Abstract

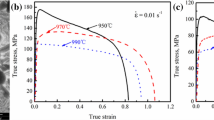

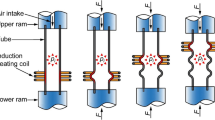

Stress states on a multi-branch tubular part are the most complicated change in all types of hydroforming process, which result in severe variation of thickness. In this paper, an experimental and numerical research was conducted on a multi-step hydroforming process including intermediate annealing treatment to obtain effect of stress state on the thickness variation of a superalloy GH4169 complex T-shaped tubular part with expanded diameter, which corresponds to a real product used in aerospace industry. The material flow behavior at typical points on hydroformed tube blank was first analyzed. Then, the thickness variation on the hydroformed GH4169 tube blanks was discussed in every step. It is shown that the materials have different flow directions to form the side branch, where the thickness is always thinned during the four-step hydroforming process. Large axial feeding induces a continuous thickening between transition areas and tube ends. The thickness invariant dividing line in the side branch zone moves toward the tube ends with forming going on. However, in the hemisphere zone, it moves slightly towards the center of the side branch. Moreover, the stress states at three typical positions, as well as their effect on the thickness variation, were analyzed based on a sequential correspondence law between stress and strain components. On this basis, the mechanism of thickening in the left transition area, thinning at the top of side branch and thickness variation at the hemispheric pole was revealed. These results are very important for obtaining the thickness distribution of a complex T-shaped tubular part in multi-step hydroforming, and revealing the thickness variation mechanism by using engineering plasticity theory.

Graphic abstract

Similar content being viewed by others

References

Mouritz AP, editor. Superalloys for gas turbine engines. Introduction to aerospace materials. Amsterdam: Elsevier; 2012. p. 251–67. https://doi.org/10.1533/9780857095152.251.

Bell C, Corney J, Zuelli N, Savings D. A state of the art review of hydroforming technology. Int J Mater Form. 2020;13:789–828. https://doi.org/10.1007/s12289-019-01507-1.

Ray P, Mac Donald BJ. Experimental study and finite element analysis of simple X- and T-branch tube hydroforming processes. Int J Mech Sci. 2005;47:1498–518. https://doi.org/10.1016/j.ijmecsci.2005.06.007.

Crapps J, Marin EB, Horstemeyer MF, Yassar R, Wang PT. Internal state variable plasticity-damage modeling of the copper tee-shaped tube hydroforming process. J Mater Process Technol. 2010;210:1726–37. https://doi.org/10.1016/j.jmatprotec.2010.06.003.

Kashani Zadeh H, Mashhadi MM. Finite element simulation and experiment in tube hydroforming of unequal T shapes. J Mater Process Technol. 2006;177:684–7. https://doi.org/10.1016/j.jmatprotec.2006.04.056.

Hwang Y-M, Wang K-H, Kang N-S. Adaptive simulations in T-shape tube hydroforming with different outlet diameters. Proc Inst Mech Eng. 2015;229:597–608. https://doi.org/10.1177/0954405413519609.

Hwang Y-M, Wang K-H, Kang N-S. T-shape tube hydroforming of magnesium alloys with different outlet diameters. J Manuf Sci Eng. 2011;133: 061012. https://doi.org/10.1115/1.4004851.

Cui X-L, Teng B, Yuan S. Hydroforming process of complex T-shaped tubular parts of nickel-based superalloy. CIRP J Manuf Sci Technol. 2020;32:476–90. https://doi.org/10.1016/j.cirpj.2021.02.001.

Yuan S. Fundamentals and processes of fluid pressure forming technology for complex thin-walled components. Engineering. 2020;7(3):358–66. https://doi.org/10.1016/j.eng.2020.08.014.

Cheng DM, Teng BG, Guo B, Yuan SJ. Thickness distribution of a hydroformed Y-shape tube. Mater Sci Eng A. 2009;499:36–9. https://doi.org/10.1016/j.msea.2007.09.100.

