Abstract

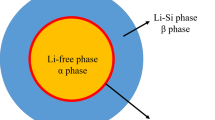

Lithiation and delithiation in electrodes lead to the evolution of internal stresses which may cause the mechanical degradation of batteries. In this work, the diffusion-induced stress of a hollow cylindrical electrode under either galvanostatic or potentiostatic charging is analytically solved based on a diffusion and mechanical coupled continuum model. The stress distributions at the end faces of the electrode with both ends traction free or fixed are also analyzed, the end effect of diffusion-induced bending is taken into account, and the resulting bending stresses are of practical importance for the stress distribution at the end faces. Using the obtained analytical expressions, a numerical example is given, and the results show that the stress distributions at the end faces change dramatically compared to the stresses remote from ends, both the charging mode and end constraints have significant effects on the distribution of stresses at the end faces of the electrodes, and the most dangerous location during the charging process is affected by the end’s constraint conditions.

Similar content being viewed by others

References

Yan, P., Zheng, J., Gu, M., Xiao, J., Zhang, J.G., Wang, C.M.: Intragranular cracking as a critical barrier for high-voltage usage of layer-structured cathode for lithium-ion batteries. Nat. Commun. 8, 14101 (2017). https://doi.org/10.1038/ncomms14101

Palacin, M.R., de Guibert, A.: Why do batteries fail? Science 351(6273), 1253292 (2016). https://doi.org/10.1126/science.1253292

Zhang, S., Zhao, K., Zhu, T., Li, J.: Electrochemomechanical degradation of high-capacity battery electrode materials. Prog. Mater .Sci. 89, 479–521 (2017). https://doi.org/10.1016/j.pmatsci.2017.04.014

Shi, F., Song, Z., Ross, P.N., Somorjai, G.A., Ritchie, R.O., Komvopoulos, K.: Failure mechanisms of single-crystal silicon electrodes in lithium-ion batteries. Nat. Commun. (2016). https://doi.org/10.1038/ncomms11886

Zhang, S.: Chemomechanical modeling of lithiation-induced failure in high-volume-change electrode materials for lithium ion batteries. NPJ Comput. Mater. (2017). https://doi.org/10.1038/s41524-017-0009-z

Mendez, J.P., Ponga, M., Ortiz, M.: Diffusive molecular dynamics simulations of lithiation of silicon nanopillars. J. Mech. Phys. Solids 115, 123–141 (2018). https://doi.org/10.1016/j.jmps.2018.03.008

Koohbor, B., Sang, L., Çapraz, Ö.Ö., Gewirth, A.A.: In situ strain measurement in solid-state Li-ion battery electrodes. J. Electrochem. Soc. 168(1), 010516 (2021). https://doi.org/10.1149/1945-7111/abd60b

Prussin, S.: Generation and Distribution of dislocations by solute diffusion. J. Appl. Phys. 32(10), 1876–1881 (1961). https://doi.org/10.1063/1.1728256

Lee, S., Wang, W.L., Chen, J.R.: Diffusion-induced stresses in a hollow cylinder. Mater. Sci. Eng. 285(1–2), 186–194 (2000)

Cheng, Y.-T., Verbrugge, M.W.: The influence of surface mechanics on diffusion induced stresses within spherical nanoparticles. J. Appl. Phys. (2008). https://doi.org/10.1063/1.3000442

Deshpande, R., Cheng, Y.-T., Verbrugge, M.W.: Modeling diffusion-induced stress in nanowire electrode structures. J. Power Sour. 195(15), 5081–5088 (2010). https://doi.org/10.1016/j.jpowsour.2010.02.021

Zhang, X.-Y., Chen, H.-S., Fang, D.: Effects of surface stress on lithium-ion diffusion kinetics in nanosphere electrodes of lithium-ion batteries. Int. J. Mech. Sci. (2020). https://doi.org/10.1016/j.ijmecsci.2019.105323

Cheng, Y.-T., Verbrugge, M.W.: Evolution of stress within a spherical insertion electrode particle under potentiostatic and galvanostatic operation. J. Power Sour. 190(2), 453–460 (2009). https://doi.org/10.1016/j.jpowsour.2009.01.021

Yang, X.-G., Bauer, C., Wang, C.-Y.: Sinusoidal current and stress evolutions in lithium-ion batteries. J. Power Sour. 327, 414–422 (2016). https://doi.org/10.1016/j.jpowsour.2016.07.070

