Abstract

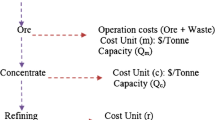

The mining industry is facing increasingly lower grades, which intensifies the need to reduce costs. The depletion of orebodies close to the surface has pushed the mining industry to progressively explore and extract deposits through underground mining. One approach that is receiving more attention is the application of pre-concentration systems prior to introducing the extracted materials to the main processing plant. Integration of pre-concentration systems into mining operations particularly in underground mines can significantly increase the sustainability and efficiency of operations. This paper reviews the technical concepts of this integration and presents a new mathematical formulation for underground cut-off grade determination, which should play an important role in resource utilisation and strategic planning in any operation. The proposed formulation is implemented on an underground operation to illustrate the impacts and advantages of underground pre-concentration integration. The outputs of this study prove the economic potential of pre-concentration systems in reduction in cut-off grade and increasing NPV.

Article Highlights

-

A comprehensive and updated review of technical concepts in integration of pre-concentration systems in underground operations.

-

Introducing a novel method for underground cut-off grade determination for increasing the sustainability of underground mines.

-

Implementation and investigation of pre-concentration systems in an underground mine, followed by potential benefits and future directions.

Similar content being viewed by others

References

Asad, M. W. A., Qureshi, M. A., & Jang, H. (2016). A review of cut-off grade policy models for open pit mining operations. Resources Policy, 1(49), 142–152. https://doi.org/10.1016/j.resourpol.2016.05.005

Bamber, A., Klein, B., Morin, M., & Scoble, M. (2004). Reducing selectivity in narrow-vein mining through the integration of underground pre-concentration. In Proceedings of the IV International Symposium on Narrow Vein Mining Techniques, QC, Canada.

Bamber, A. S., Klein, B., Morin, M., & Scoble, M. J. (2005). Integration of pre-concentration underground: Reducing mining costs. In Proceedings of the XVII international conference on mine planning and equipment selection, United States of America.

Bamber, A., Klein, B., Scoble, M., & Widdifield, J. (2006). Integrated underground mining and processing of massive sulfide ores. In Proceedings of 38th annual meeting of the Canadian mineral processors, Ottawa, Canada.

Bamber, A. S. (2008). Integrated mining, pre-concentration and waste disposal systems for the increased sustainability of hard rock metal mining, Doctoral dissertation, University of British Columbia, Vancouver, Canada.

Bamber, A. S., Klein, B., Pakalnis, R. C., & Scoble, M. J. (2008). Integrated mining, processing and waste disposal systems for reduced energy and operating costs at Xstrata Nickel’s Sudbury operations. Mining Technology, 117(3), 142–153. https://doi.org/10.1179/174328608X396535

Batterham, R., & Elvish, R. (2009). Smarter mineral processing, or, what do mill operators think. In 10th Mill Operators Conference Proceedings, Adelaide, SA (pp. 12–14). Retrieved from: https://app.knovel.com/hotlink/pdf/id:kt008V7C34/tenth-mill-operators/smarter-mineral-abstract.

Bettens, A. H., & Lapointe, C. (1954). Electronic Concentration of Low Grade Ores With Lapointe Picker, Department of Mines and Technical Surveys. Mines Branch, Canada.

Bowman, D. J., & Bearman, R. A. (2014). Coarse waste rejection through size based separation. Minerals Engineering, 62, 102–110. https://doi.org/10.1016/j.mineng.2013.12.018

Brewis, T. (1995). Andina develops for the future. Mining Magazine, 172(2), 6.

Burns, R., & Grimes, A. (1986). The application of pre-concentration by screening at Bougainville Copper Limited. In Proceedings of the AUSIMM mineral development symposium, Madang, Papua New Guinea.

Carrasco, C. (2013) Development of geometallurgical tests to identify, rank, and predict preferential coarse size by size Au deportment to support feed preconcentration at Telfer Au-Cu mine, Newcrest Western Australia. Published Mphil Thesis, University of Queensland, Australia.

Coghill, P., Miljak, D. & McGann, A. (2016). Modelling grade variation in crushed ore at Cadia Ridgeway and its potential consequences for bulk ore sorting. In proceedings of the 3rd AusIMM International Geometallurgy Conference; Perth, Australia. 89–96. http://hdl.handle.net/102.100.100/90312?index=1

Colborne, G. F. (1963). Electronic ore sorting at Beaverlodge. Canadian Mining and Metallurgical Bulletin, 56, 664–668.

Cutmore, N. G., Liu, Y., & Middleton, A. G. (1997). Ore characterisation and sorting. Minerals Engineering, 10(4), 421–426. https://doi.org/10.1016/S0892-6875(97)00018-6

Dagdelen, K., & Kawahata, K. (2008). Value creation through strategic mine planning and cut-off grade optimization. Mining Engineering, 60(1), 39.

Denysschen, D. F., & Wagner, B. N. (2009). Pre-concentration of low grade lateritic sulphide nickel ore. In the proceedings of the 5th BASE METALS conference, Kasane, South Africa (pp. 291–306).

