Abstract

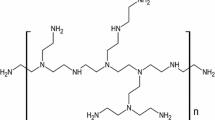

Effects of graphene oxide (GO) on various properties of rubber hybrid nanocomposites based on PVMQ/XNBR-g-GMA/XNBR (phenyl-vinyl-methyl-polysiloxane/carboxylated nitrile rubber-grafted maleic anhydride/XNBR) were identified. These nanocomposites were prepared with melt mixing method and fabricated by a laboratory two-roll mill. To evaluate the adhesion between the blend phases, i.e., PVMQ and XNBR, the results of microscopic and swelling tests were used simultaneously. The results showed that the adhesion of GO on PVMQ/XNBR rubber matrix was increased by the incorporation of XNBR-g-GMA as a compatibilizer. By increasing the amount of GO in the blend to 10 phr, the scorch time and curing time decreased by 24% and 26%, respectively, while the curing rate and maximum curing torque increased by 27% and 15%, respectively. Tear strength, hardness, and compression set of samples increased with increasing the GO content. The SEM images showed that the porosity of the prepared nanocomposites decreased from 17.34 to 4.84 µm for 5 phr GO. In the presence of a compatibilizer, the size of XNBR dispersed phase declined. This means that a stronger bond is formed between the blend phases. The results of TEM images also illustrated that the addition of compatibilizer to the PVMQ/XNBR rubber matrix resulted in excellent dispersion of GO nanoplatelets. To predict the mechanical and rheological properties, Mooney–Rivlin and Carreau–Yasuda models were applied, respectively. The parameters of these models were theoretically determined and compared with the experimental data, and a good agreement was observed.

Similar content being viewed by others

Abbreviations

- \(\varepsilon_{{\text{m}}}\) :

-

Average strain

- \(\varepsilon_{{\text{m}}}\) :

-

Total strain

- \(\sigma _{{\text{m}}}\) :

-

Average stress

- \({\text{A}}_{{\text{f}}}\) :

-

Strain concentration tensor

- \(C\) :

-

Effective elastic modulus

- \(S\) :

-

Eshelby tensor

- \(\bar{\varepsilon}\) :

-

Average strain

- \(\bar{\sigma }\) :

-

Average stress

- n :

-

Number of nanoparticles

- \(V_{{\text{i}}}\) :

-

Volume fraction of the of nanoparticles

- \(V_{{\text{m}}}\) :

-

Volume fraction of the matrix

- \(\varepsilon _{{\text{i}}}\) :

-

Strain tensor of the dispersed phase

- \(\sigma _{{\text{i}}}\) :

-

Stress tensor of the dispersed phase

- \({\text{A}}_{{\text{i}}}\) :

-

Strain concentration tensor for each nanoparticle

- \({G}\) :

-

Effective shear modulus

- \(K\) :

-

Bulk modulus

- \(\alpha _{{{\text{f~}}}} ,\beta _{{{\text{f~}}}} ,\delta _{{{\text{f~}}}} ,{\text{n}}_{{{\text{f~}}}}\) :

-

Dimensionless parameters

- p, k, n, m, l :

-

Hill’s model parameters

- \(E\) :

-

Young's modulus

- \({\text{m}}\) :

-

Sample mass

- \({\text{m}}_{0}\) :

-

Initial mass

- \(\left( {{\text{wt}}.{\text{~\% }}} \right)_{{{\text{PVMQ}}}}\) :

-

Weight percentages of PVMQ

- \(\left( {{\text{wt}}.{\text{~\% }}} \right)_{{{\text{GO}}}}\) :

-

Weight percentages of nanoparticles

- \(C_{1} , C_{2}\) :

-

Constants

- \(\lambda\) :

-

Strain ratio

- \(\sigma\) :

-

Applied stress

- \(\lambda _{{\text{m}}}\) :

-

Maximum strain ratio

- \(G_{{\text{c}}}\) :

-

Elastic modulus from the cross-linking constraints

- \(\sigma _{{\text{M}}}\) :

-

Reduced stress

- \(G_{{\text{e}}}\) :

-

Entanglement modulus

- \(\varphi\) :

-

Volume fraction of nanoparticles

- \(V_{{\text{C}}}\) :

-

Effective cross-linking density

- {R 0 2 } :

-

Mean square end-to-end distance

- R C :

-

Average square end-to-end distance of the cross-linking

- N :

