Abstract

This work aims to develop a novel and practical equation for predicting the axial load of rectangular concrete-filled steel tubular (CFST) columns based on soft computing techniques. More precisely, a dataset containing 880 experimental tests was first collected from the available literature for the development of an artificial neural network (ANN) model. An optimization strategy was conducted to obtain a final set of ANN’s architecture as well as its weight and bias parameters. The performance of the developed ANN was then compared to current codes (AS, EN, AIJ, ACI, AISC, LRFD, and DBJ) and existing empirical equations. The accuracy of the present model was found superior to the results obtained by others when predicting the axial load of rectangular CFST columns. For practical application, an explicit equation and an Excel-based Graphical User Interface were derived based on the ANN model. The graphical user interface is provided freely for all interested users, to support the design, teaching, and interpretation of the axial behavior of CFST columns.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings will be made available on request.

Abbreviations

- ANN(s):

-

Artificial neural network(s)

- A c :

-

Area of concrete core section

- A s :

-

Area of steel tube section

- A sc :

-

Area of composite section

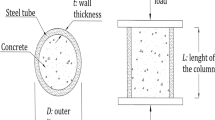

- B :

-

Width of tubes section

- BPNN:

-

Back propagation neural network

- CFST:

-

Concrete filled steel tube

- Co:

-

Competitive transfer function

- E c :

-

Concrete modulus of elasticity

- E s :

-

Steel modulus of elasticity

- \(f_{{\text{c}}}^{\prime }\) :

-

Concrete compressive strength

- f y :

-

Steel yield limit

- f u :

-

Steel ultimate strength

- GP:

-

Genetic programming

- GUI:

-

Graphical user interface

- H :

-

Height of tubes section

- HTS:

-

Hyperbolic tangent sigmoid transfer function

- I s :

-

Moment of inertia of steel tube section

- I c :

-

Moment of inertia of concete core section

- L :

-

Length of column

- L e :

-

Effective length of column

- Li:

-

Linear transfer function

- LS:

-

Log-sigmoid transfer function

- MAPE:

-

Mean absolute percentage error

- MSE:

-

Mean square error

- N :

-

Axial load capacity

- N b :

-

Buckling capacity of column

- N cr :

-

Elastic critical bucking load

- N pl :

-

Squash load

- NRB:

-

Normalized radial basis transfer function

- PLi:

-

Positive linear transfer function

- R :

-

Pearson correlation coefficient

- RB:

-

Radial basis transfer function

- SM:

-

Soft max transfer function

- SSE:

-

Sum square error

- SP:

-

Superplasticizer

- SSL:

-

Symmetric saturating linear transfer function

- t :

-

Wall thickness of steel tubes

- TB:

-

Triangular basis transfer function

- \(\xi\) :

-

Confinement factor

- \(\rho\) :

-

Concrete density

- \(N_{{\text{u}}}^{{{\text{predicted}}}}\) :

-

Prediction of axial load of CFST columns

- [I w]:

-

Weight matrix of the hidden layer

- [b i]:

-

Bias matrix of the hidden layer

- [L W]:

-

Weight matrix of the output layer

- [b o]:

-

Bias matrix of the output layer

- B min, B max :

-

Min and max values of width of tubes sections

- H min, H max :

-

Min and max values of height of tubes sections

- t min, t max :

-

Min and max values of thickness of tubes sections

- L emin, L emax :

-

Min and max values of effective length of column

- f ymin, f ymax :

-

Min and max values of steel yield limit

- \(f_{0}^{\prime }\), \(f_{{{\text{c}}\max }}^{\prime }\) :

-

Min and max values of concrete compressive strength

References

Han LH, Li W, Bjorhovde R (2014) Developments and advanced applications of concrete-filled steel tubular (CFST) structures: members. J Constr Steel Res 100:211–228

Liew JR, Xiong M, Xiong D (2016) Design of concrete filled tubular beam-columns with high strength steel and concrete. Structures 8:213–226

Han LH, Ma DY, Zhou K (2018) Concrete-encased CFST structures: behaviour and application. In: Proceedings of the 12th international conference on advances in steel-concrete composite structures. ASCCS 2018, pp 1–10. Editorial Universitat Politècnica de València