Deshpande, R., Qi, Y., Cheng, Y.-T.: Effects of concentration-dependent elastic modulus on diffusion-induced stresses for battery applications. J. Electrochem. Soc. 157(8), A967–A971 (2010). https://doi.org/10.1149/1.3454762

Cai, X., Guo, Z.: Influence of Li concentration-dependent diffusion coefficient and modulus hardening on diffusion-induced stresses in anisotropic anode particles. J. Electrochem. Soc. 168(1), 010517 (2021). https://doi.org/10.1149/1945-7111/abd82e

Deshpande, R., Cheng, Y.-T., Verbrugge, M.W., Timmons, A.: Diffusion induced stresses and strain energy in a phase-transforming spherical electrode particle. J. Electrochem. Soc. 158(6), A718–A724 (2011). https://doi.org/10.1149/1.3565183

Zhang, X., Hao, F., Chen, H., Fang, D.: Diffusion-induced stress and delamination of layered electrode plates with composition-gradient. Mech. Mater. 91, 351–362 (2015)

Hu, H., Yu, P., Suo, Y.: Stress induced by diffusion and local chemical reaction in spherical composition-gradient electrodes. Acta Mech. 231(7), 2669–2678 (2020). https://doi.org/10.1007/s00707-020-02652-4

Christensen, J., Newman, J.: Stress generation and fracture in lithium insertion materials. J. Solid State Electrochem. 10(5), 293–319 (2006). https://doi.org/10.1007/s10008-006-0095-1

Bower, A.F., Guduru, P.R., Sethuraman, V.A.: A finite strain model of stress, diffusion, plastic flow, and electrochemical reactions in a lithium-ion half-cell. J. Mech. Phys. Solids 59(4), 804–828 (2011). https://doi.org/10.1016/j.jmps.2011.01.003

Zhang, X., Shyy, W., Sastry, A.M.: Numerical simulation of intercalation-induced stress in Li-ion battery electrode particles. J. Electrochem. Soc. 154(10), A910–A916 (2007). https://doi.org/10.1149/1.2759840

Bower, A.F., Guduru, P.R., Chason, E.: Analytical solutions for composition and stress in spherical elastic-plastic lithium-ion electrode particles containing a propagating phase boundary. Int. J. Solids Struct. 69–70, 328–342 (2015). https://doi.org/10.1016/j.ijsolstr.2015.05.018

Christensen, J., Newman, J.: A mathematical model of stress generation and fracture in lithium manganese oxide. J. Electrochem. Soc. 153(6), A1019–A1030 (2006). https://doi.org/10.1149/1.2185287

Cui, Z., Gao, F., Qu, J.: A finite deformation stress-dependent chemical potential and its applications to lithium ion batteries. J. Mech. Phys. Solids 60(7), 1280–1295 (2012). https://doi.org/10.1016/j.jmps.2012.03.008

Anand, L.: A Cahn-Hilliard-type theory for species diffusion coupled with large elastic-plastic deformations. J. Mech. Phys. Solids 60(12), 1983–2002 (2012). https://doi.org/10.1016/j.jmps.2012.08.001

Zhang, K., Li, Y., Wang, F., Zheng, B., Yang, F., Lu, D.: An analytical model for lithiation-induced concurrent plastic flow and phase transformation in a cylindrical silicon electrode. Int. J. Solids Struct. 202, 87–98 (2020). https://doi.org/10.1016/j.ijsolstr.2020.06.008

Chen, Y., Chen, H., Luan, W.: Shakedown, ratcheting and fatigue analysis of cathode coating in lithium-ion battery under steady charging-discharging process. J. Mech. Phys. Solids 150, 104366 (2021). https://doi.org/10.1016/j.jmps.2021.104366

Drozdov, A.D.: A model for the mechanical response of electrode particles induced by lithium diffusion in Li-ion batteries. Acta Mech. 225(11), 2987–3005 (2014). https://doi.org/10.1007/s00707-014-1096-2

Bagheri, A., Arghavani, J., Naghdabadi, R., Brassart, L.: A theory for coupled lithium insertion and viscoplastic flow in amorphous anode materials for Li-ion batteries. Mech. Mater. (2021). https://doi.org/10.1016/j.mechmat.2020.103663

