Abstract

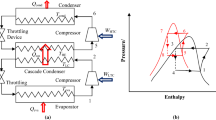

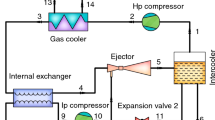

In this paper, thermo-economic optimization and comparative analysis of a cascade refrigeration system configured with flash gas removal in its high-temperature cycle (HTC) and flash intercooling with indirect subcooling in lower temperature cycle (LTC) using different natural refrigerant pairs is performed. Thermo-economic optimization is carried out to maximize the exergetic efficiency and minimize the overall cost rate. The optimization model involves six design variables which include subcooling and de-superheating parameters, LTC evaporation and condensation temperatures, HTC condenser temperature and cascade temperature difference. The comparative analysis of twenty-two natural refrigerant pairs based on the results of thermodynamic and economic optimizations reveals that R717-R290 is most efficient pair and R290-R1150 is least efficient refrigerant pair thermodynamically whereas R717-R1270 is the best and R600a-R290 is the worst pair economically. Seven potential refrigerant pairs are chosen via the thermodynamic and economic optimization results and they are further compared based on their performances obtained through multi-objective optimization (maximization of exergetic efficiency and minimization of total cost rate). Multi-objective genetic algorithm is used for optimization which results in seventy non-dominated Pareto optimal solutions where the TOPSIS method is used to select a unique solution for each refrigerant pair. A comparison of refrigerant pairs using these unique solutions shows that R717-R1270 is the best refrigerant pair for the cascade system under consideration. It is also found that R717-R1270 results in 7.77% rise in COP and 5.32% reduction in overall cost when compared with NH3–CO2 refrigerant pair working under identical operating conditions.

Similar content being viewed by others

Availability of Data and Material

All the data generated or analysed in current study is available from corresponding author on reasonable request.

Code Availability

Codes used in the current study are available from corresponding author on reasonable request.

Abbreviations

- CFC:

-

Chlorofluorocarbon

- COP:

-

Coefficient of performance

- \(F\) :

-

Correction factor

- GWP:

-

Global warming potential

- \(h\) :

-

Specific enthalpy (kJ/kg)

- HCFC:

-

Hydrochlorofluorocarbon

- HFC:

-

Hydrofluorocarbon

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- ODP:

-

Ozone depletion potential

- \(p\) :

-

Pressure (kPa)

- \(\dot{Q}\) :

-

Heat flow rate (kW)

- \(s\) :

-

Specific entropy (kJ/kgK)

- \(T\) :

-

Temperature (°C)

- \(\Delta T_{{{\text{lm}}}}\) :

-

Logarithmic mean temperature difference (K)

- \(U\) :

-

Overall heat transfer coefficient (kW/m2K)

- \(\dot{V}\) :

-

Volume flow rate (m3/s)

- \(\dot{W}\) :

-

Work input (kW)

- \(Z\) :

-

Capital cost ($)

- \(\dot{Z}\) :

-

Capital cost rate ($/year

- \(\alpha _{{{\text{el}}}}\) :

-

Energy charge ($/kWh)

- \(\phi\) :

-

Maintenance factor

- \(\eta\) :

-

Energy efficiency (%)

- \(\psi\) :

-

Exergy efficiency (%)

- \(\delta\) :

-

Pressure ratio

- \(\Delta\) :

-

Difference

- $:

-

US dollar

- 0:

-

Ambient state

- \({\text{ca,~i}}\) :

-

Condenser air inlet

- \({\text{ca,~e}}\) :

-

Condenser air exit

- \({\text{cas}}\) :

-

Cascade

- \({\text{cc}}\) :

-

Cascade condenser

- \({\text{cond}}\) :

-

Condenser

- \({\text{comp}}\) :

-

Compressor

- \({\text{cs}}\) :

-

Cold space

- \({\text{e}}\) :

-

Exit

- \({\text{ea,~i}}\) :

-

Evaporator air inlet

- \({\text{ea,~e}}\) :

-

Evaporator air exit

- \({\text{el}}\) :

-

Electrical

- \({\text{env}}\) :

-

Environmental

- \({\text{evap}}\) :

-

Evaporator

- \({\text{i}}\) :

-

Inlet

- \(k\) :

-

kth component

- \({\text{m}}\) :

-

Mechanical

- \({\text{op}}\) :

-

Operational

- \({\text{s}}\) :

-

Isentropic

- \({\text{sup}}\) :