Zhou X, Liu J (2019) Application of steel-tubed concrete structures in high-rise buildings. Int J High-Rise Build 8(3):161–167

Eurocode 4, CEN, EN1994-1 (2004) Design of composite steel and concrete structures—Part 1-1: general rules and rules for buildings. Brussels, Belgium

AISC (2016) Specification for structural steel buildings ANSI/AISC 360–16. American Institute of Steel Construction, Chicago

ACI Committee 318-14 (2014) Building code requirements for structural concrete and commentary. American Concrete Institute

AIJ (1997) AI of recommendations for design and construction of concrete filled steel tubular structures. Architectural Institute of Japan

The Construction Department of Fujian Province (2010) DBJ13-51-2010, technical specification for concrete-filled steel tubular structures, Fuzhou, China

AS5100 (2004) Bridge design, Part 6: steel and composite construction. Australian Standard

Uy B (2000) Strength of concrete filled steel box columns incorporating local buckling. J Struct Eng 126(3):341–352

Sakino K, Nakahara H, Morino S, Nishiyama I (2004) Behavior of centrally loaded concrete-filled steel-tube short columns. J Struct Eng 130(2):180–188

Han LH, Yao GH, Zhao XL (2005) Tests and calculations for hollow structural steel (HSS) stub columns filled with self-consolidating concrete (SCC). J Constr Steel Res 61:1241–1269

Yu M, Zha X, Ye J, Li Y (2013) A unified formulation for circle and polygon concrete-filled steel tube columns under axial compression. Eng Struct 49:1–10

Ding F, Fang C, Bai Y, Gong Y (2014) Mechanical performance of stirrup-confined concrete-filled steel tubular stub columns under axial loading. J Constr Steel Res 98:146–157

Du Y, Chen Z, Xiong MX (2016) Experimental behavior and design method of rectangular concrete-filled tubular columns using Q460 high-strength steel. Constr Build Mater 125:856–872

Wang ZB, Tao Z, Han LH, Uy B, Lam D, Kang WH (2017) Strength, stiffness and ductility of concrete-filled steel columns under axial compression. Eng Struct 2017(135):209–221

Chen S, Zhang R, Jia LJ, Wang JY, Gu P (2018) Structural behavior of UHPC filled steel tube columns under axial loading. Thin-Wall Struct 130:550–563

Armaghani DJ, Asteris PG (2020) A comparative study of ANN and ANFIS models for the prediction of cement-based mortar materials compressive strength. Neural Comput Appl. https://doi.org/10.1007/s00521-020-05244-4

Asteris PG, Mokos VG (2019) Concrete compressive strength using artificial neural networks. Neural Comput Appl. https://doi.org/10.1007/s00521-019-04663-2

Ly H-B, Pham BT, Le LM, Le T-T, Le VM, Asteris PG (2020) Estimation of axial load-carrying capacity of concrete-filled steel tubes using surrogate models. Neural Comput Appl. https://doi.org/10.1007/s00521-020-05214-w

Thanh Duong H, Chi Phan H, Le T-T, Duc Bui N (2020) Optimization design of rectangular concrete-filled steel tube short columns with balancing composite motion optimization and data-driven model. Structures 28:757–765. https://doi.org/10.1016/j.istruc.2020.09.013

Huang J, Asteris PG, Manafi Khajeh Pasha S, Mohammed AS, Hasanipanah M (2020) A new auto-tuning model for predicting the rock fragmentation: a cat swarm optimization algorithm. Eng Comput. https://doi.org/10.1007/s00366-020-01207-4

Al-Khaleefi AM, Terro MJ, Alex AP, Wang Y (2002) Prediction of fire resistance of concrete filled tubular steel columns using neural networks. Fire Saf J 37:339–352

Behnam A, Esfahani MR (2018) Prediction of biaxial bending behavior of steel-concrete composite beam-columns by artificial neural network. Iran Univ Sci Technol 8:381–399

