Abstract

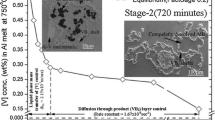

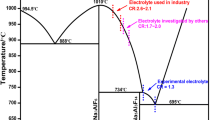

Impurity levels of titanium (Ti) and vanadium (V) depreciate the electrical conductivity of aluminum (Al) when present in solution. Industrially, a boron (B) based alloy is introduced to remove these impurities from the Al melt as borides. Subsequently, these boride particles are separated from the Al melt by gravity settling or filtration, rendering much improved electrical conductivity to the solidified Al material. However, the kinetics of V removal from molten Al in the presence of Ti is not well delineated yet. Additionally, the mechanism for the formation of TiB2 and VB2 in molten Al remains unclear, especially for the formation of VB2 in the presence of Ti. In this study, the kinetics of Ti and V removal from molten Al is investigated in detail by inoculating an Al–0.50 pct Ti–0.50 pct V alloy melt with an Al–5 pct B master alloy at 750 ± 10 °C. Samples are taken at 5, 10, 15, 30, 45 and 60 minutes during the boron treatment. Then, the collected samples are characterized for both the reaction products (TiB2/VB2) and the change in Ti and V concentrations in the molten Al alloy. Reaction products of TiB2 and VB2 in the form of boride cluster rings are observed. The TiB2/VB2 cluster rings are less dense than those observed in the Al–1 pct V–0.45 pct B alloy. The reaction rate between Ti and V with B/AlB2 is rapid, which leads to the formation of cluster rings in the first 5-minute reaction period. The mass transfer coefficients (km) of Ti and V in the molten Al alloy at 750 ± 10 °C are determined to be 5.13 × 10−4 and 3.00 × 10−4 m/s, respectively. These calculated values of km are within the range of 10−3 to 10−4 m/s for typical solid–liquid metallurgical reactions. Therefore, the reaction between Ti/V with B/AlB2 can be assumed to be predominately controlled by the mass transfer of Ti/V through the Al melt. The removal rates of Ti and V are almost the same in the molten Al–0.50 pct Ti–0.50 pct V–0.235 pct B alloy at 750 °C, and they exhibited a strong linear relationship with each other, although thermodynamic predictions suggest that in the presence of Ti, there should be no removal of V in the form of VB2. The reasons are discussed in detail based on kinetic analyses. The findings of this study provide an important scientific basis for boron treatment of molten Al alloys for improved electrical conductivity.

Similar content being viewed by others

References

S. Karabay and I. Uzman: Mater. Manuf. Process., 2005, vol. 20, pp. 231–43. .

P.S. Cooper and M.A. Kearns: ICAA5., 1996, vol. 217, pp. 141–6. .

G.G. Gauthier: J. Inst. Met., 1936, vol. 59, pp. 129–50. .

W.A. Dean: Aluminum., 1967, vol. 1, p. 174. .

G. Dube: European Patent No. 0112024, 1983.

W. Stiller and T. Ingenlath: Aluminium (Engl. Ed.)., 1984, vol. 60, pp. 577–80. .

G.Q. Wang, S.H. Liu, C.M. Li, and Q. Gao: Trans. Nonferr. Met. Soc., 2002, vol. 12, pp. 1112–6. .

W.C. Setzer and G.W. Boone: TMS Light Metals. vol. 1992, TMS, Warrendale, 1991, pp. 837–44.

A. Khaliq, M.A. Rhamdhani, G.A. Brooks, and J. Grandfield: TMS Light Metals. TMS, Warrendale, 2014, pp. 963–8.

A. Khaliq, M.A. Rhamdhani, G. Brooks, J. Grandfield, J. Mitchell, and D. Cameron: Proc. EMC (Eur. Metall. Conf.), 2011, pp. 825–38.

A. Khaliq: PhD Thesis, Swinburne University of Technology, Melbourne, 2013.

A. Khaliq, M.A. Rhamdhani, G. Brooks, and J. Grandfield: 2nd Int. Conf. Aerosp. Sci. Eng. (ICASE), 2011, Islamabad, Pakistan, pp. 1–7.

A. Khaliq, M.A. Rhamdhani, G.A. Brooks, and J. Grandfield: High Temp. Process. Symp. (HTPS), 2011, Swinburne University of Technology, Melbourne, Australia.

A. Khaliq, M.A. Rhamdhani, G.A. Brooks, and J. Grandfield: High Temp. Process. Symp. (HTPS), 2013, Swinburne University of Technology, Melbourne, Australia.