-

Average number of statistical segments

- \(A_{{\text{c}}}\) :

-

Fluctuations of the effective cross-linking linkages

- ρ :

-

Density of PVMQ

- M S :

-

Molar mass of statistical segments for PVMQ

- M C :

-

Mean molar mass of the cross-links

- T :

-

Temperature

- N A :

-

Avogadro’s number

- k B :

-

Boltzmann constant

- l S :

-

Average length of the Kuhn's statistical segment

- n S :

-

Density of rubber segments

- d 0 :

-

Tube radius

- \(n_{{\text{e}}}\) :

-

Effective entanglements

- \(v_{{\text{m}}}\) :

-

Poisson’s ratio

- \(E_{{\text{m}}}\) :

-

Matrix Young’s modulus

- \(\nu _{{12}}\) :

-

In-plain Poisson’s ratio

- \(\nu _{{13}}\) :

-

Out-of-plain Poisson’s ratio

- \(G_{{13}}\) :

-

Out-of-plain shear modulus

- \(E_{3}\) :

-

Out-of-plain Young’s modulus

- \(E_{1}\) :

-

In-plain Young’s modulus

- \(\eta ^{{\text{*}}}\) :

-

Complex viscosity

- n :

-

Shear-thinning exponent

- \({\text{A}}\) :

-

Power law constant

- ω :

-

Angular frequency

- λ :

-

Relaxation time

- a :

-

Yasuda factor

- m :

-

Dimensionless power index

- η 0 :

-

Zero-shear viscosity

- σ 0 :

-

Yield stress

- \({\text{G}}^{\prime}\) :

-

Storage modulus

References

Shit SC, Shah P (2013) A review on silicone rubber. Natl Acad Sci Lett 36:355–365

Bazli L, Khavandi A, Boutorabi MA, Karrabi M (2016) Morphology and viscoelastic behavior of silicone rubber/EPDM/Cloisite 15A nanocomposites based on Maxwell model. Iran Polym J 25:907–918

Wang S, Long C, Wang X, Li Q, Qi Z (1998) Synthesis and properties of silicone rubber/organomontmorillonite hybrid nanocomposites. J Appl Polym Sci 69:1557–1561

Aliabadi MM, Naderi G, Shahtaheri SJ, Rahimi Forushani A, Mohammadfam I, Jahangiri M (2014) Mechanical and barrier properties of XNBR-clay nanocomposite: a promising material for protective gloves. Iran Polym J 23:289–296

Jiang P, Yang C, He X, Rodrigues AM (2017) Viscoelastic changes in chlorinated butyl rubber modified with graphene oxide. Iran Polym J 26:861–870

Feng T, Rai A, Hun D, Shrestha SS (2021) Molecular dynamics simulations of energy accommodation between gases and polymers for ultra-low thermal conductivity insulation. Int J Heat Mass Transf 164:120459

Shuang F, Aifantis KE (2021) Modelling dislocation-graphene interactions in a BCC Fe matrix by molecular dynamics simulations and gradient plasticity theory. Appl Surf Sci 535:147602

Barghamadi M, Ghoreishy MHR, Karrabi M, Mohammadian-Gezaz S (2021) Modeling of nonlinear hyper-viscoelastic and stress softening behaviors of acrylonitrile butadiene rubber/polyvinyl chloride nanocomposites reinforced by nanoclay and graphene. Polym Compos 42:583–596

Huang YX, Huang HX (2019) Rheological behavior of well-dispersed polypropylene/halloysite nanotube composites prepared by water-assisted mixing extrusion. Iran Polym J 28:813–822

Liu J, Martin PF, McGrail BP (2021) Rare-earth element extraction from geothermal brine using magnetic core-shell nanoparticles-techno-economic analysis. Geothermics 89:101938

Paraskar P, Bari P, Mishra S (2020) Influence of amine functionalized graphene oxide on mechanical and thermal properties of epoxy matrix composites. Iran Polym J 29:47–55

Hussain F, Hojjati M, Okamoto M, Gorga RE (2006) Polymer-matrix nanocomposites, processing, manufacturing, and application: an overview. J Compos Mater 40:1511–1575

Thomas B, Maria HJ, George G, Thomas S, Unnikrishnan C, Joseph K (2019) A novel green approach for the preparation of high performance nitrile butadiene rubber-pristine graphene nanocomposites. Compos Part B Eng 175:107174