Xiao YF (2012) Approach of concrete-filled steel tube ultrasonic method based on Ann. In: Proceedings of the applied mechanics and materials, vol 105. Trans Tech Publ, pp 1611–1615

Du Y, Chen Z, Zhang C, Cao X (2017) Research on axial bearing capacity of rectangular concrete-filled steel tubular columns based on artificial neural networks. Front Comput Sci 11:863–873

Wei H, Du Y, Wang HJ (2012) Seismic behavior of concrete filled circular steel tubular columns based on artificial neural network. In: Proceedings of the advanced materials research, vol 502. Trans Tech Publ, pp 189–192

Jegadesh S, Jayalekshmi S (2015) Application of artificial neural network for calculation of axial capacity of circular concrete filled steel tubular columns. Int J Earth Sci 8:35–42

Kloppel VK, Goder W (1957) An investigation of the load carrying capacity of concrete-filled steel tubes and development of design formula. Der Stahlbau 26(1):1–10

Furlong RW (1967) Strength of steel-encased concrete beam columns. J Struct Div 93(5):113–124

Knowles RB, Park R (1969) Strength of concrete filled steel tubular columns. J Struct Div 95(12):2565–2588

Gardner NJ, Jacobson ER (1967) Structural behavior of concrete filled steel tubes. ACI J 64(7):404–413

Tomii M (1977) Experimental studies on concrete filled steel tubular stub columns under concentric loading, In: Proceedings of international colloquium on stability of structures under static and dynamic loads, SSRC/ASCE/Washington, DC, pp 718–41

Uy B (2001) Strength of short concrete filled high strength steel box columns. J Constr Steel Res 57(2):113–134

Varma AH, Ricles JM, Sause R, Lu L-W (2002) Experimental behaviour of high strength square concrete-filled steel tube beam-columns. J Struct Eng 128(3):309–318

Mursi M, Uy B (2003) Strength of concrete filled steel box columns incorporating interaction buckling. J Struct Eng 129:626–639

Mursi M, Uy B (2004) Strength of slender concrete filled high strength steel box columns. J Constr Steel Res 60:1825–1848

Lam D, Williams CA (2004) Experimental study on concrete filled square hollow sections. Steel Compos Struct 4(2):95–112

Tao Z, Uy B, Han LH, Wang ZB (2009) Analysis and design of concrete-filled stiffened thin-walled steel tubular columns under axial compression. Thin-Wall Struct 47:1544–1556

Aslani F, Uy B, Tao Z, Mashiri F (2015) Behaviour and design of composite columns incorporating compact high-strength steel plates. J Constr Steel Res 107:94–110

Dundu M (2016) Column buckling tests of hot-rolled concrete filled square hollow sections of mild to high strength steel. Eng Struct 127:73–85

Khan M, Uy B, Tao Z, Mashiri F (2017) Concentrically loaded slender square hollow and composite columns incorporating high strength properties. Eng Struct 131:69–89

Khan M, Uy B, Tao Z, Mashiri F (2017) Behaviour and design of short high-strength steel welded box and concrete-filled tube (CFT) sections. Eng Struct 147:458–472

Xiong MX, Xiong DX, Liew JR (2017) Axial performance of short concrete filled steel tubes with high-and ultra-high-strength materials. Eng Struct 136:494–510

Zhu A, Zhang X, Zhu H, Zhu J, Lu Y (2017) Experimental study of concrete filled cold-formed steel tubular stub columns. J Constr Steel Res 134:17–27

Han LH (2002) Tests on stub columns of concrete-filled RHS sections. J Constr Steel Res 58(3):353–372

Liu D, Gho WM, Yuan J (2003) Ultimate capacity of high-strength rectangular concrete-filled steel hollow section stub columns. J Constr Steel Res 59(12):1499–1515

Liu D (2005) Tests on high-strength rectangular concrete-filled steel hollow section stub columns. J Constr Steel Res 61(7):902–911

Du Y, Chen Z, Yu Y (2016) Behavior of rectangular concrete-filled high-strength steel tubular columns with different aspect ratio. Thin-Wall Struct 109:304–318

