Abstract

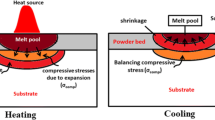

A thermomechanical model is developed to predict the temperature, degree of crystallization, residual stress, and strain in the selective laser sintering process for polymeric powder. Especially, a transient heat transfer model is used to calculate the temperature evolution. An elastic–viscoplastic model is developed to describe the temperature- and time-dependent stress–strain behavior of polymeric materials with crystallization-induced strain being included. A crystallization model is used to predict the relative crystallization degree during the cooling process. The sintering process and cooling process of polyamide 12 are simulated using the developed model. The melt pool depth and the deformation of the printed parts are validated by the experimental results. The evolutions of the temperature, relative degree of crystallization, strain, and stress are evaluated. The effects of the cooling rate on the strain and stress evolutions are discussed.

Similar content being viewed by others

References

Goodridge, R.D., Tuck, C.J., Hague, R.J.M.: Laser sintering of polyamides and other polymers. Prog. Mater Sci. 57, 229–267 (2012)

Yuan, S., Shen, F., Chua, C.K., Zhou, K.: Polymeric composites for powder-based additive manufacturing: materials and applications. Prog. Polym. Sci. 91, 141–168 (2019)

Valino, A.D., Dizon, J.R.C., Espera, A.H., Chen, Q., Messman, J., Advincula, R.C.: Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 98, 101162 (2019)

Tan, L.J., Zhu, W., Zhou, K.: Recent progress on polymer materials for additive manufacturing. Adv. Funct. Mater. 30(43), 2003062 (2020)

Verbelen, L., Dadbakhsh, S., Van den Eynde, M., Kruth, J.-P., Goderis, B., Van Puyvelde, P.: Characterization of polyamide powders for determination of laser sintering processability. Eur. Polym. J. 75, 163–174 (2016)

Laumer, T., Stichel, T., Nagulin, K., Schmidt, M.: Optical analysis of polymer powder materials for Selective Laser Sintering. Polym. Testing 56, 207–213 (2016)

Caulfield, B., McHugh, P.E., Lohfeld, S.: Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J. Mater. Process. Technol. 182, 477–488 (2007)

Peyre, P., Rouchausse, Y., Defauchy, D., Régnier, G.: Experimental and numerical analysis of the selective laser sintering (SLS) of PA12 and PEKK semi-crystalline polymers. J. Mater. Process. Technol. 225, 326–336 (2015)

Yuan, S., Bai, J., Chua, C.K., Wei, J., Zhou, K.: Material evaluation and process optimization of CNT-coated polymer powders for selective laser sintering. Polymers (Basel) 8(10), 370 (2016)

Yuan, S., Bai, J., Chua, C.K., Wei, J., Zhou, K.: Highly enhanced thermal conductivity of thermoplastic nanocomposites with a low mass fraction of MWCNTs by a facilitated latex approach. Compos. A Appl. Sci. Manuf. 90, 699–710 (2016)

Sachdeva, A., Singh, S., Sharma, V.S.: Investigating surface roughness of parts produced by SLS process. Int. J. Adv. Manuf. Technol. 64, 1505–1516 (2012)

Li, J., Yuan, S., Zhu, J., Li, S., Zhang, W.: numerical model and experimental validation for laser sinterable semi-crystalline polymer: shrinkage and warping. Polymers (Basel) 12(6), 1373 (2020)

Wang, R.-J., Wang, L., Zhao, L., Liu, Z.: Influence of process parameters on part shrinkage in SLS. Int. J. Adv. Manuf. Technol. 33, 498–504 (2006)

Chowdhury, S., Mhapsekar, K., Anand, S.: Part build orientation optimization and neural network-based geometry compensation for additive manufacturing process. J. Manuf. Sci. Eng. (2018). https://doi.org/10.1115/1.4038293

Shen, F., Yuan, S., Chua, C.K., Zhou, K.: Development of process efficiency maps for selective laser sintering of polymeric composite powders: modeling and experimental testing. J. Mater. Process. Technol. 254, 52–59 (2018)

Dong, L., Makradi, A., Ahzi, S., Remond, Y.: Three-dimensional transient finite element analysis of the selective laser sintering process. J. Mater. Process. Technol. 209, 700–706 (2009)

Riedlbauer, D., Drexler, M., Drummer, D., Steinmann, P., Mergheim, J.: Modelling, simulation and experimental validation of heat transfer in selective laser melting of the polymeric material PA12. Comput. Mater. Sci. 93, 239–248 (2014)

Balemans, C., Looijmans, S.F.S.P., Grosso, G., Hulsen, M.A., Anderson, P.D.: Numerical analysis of the crystallization kinetics in SLS. Addit. Manuf. 33, 101126 (2020)

Khairallah, S.A., Anderson, A.: Mesoscopic simulation model of selective laser melting of stainless steel powder. J. Mater. Process. Technol. 214, 2627–2636 (2014)

Yan, W., Ge, W., Qian, Y., Lin, S., Zhou, B., Liu, W.K., et al.: Multi-physics modeling of single/multiple-track defect mechanisms in electron beam selective melting. Acta Mater. 134, 324–333 (2017)

Dai, D., Gu, D., Ge, Q., Ma, C., Shi, X., Zhang, H.: Thermodynamics of molten pool predicted by computational fluid dynamics in selective laser melting of Ti6Al4V: surface morphology evolution and densification behavior. Comput. Model. Eng. Sci. 124, 1085–1098 (2020)

Cao, L.: Mesoscopic-scale numerical investigation including the inuence of process parameters on LPBF multi-layer multi-path formation. Comput. Model. Eng. Sci. 126, 5–23 (2021)