Larché, F., Cahn, J.W.: A linear theory of thermochemical equilibrium of solids under stress. Acta Metall. 21(8), 1051–1063 (1973). https://doi.org/10.1016/0001-6160(73)90021-7

Liu, Y., Lv, P., Ma, J., Bai, R., Duan, H.L.: Stress fields in hollow core-shell spherical electrodes of lithium ion batteries. Proc. R. Soc. A Math. Phys. Eng. Sci. (2014). https://doi.org/10.1098/rspa.2014.0299

Haftbaradaran, H., Qu, J.: Two-dimensional chemo-elasticity under chemical equilibrium. Int. J. Solids Struct. 56–57, 126–135 (2015). https://doi.org/10.1016/j.ijsolstr.2014.11.025

Gao, X., Fang, D., Qu, J.: A chemo-mechanics framework for elastic solids with surface stress. Proc. R. Soc. A Math. Phys. Eng. Sci. (2015). https://doi.org/10.1098/rspa.2015.0366

Ryu, I., Choi, J.W., Cui, Y., Nix, W.D.: Size-dependent fracture of Si nanowire battery anodes. J. Mech. Phys. Solids 59(9), 1717–1730 (2011). https://doi.org/10.1016/j.jmps.2011.06.003

Eshghinejad, A., Li, J.: The coupled lithium ion diffusion and stress in battery electrodes. Mech. Mater. 91, 343–350 (2015). https://doi.org/10.1016/j.mechmat.2015.09.015

Bagheri, A., Arghavani, J., Naghdabadi, R.: On the effects of hydrostatic stress on Li diffusion kinetics and stresses in spherical active particles of Li-ion battery electrodes. Mech. Mater. (2019). https://doi.org/10.1016/j.mechmat.2019.103134

Chen, H., Huang, H.-Y.S.: Modeling and simulation of the non-equilibrium process for a continuous solid solution system in lithium-ion batteries. Int. J. Solids Struct. 212, 124–142 (2021). https://doi.org/10.1016/j.ijsolstr.2020.11.014

Holzapfel, M., Buqa, H., Scheifele, W., Novak, P., Petrat, F.M.: A new type of nano-sized silicon/carbon composite electrode for reversible lithium insertion. Chem. Commun. 12, 1566–1568 (2005). https://doi.org/10.1039/b417492e

Patel, P., Kim, I.S., Kumta, P.N.: Nanocomposites of silicon/titanium carbide synthesized using high-energy mechanical milling for use as anodes in lithium-ion batteries. Mater. Sci. Eng. B Solid State Mater. Adv. Technol. 116(3), 347–352 (2005). https://doi.org/10.1016/j.mseb.2004.05.046

Zhu, X., Xie, Y., Chen, H., Luan, W.: Numerical analysis of the cyclic mechanical damage of Li-ion battery electrode and experimental validation. Int. J. Fatigue 142, 105915 (2021). https://doi.org/10.1016/j.ijfatigue.2020.105915

Chan, C.K., Peng, H., Liu, G., McIlwrath, K., Zhang, X.F., Huggins, R.A., Cui, Y.: High-performance lithium battery anodes using silicon nanowires. Nat. Nanotechnol. 3(1), 31–35 (2008). https://doi.org/10.1038/nnano.2007.411

Xiao, X., Liu, P., Verbrugge, M.W., Haftbaradaran, H., Gao, H.: Improved cycling stability of silicon thin film electrodes through patterning for high energy density lithium batteries. J. Power Sour. 196(3), 1409–1416 (2011). https://doi.org/10.1016/j.jpowsour.2010.08.058

Bhandakkar, T.K., Gao, H.: Cohesive modeling of crack nucleation in a cylindrical electrode under axisymmetric diffusion induced stresses. Int. J. Solids Struct. 48(16–17), 2304–2309 (2011). https://doi.org/10.1016/j.ijsolstr.2011.04.005

Yao, Y., McDowell, M.T., Ryu, I., Wu, H., Liu, N., Hu, L., Nix, W.D., Cui, Y.: Interconnected silicon hollow nanospheres for lithium-ion battery anodes with long cycle life. Nano Lett. 11(7), 2949–2954 (2011). https://doi.org/10.1021/nl201470j