Evirgen B, Tuncan A, Taskin K (2014) Structural behavior of concrete filled steel tubular sections (CFT/CFSt) under axial compression. Thin-Wall Struct 80:46–56

Ibañez C, Hernández-Figueirido D, Piquer A (2018) Shape effect on axially loaded high strength CFST stub columns. J Constr Steel Res 147:247–256

Uy B (1998) Local and post-local buckling of concrete filled steel welded box columns. J Constr Steel Res 47(1–2):47–72

Chitawadagi MV, Narasimhan MC, Kulkarni SM (2010) Axial capacity of rectangular concrete-filled steel tube columns—DOE approach. Constr Build Mater 24(4):585–595

Tao Z, Han LH, Wang DY (2008) Strength and ductility of stiffened thin-walled hollow steel structural stub columns filled with concrete. Thin-Wall Struct 46(10):1113–1128

Tao Z, Han LH, Wang ZB (2005) Experimental behaviour of stiffened concrete-filled thin-walled hollow steel structural (HSS) stub columns. J Constr Steel Res 61(7):962–983

Han LH, Yao GH (2003) Influence of concrete compaction on the strength of concrete-filled steel RHS columns. J Constr Steel Res 59(6):751–767

Lue DM, Liu JL, Yen T (2007) Experimental study on rectangular CFT columns with high-strength concrete. J Constr Steel Res 63(1):37–44

Yu Q, Tao Z, Wu YX (2008) Experimental behaviour of high performance concrete-filled steel tubular columns. Thin-Wall Struct 46(4):362–370

Liu D, Gho WM (2005) Axial load behaviour of high-strength rectangular concrete-filled steel tubular stub columns. Thin-Wall Struct 43(8):1131–1142

Zhu J-Y, Chan T-M (2018) Experimental investigation on octagonal concrete filled steel stub columns under uniaxial compression. J Constr Steel Res 147:457–467

Young B, Ellobody E (2006) Experimental investigation of concrete-filled cold-formed high strength stainless steel tube columns. J Constr Steel Res 62(5):484–492

Uy B, Tao Z, Han LH (2011) Behaviour of short and slender concrete-filled stainless steel tubular columns. J Constr Steel Res 67(3):360–378

Han LH, Yao GH (2004) Experimental behaviour of thin-walled hollow structural steel (HSS) columns filled with self-consolidating concrete (SCC). Thin-Wall Struct 42(9):1357–1377

Han LH, Yao GH (2003) Behaviour of concrete-filled hollow structural steel (HSS) columns with pre-load on the steel tubes. J Constr Steel Res 59(12):1455–1475

AISC, LRFD (1999) Resistance factor design specification for structural steel buildings. American Institute of Steel Construction, Chicago

Eurocode 3, CEN, EN1993-1 (2005) Design of steel structures—Part 1-1: general rules and rules for buildings. Brussels

Eurocode 2, CEN, EN1992-1 (2004) Design of concrete structures—Part 1-1: general rules and rules for buildings. Brussels

Tran VL, Thai DK, Kim SE (2019) Application of ANN in predicting ACC of SCFST column. Compos Struct 228:111332

Taormina R, Chau K, Sethi R (2012) Artificial neural network simulation of hourly groundwater levels in a coastal aquifer system of the Venice lagoon. Eng Appl Artif Intell 25:1670–1676. https://doi.org/10.1016/j.engappai.2012.02.009

Le T-T (2020) Practical machine learning-based prediction model for axial capacity of square CFST columns. Mech Adv Mater Struct. https://doi.org/10.1080/15376494.2020.1839608

Ali F, McKinney J (2014) Artificial neural networks for the spalling classification and failure prediction times of high strength concrete columns. Fire Eng 5:203–214. https://doi.org/10.1260/2040-2317.5.3.203

Hasanzadehshooiili H, Lakirouhani A, Šapalas A (2012) Neural network prediction of buckling load of steel arch-shells. Arch Civ Mech Eng 12:477–484. https://doi.org/10.1016/j.acme.2012.07.005

