Abstract

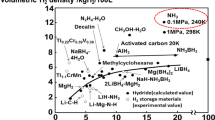

Recently, a new production process of various metals and alloys from their oxides and ores by Cold Hydrogen Plasma (CHP) has been introduced. CHP is produced by using a microwave oven, using less power than the microwave ovens used domestically for cooking food. CHP is very efficient in producing metals and alloys from their oxides because of excited species. These excited species decrease the thermodynamic and kinetic barriers of reduction, making the reduction easier and faster. In the current investigation, nickel has been produced from nickel oxide (NiO) pellets of ~ 2.5 gm to ~ 7.5 gm. The hydrogen flow rate ranges from 70 ml/s to 150 ml/s, and power varies from 600 to 750 W. The time taken for reduction changed between 300 to 1200 s. CHP reduces very fast due to the active oxygen present in it. This faster production of nickel from pellets upto ~ 7.5 gm at such low power opens up the possibilities of upscaling the reduction of NiO by CHP.

Similar content being viewed by others

References

Meshram P, Abhilash PBD (2019) Advanced review on extraction of nickel from primary and secondary sources. Miner Process Extr Metall Rev 40:157–193. https://doi.org/10.1080/08827508.2018.1514300

Oxley A, Smith ME, Caceres O (2016) Why heap leach nickel laterites? Miner Eng 88:53–60. https://doi.org/10.1016/j.mineng.2015.09.018

Petrus HTBM, Putera ADP, Sugiarto E et al (2019) Kinetics on roasting reduction of limonitic laterite ore using coconut-charcoal and anthracite reductants. Miner Eng 132:126–133. https://doi.org/10.1016/j.mineng.2018.11.043

Zhu D, Pan L, Guo Z et al (2019) Utilization of limonitic nickel laterite to produce ferronickel concentrate by the selective reduction-magnetic separation process. Adv Powder Technol 30:451–460. https://doi.org/10.1016/j.apt.2018.11.024

Garces-Granda A, Lapidus GT, Restrepo-Baena OJ (2018) The effect of calcination as pre treatment to enhance the nickel extraction from low-grade laterites. Miner Eng 120:127–131. https://doi.org/10.1016/j.mineng.2018.02.019

Rodrigues F, Pickles CA, Peacey J et al (2017) Factors affecting the upgrading of a nickeliferous limonitic laterite ore by reduction roasting, thermal growth and magnetic separation. Minerals 7:176. https://doi.org/10.3390/min7090176

Moats MS, Davenport WG (2014) Nickel and Cobalt Production. In: Treatise on Process Metallurgy. 3. Elsevier. 625–669

Yang J, Zhang G, Ostrovski O, Jahanshahi S (2019) Selective reduction of an Australian garnieritic laterite ore. Miner Eng 131:79–89. https://doi.org/10.1016/j.mineng.2018.10.018

de Alvarenga OV, dos Santos CG, de Albuquerque BE (2019) Assessing the influence of nacl on the reduction of a siliceous laterite nickel ore under caron process conditions. Metall Mater Trans B Process Metall Mater Process Sci. 50:1309–1321https://doi.org/10.1007/s11663-019-01552-w

Gomaa MM, Yazdi GR, Schmidt S et al (2017) Effect of precursor solutions on the structural and optical properties of sprayed NiO thin films. Mater Sci Semicond Process 64:32–38. https://doi.org/10.1016/j.mssp.2017.03.009

Fedorov AV, Kukushkin RG, Yeletsky PM et al (2020) Temperature-programmed reduction of model CuO, NiO and mixed CuO–NiO catalysts with hydrogen. J Alloys Compd 844:156135. https://doi.org/10.1016/j.jallcom.2020.156135

Ma B, Xing P, Yang W et al (2017) Solid-state metalized reduction of magnesium-rich low-nickel oxide ores using coal as the reductant based on thermodynamic analysis. Metall Mater Trans B 48:2037–2046 https://doi.org/10.1007/s11663-017-0977-x