Ahmetoglu M, Sutter K, Li X, Altan T. Tube hydroforming: current research, applications and need for training. J Mater Process Technol. 2000;98:224–31. https://doi.org/10.1016/S0924-0136(99)00203-4.

Guo XZ, Tao J, Yuan Z, Tang QS. Hydroforming simulation and preparation of low activation martensitic steel Y-shapes. Nucl Eng Des. 2011;241:2802–6. https://doi.org/10.1016/j.nucengdes.2011.06.006.

Peng J, Zhang W, Liu G, Zhu S, Yuan S. Effect of internal pressure distribution on thickness uniformity of hydroforming Y-shaped tube. Trans Nonferrous Met Soc China. 2011;21:s423–8. https://doi.org/10.1016/S1003-6326(11)61618-X.

Hwang Y-M, Su Y-H, Chen B-J. Tube hydroforming of magnesium alloys at elevated temperatures. J Eng Mater Technol. 2010;132: 031012. https://doi.org/10.1115/1.4001833.

Hwang YM, Wang KH. Study on Y-shape tube hydroforming of magnesium alloys at elevated temperatures. Int J Mater Form. 2010;3:175–8. https://doi.org/10.1007/s12289-010-0735-y.

Lei L-P, Kim J, Kang B-S. Bursting failure prediction in tube hydroforming processes by using rigid-plastic FEM combined with ductile fracture criterion. Int J Mech Sci. 2002;44:1411–28. https://doi.org/10.1016/S0020-7403(02)00045-0.

Di Lorenzo R, Ingarao G, Chinesta F. Integration of gradient based and response surface methods to develop a cascade optimisation strategy for Y-shaped tube hydroforming process design. Adv Eng Softw. 2010;41:336–48. https://doi.org/10.1016/j.advengsoft.2009.06.010.

Rajenthirakumar D. Experimental and numerical investigations on sheet and tube hydroforming of inconel alloy. Chennai: Anna University; 2010. p. 625.

Academic Committee of the Superalloys. The Chinese Society for Metals (ed). China superalloys handbook, 1st edn. Beijing: China Quality and Standards Publishing and Media Co. Ltd; 2012. p. 690.

An XL, Zhang B, Chu CL, Zhou L, Chu PK. Evolution of microstructures and properties of the GH4169 superalloy during short-term and high-temperature processing. Mater Sci Eng A. 2019;744:255–66. https://doi.org/10.1016/j.msea.2018.12.019.

Li HY, Wang XS, Yuan SJ, Miao QB, Wang ZR. Typical stress states of tube hydroforming and their distribution on the yield ellipse. J Mater Process Technol. 2004;151:345–9. https://doi.org/10.1016/j.jmatprotec.2004.04.085.

Wang Z, Hu W, Yuan SJ, Wang X. Sequential correspondence law between stress and strain components and its application in plastic deformation process, in: Engineering Plasticity: Theory and Applications in Metal Forming. Singapore: John Wiley and Sons Singapore Pte. Ltd; 2018. p. 295–316. https://doi.org/10.1002/9781119237310.ch7.

Wang Z. Physical essence of Lode parameter and its effect of plastic flow. Acta Mech Solida Sin (Chinese). 2006;27:277–82. https://doi.org/10.19636/j.cnki.cjsm42-1250/o3.2006.03.010.

Acknowledgements

This investigation is financially supported by the National Natural Science Foundation of China (Number U1937205, 51805357), the Project Funded by China Postdoctoral Science Foundation (Number 2020M670907), and the Project Supported by Heilongjiang Postdoctoral Foundation (Number LBH-Z20017). The authors wish to express their gratitude to the funding support. The authors also would like to thank for the contributions of Xiaohui Lu to the experiments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cui, XL., Yuan, S. Analysis of thickness variation and stress state in hydroforming of complex T-shaped tubular part of nickel-based superalloy. Archiv.Civ.Mech.Eng 21, 111 (2021). https://doi.org/10.1007/s43452-021-00263-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00263-x