Nguyen HQ, Ly H-B, Tran VQ, Nguyen T-A, Le T-T, Pham BT (2020) Optimization of artificial intelligence system by evolutionary algorithm for prediction of axial capacity of rectangular concrete filled steel tubes under compression. Materials 13:1205. https://doi.org/10.3390/ma13051205

Asteris PG, Armaghani DJ, Hatzigeorgiou GD, Karayannis CG, Pilakoutas K (2019) Predicting the shear strength of reinforced concrete beams using artificial neural networks. Comput Concr 24:469–488. https://doi.org/10.12989/cac.2019.24.5.469

Nguyen QH, Ly H-B, Tran VQ, Nguyen T-A, Phan V-H, Le T-T, Pham BT (2020) A novel hybrid model based on a feedforward neural network and one step secant algorithm for prediction of load-bearing capacity of rectangular concrete-filled steel tube columns. Molecules 25:3486. https://doi.org/10.3390/molecules25153486

Le T-T (2020) Prediction of tensile strength of polymer carbon nanotube composites using practical machine learning method. J Compos Mater. https://doi.org/10.1177/0021998320953540

Asteris PG, Roussis PC, Douvika MG (2017) Feed-forward neural network prediction of the mechanical properties of sandcrete materials. Sensors 17:1344. https://doi.org/10.3390/s17061344

Asteris PG, Nikoo M (2019) Artificial bee colony-based neural network for the prediction of the fundamental period of infilled frame structures. Neural Comput Appl. https://doi.org/10.1007/s00521-018-03965-1

Pham BT, Nguyen-Thoi T, Ly H-B, Nguyen MD, Al-Ansari N, Tran V-Q, Le T-T (2020) Extreme learning machine based prediction of soil shear strength: a sensitivity analysis using Monte Carlo simulations and feature backward elimination. Sustainability 12:2339. https://doi.org/10.3390/su12062339

Le T-T (2020) Surrogate neural network model for prediction of load-bearing capacity of CFSS members considering loading eccentricity. Appl Sci 10:3452. https://doi.org/10.3390/app10103452

Le-Duc T, Nguyen Q-H, Nguyen-Xuan H (2020) Balancing composite motion optimization. Inf Sci 520:250–270. https://doi.org/10.1016/j.ins.2020.02.013

Yao X, Liu Y, Lin G (1999) Evolutionary programming made faster. IEEE Trans Evol Comput 3:82–102. https://doi.org/10.1109/4235.771163

Zhang Z (1984) Experimental research on short filled concrete square steel tube columns under axial compressive load. Masters thesis, Harbin University of Technology, Harbin, China

Lu X, Yu Y, Chen Y (1999) Studies on the behavior of concrete-filled rectangular tubular short column: 1 experiment. Build Struct China 29(10):41–43

Guo L (2006) Theoretical and experimental reearch on the behavior of concrete-filled rectangular hollow section steel tubes. PhD thesis, Harbin Institute of Technology, Harbin, China

Ye Z (2001) Conpressive behavior of high-strength concrete-filled square and rectangular steel tubes. Masters thesis, Harbin Institute of Technology, Harbin, China

Guo L-H, Zhang S-M, Kim W-J (2006) Elastic and elastic-plastic buckling behavior of SHS steel tube filled with concrete. Harbin Gongye Daxue Xuebao J Harbin Inst Technol 38(8):1350–1354

Wei Z, Han L (2000) Research on the bearing capacity of early-strength concrete filled square steel tube. In: Proceedings 6th ASCCS conference; composite and hybrid structures, vol 1, Los Angeles, pp 395–402, 2000

Zhang S, Zhou M (2000) Stress–strain behavior of concrete-filled square steel tubes. In: Proceedings 6th ASCCS conference; composite and hybrid structures, vol 1, Los Angeles, pp 403–410

Tomii M, Sakino K (1979) Experimental studies on the ultimate moment of concrete filled square steel tubular beam-columns. Trans Archit Inst Jpn 275:55–65

Inai E, Sakino K (1996) Simulation of flexural behavior of square concrete filled steel tubular columns. In: Proceedings of the Third Joint Technical Coordinating Committee Meeting, US–Japan Cooperative Research Program, Phase 5: composite and hybrid structures, Hong Kong, National Science Foundation, Arlington, Virginia