Kharchenko Y V, Blikharskyy ZY, Vira V V, Vasyliv BD (2019) Study of structural changes in a nickel oxide containing anode material during reduction and oxidation at 600°C. In: Fesenko O., Yatsenko L. (eds) Nanocomposites, Nanostructures, and Their Applications. Springer Science and Business Media, LLC, Institute of Building and Environmental Engineering, Lviv Polytechnic National University, Lviv, Ukraine https://doi.org/10.1007/978-3-030-17759-1_42

Bakhshandeha S, Setoudeh N, Ali Askari Zamanic M, Mohassel A (2019) Carbothermic reduction of nickel oxide. Adv Process Mater Eng 13(63):75 https://ma.iaumajlesi.ac.ir/article_667347_en.html

Cabascango VEQ, Bazhin VY (2020) Nickel oxide reduction in CO/CO2 gas mixtures in reverberatory furnaces. In. J Phys: Conf Ser. IOP Publishing. 22028 https://doi.org/10.1088/1742-6596/1515/2/022028

Hidayat T, Rhamdhani MA, Jak E, Hayes PC (2009) The kinetics of reduction of dense synthetic nickel oxide in H 2–N2 and H2–H2O atmospheres. Metall Mater Trans B Process Metall Mater Process Sci 40:1–16. https://doi.org/10.1007/s11663-008-9212-0

Reid JG, Fittock JE (2004) Yabulu 25 years on. In: International Laterite Nickel Symposium, TMS Annual Meeting, The Minerals, Metals and Materials Society, Charlotte, NC, USA, pp. 599–618.

Utigard TAA, Wu M, Plascencia G, Marin T (2005) Reduction kinetics of goro nickel oxide using hydrogen. Chem Eng Sci 60:2061–2068. https://doi.org/10.1016/j.ces.2004.11.024

Rashed AH, Rao YK (1997) Kinetics of reduction of nickel oxide with hydroge gas in the 230–452°c range. Chem Eng Commun 156:1–30. https://doi.org/10.1080/00986449708936666

Benton AF, Emmett PH (1924) The reduction of nickelous and ferric oxides by hydrogen. J Am Chem Soc 46:2728–2737. https://doi.org/10.1021/ja01677a018

L’vov BV, Galwey AK, L’vov BV, et al. 2012. The mechanism and kinetics of NiO reduction by hydrogen Thermochemical approach. J Therm Anal Calorim. 110 601 610. https://doi.org/10.1007/s10973-011-2000-0

Chatterjee R, Banerjee SSS, Banerjee SSS, Ghosh D (2012) Reduction of nickel oxide powder and pellet by hydrogen. Trans Indian Inst Met 65:265–273. https://doi.org/10.1007/s12666-012-0130-0

Manukyan KV, Avetisyan AG, Shuck CE et al (2015) Nickel oxide reduction by hydrogen: kinetics and structural transformations. J Phys Chem C 119:16131–16138. https://doi.org/10.1021/acs.jpcc.5b04313

Lee DS, Dong, Min J, Min DJ, 2019. A Kinetics of Hydrogen Reduction of Nickel Oxide at Moderate Temperature. Met Mater Int. 25 982 990. https://doi.org/10.1007/s12540-019-00261-y

Yu D, Zhu M, Utigard TA, Barati M (2013) TGA kinetic study on the hydrogen reduction of an iron nickel oxide. Miner Eng 54:32–38. https://doi.org/10.1016/j.mineng.2013.03.018

Zhou Z, Han L, Bollas GM (2014) Kinetics of NiO reduction by H2 and Ni oxidation at conditions relevant to chemical-looping combustion and reforming. Int J Hydrogen Energy 39:8535–8556 https://doi.org/10.1016/j.ijhydene.2014.03.161

Sabat KC, Rajput P, Paramguru RK et al (2014) Reduction of oxide minerals by hydrogen plasma: an overview. Plasma Chem Plasma Process 34:1–23. https://doi.org/10.1007/s11090-013-9484-2

Rajput P, Sabat KC, Paramguru RK et al (2014) Direct reduction of iron in low temperature hydrogen plasma. Ironmak Steelmak 41:721–731. https://doi.org/10.1179/1743281214Y.0000000186

