng 127:543–552

Uesugi M, Kishida H (1986) Frictional resistance at yield between dry sand and mild steel. Soils Found 26(4):139–149. https://doi.org/10.3208/sandf1972.26.4_139

Vukelic A, Szavits-Nossan A, Kvasnicka P (2008) The influence of bentonite extrusion on shear strength of GCL/geomembrane interface. Geotext Geomembr 26:82–90

Zhang G, Zhang JM (2006) Large-scale apparatus for monotonic and cyclic soil-structure interface test. Geotech Test J 29:401–408. https://doi.org/10.1520/GTJ100225

Acknowledgements

The authors would like to greatly acknowledge all these financial supports and express the most sincere gratitude.

Funding

This work was supported by the National Natural Science Foundation of China under Grant Nos. 41931289, 41725012 and 42007249, the Shanghai Science and Technology Innovation Action Plan under Grant No. 20DZ1203402 and the China Postdoctoral Science Foundation under Grant No. 2020M671218.

Author information

Authors and Affiliations

Contributions

Shi-Jin Feng contributed to conceptualization, writing—review and editing, and supervision. Yang Shen provided methodology and performed formal analysis and investigation. Qi-Teng Zheng performed formal analysis and investigation and writing—original draft preparation. Jia-Liang Shi provided methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Feng, SJ., Shen, Y., Zheng, QT. et al. Multi-functional direct shear apparatus for geosynthetic interfaces with its application on various GMB/GCL interfaces. Acta Geotech. 17, 993–1008 (2022). https://doi.org/10.1007/s11440-021-01279-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-021-01279-6