Nakahara H, Sakino K (1998) Axial compressive and uniform bending tests of high strength concrete filled square steel tubular columns. In: Proceedings of the fifth pacific structural steel conference, Seoul, Korea, pp 943–948

Lu YQ, Kennedy DJL (1994) The flexural behaviour of concrete-filled hollow structural sections. Can J Civ Eng 21(1):111–130

Yamamoto T, Kawaguchi J, Morino S (2000) Experimental study of scale effects on the compressive behavior of short concrete-filled steel tube columns. In: Proc. of composite construction in steel and concrete IV, pp 879–890, May 28–June 2, 2000, Banff, Alberta, Canada

Matsui C, Tsuda K, Ishibashi Y (1995) Slender concrete filled steel tubular columns under combined compression and bending. In: Structural steel, PSSC95, 4th pacific structural steel conference, vol 3, Steel-Concrete Composite Structures, Singapore, pp 29–36, 1995.

Grauers M (1993) Composite columns of hollow steel sections filled with high strength concrete. Diss.: 1993, Chalmers Univ. of Technology, Göteborg

Schneider SP (1998) Axially loaded concrete-filled steel tubes. J Struct Eng 124(10):1125–1138

Chung J, Matsui C, Tsuda K (2001) Simplified design formula of slender concrete filled steel tubular beam-columns. Struct Eng Mech 12(1):71–84

Ghannam S, Jawad YA, Hunaiti Y (2004) Failure of lightweight aggregate concrete-filled steel tubular columns. Steel Compos Struct 4(1):1–8

Guo L, Zhang S, Wang Y, Liu J (2005) Analytical and experimental research on axially loaded slender HSC filled RHS steel tubular columns. Ind Constr China 35(3):75–79

Luo L (1986) Experimental research on long filled concrete square steel tube columns under axial compressive load. Masters thesis, Zheng Zhou University of Technology, 1986

Ye Z (2001) Compressive behavior of high-strength concrete-filled square and rectangular steel tubes. Masters thesis, Harbin Institute of Technology, Harbin, China, 2001

Lin CY (1988) Axial capacity of concrete infilled cold-formed steel columns. In: Ninth international specialty conference on cold-formed steel structures, St. Louis, Missouri, USA, pp 443–457, 1988

Shakir-Khalil H, Mouli M (1990) Further tests on concrete-filled rectangular hollow-section columns. Struct Eng 68(20):405–413

Matsui C, Tsuda K (1996) Strength and behavior of slender concrete filled steel tubular columns. In: Chang PTY, Lu LW, Wei L (eds) Proceedings of the second international symposium on civil infrastructure systems, Hong Kong, China, 1996

Han L-H, Yang Y-F (2003) Analysis of thin-walled steel RHS columns filled with concrete under long-term sustained loads. Thin-Wall Struct 41(9):849–870

Vrcelj Z, Uy B (2002) Behaviour and design of steel square hollow sections filled with high strength concrete. Aust J Struct Eng 3(3):153–170

Cederwall K, Engstrom B, Grauers M (1990) High-strength concrete used in composite columns. Spec Publ 121:195–214

Chen J, Jin W (2010) Experimental investigation of thin-walled complex section concrete-filled steel stub columns. Thin-Wall Struct 48(9):718–724

Armaghani DJ, Hajihassani M, Sohaei H, Mohamad ET, Marto A, Motaghedi H, Moghaddam MR (2015) Neuro-fuzzy technique to predict air-overpressure induced by blasting. Arab J Geosci 8(12):10937–10950

Momeni E, Nazir R, Armaghani DJ, Maizir H (2015) Application of artificial neural network for predicting shaft and tip resistances of concrete piles. Earth Sci Res J 19(1):85–93

Khandelwal M, Armaghani DJ, Faradonbeh RS, Ranjith PG, Ghoraba S (2016) A new model based on gene expression programming to estimate air flow in a single rock joint. Environ Earth Sci 75(9):739