Sabat KC, Paramguru RK, Pradhan S, Mishra BK (2015) Reduction of Cobalt Oxide (Co3O4) bylLow temperature hydrogen plasma. Plasma Chem Plasma Process 35:387–399. https://doi.org/10.1007/s11090-014-9602-9

Sabat KC (2019) Hydrogen Plasma - Thermodynamics. In: J Phys: Conf Ser. Institute of Physics Publishing. 1–20 https://doi.org/10.1088/1742-6596/1172/1/012086

Sabat KC (2019) Iron production by hydrogen plasma. In: Internat Conf Appl Phys, Pow mater Sci. Institute of Physics Publishing. 1–5 https://doi.org/10.1088/1742-6596/1172/1/012043

Sabat KC, Paramguru RK, Mishra BK (2017) Reduction of oxide mixtures of (Fe2O3 + CuO) and (Fe2O3 + Co3O4) by low-temperature hydrogen plasma. Plasma Chem Plasma Process 37:979–995. https://doi.org/10.1007/s11090-017-9818-6

Sabat KC (2021) Physics and Chemistry of Solid State Direct Reduction of Iron Ore by Hydrogen Plasma. Phys Chem Solid State 22:312–320. https://doi.org/10.15330/pcss.22.2.292-300

Sabat KC (2019) Formation of CuCo alloy from their oxide mixtures through reduction by low-temperature hydrogen plasma. Plasma Chem Plasma Process 39:1071–1086. https://doi.org/10.1007/s11090-019-09963-y

Sabat KC, Paramguru RK, Mishra BK (2018) Formation of copper–nickel alloy from their oxide mixtures through reduction by low-temperature hydrogen plasma. Plasma Chem Plasma Process 38:621–635. https://doi.org/10.1007/s11090-018-9880-8

Sabat KC, Murphy AB (2017) Hydrogen plasma processing of iron ore. Metall Mater Trans B Process Metall Mater Process Sci 48:1561–1594. https://doi.org/10.1007/s11663-017-0957-1

Liu S-H, Zhang S-L, Li C-X et al (2019) Generation of long laminar plasma jets: experimental and numerical analyses. Plasma Chem Plasma Process 39:377–394. https://doi.org/10.1007/s11090-018-9949-4

Nguyen VT, Murphy AB, Delaney GW, et al (2021) Progress towards a complete model of metal additive manufacturing. In: Mater Sci Forum. Trans Tech Publications Ltd. 1031–1038 https://doi.org/10.4028/www.scientific.net/msf.1016.1031

Mostaghimi J, Boulos MI (2015) Thermal plasma sources: how well are they adopted to process needs? Plasma Chem Plasma Process 35:421–436. https://doi.org/10.1007/s11090-015-9616-y

Mandal AK, Dishwar RK, Sinha OP (2018) Design, fabrication, and characterization of an indigenously fabricated prototype transferred arc plasma furnace. IEEE Trans Plasma Sci 46:1793–1799. https://doi.org/10.1109/TPS.2018.2817234

Souza Filho IR, Ma Y, Kulse M et al (2021) Sustainable steel through hydrogen plasma reduction of iron ore: process, kinetics, microstructure, chemistry. Acta Mater. https://doi.org/10.1016/j.actamat.2021.116971

Saravanakumar R, Ramachandran K, Padmanabhan PVA (2021) Plasma Assisted Aluminothermic Reduction of Cr and Fe Oxides from Chromium Bearing Waste. Plasma Chem Plasma Process 41:155–169. https://doi.org/10.1007/s11090-020-10131-w

Ramos SV, Cisquini P, Nascimento RC Jr et al (2021) Morphological changes and kinetic assessment of Cu2O powder reduction by non-thermal hydrogen plasma. J Mater Res Technol 11:328–341. https://doi.org/10.1016/j.jmrt.2020.12.038

Mandal AK, Dishwar RK, Sinha OP (2018) Behavior of an indigenously fabricated transferred arc plasma furnace for smelting studies. Plasma Sci Technol. https://doi.org/10.1088/2058-6272/aa9cde