-

Superheat

References

Park, H.; Kim, D.H.; Kim, M.S.: Thermodynamic analysis of optimal intermediate temperatures in R134a–R410A cascade refrigeration systems and its experimental verification. Appl. Therm. Eng. 54, 319–327 (2013). https://doi.org/10.1016/j.applthermaleng.2013.01.005

Dubey, A.M.; Kumar, S.; Agrawal, G.D.: Thermodynamic analysis of a transcritical CO2/propylene (R744–R1270) cascade system for cooling and heating applications. Energy Convers Manage. 86, 774–783 (2014). https://doi.org/10.1016/j.enconman.2014.05.105

Emani, M.S.; Mandal, B.K.: The use of natural refrigerants in refrigeration and air conditioning systems: a review. IOP Conf. Ser. Mater. Sci. Eng. 377, 012064 (2018). https://doi.org/10.1088/1757-899X/377/1/012064

Abas, N.; Kalair, A.R.; Khan, N.; Haider, A.; Saleem, Z.; Saleem, M.S.: Natural and synthetic refrigerants, global warming: a review. Renew. Sustain. Energy Rev. 90, 557–569 (2018). https://doi.org/10.1016/j.rser.2018.03.099

Bingming, W.; Huagen, W.; Jianfeng, L.; Ziwen, X.: Experimental investigation on the performance of NH3/CO2 cascade refrigeration system with twin-screw compressor. Int. J. Refrig. 32, 1358–1365 (2009). https://doi.org/10.1016/j.ijrefrig.2009.03.008

Bhattacharyya, S.; Garai, A.; Sarkar, J.: Thermodynamic analysis and optimization of a novel N2O-CO2 cascade system for refrigeration and heating. Int. J. Refrig. 32, 77–84 (2009). https://doi.org/10.1016/j.ijrefrig.2008.09.008

Lee, T.S.; Liu, C.H.; Chen, T.W.: Thermodynamic analysis of optimal condensing temperature of cascade-condenser in CO2/NH3 cascade refrigeration systems. Int. J. Refrig. 29, 1100–1108 (2006). https://doi.org/10.1016/j.ijrefrig.2006.03.003

Bhattacharyya, S.; Bose, S.; Sarkar, J.: Exergy maximization of cascade refrigeration cycles and its numerical verification for transcritical CO2-C3H8 system. Int. J. Refrig. 30, 624–632 (2007). https://doi.org/10.1016/j.ijrefrig.2006.11.008

Getu, H.M.; Bansal, P.K.: Thermodynamic analysis of an R744–R717 cascade refrigeration system. Int. J. Refrig. 31, 45–54 (2008). https://doi.org/10.1016/j.ijrefrig.2007.06.014

Mosaffa, A.H.; Farshi, L.G.; Infante Ferreira, C.A.; Rosen, M.A.: Exergoeconomic and environmental analyses of CO2/NH3 cascade refrigeration systems equipped with different types of flash tank intercoolers. Energy Convers. Manage. 117, 442–453 (2016). https://doi.org/10.1016/j.enconman.2016.03.053

Dopazo, J.; Fernández-Seara, J.; Sieres, J.; Uhía, F.J.: Theoretical analysis of a CO2–NH3 cascade refrigeration system for cooling applications at low temperatures. Appl. Therm. Eng. 29, 1577–1583 (2009). https://doi.org/10.1016/j.applthermaleng.2008.07.006

Dopazo, J.; Fernández-Seara, J.: Experimental evaluation of a cascade refrigeration system prototype with CO2 and NH3 for freezing process applications. Int. J. Refrig. 34, 257–267 (2011). https://doi.org/10.1016/j.ijrefrig.2010.07.010

Yarmohammadi, S.; Mohammadzadeh, K.; Farhadi, M.; Hajimiri, H.; Modir, A.: Multi-objective optimization of thermal and flow characteristics of R-404A evaporation through corrugated tubes. J. Energy Storage. 27, 101137 (2020). https://doi.org/10.1016/j.est.2019.101137

Rezayan, O.; Behbahaninia, A.: Thermoeconomic optimization and exergy analysis of CO2/NH3 cascade refrigeration systems. Energy 36, 888–895 (2011). https://doi.org/10.1016/j.energy.2010.12.022

Aminyavari, M.; Naja, B.; Shirazi, A.; Rinaldi, F.: Exergetic, economic and environmental (3E) analyses, and multi-objective optimization of a CO2/NH3 cascade refrigeration system. Appl. Therm. Eng. 65, 42–50 (2014). https://doi.org/10.1016/j.applthermaleng.2013.12.075