Dominy, S. C., Hughes, T. R., Grigg, N. J., Gray, A. H., & Cormackd, G. (2009). Development of underground gravity gold processing plants. In The proceedings of the physical separation conference, Falmouth, UK.

Duffy, K., Valery, W., Jankovic, A., & Holtham, P. (2015). Integrating bulk ore sorting into a mining operation to maximise profitability. In the Proceedings of metallurgical plant design and operating strategies, Perth, Australia.

Espejel, C., Scott, M., & Nehring, M. (2017). Economic benefits and technical complexities of grade engineering® in strategic mine planning of metalliferous projects. In the proceedings of the 26th international conference mine planning and equipment selection, Lulea, Sweden.

Fathollahzadeh, K., Cigla, M., Mardaneh, E., & Asad, W. (2019). An application of an open pit mine production scheduling model with grade engineering. In The proceedings of international symposium on mine planning & equipment selection, Perth, Australia.

Goode, J. (2006). Ore sorter to shake up nickel production. Australian Paydirt, Available at: http://www.eagleres.com.au/paydirt/item/may-2006-ore-sorter.

Kennedy, A. (1985). Mineral processing developments at Hammaslahti, Finalnd. Mining Magazine, 152(2), 122–125.

Keys, N. J., Gordon, R. J., & Peverett, N. F. (1974). Photometric sorting of ore on a South African gold mine. Journal of the Southern African Institute of Mining and Metallurgy, 75(2), 13–21.

Kinver, P. (2002). Anglo Platinum’s Western Bushveld Operations. Anglo Platinum Annual Facility Visit Presentation.

Klein, B., Dunbar, W. S., & Scoble, M. (2002). Integrating mining and mineral processing for advanced mining systems. CIM Bulletin, 63–67.

Klein, B., Hall, R., Scoble, M., & Dunbar, W. S. (2003). Simulation of integrated underground mining-processing. In Proceedings of 31st international symposium on application of computers and operations research in the mineral industries, Cape Town, South Africa.

Klein, B., Erdenebat, E., Nadolski, S. (2018). Assessing ore heterogeneity for bulk sorting at the New Afton Copper Mine. In The proceedings of 8th sensor-based sorting and control, Aahen, Germany.

Knights, P., Kizil, M., & Nehring, M. (2018). Selection of precision surface mining methods for complex metalliferous orebodies. In complex orebodies conference, Brisbane, Australia.

Lane, K. F. (1964). Choosing the optimum cut-off grade. Quarterly of the Colorado School of Mines, Golden, 811–829.

Lane, K. F. (1988). The economic definition of ore-cut-off grades in theory and practice (p. 145). Mining Journal Books Limited.

Li, G., Klein, B., Sun, C., Kou, J., & Yu, L. (2019). Development of a bulk ore sorting model for sortability assessment. Minerals Engineering, 141, 1–8. https://doi.org/10.1016/j.mineng.2019.105856

Lloyd, P. J. D. (1978). Potential of integrated mining and extraction systems on the Witwatersrand. In 11th commonwealth mining and metallurgical congress.

Mainza, A. N., Powell, M. S., & Morrison, R. D. (2006). A review of SAG circuits closed with hydrocyclones. In Proceedings of SAG Conference, Vancouver, Canada.

McCulloch Jr, W. E., Bhappu, R. B., & Hightower, J. D. (1999). Copper ore preconcentration by heavy media separation for reduced capital and operating costs. Copper 99- Cobre 99, 13–27.

Miller, V. R., Nash, R. W., & Schwaneke, A. E. (1978). Preconcentration of native copper and porphyry copper ores by electronic sorting. Minerals Engineering, 30(8), 1194–1201.

Morin, M., Bamber, A., & Scoble, M. (2004). Systems analysis and simulation of narrow-vein mining method with underground preconcentration. In Proceedings of 2nd international symposium on narrow-vein deposits. Canada.

Mudd, G. M. (2004). One Australian perspective on sustainable mining: declining ore grades and increasing waste volumes. In Proceedings of the 11th international conference on tailings and mine waste (pp. 359–369). Available at: http://users.monash.edu.au/~gmudd/files/2004-TMW-SustainableMining.pdf.

Munro, P. D., Schache, I. S., Park, W. G., & Watsford, R. M. S. (1982). The design, construction and commissioning of a heavy media plant for silver-lead-zinc ore treatment—Mount Isa Limited. In Proceedings of the XIV International Mineral Processing Congress, Toronto, Canada.

Nadolski, S., Klein, B., Elmo, D., & Scoble, M. (2015). Cave-to-mill: A mine-to-mill approach for block cave mines. Mining Technology, 124(1), 47–55. https://doi.org/10.1179/1743286315Y.0000000001

Nadolski, S., Klein, B., Hart, C. J. R., Moss, A., & Elmo, D. (2018a). An approach to evaluating block and panel cave projects for sensor-based sorting applications. In Proceedings of the fourth international symposium on block and sublevel caving (pp. 133–140). Australian Centre for Geomechanics.

Nadolski, S., Samuels, M., Klein, B., & Hart, C. J. (2018b). Evaluation of bulk and particle sensor-based sorting systems for the New Afton block caving operation. Minerals Engineering, 121, 169–179.