Dishwar RK, Agrawal S, Mandal AK, Sinha OP (2020) Smelting process of chromite ore fines to produce crude Fe–Cr–Ni–N Alloy. Trans Indian Inst Met 73:537–542. https://doi.org/10.1007/s12666-020-01861-8

Mandal AK, Sinha OP (2016) Recovery of multi-metallic components from bottom ash by smelting reduction under plasma environment. Metall Mater Trans B 47:19–22. https://doi.org/10.1007/s11663-015-0484-x

Du C, Qiu R, Ruan J (2018) Scientific and industrial application of plasma fluidized bed. In: Plasma Fluidized Bed. Springer. 81–121 https://doi.org/10.1007/978-981-10-5819-6_8

Samal S (2017) Thermal plasma technology: the prospective future in material processing. J Clean Prod 142:3131–3150. https://doi.org/10.1016/j.jclepro.2016.10.154

Mandal AK, Pramanik S, Sinha OP (2019) Effect of exposure time, lining material and plasma gas on the extraction of aluminium from waste by smelting reduction. Trans Indian Inst Met 72:1181–1186. https://doi.org/10.1007/s12666-019-01602-6

Gleizes A, Cressault Y (2017) Effect of metal vapours on the radiation properties of thermal plasmas. Plasma Chem Plasma Process 37:581–600. https://doi.org/10.1007/s11090-016-9761-y

Ishigaki T (2017) Synthesis of functional oxide nanoparticles through rf thermal plasma processing. Plasma Chem Plasma Process 37:783–804. https://doi.org/10.1007/s11090-017-9788-8

Bazaka K, Baranov O, Cvelbar U et al (2018) Oxygen plasmas: a sharp chisel and handy trowel for nanofabrication. Nanoscale 10:17494–17511 https://doi.org/10.1039/C8NR06502K

Gueroult R, Rax JM, Fisch NJ (2018) Plasma separation for rare earth elements recycling. 45th EPS Conf Plasma Physics, EPS 2018 2018-July:925–928http://ocs.ciemat.es/EPS2018ABS/pdf/P2.3013.pdf

Murphy AB (2000) Transport coefficients of hydrogen and argon–hydrogen plasmas. Plasma Chem Plasma Process 20:279–297. https://doi.org/10.1023/A:1007099926249

Sabat KC, Paramguru RK, Mishra BK (2016) Reduction of copper oxide by low-temperature hydrogen plasma. Plasma Chem Plasma Process 36:1111–1124. https://doi.org/10.1007/s11090-016-9710-9

National Institute of Standards and Technology (2012) NIST-JANAF Thermochemical Tables. https://janaf.nist.gov/. Accessed 13 Mar 2021

Kubaschewski O, Alcock CB (1979) Metallurgical thermochemistry, 5th edn. Pergamon Press, Oxford, Newyork https://doi.org/10.1002/crat.19800150208

Chase M (1998) NIST-JANAF Thermochemical Tables, 4th Edition. J. Phys. Chem. Ref. Data, Monogr. 9 1952 https://doi.org/10.18434/T42S31

Lee H-G (1999) Chemical thermodynamics for metals and materials. Imperial college press, London, UK

Turkdogan ET (1980) Physical chemistry of high temperature technology. Academic Press, Newyork, USA

Gamsjäger H, Bugajski J, Preis W, et al (2005) Chemical thermodynamics of nickel. Elsevier Amsterdam https://www.oecdnea.org/dbtdb/pubs/vol6-nickel.pdf

Dieke GH (1958) The molecular spectrum of hydrogen and its isotopes. J Mol Spectrosc 2:494–517. https://doi.org/10.1016/0022-2852(58)90095-X

III RDJ NIST Computational Chemistry Comparison and Benchmark Database, NIST Standard Reference Database Number 101 Release 21, August 2020,. https://cccbdb.nist.gov/exp2x.asp?casno=1333740&charge=0