Zhang, K., Li, Y., Zheng, B., Wu, G., Wu, J., Yang, F.: Large deformation analysis of diffusion-induced buckling of nanowires in lithium-ion batteries. Int. J. Solids Struct. 108, 230–243 (2017). https://doi.org/10.1016/j.ijsolstr.2016.12.020

Zhang, K., Li, Y., Wu, J., Zheng, B., Yang, F.: Lithiation-induced buckling of wire-based electrodes in lithium-ion batteries: a phase-field model coupled with large deformation. Int. J. Solids Struct. 144–145, 289–300 (2018). https://doi.org/10.1016/j.ijsolstr.2018.05.014

Zhang, K., Li, Y., Wang, F., Zheng, B., Yang, F.: Stress effect on self-limiting lithiation in silicon-nanowire electrode. Appl. Phys. Express (2019). https://doi.org/10.7567/1882-0786/ab0ce8

Xing, H., Liu, Y., Wang, B.: Mechano-electrochemical and buckling analysis of composition-gradient nanowires electrodes in lithium-ion battery. Acta Mech. 230(12), 4145–4156 (2019). https://doi.org/10.1007/s00707-019-02486-9

Zhang, Y., Zhan, S., Zhang, K., Zheng, B., Lyu, L.: Buckling behavior of a wire-like electrode with a concentration-dependent elastic modulus based on a deformed configuration. Eur. J. Mech. A. Solids 85, 104111 (2021). https://doi.org/10.1016/j.euromechsol.2020.104111

Chakraborty, J., Please, C.P., Goriely, A., Chapman, S.J.: Combining mechanical and chemical effects in the deformation and failure of a cylindrical electrode particle in a Li-ion battery. Int. J. Solids Struct. 54, 66–81 (2015). https://doi.org/10.1016/j.ijsolstr.2014.11.006

Guo, Z., Zhang, T., Hu, H., Song, Y., Zhang, J.: Effects of hydrostatic stress and concentration-dependent elastic modulus on diffusion-induced stresses in cylindrical li-ion batteries. J. Appl. Mech. (2013). https://doi.org/10.1115/1.4025271

Yang, F.: Effect of diffusion-induced bending on diffusion-induced stress near the end faces of an elastic hollow cylinder. Mech. Res. Commun. 51, 72–77 (2013). https://doi.org/10.1016/j.mechrescom.2013.05.006

Zhang, X.L., Zhong, Z.: A coupled theory for chemically active and deformable solids with mass diffusion and heat conduction. J. Mech. Phys. Solids 107, 49–75 (2017). https://doi.org/10.1016/j.jmps.2017.06.013

Wang, X.-Q., Yang, Q.-S.: An analytical solution for chemo-mechanical coupled problem in deformable sphere with mass diffusion. Int. J. Appl. Mech. (2020). https://doi.org/10.1142/s1758825120500763

Haftbaradaran, H., Song, J., Curtin, W.A., Gao, H.: Continuum and atomistic models of strongly coupled diffusion, stress, and solute concentration. J. Power Sour. 196(1), 361–370 (2011). https://doi.org/10.1016/j.jpowsour.2010.06.080

Timoshenko, S.: Strength of Materials, Part 2: Advanced Theory and Problems, 3rd edn. Van Nostrand Reinhold Company, New York (1958)

Crank, J.: The Mathematics of Diffusion, 2nd edn. Oxford University Press, Oxford (1975)

Song, Y., Lu, B., Ji, X., Zhang, J.: Diffusion induced stresses in cylindrical lithium-ion batteries: analytical solutions and design insights. J. Electrochem. Soc. 159(12), A2060–A2068 (2012). https://doi.org/10.1149/2.079212jes

Song, X., Lu, Y., Wang, F., Zhao, X., Chen, H.: A coupled electro-chemo-mechanical model for all-solid-state thin film Li-ion batteries: The effects of bending on battery performances. J. Power Sour. (2020). https://doi.org/10.1016/j.jpowsour.2020.227803

Acknowledgements

This work was supported by the National Natural Science Foundation of China under the Grant Numbers: 11932002, 11802116, 11772012 and 11632005, which are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Liu, X. & Yang, Q. Transient analysis of diffusion-induced stress for hollow cylindrical electrode considering the end bending effect. Acta Mech 232, 3591–3609 (2021). https://doi.org/10.1007/s00707-021-03014-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-021-03014-4