Alavi AH, Gandomi AH (2012) Energy-based numerical models for assessment of soil liquefaction. Geosci Front 3(4):541–555

Wu H-H, Wu S (2009) Various proofs of the Cauchy–Schwarz inequality. Octogon Math Mag 17(1):221–229

Apostolopoulou M, Armaghani DJ, Bakolas A, Douvika MG, Moropoulou A, Asteris PG (2019) Compressive strength of natural hydraulic lime mortars using soft computing techniques. Procedia Struct Integr 17:914–923

Apostolopoulou M, Asteris PG, Armaghani DJ, Douvika MG, Lourenço PB, Cavaleri L, Bakolas A, Moropoulou A (2020) Mapping and holistic design of natural hydraulic lime mortars. Cem Concr Res 136:106167. https://doi.org/10.1016/j.cemconres.2020.106167

Cavaleri L, Chatzarakis GE, Di Trapani F, Douvika MG, Roinos K, Vaxevanidis NM, Asteris PG (2017) Modeling of surface roughness in electro-discharge machining using artificial neural networks. Adv Mater Res 6(2):169–184

Apostolopoulou M, Douvika MG, Kanellopoulos IN, Moropoulou A, Asteris PG (2018) Prediction of compressive strength of mortars using artificial neural networks. In: 1st international conference TMM_CH, transdisciplinary multispectral modelling and cooperation for the preservation of cultural heritage, Athens, Greece, 10–13 October

Chen H, Asteris PG, Armaghani DJ, Gordan B, Pham BT (2019) Assessing dynamic conditions of the retaining wall using two hybrid intelligent models. Appl Sci 2019(9):1042

Psyllaki P, Stamatiou K, Iliadis I, Mourlas A, Asteris P, Vaxevanidis N (2018) Surface treatment of tool steels against galling failure. MATEC Web Conf 188:04024

Armaghani DJ, Hatzigeorgiou GD, Karamani Ch, Skentou A, Zoumpoulaki I, Asteris PG (2019) Soft computing-based techniques for concrete beams shear strength. Procedia Struct Integr 17(2019):924–933

Asteris PG, Armaghani DJ, Hatzigeorgiou, Karayannis CG, Pilakoutas K (2019) Predicting the shear strength of reinforced concrete beams using artificial neural networks. Comput Concr 24(5):469–488

Zhou J, Asteris PG, Armaghani DJ, Pham BT (2020) Prediction of ground vibration induced by blasting operations through the use of the Bayesian network and random forest models. Soil Dyn Earthq Eng 139:106390. https://doi.org/10.1016/j.soildyn.2020.106390

Asteris PG, Apostolopoulou M, Armaghani DJ, Cavaleri L, Chountalas AT, Guney D, Hajihassani M, Hasanipanah M, Khandelwal M, Karamani C, Koopialipoor M, Kotsonis E, Le T-T, Lourenço PB, Ly H-B, Moropoulou A, Nguyen H, Pham BT, Samui P, Zhou J (2020) On the metaheuristic models for the prediction of cement-metakaolin mortars compressive strength. Metaheuristic Comput Appl 1(1):63–99. https://doi.org/10.12989/mca.2020.1.1.063

Lourakis MIA (2005) A brief description of the Levenberg-Marquardt algorithm implemented by levmar. Hellas (FORTH), Institute of Computer Science Foundation for Research and Technology. http://www.ics.forth.gr/~lourakis/levmar/levmar

Funding

This research received no external funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding the publication of this paper.

Supplementary Information

Below is the link to the electronic supplementary material.

366_2021_1461_MOESM1_ESM.xlsx

Supplementary file1The Excel-based Graphical User Interface for prediction of axial compressive load of CFST columns, based on the optimal machine learning model is appended to this paper (XLSX 438 kb)

Rights and permissions

About this article

Cite this article

Le, TT., Asteris, P.G. & Lemonis, M.E. Prediction of axial load capacity of rectangular concrete-filled steel tube columns using machine learning techniques. Engineering with Computers 38 (Suppl 4), 3283–3316 (2022). https://doi.org/10.1007/s00366-021-01461-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-021-01461-0