Abstract

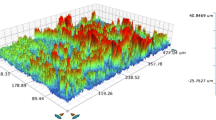

As a widely used orthopedic implant, titanium alloy will face the corrosion of body fluid in human body. In addition, the wear of implants and bones in human body will also reduce the service life of implants. To improve the wear resistance and corrosion resistance of biological titanium alloy, Ti6Al4V alloy was modified by plasma nitriding and plasma-enhanced chemical vapor deposition (PN + PECVD) composite process, and then samples were ablated by nanosecond laser to form a regular surface texture. The textured Ti6Al4V and PN + PECVD samples marked as Ti6Al4V-T and PN + PECVD-T samples. The microstructure and phase composition of the samples before and after modification were observed by scanning electron microscope (SEM), energy-dispersive spectrometer (EDS) and X-ray diffraction (XRD). It was found that after PN + PECVD process, a TiN film with a thickness of 2 μm was formed on the surface of Ti6Al4V. The surface texture of Ti6Al4V-T sample was regular, but the PN + PECVD-T sample texture was wide and shallow irregular after nanosecond laser ablation. The Ti–O and Ti–N–O non-stoichiometric compounds appeared on the samples after nanosecond laser ablation. Through the wear and electrochemical corrosion test in SBF, it was found that PN + PECVD sample had the best wear resistance and corrosion resistance. The wear resistance and corrosion resistance of Ti6Al4V-T and PN + PECVD-T samples were much better than that of Ti6Al4V substrate. The results show that, nitrogen oxides formed on the surface had higher microhardness and surface density, which was beneficial to improve the wear resistance and corrosion resistance of implants.

Similar content being viewed by others

References

B. Henriques, M. Sampaio, M. Buciumeanu, J. Souza, J.R. Gomes, F. Silva, O. Carvalho, Mater. Sci. Eng. C 79, 177–184 (2017)

Y. Liu, W.S. Liu, Y.Z. Ma, C.P. Liang, C. Liu, C. Zhang, Q.S. Cai, Surf. Coat. Technol. 353, 32–40 (2018)

D. Duraccio, F. Mussano, M.G. Faga, J. Mater. Sci. 50, 4779–4812 (2015)

A.S. Li, F.H. Su, P.K. Chu, J.F. Sun, Appl. Surf. Sci. 515, 146065 (2020). https://doi.org/10.1016/j.apsusc.2020.146065

Y.F. Wang, Z. Yu, K.M. Li, J. Hu, Appl. Surf. Sci. 501, 144279 (2020). https://doi.org/10.1016/j.apsusc.2019.144279

R. Barkallah, R. Taktak, N. Guermazi, K. Elleuch, J. Bouaziz, Eng. Fract. Mech. 241, 107399 (2021). https://doi.org/10.1016/j.engfracmech.2020.107399

Y. Lin, Z.B. Cai, Z.Y. Li, M.G. Yin, W.J. Wang, W.F. He, Z.R. Zhou, Wear 426, 112–121 (2019)

K. Szymkiewicz, J. Morgiel, Ł Maj, M. Pomorska, O. Tkachuk, L. Pohrelyuk, T. Wierzchoń, J. Alloy Compd. 845, 156320 (2020). https://doi.org/10.1016/j.jallcom.2020.156320

B.M. Shi, S.M. Huang, P. Zhu, C.G. Xu, P. Guo, Y.Y. Fu, Mater. Lett. 276, 128093 (2020). https://doi.org/10.1016/j.matlet.2020.128093

S.C. Liao, C.Y. Chen, Y.H. Hsu, C.T. Li, C.C. Hsieh, M.S. Tsai, M.Y. Chan, C.H. Lee, S.H. Wang, S.K. Ng, H.K. Tsou, W.Y. Wu, Surf. Coat. Technol. 394, 125814 (2020). https://doi.org/10.1016/j.surfcoat.2020.125814

W.Y. Ge, Z. Chang, A. Siddique, B. Shi, C. Liu, Ceram. Int. 46, 7355–7361 (2020)

L.T. Gui, M.J. Long, H.H. Zhang, D.F. Chen, S. Liu, Q.Z. Wang, H.M. Duan, J. Mater. Res. Technol. 9, 5499–5514 (2020)

N. Sirdeshmukh, G. Dongre, Mater. Today (2021). https://doi.org/10.1016/j.matpr.2020.12.433

J.M. Ramis, S.F. Taxt-Lamolle, S.P. Lyngstadaas, J.E. Reseland, J.E. Ellingsen, M. Monjo, Implant Dent. 21, 141–149 (2012)

H. Okawara, Y. Arai, H. Matsuno, P. Marcián, L. Borák, K. Aoki, N. Wakabayashi, J. Mech. Behav. Biomed. 116, 104370 (2021). https://doi.org/10.1016/j.jmbbm.2021.104370

T. Wang, Y. Wan, Z. Liu, J. Mater. Sci. 51, 9551–9561 (2016)

R.S. Liddell, E. Ajami, Y. Li, E. Bajenova, Y. Yang, J.E. Davies, Acta Biomater. 121, 514–526 (2021)

