Abstract

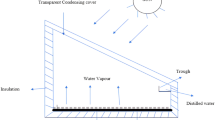

In the present study, a galvanized iron stepped solar still is examined via a solar simulator with a radiation power of 904 W/m2. To enhance the evaporation rate, a number of galvanized iron fins were fabricated to create hot points on step surfaces. For the experimental study, the input feedwater flow rate was set to be 0.086, 0.098, 0.146, 0.167, and 0.190 lit/min, measuring the temperatures of different points in the system and freshwater production rate in the internal and external condenser during 150 min at each of these flow rates. Then, the temperature variations and distillate production rates were provided in the form of diagrams. To complete the study, the cost of distillate production in different conditions was calculated. The results showed that the distillate production rate, and consequently, the cost of distillate production were lower at smaller flow rates. In all the distillation production tests, the curve began at a relatively small slope and then continued to rise linearly. As a result, it was observed that distillate production would continue if the solar simulator operated for a longer time. Furthermore, the optimal initial feedwater flow rate for the maximization of distillation production seemed to occur at the flow rates of 0.086 and 0.098 lit/min. The lowest prime cost of distillate production was obtained to be 9.4 ¢/L at the lowest flow rates, which was found to be acceptable in comparison with similar studies.

Similar content being viewed by others

References

Kaushal A (2010) Solar stills: a review. Renew Sustain Energy Rev 14(1):446–453

Taghvaei H et al (2014) A thorough investigation of the effects of water depth on the performance of active solar stills. Desalination 347:77–85

Jani HK, Modi KV (2018) A review on numerous means of enhancing heat transfer rate in solar-thermal based desalination devices. Renew Sustain Energy Rev 93:302–317

Abu-Qudais M, Othman ON (1996) Experimental study and numerical simulation of a solar still using an external condenser. Energy 21(10):851–855

Ahmed S (1988) Study of single-effect solar still with an internal condenser. Sol Wind Technol 5(6):637–643

Fath HE (1996) High performance of a simple design, two effect solar distillation unit. Desalination 107(3):223–233

Janarthanan B, Chandrasekaran J, Kumar S (2006) Performance of floating cum tilted-wick type solar still with the effect of water flowing over the glass cover. Desalination 190(1–3):51–62

Kumar A, Anand J (1992) Modelling and performance of a tubular multiwick solar still. Energy 17(11):1067–1071

Bhargva M, Yadav A (2019) Experimental comparative study on a solar still combined with evacuated tubes and a heat exchanger at different water depths. Int J Sustain Eng 13(3):218–29

Patel J, Markam BK, Maiti S (2019) Potable water by solar thermal distillation in solar salt works and performance enhancement by integrating with evacuated tubes. Sol Energy 188:561–572

Sharshir SW et al (2019) Augmentation of a pyramid solar still performance using evacuated tubes and nanofluid: experimental approach. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2019.113997

Omara Z, Hamed MH, Kabeel A (2011) Performance of finned and corrugated absorbers solar stills under Egyptian conditions. Desalination 277(1–3):281–287

Bhardwaj R, Ten Kortenaar M, Mudde R (2016) Inflatable plastic solar still with passive condenser for single family use. Desalination 398:151–156

Alaian W, Elnegiry E, Hamed AM (2016) Experimental investigation on the performance of solar still augmented with pin-finned wick. Desalination 379:10–15

Kumar RA, Esakkimuthu G, Murugavel KK (2016) Performance enhancement of a single basin single slope solar still using agitation effect and external condenser. Desalination 399:198–202

Rahbar N, Esfahani JA, Asadi A (2016) An experimental investigation on productivity and performance of a new improved design portable asymmetrical solar still utilizing thermoelectric modules. Energy Convers Manage 118:55–62

Gnanaraj SJP, Velmurugan V (2019) An experimental study on the efficacy of modifications in enhancing the performance of single basin double slope solar still. Desalination 467:12–28

Dumka P et al (2019) Comparative analysis and experimental evaluation of single slope solar still augmented with permanent magnets and conventional solar still. Desalination 459:34–45

Muthu Manokar A, Prince Winston D (2017) Comparative study of finned acrylic solar still and galvanised iron solar still. Mater Today: Proc 4(8):8323–8327

Sarhaddi F et al (2017) Comparative study of two weir type cascade solar stills with and without PCM storage using energy and exergy analysis. Energy Convers Manage 133:97–109

Kumbhar SV (2019) Double slope solar still distillate output data set for conventional still and still with or without reflectors and PCM using high TDS water samples. Data in brief. https://doi.org/10.1016/j.dib.2019.103852

Panchal H et al (2019) Economic and exergy investigation of triangular pyramid solar still integrated to inclined solar still with baffles. Int J Ambient Energy 40(6):571–576

Montazeri M, Banakar A, Ghobadian B (2017) Enhancement of cascade solar still productivity with sloping absorber plate. Maejo Int J Sci Technol 11(1):35

Kabeel A, Abdelgaied M (2020) Enhancement of pyramid-shaped solar stills performance using a high thermal conductivity absorber plate and cooling the glass cover. Renew Energy 146:769–775

Kabeel A, Abdelaziz GB, El-Said EM (2019) Experimental investigation of a solar still with composite material heat storage: energy, exergy and economic analysis. J Clean Prod 231:21–34

Feilizadeh M et al (2019) Experimental investigation of an active thermosyphon solar still with enhanced condenser. Renew Energy 143:328–334

Nasri B et al (2019) Improvement of glass solar still performance using locally available materials in the southern region of Algeria. Groundwater Sustain Dev. https://doi.org/10.1016/j.gsd.2019.100213

Bilal A et al (2019) Investigating the effect of pumice stones sensible heat storage on the performance of a solar still. Groundwater Sustain Dev. https://doi.org/10.1016/j.gsd.2019.100228

Ghafuoryan MM, Shakib SE, Dastjerd FT (2015) Modeling and optimizing of a combined CHP system, compression chiller and reverse osmosis plant (CHP+ C+ W) in two strategies of connections with grid. J Braz Soc Mech Sci Eng 37(6):1751–1763

Oskoonejad MM (2007) Engineering Economy. Amirkabir University

Sanaye S, Ghafurian MM (2016) Applying relative equivalent uniform annual benefit for optimum selection of a gas engine combined cooling, heating and power system for residential buildings. Energy Build 128:809–818

Sanaye S, Ghafurian MM, Dastjerd FT (2016) Applying relative net present or relative net future worth benefit and exergy efficiency for optimum selection of a natural gas engine based CCHP system for a hotel building. J Nat Gas Sci Eng 34:305–317

Gorjian S et al (2014) Experimental performance evaluation of a stand-alone point-focus parabolic solar still. Desalination 352:1–17

Dashtban M, Tabrizi FF (2011) Thermal analysis of a weir-type cascade solar still integrated with PCM storage. Desalination 279(1):415–422

Kumar S, Tiwari GN (2009) Life cycle cost analysis of single slope hybrid (PV/T) active solar still. Appl Energy 86(10):1995–2004

Ahmed MI, Hrairi M, Ismail AF (2009) On the characteristics of multistage evacuated solar distillation. Renew Energy 34(6):1471–1478

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Monica Carvalho.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shahraki Shahdabadi, R., Mortazavi, A., Lotfi, P. et al. An experimental study of feedwater flow rate effects on technical and economic performances of a stepped solar still. J Braz. Soc. Mech. Sci. Eng. 43, 372 (2021). https://doi.org/10.1007/s40430-021-03091-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-03091-5