Sadeghi S, Arjmand M, Otero Navas I, Zehtab Yazdi A, Sundararaj U (2017) Effect of nanofiller geometry on network formation in polymeric nanocomposites: comparison of rheological and electrical properties of multiwalled carbon nanotube and graphene nanoribbon. Macromolecules 50:3954–3967

Rane AV, Kanny K, Abitha VK, Thomas S (2018) Micro and nano technologies. Woodhead Publishing, Cambridge

Chandran NCS, Thomas S (2020) Rheology of polymer-clay nanocomposites. Elsevier, Amsterdam

Mercier S, Molinari A (2009) Homogenization of elastic-viscoplastic heterogeneous materials: self-consistent and Mori-Tanaka schemes. Int J Plast 25:1024–1048

Desrumaux F, Meraghni F, Benzeggagh ML (2001) Generalised Mori-Tanaka scheme to model anisotropic damage using numerical Eshelby tensor. J Compos Mater 35:603–624

Raju B, Hiremath SR, Mahapatra DR (2018) A review of micromechanics based models for effective elastic properties of reinforced polymer matrix composites. Compos Struct 204:607–619

Ji XY, Cao YP, Feng XQ (2010) Micromechanics prediction of the effective elastic moduli of graphene sheet-reinforced polymer nanocomposites. Model Simul Mater Sci Eng 18:45005

Bose S, Kim NH, Kuila T, Lau K, Lee JH (2011) Electrochemical performance of a graphene–polypyrrole nanocomposite as a supercapacitor electrode. Nanotechnology 22:295202

Azizli MJ, Barghamadi M, Rezaeeparto K, Mokhtary M, Parham S, Goodarzi V, Soltani S (2020) Enhancement of thermal, morphological, and mechanical properties of compatibilized based on PA6-enriched graphene oxide/EPDM-g-MA/CR: graphene oxide and EPDM-g-MA compatibilizer role. J Appl Polym Sci 138:49901

Barghamadi M, Ghoreishy MHR, Karrabi M, Mohammadian-Gezaz S (2020) Investigation on the kinetics of cure reaction of acrylonitrile-butadiene rubber (NBR)/polyvinyl chloride (PVC)/graphene nanocomposite using various models. J Appl Polym Sci 137:48632

Gogoi P, Boruah R, Dolui SK (2015) Jatropha curcas oil based alkyd/epoxy/graphene oxide (GO) bionanocomposites: effect of GO on curing, mechanical and thermal properties. Prog Org Coatings 84:128–135

Mondal D, Ghorai S, Rana D, Debapriya D, Chattopadhyay D (2019) The rubber-filler interaction and reinforcement in styrene butadiene rubber/devulcanize natural rubber composites with silica-graphene oxide. Polym Compos 40:E1559–E1572

George SC, Prasad K, Misra JP, Thomas S (1999) Separation of alkane-acetone mixtures using styrene-butadiene rubber/natural rubber blend membranes. J Appl Polym Sci 74:3059–3068

Hayashi A, Kanzaki T (1987) Swelling of agarose gel and its related changes. Food Hydrocoll 1:317–325

Yang G, Liao Z, Yang Z, TangZ GB (2015) Effects of substitution for carbon black with graphene oxide or graphene on the morphology and performance of natural rubber/carbon black composites. J Appl Polym Sci 132:41832

Aswathi MK, Ajitha AR, Padmanabhan M, Mathew LP, Thomas S (2019) Morphologically correlated surface characteristics of poly (trimethylene terephthalate)/multiwalled carbon nanotube nanocomposites. Funct Compos Struct 1:45002

Wan C, Chen B (2012) Reinforcement and interphase of polymer/graphene oxide nanocomposites. J Mater Chem 22:3637–3646

Yaragalla S, Rajendran R, Jose J, AlMaadeed AM, Kalarikkal N, Thomas S (2016) Preparation and characterization of green graphene using grape seed extract for bioapplications. Mater Sci Eng C 65:345–353

Kang H, Tang Y, Yao L, Yang F, Fang Q, Hui D (2017) Fabrication of graphene/natural rubber nanocomposites with high dynamic properties through convenient mechanical mixing. Compos Part B Eng 112:1–7

