Abstract

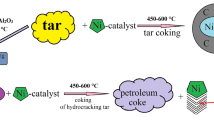

Coking has been studied with and without the 7% Ni/CNT catalyst. It has been shown that tar coking results in the formation of gaseous and liquid products and petroleum coke at a temperature of 350°C without the catalyst. Thermolysis products are formed due to the elimination of side hydrocarbon chains from the initial polyaromatic hydrocarbons. Gaseous products consist of C1–C6 hydrocarbons and sulfur-containing gases H2S and COS. The fractional composition of liquid thermolysis products is studied. It has been found that 50% of the liquid products are gasoline and diesel fractions. The 7% Ni/CNT catalyst is prepared via impregnation. The effect of the 7% Ni/CNT catalyst on the tar coking process in the 300–550°C range of temperatures is studied. The addition of the 7% Ni/CNT catalyst to tar increases the yield and lowers the content of sulfur in petroleum coke due to the conversion of some into hydrogen sulfide and COS, which are removed with the gas phase. Electron microscope study shows that the petroleum coke resulting from the catalytic coking of tar proves to be reinforced with carbon nanotubes.

Similar content being viewed by others

REFERENCES

Kapustin, V.M. and Gureev, A.A., Tekhnologiya pererabotki nefti (Oil Refining Technology), vol. 2: Destruktivnye protsessy (Destructive Processes), Moscow: KolosS, 2008.

Pokhodenko, N.T. and Brondz, B.I., Poluchenie i obrabotka neftyanogo koksa (Production and Processing of Petroleum Coke), Moscow: Khimiya, 1986.

Igonin, P.G., Khim. Tekhnol. Topl. Masel, 1957, no. 6, pp. 66–68.

Kelemen, S.R., Siskin, M., Gorbaty, M.L., Ferrughelli, D.T., Kwiatek, P.J., Brown, L.D., Eppig, C.P., and Kennedy, R.J., Energy Fuels, 2007, vol. 21, no. 2, pp. 927–940.

Chesnokov, V.V. and Buyanov, R.A., Russ. Chem. Rev., 2000, vol. 69, no. 7, pp. 623–638.

Buyanov, R.A. and Chesnokov, V.V., Katal. Prom-sti, 2006, no. 2, pp. 3–15.

Chesnokov, V.V., Chichkan’, A.S., and Parmon, V.N., Catal. Ind., 2018, vol. 10, no. 3, pp. 244–250.

Kondrasheva, N.K., Rudko, V.A., and Nazarenko, M.Yu., Koks Khim., 2018, no. 12, pp. 26–31.

D’yachkov, P.N., Uglerodnye nanotrubki: stroenie, svoistva, primenenie (Carbon Nanotubes: Structure, Properties, and Application), Moscow: BINOM, 2006.

Chesnokov, V.V., Buyanov, R.A., and Chichkan’, A.S., Kinet. Catal., 2010, vol. 51, no. 5, pp. 776–781.

Franklin, R.E., Acta Crystallogr., 1951, vol. 4, no. 3, pp. 253–261.

Maire, J. and Mering, J., in Chemistry and Physics of Carbon, New York: Marcel Dekker, 1970, vol. 6, pp. 125–189.

Chesnokov, V.V., Chichkan’, A.S., Paukshtis, E.A., Chesalov, Yu.A., and Krasnov, A.V., Kinet. Catal., 2019, vol. 60, no. 4, pp. 439–445.

Chesnokov, V.V., Chichkan’, A.S., and Paukshtis, E.A., Pet. Chem., 2019, vol. 59, no. 2, pp. 186–191.

Chesnokov, V.V., Chichkan’, A.S., and Parmon, V.N., Dokl. Phys. Chem., 2019, vol. 484, no. 2, pp. 32–35.

FUNDING

This work was supported by the Russian Science Foundation, project no. 17-73-30032.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chesnokov, V.V., Chichkan’, A.S. & Parmon, V.N. Effect of Nickel-Containing Catalyst on the Tar Coking Process. Catal. Ind. 13, 143–149 (2021). https://doi.org/10.1134/S2070050421020045

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070050421020045