A. Khaliq, M.A. Rhamdhani, G. Brooks, and J. Grandfield: TMS Light Metals. TMS, Warrendale, PA, 2011, pp. 751–6.

A. Khaliq, M.A. Rhamdhani, G.A. Brooks, and J. Grandfield: Metall. Mater. Trans. B., 2014, vol. 45B, pp. 784–94. .

A. Khaliq, M.A. Rhamdhani, G.A. Brooks, and J. Grandfield: Can. Metall. Q., 2016, vol. 55, pp. 161–72. .

S. Karabay and I. Uzman: J. Mater. Sci. Technol., 2005, vol. 160, pp. 174–82. .

R. Cook, M.A. Kearns, and P.S. Cooper: Light Metals. TMS, Warrendale, 1997, pp. 809–14.

X. Cui, Y. Wu, H. Cui, G. Zhang, B. Zhou, and X. Liu: J. Alloys Compd., 2018, vol. 735, pp. 62–7. .

T.L. Bao-gui and H. Chong-qi: Electrical Wires and Cables (in Chinese), 1984, pp. 36–40.

M. Easton and D. Stjohn: Metall. Mater. Trans. A., 1999, vol. 30A, pp. 1613–23. .

M. Easton and D. StJohn: Metall. Mater. Trans. A., 1999, vol. 30A, pp. 1625–33. .

A. Khaliq, M.A. Rafiq, H.T. Ali, F. Ahmed, S. Mehmood, J. Grandfielde, and S.A. Ranjha: J. Min. Metall. Sect. B., 2017, vol. 53, pp. 75–81. .

A. Khaliq, M.A. Rhamdhani, G.A. Brooks, and J. Grandfield: Metall. Mater. Trans. B., 2016, vol. 47B, pp. 595–607. .

A. Khaliq, M.A. Rhamdhani, G.A. Brooks, and J. Grandfield: Metall. Mater. Trans. B., 2014, vol. 45B, pp. 752–68. .

C.W. Bale, E. Bélisle, P. Chartrand, S.A. Decterov, G. Eriksson, K. Hack, I.-H. Jung, Y.-B. Kang, J. Melançon, A.D. Pelton, C. Robelin, and S. Petersen: Calphad., 2009, vol. 33, pp. 295–311. .

C.W. Bale, P. Chartrand, S.A. Degterov, G. Eriksson, K. Hack, R. Ben Mahfoud, J. Melançon, A.D. Pelton, and S. Petersen: Calphad., 2002, vol. 26, pp. 189–228. .

A.D. Pelton, et al.: Metall. Mater. Trans. B., 2000, vol. 31B, pp. 651–9. .

M. Hillert, et al.: Metall. Mater. Trans. A., 1985, vol. 16A, pp. 261–6. .

F.H. Hayes: Res. Adv. Tech., 1989, vol. 80, pp. 361–5. .

H. Okamoto: J. Phase Equilib., 2001, vol. 22, p. 86. .

H.T. Ali, A. Khaliq, and M. Yusuf: Trans. Nonferr. Met. Soc. China, 2020, pp. 1–27.

A. Khaliq, S. Mehmood, S.A. Ranjha, M.A. Javed, and K.S. Munir: Microsc. Microanal., 2018, vol. 24, pp. 2262–3. .

R.J. Pomfret and P. Grievson: Can. Metall. Q., 1983, vol. 22, pp. 287–99. .

M.A. Rhamdhani: PhD Thesis, McMaster University, 2005, p. 216.

A. Khaliq, M.A. Rhamdhani, G.A. Brooks, and J. Grandfield: Metall. Mater. Trans. B., 2014, vol. 45B, pp. 769–83. .

T.A. Engh: Principles of Metal Refining. Oxford University Press, Oxford, 1992.

C.J. Simensen and C. Berg: Aluminium Dusseldorf., 1980, vol. 56, pp. 335–40. .

Acknowledgments

This research has been funded by Scientific Research Deanship at University of Ha’il, Saudi Arabia through Project Number RG-20 041.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted January 7, 2021; accepted May 26, 2021.

Rights and permissions

About this article

Cite this article

Khaliq, A., Alghamdi, A.S., Rajhi, W. et al. Thermodynamic and Kinetic Analyses of the Removal of Impurity Titanium and Vanadium from Molten Aluminum for Electrical Conductor Applications. Metall Mater Trans B 52, 3130–3141 (2021). https://doi.org/10.1007/s11663-021-02241-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02241-3