Kim B, Lee SB, Lee J, Cho S, Park H, Yeom S, Park SH (2012) A comparison among Neo-Hookean model, Mooney-Rivlin model, and Ogden model for chloroprene rubber. Int J Precis Eng Manuf 13:759–764

Hasanabadi N, Nazockdast H, Balog S, Lattuada M (2017) Rheological characterization of nanostructured material based on Polystyrene-b-poly (ethylene-butylene)-b-polystyrene (SEBS) block copolymer: effect of block copolymer composition and nanoparticle geometry. Compos Sci Technol 149:192–206

Xing W, Wu J, Huang G, Li H, Tang M, Fu X (2014) Enhanced mechanical properties of graphene/natural rubber nanocomposites at low content. Polym Int 63:1674–1681

Ponnamma D, Sadasivuni KK, Strankowski M, Moldenaers P, Thomas S, Grohensa Y (2013) Interrelated shape memory and Payne effect in polyurethane/graphene oxide nanocomposites. RSC Adv 3:16068–16079

Sharma P, Mali HS, Dixit A (2020) Mechanical behavior and fracture toughness characterization of high strength fiber reinforced polymer textile composites. Iran Polym J30:193–233

Shokrieh MM, Esmkhani M, Shokrieh Z, Zhao Z (2014) Stiffness prediction of graphene nanoplatelet/epoxy nanocomposites by a combined molecular dynamics-micromechanics method. Comput Mater Sci 92:444–450

Farfán-Cabrera LI, Pascual-Francisco JB, Barragán-Pérez O, Gallardo-Hernández EA, Susarrey-Huertab O (2017) Determination of creep compliance, recovery and Poisson’s ratio of elastomers by means of digital image correlation (DIC). Polym Test 59:245–252

Azizli MJ, Barghamadi M, Rezaeeparto K, Mokhtary M, Parham S (2020) Compatibility, mechanical and rheological properties of hybrid rubber NR/EPDM-g-MA/EPDM/graphene oxide nanocomposites: theoretical and experimental analyses. Compos Commun 22:100442

Wetton RE, Corish PJ (1988) DMTA studies of polymer blends and compatibility. Polym Test 8:303–312

Essawy HA, Khalil AM, Tawfik ME, El-Sabbagh SH (2014) Compatibilization of NBR/SBR blends using amphiphilic montmorillonites: A dynamic mechanical thermal study. J Elastomers Plast 46:514–526

Barghamadi M, Karrabi M, Ghoreishy MHR, Mohammadian-Gezaz S (2019) Effects of two types of nanoparticles on the cure, rheological, and mechanical properties of rubber nanocomposites based on the NBR/PVC blends. J Appl Polym Sci 136:47550

Azizli MJ, Mokhtary M, Khonakdar HA, Goodarzi V (2020) Compatibilizer/graphene/carboxylated acrylonitrile butadiene rubber (XNBR)/ethylenepropylenediene monomer (EPDM) nanocomposites: morphology, compatibility, rheology and mechanical properties. J Appl Polym Sci 137:49331

Gao J, Yang J, Du Y, Liu X (2013) Dynamic rheological behavior and mechanical properties of PVC/ACS blends. Iran Polym J 22:285–292

Tripathi SN, Malik RS, Choudhary V (2015) Melt rheology and thermomechanical behavior of poly (methyl methacrylate)/reduced graphene oxide nanocomposites. Polym Adv Technol 26:1558–1566

Zare Y, Park SP, Rhee KY (2019) Analysis of complex viscosity and shear thinning behavior in poly (lactic acid)/poly (ethylene oxide)/carbon nanotubes biosensor based on Carreau-Yasuda model. Results Phys 13:102245

Azizli MJ, Ziaee M, Rezaeinia S, Seyfi J, Mansourian-Tabaei M, Hoseinzadeh M, Azizli MH (2018) Studying the roles of nanoclay and blend composition on the improved properties of natural rubber/chloroprene composites. Polym Compos 39:1562–1574

Acknowledgements

The financial support by Khazra Sazan Rad Polymer Parsian, Consulting Polymer Engineers is acknowledged by the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Azizli, M.J., Barghamadi, M., Rezaeeparto, K. et al. Theoretical and experimental analyses of rheological, compatibility and mechanical properties of PVMQ/XNBR-g GMA/XNBR/GO ternary hybrid nanocomposites. Iran Polym J 30, 1001–1018 (2021). https://doi.org/10.1007/s13726-021-00953-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00953-6