Yan, W., Lin, S., Kafka, O.L., Lian, Y., Yu, C., Liu, Z., et al.: Data-driven multi-scale multi-physics models to derive process–structure–property relationships for additive manufacturing. Comput. Mech. 61, 521–541 (2018)

Li, J., Jin, R., Yu, H.Z.: Integration of physically-based and data-driven approaches for thermal field prediction in additive manufacturing. Mater. Des. 139, 473–485 (2018)

Francis, J., Bian, L.: Deep learning for distortion prediction in laser-based additive manufacturing using big data. Manuf. Lett. 20, 10–14 (2019)

Wang, C., Li, S., Zeng, D., Zhu, X.: Quantification and compensation of thermal distortion in additive manufacturing: a computational statistics approach. Comput. Methods Appl. Mech. Eng. 375, 113611 (2021)

Manshoori Yeganeh, A., Movahhedy, M.R., Khodaygan, S.: An efficient scanning algorithm for improving accuracy based on minimising part warping in selected laser sintering process. Virtual Phys. Prototyp. 14, 59–78 (2018)

Arruda, E.M., Boyce, M.C., Jayachandran, R.: Effects of strain rate, temperature and thermomechanical coupling on the finite strain deformation of glassy polymers. Mech. Mater. 19, 193–212 (1995)

Dupaix, R.B., Boyce, M.C.: Constitutive modeling of the finite strain behavior of amorphous polymers in and above the glass transition. Mech. Mater. 39, 39–52 (2007)

Garcia-Gonzalez, D., Zaera, R., Arias, A.: A hyperelastic-thermoviscoplastic constitutive model for semi-crystalline polymers: application to PEEK under dynamic loading conditions. Int. J. Plast. 88, 27–52 (2017)

Yu, C., Kang, G., Chen, K.: A hygro-thermo-mechanical coupled cyclic constitutive model for polymers with considering glass transition. Int. J. Plast. 89, 29–65 (2017)

Benedetti, L., Brulé, B., Decreamer, N., Evans, K.E., Ghita, O.: Shrinkage behaviour of semi-crystalline polymers in laser sintering: PEKK and PA12. Mater. Des. 181, 107906 (2019)

Zhu, W., Yan, C., Shi, Y., Wen, S., Liu, J., Shi, Y.: Investigation into mechanical and microstructural properties of polypropylene manufactured by selective laser sintering in comparison with injection molding counterparts. Mater. Des. 82, 37–45 (2015)

Zhao, M., Wudy, K., Drummer, D.: Crystallization kinetics of polyamide 12 during selective laser sintering. Polymers 10(2), 168 (2018)

Shen, F., Kang, G., Lam, Y.C., Liu, Y., Zhou, K.: Thermo-elastic-viscoplastic-damage model for self-heating and mechanical behavior of thermoplastic polymers. Int. J. Plast. 121, 227–243 (2019)

Maurel-Pantel, A., Baquet, E., Bikard, J., Bouvard, J.L., Billon, N.: A thermo-mechanical large deformation constitutive model for polymers based on material network description: application to a semi-crystalline polyamide 66. Int. J. Plast. 67, 102–126 (2015)

Melro, A.R., Camanho, P.P., Andrade Pires, F.M., Pinho, S.T.: Micromechanical analysis of polymer composites reinforced by unidirectional fibres: part I - constitutive modelling. Int. J. Solids Struct. 50, 1897–1905 (2013)

Nguyen, V.D., Lani, F., Pardoen, T., Morelle, X.P., Noels, L.: A large strain hyperelastic viscoelastic-viscoplastic-damage constitutive model based on a multi-mechanism non-local damage continuum for amorphous glassy polymers. Int. J. Solids Struct. 96, 192–216 (2016)

Zerbe, P., Schneider, B., Moosbrugger, E., Kaliske, M.: A viscoelastic-viscoplastic-damage model for creep and recovery of a semicrystalline thermoplastic. Int. J. Solids Struct. 110–111, 340–350 (2017)

Soldner, D., Greiner, S., Burkhardt, C., Drummer, D., Steinmann, P., Mergheim, J.: Numerical and experimental investigation of the isothermal assumption in selective laser sintering of PA12. Addit. Manuf. 37, 101676 (2021)

Nakamura, K., Watanabe, T., Katayama, K., Amano, T.: Some aspects of nonisothermal crystallization of polymers. I. Relationship between crystallization temperature, crystallinity, and cooling conditions. J. Appl. Polym. Sci. 16, 1077–1091 (1972)

Nakamura, K., Katayama, K., Amano, T.: Some aspects of nonisothermal crystallization of polymers. II. Consideration of the isokinetic condition. J. Appl. Polym. Sci. 17, 1031–1041 (1973)

Patel, R.M., Spruiell, J.E.: Crystallization kinetics during polymer processing—analysis of available approaches for process modeling. Polym. Eng. Sci. 31, 730–738 (1991)

EMS-CHEMIE: Grilamid polyamide 12 technical polymer for highest demands. pp. 1–40 (2017)

Acknowledgements

The authors acknowledge the financial support from the National Natural Science Foundation of China (No. 12002234), the research start-up foundation of Tianjin University (0903061122), and the opening project of Tianjin Key Laboratory of Modern Engineering Mechanics, Tianjin University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shen, F., Zhu, W., Zhou, K. et al. Modeling the temperature, crystallization, and residual stress for selective laser sintering of polymeric powder. Acta Mech 232, 3635–3653 (2021). https://doi.org/10.1007/s00707-021-03020-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-021-03020-6