Abstract

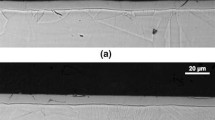

316L austenitic stainless steel was carburized in sodium containing a high-carbon activity at two different temperatures, 500 °C and 600 °C for 1000 h. The carbon profile, carbide mass fraction and residual stress tensor profile were determined using electron probe microanalysis and high-energy X-ray diffraction. The carbon profile and carbides mass fractions were also predicted using a thermodynamic and kinetic modeling tool (DICTRA). At 600 °C, the experimental results and predictions suggested that the carbon absorbed by the sample was mainly trapped to form M23C6 and M7C3 carbides. The residual stress profile in austenite was strongly dependent on the M23C6 precipitation and the induced modification of the substrate chemical composition. At 500 °C, results and predictions suggested that the carbon was mainly dissolved in austenite. The residual stress profile was governed by the formation of expanded austenite at the sample surface.

Similar content being viewed by others

References

F. Rouillard and M. Romedenne, Etat de l’art sur l’interaction B4C—acier de gaine et loi de durée de vie des gaines des éléments absorbants, NT DPC/SCCME 17-789-A 2017 (2017).

F. Rouillard, Influence de la carburation sur le comportement mécanique des aciers: Données d’entrée pour la loi de durée de vie des gaines des Eléments Absorbants et Réflexions, NT DPC/SCCME 18-872-A (2017).

A. Thorley and C. Tyzack, in British Nuclear Energy Society, Conference Proceedings (1971).

Y. Peng, Z. Liu, Y. Jiang, B. Wang, J. Gong, and M. A. J. Somers, Scripta Materialia 157, 106 (2018).

T. Christiansen and M. A. J. Somers, Metallurgical and Materials Transactions A 40A, 1791 (2009).

M. Romedenne, F. Rouillard, B. Duprey, D. Hamon, M. Tabarant, and D. Monceau, Oxidation of Metals 87, 643 (2017).

M. Romedenne, Thèse de doctorat de l’Université de Toulouse (2018).

M. Romedenne, F. Rouillard, D. Hamon, B. Malard, and D. Monceau, Corrosion Science 159, 108147 (2019).

J. Kieffer and D. Karkoulis, Journal of Physics: Conference Series 425, 202012 (2013).

L. Lutterotti, S. Matthies, and H. R. Wenk, in Proceeding of the 12th International Conference on Textures of Materials (ICOTOM-12), Vol. 1 (1999), p. 1599.

G. Geandier, L. Vautrot, B. Denand, and S. Denis, Materials 11, 1415 (2018).

V. Hauk, (Elsevier, Amsterdam, 1997).

I. Noyan and J. Cohen, (Springer Verlag, New York, 1987).

H. Kahn, G. M. Michal, F. Ernst, and A. H. Heuer, Metallurgical and Materials Transactions A 40A, 1799 (2009).

D. J. Dyson and B. Holmes, Journal of the Iron and Steel Institute 208, 469 (1970).

A. Engström, L. Höglund, and J. Ågren, Metallurgical and Materials Transactions A 25, 1127 (1994).

T. Turpin, J. Dulcy, and M. Gantois, Metallurgical and Materials Transactions A 36, 2751 (2005).

C. Sudha, N. S. Bharasi, R. Anand, H. Shaikh, R. Dayal, and M. Vijayalakshmi, Journal of Nuclear Materials 402, 186 (2010).

J. Garcia and O. Prat, Applied Surface Science 257, 8894 (2011).

D. Rong, J. Gong, and Y. Jiang, Procedia Engineering 130, 676 (2015).

T. L. Christiansen, K. Stahl, B. K. Brink, and M. A. J. Somers, Steel Research International 87, 1935 (2016).

H. J. Christ, Materials and Corrosion 49, 258 (1998).

S. I. Ford, P. R. Munroe, and D. J. Young, in John Stringer Symposium on High Temperature Corrosion, eds. P. F. Tortorelli, I. G. Wright, and P. Y. Hou (ASM International, 2003), pp. 77–85.

Y. Gong, D. J. Young, C. Atkinson, T. Olszewski, W. J. Quadakkers, and R. C. Reed, Corrosion Science 173, 108699 (2020).

H. Wen, B. Zhao, X. Dong, F. Sun, and L. Zhang, Materials Letters 261, 126984 (2020).

Z. Ding, B. Liang, Z. Xu, and L. Dong, American Chemical Society Applied Materials and Interfaces 12, 19235 (2020).

Y. Sun, X. Li, and T. Bell, Materials Science and Technology 15, 1171 (1999).

Y. Cao, F. Ernest, and G. M. Michal, Acta Materialia 51, 4171 (2003).

F. Ernst, Y. Cao, and G. M. Michal, Acta Materialia 52, 1469 (2004).

T. L. Christiansen, T. S. Hummelshoj, and M. A. J. Somers, Surface Engineering 26, 242 (2010).

G. M. Michal, F. Ernst, H. Kahn, Y. Cao, F. Oba, N. Agarwal, and A. H. Heuer, Acta Materialia 54, 1597 (2006).

LabEx DAMAS. Available online: http://labex-damas.univ-lorraine.fr.

Acknowledgements

The authors gratefully acknowledge the Deutsches Elektronen-Synchrotron (DESY-Petra III, Hamburg, Germany) for provision of beamtime at the PETRA P07-EH2 beamline.

Funding

This work was supported by the French Alternative Energies and Atomic Energy Commission and the French State through the program “Investment in the future” operated by the National Research Agency (ANR) and referenced by ANR-11-LABX-0008-01 [32].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Slim, M.F., Geandier, G., Romedenne, M. et al. Carburization and Stress Profiles Characterized by High-Energy X-ray Diffraction in 316L Austenitic Stainless Steel After Exposure at 500 °C and 600 °C in Carburizing Liquid Sodium. Oxid Met 96, 185–199 (2021). https://doi.org/10.1007/s11085-021-10039-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-021-10039-6