Z. Yu, J. Hu, K.M. Li, J. Mater. Process. Technol. 268, 10–17 (2019)

D. Huerta-Murillo, A. Garcia-Giron, J.M. Romano, J.T. Cardoso, F. Cordovilla, M. Walker, S.S. Dimov, J.L. Ocana, Appl. Surf. Sci. 463, 838–846 (2019)

Y. Xu, W. Liu, G.Q. Zhang, Z.P. Li, H.X. Hu, C.C. Wang, X.Q. Zeng, S.C. Zhao, Y.D. Zhang, T.H. Ren, J. Mech. Behav. Biomed. Mater. 109, 103823 (2020). https://doi.org/10.1016/j.jmbbm.2020.103823

N.K. Awad, S.L. Edwards, Y.S. Morsi, Mater. Sci. Eng. C 76, 1401–1412 (2017)

S. Yuan, N.M. Lin, J.J. Zou, Z.Q. Liu, Y. Yu, Y. Ma, Z.X. Wang, B. Zhao, Q.F. Zeng, L.H. Tian, L. Qin, H.X. Zhang, Z.H. Wang, X.P. Liu, B. Tang, Y.C. Wu, J. Mater. Res. Technol. 9, 6360–6375 (2020)

K. Balasubramanian, S.R. Bragadeesvaran, S.A. Adarsh, M. Baranitharan, K. Gokulakrishnan, Mater. Today (2020). https://doi.org/10.1016/j.matpr.2020.03.039

O. Unal, E. Maleki, R. Varol, Vacuum 150, 69–78 (2018). https://doi.org/10.1016/j.vacuum.2018.01.027

Y. Yusliza, M.J. Ghazali, Y. Otsuka, S. Morakul, S. Nakamura, M.F. Abdollah, Ceram. Int. 46, 3949–3959 (2020)

D.X. Li, X.X. Chen, C.H. Guo, J. Tao, C.X. Tian, Y.M. Deng, W.W. Zhang, Procedia Eng. 174, 370–376 (2017)

Y.C. Shao, Y.A. Zhao, H. Ma, C. Li, D.W. Li, C. Wang, Y.X. Leng, J.D. Shao, Opt. Commun. 461, 125258 (2020). https://doi.org/10.1016/j.optcom.2020.125258

J. Sun, Q.T. Yao, Y.H. Zhang, X.D. Du, Y.C. Wu, W.P. Tong, Surf. Coat. Technol. 309, 382–389 (2017)

S. Das, S. Guha, R. Ghadai, A. Sharma, Ceram. Int. (2021). https://doi.org/10.1016/j.ceramint.2021.02.254

X. Xu, M.D. Sumption, J. Lee, J. Rochester, X. Peng, J. Alloy Compd. 845, 156182 (2020). https://doi.org/10.1016/j.jallcom.2020.156182

O. Ivanova, A.R. Yavari, K. Georgarakis, Y. Podrezov, J. Alloy Compd. 617, 34–38 (2014)

J.B. Zhang, H.F. Wang, W.W. Kuang, Y.C. Zhang, S. Li, Y.H. Zhao, D.M. Herlach, Acta Mater. 148, 86–99 (2018)

R. Mundotia, D.C. Kothari, A. Kale, U. Mhatre, K. Date, N. Thorat, T. Ghorude, Mater. Today 26, 603–612 (2019)

Z. Yan, D. Jiang, X.M. Gao, M. Hu, D.S. Wang, Y.L. Fu, J.Y. Sun, D.P. Feng, L.J. Weng, Tribol. Int. 124, 61–69 (2018)

D. Kummel, D. Linsler, R. Schneider, J. Schneider, Tribol. Int. 150, 106376 (2020). https://doi.org/10.1016/j.triboint.2020.106376

H. Liu, J.J. Yang, X.Y. Zhao, Y.Y. Sheng, W. Li, C.L. Chang, Q. Zhang, Z.T. Yu, X.J. Wang, Corros. Sci. 161, 108195 (2019). https://doi.org/10.1016/j.corsci.2019.108195

W.F. Cui, F.J. Niu, Y.L. Tan, G.W. Qin, Trans. Nonferr. Met. Soc. China 29, 1026–1035 (2019)

M.S. Ahmed, P. Munroe, Z.T. Jiang, X.L. Zhao, W. Rickard, Z.F. Zhou, L.K.Y. Li, Z.H. Xie, Corros. Sci. 53, 0–3687 (2011)

F. Movassagh-Alanagh, A. Abdollah-Zadeh, M. Aliofkhazraei, M. Abedi, Wear 390, 93–103 (2017)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 16, 2020; accepted April 8, 2021.

Rights and permissions

About this article

Cite this article

Zhang, J., Yu, Z. & Hu, J. Effect of Nanosecond Laser-Textured Ablation on Performance of Ti6Al4V Alloy Prepared by Composite Nitriding Process. Metall Mater Trans A 52, 3289–3301 (2021). https://doi.org/10.1007/s11661-021-06291-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06291-9