Cullity SR, Stock BD (2001) Elements of x-ray diffraction. Prentice Hall, USA

Dereń J, Stoch J (1970) Effect of biography on stoichiometric composition and chemisorptive properties of nickel oxide (oxygen chemisorption). J Catal 18:249–259. https://doi.org/10.1016/0021-9517(70)90319-2

Holder CF, Schaak RE (2019) Tutorial on Powder X-ray Diffraction for Characterizing Nanoscale Materials. ACS Nano 13:7359–7365. https://doi.org/10.1021/acsnano.9b05157

Soo Kim D, Chul Lee H (2012) Nickel vacancy behavior in the electrical conductance of nonstoichiometric nickel oxide film. J Appl Phys. 112: 034504 https://doi.org/10.1063/1.4742993

Dubey P, Kaurav N, Devan RS et al (2018) The effect of stoichiometry on the structural, thermal and electronic properties of thermally decomposed nickel oxide. RSC Adv 8:5882–5890 https://doi.org/10.1039/c8ra00157j

Dereń J, Mrowec S (1973) Semiconducting and transport properties of mono- and polycrystalline nickel oxide. J Mater Sci 8:545–558. https://doi.org/10.1007/BF00550459

Dereń J, Nowotny J (1969) Mechanism and kinetics of interaction between gaseous oxygen and nickel oxide surfaces. Oxid Met 1:73–91. https://doi.org/10.1007/BF00609925

Dubey P, Kaurav N (2017) Synthesis and thermogravimetric analysis of non-stoichiometric nickel oxide compounds. J Phys Conf Ser. 839: 012040https://doi.org/10.1088/1742-6596/836/1/012040

Bielański A (1979) Oxygen in catalysis on transition metal oxides. Catal Rev 19:1–41. https://doi.org/10.1080/03602457908065099

Yang R, Zhang D, Zhu K et al (2019) In situ study of the conversion reaction of Co2 and Co2-H2 mixtures in radio frequency discharge plasma. Wuli Huaxue Xuebao/ Acta Phys - Chim Sin 35:292–298. https://doi.org/10.3866/PKU.WHXB201803121

Dubey P, Kaurav N (2019) Stoichiometric and Nonstoichiometric Compounds. IntechOpen. https://doi.org/10.5772/intechopen.89402

Passerini S, Scrosati B (1994) Characterization of nonstoichiometric nickel oxide thin-film electrodes. J Electrochem Soc 141:889–895. https://doi.org/10.1149/1.2054853

Pizzini S, Morlotti R (1967) Thermodynamic and transport properties of stoichiometric and nonstoichiometric nickel oxide. J Electrochem Soc 114:1179–1189. https://doi.org/10.1149/1.2426441

Karsthof R, Anton AM, Kremer F, Grundmann M (2020) Nickel vacancy acceptor in nickel oxide: doping beyond thermodynamic equilibrium. Phys Rev Mater 4:1–9. https://doi.org/10.1103/PhysRevMaterials.4.034601

Hala M, Capek J, Zabeida O et al (2012) Hysteresis-free deposition of niobium oxide films by HiPIMS using different pulse management strategies. J Phys D Appl Phys 45:1–28. https://doi.org/10.1088/0022-3727/45/5/055204

Acknowledgements

I am thankful to Prof. (Dr.) Barada Kanta Mishra, Director, Indian Institute of Technology Goa, India, and Prof. (Dr.) Raja Kishore Paramguru, Professor (Retd.), Mechanical Engineering, KIIT and Chief Scientist (Retd.) CSIR-IMMT, Bhubaneswar, for their guidance throughout my research. I would also like to thank CSIR, New Delhi, for providing financial support to carry out research work under the project MINMET, Project No. ESC 205. Last but not least, I am sincerely thankful to Prof. (Dr.) Seshadri Seetharaman, KTH Royal Institute of Technology, Stockholm (KTH), Sweden, for sharing his immense knowledge and expertise on the reduction of NiO.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sabat, K.C. Production of Nickel by Cold Hydrogen Plasma. Plasma Chem Plasma Process 41, 1329–1345 (2021). https://doi.org/10.1007/s11090-021-10194-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-021-10194-3