Eini, S.; Shahhosseini, H.; Delgarm, N.; Lee, M.; Bahadori, A.: Multi-objective optimization of a cascade refrigeration system: exergetic, economic, environmental, and inherent safety analysis. Appl. Therm. Eng. 107, 804–817 (2016). https://doi.org/10.1016/j.applthermaleng.2016.07.013

Soltani, R.; Dincer, I.; Rosen, M.A.: Optimization of a cascade refrigeration system using C3H8 in high temperature circuit (HTC) and a mixture of C2H6/CO2 in low temperature circuit (LTC). Appl. Therm. Eng. 104, 96–103 (2016). https://doi.org/10.1016/j.applthermaleng.2016.05.059

Kilicarslan, A.; Hosoz, M.: Energy and irreversibility analysis of a cascade refrigeration system for various refrigerant couples. Energy Convers. Manage. 51, 2947–2954 (2010). https://doi.org/10.1016/j.enconman.2010.06.037

Sun, Z.; Liang, Y.; Liu, S.; Ji, W.; Zang, R.; Liang, R.: Comparative analysis of thermodynamic performance of a cascade refrigeration system for refrigerant couples R41/404A and R23/R404A. Appl. Energy. 184, 19–25 (2016). https://doi.org/10.1016/j.apenergy.2016.10.014

Sun, Z.; Wang, Q.; Xie, Z.; Liu, S.; Su, D.; Cui, Q.: Energy and exergy analysis of low GWP refrigerants in cascade refrigeration system. Energy 170, 1170–1180 (2019). https://doi.org/10.1016/j.energy.2018.12.055

Sun, Z.; Wang, Q.; Dai, B.; Wang, M.; Xie, Z.: Options of low global warming potential refrigerant group for a three-stage cascade refrigeration system. Int. J. Refrig. 100, 471–483 (2019). https://doi.org/10.1016/j.ijrefrig.2018.12.019

Sarkar, J.; Bhattacharyya, S.; Lal, A.: Selection of suitable natural refrigerants pairs for cascade refrigeration system. Proc IMechE Part A: J Power Energy. 227(5), 612–622 (2013). https://doi.org/10.1177/0957650913487730

Singh, K.K.; Kumar, R.; Gupta, A.: Comparative energy, exergy and economic analysis of a cascade refrigeration system incorporated with flash tank (HTC) and a flash intercooler with indirect subcooler (LTC) using natural refrigerant couples. Sustain. Energy Technol. Assess. 39, 100716 (2020). https://doi.org/10.1016/j.seta.2020.100716

Roy, R.; Mandal, B.K.: Thermo-economic analysis and multi-objective optimization of vapour cascade refrigeration system using different refrigerant combination. J. Therm. Anal. calorim. 139, 3247–3261 (2020). https://doi.org/10.1007/s10973-019-08710-x

Roy, R.; Mandal, B.K.: Energetic and exergetic performance comparison of cascade refrigeration system using R170–R161 and R41–R404A as refrigerant pairs. Heat Mass Transf. 55, 723–731 (2019). https://doi.org/10.1007/s00231-018-2455-7

Paradeshi, L.; Srinivas, M.; Jayaraj, S.: Thermodynamic analysis of a direct expansion solar-assisted heat pump system working with R290 as a drop-in substitute for R22. J. Therm. Anal. Calorim. 136(1), 63–78 (2019). https://doi.org/10.1007/s10973-018-7928-x

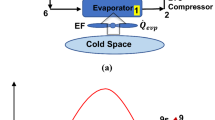

Shovon, M.K.B.; Raman, S.K.; Suryam, A.; Kim, T.H.; Kim, H.D.: Performance of ejector refrigeration cycle based on solar energy working with various refrigerants. J. Therm. Anal. Calorim. 141, 301–312 (2020). https://doi.org/10.1007/s10973-020-09319-1

Saleh, S.; Pirouzfar, V.; Alihosseini, A.: Performance analysis and development of a refrigeration cycle through various environmentally friendly refrigerants. J. Therm. Anal. Calorim. 136, 1817–1830 (2019). https://doi.org/10.1007/s10973-018-7809-3

Turgut, M.S.; Turgut, O.E.: Comparative investigation and multi objective design optimization of a cascaded vapor compression absorption refrigeration system operating with different refrigerants in the vapor compression cycle. Heat Mass Transf. 55, 467–488 (2019). https://doi.org/10.1007/s00231-018-2430-3

Sun, X.; Liu, L.; Dong, Y.; Zhuang, Y.; Li, J.; Du, J.; Yin, H.C.: Multi-objective optimization and thermo-economic analysis of an enhanced compression-absorption cascade refrigeration system and ORC integrated system for cooling and power cogeneration. Energy Convers. Manage. 236, 114068 (2021). https://doi.org/10.1016/j.enconman.2021.114068

Baakeem, S.S.; Orfi, J.; Alabdulkarem, A.: Optimization of a multistage vapor-compression refrigeration system for various refrigerants. Appl. Therm. Eng. 136, 84–96 (2018). https://doi.org/10.1016/j.applthermaleng.2018.02.071

Klein, S.A.; Alvarado, F.L.: EES: engineering equation solver for the Microsoft Windows operating system. F-Chart software (1992)

Sanaye, S.; Shirazi, A.: Four E analysis and multi-objective optimization of an ice thermal energy storage for air-conditioning applications. Int. J. Refrig. 36, 828–841 (2013). https://doi.org/10.1016/j.ijrefrig.2012.10.014

Mosaffa, A.H.; Farshi, L.G.: Exergoeconomic and environmental analyses of an air conditioning system using thermal energy storage. Appl. Energy. 162, 515–526 (2016). https://doi.org/10.1016/j.apenergy.2015.10.122

Xu, G.; Liang, F.; Yang, Y.; Hu, Y.; Zhang, K.; Liu, W.: An improved CO2 separation and purification system based on cryogenic separation and distillation theory. Energies 7, 3484–3502 (2014). https://doi.org/10.3390/en7053484

Torrella, E.; Larumbe, J.A.; Cabello, R.; Llopis, R.; Sanchez, D.: A general methodology for energy comparison of intermediate configurations in two-stage vapour compression refrigeration systems. Energy 36, 4119–4124 (2011). https://doi.org/10.1016/j.energy.2011.04.034

Wijbenga, H.; Van Der Hoff, M.; Janssen, M.; Infante Ferreira, C.A.: Life cycle performance of refrigeration systems in the Dutch food and beverages sector. In: 4th IIR conf thermophys prop transf process refrig, Delft, The Netherlands (2016)

Infante Ferreira, C.A.: Refrigeration and heat pumping in food processing plants. In: Stougie L, editor. Energy effic qual energy food process ind. Delft, The Netherlands: Interduct: Delft University of Technology. 57–79 (2002)

Navidbakhsh, M.; Shirazi, A.; Sanaye, S.: Four E analysis and multi-objective optimization of an ice storage system incorporating PCM as the partial cold storage for air-conditioning applications. Appl. Therm. Eng. 58, 30–41 (2013). https://doi.org/10.1016/j.applthermaleng.2013.04.002

Bejan, A.;, Tsatsaronis, G.;, Moran, M.J.: Thermal design and optimization. Wiley (1996)

Fettaka, S.; Thibault, J.; Gupta, Y.: Design of shell-and-tube heat exchangers using multi-objective optimization. Int. J. Heat Mass Transfer. 60, 343–354 (2013). https://doi.org/10.1016/j.ijheatmasstransfer.2012.12.047

Srinivas, N.; Deb, K.: Multiobjective optimization using nondominated sorting in genetic algorithms. Evol. Comput. 2, 221–248 (1994). https://doi.org/10.1162/evco.1994.2.3.221

Knowles, J.; Corne, D.: The Pareto archived evolution strategy: a new baseline algorithm for Multiobjective optimization, in Proc. of the 1999 Cong. on Evolutionary Computation., Washington: IEEE Service Center. (1999)

Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T.: A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 6, 182–197 (2002). https://doi.org/10.1109/4235.996017

Tooru, A.; Hideaki, C.: A new condensed gas calorimeter: thermodynamic properties of solid and liquid dinitrogen oxide. Bull. Chem. Soc. Jpn. 47(9), 2126–2136 (1974). https://doi.org/10.1246/bcsj.47.2126

Funding

No funds, grants or other support was received.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by KKS, RK and AG. The first draft of the manuscript was written by KKS and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interest to disclose.

Rights and permissions

About this article

Cite this article

Singh, K.K., Kumar, R. & Gupta, A. Multi-objective Optimization of Thermodynamic and Economic Performances of Natural Refrigerants for Cascade Refrigeration. Arab J Sci Eng 46, 12235–12252 (2021). https://doi.org/10.1007/s13369-021-05924-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05924-w