Newman, P. C., & Whelan, P. F. (1952). Photometric separation of ores in lump form. In Proceedings of recent developments in mineral dressing symposium. London.

Nielsen, B., Rohleder, J., Lehto, H., & Robben, C. (2018). Sensor-based ore sorting to maximise profit in a gold operation. AusIMM Bulletin, 62–65.

Peters, O., Scoble, M., & Schumacher, T. (1999). The technical and economic potential of mineral processing underground. In Annual General Meeting, Can. Inst. Min. Metall., Calgary, CD ROM.

Prior, T., Giurco, D., Mudd, G., Mason, L., & Behrisch, J. (2012). Resource depletion, peak minerals and the implications for sustainable resource management. Global Environmental Change, 22(3), 577–587.

Reple, A., Chieregati, A. C., Valery, W., & Prati, F. (2020). Bulk ore sorting cut-off estimation methodology: Phu Kham Mine case study. Minerals Engineering, 149, 105498. https://doi.org/10.1016/j.mineng.2018.08.006

Rule, C. M., Fouchee, R. J., & Swart, W. C. E. (2015). Run of mine ore upgrading–proof of concept plant for XRF ore sorting. In Proceedings of the 6th international conference on semi-autogenous and high pressure grinding technology, Vancouver, Canada.

Salter, J. D. (1989). A 100t/h pilot plant for sorting kimberlite from waste rocks using microwave attenuation discrimination. In Proceedings of the role of the practical metallurgist symposium, mine metallurgical manager's Association of South Africa, Johannesburg, South Africa.

Schodde, R. (2017). Long term trends in global exploration–Are we finding enough metals? In 11th Fennoscandian exploration and mining conference, Levi, Finland.

Scoble, M., Klein, B., & Dunbar, W. S. (2003). Mining waste: Transforming mining systems for waste management. International Journal of Surface Mining, Reclamation and Environment, 17(2), 123–135. https://doi.org/10.1076/ijsm.17.2.123.14129

Scott, M. C. (2014). Evaluation of energy-efficiency, emission pricing and pre-concentration for the optimised development of a Au-Cu deposit. Doctoral Thesis, University of Queensland, Australia

Sotoudeh, F., Nehring, M., Kizil, M., & Knights, P. (2019a). Application of pre-concentration technologies in sublevel stope mining. In International future mining conference, Sydney, Australia (pp. 114–122).

Sotoudeh, F., Nehring, M., Kizil, M., & Knights, P. (2019b). Economic and environmental impacts of utilising a pre-concentration process in underground metal mining. In International symposium on mine planning & equipment selection (pp. 326–332). Springer, Cham. https://doi.org/10.1007/978-3-030-33954-8_40.

Sotoudeh, F., Nehring, M., Kizil, M., & Knights, P. (2020a). Integrated underground mining and pre-concentration systems: A critical review of technical concepts and developments. International Journal of Mining, Reclamation and Environment. https://doi.org/10.1080/17480930.2020.1782573

Sotoudeh, F., Nehring, M., Kizil, M., Knights, P., & Mousavi, A. (2020b). Production scheduling optimisation for sublevel stoping mines using mathematical programming: A review of literature and future directions. Resources Policy, 68, 101809. https://doi.org/10.1016/j.resourpol.2020.101809

Sotoudeh, F., Nehring, M., Kizil, M., & Knights, P., Mousavi, A. (2020c). A new cut-off grade method to maximise resource utilisation of underground metalliferous mining operations. In Preconcentration digital conference, AusIMM, Australia.

Topp V., Soames, L., Parham, D., & Bloch, H. (2008). Productivity in the mining industry: Measurement and interpretation. Productivity commission, Australian Government. Staff Working Paper, Canberra, Available at: https://www.pc.gov.au/research/supporting/mining-productivity.

Trafford, G. T. (1998). Results nearly double grade to 13 grams gold per tonne. Weymin Mining Corporation.

Valery, W., Duffy, K., Holtham, P., Reple, A., Walker, P., & Rosario, P. (2016). Techno-economic evaluation of bulk ore sorting for copper ore at the Panaust Phu Kham Operation. In 28th international mineral processing congress, Canadian Institute of Mining, Metallurgy and Petroleum.

Vatcha, M. T., Cochrane, L. B., & Rousell, D. H. (2000). Preconcentration by magnetic sorting of Ni–Cu ore at Whistle mine, Sudbury, Canada. Mineral Processing and Extractive Metallurgy, 109(3), 156–160. https://doi.org/10.1179/mpm.2000.109.3.156

Walters S. G. (2016). Driving Productivity by increasing feed quality through application of innovative grade engineering® technologies, Available at: https://www.crcore.org.au/images/CRC-ORE/papers/Walters-S-2016-Grade-Engineering-Whitepaper.pdf.

West, J. (2011). Decreasing metal ore grades: Are they really being driven by the depletion of high-grade deposits? Journal of Industrial Ecology, 15(2), 165–168. https://doi.org/10.1111/j.1530-9290.2011.00334.x

Winckers, A. H. (1981). The use of rubber mill liners at Cominco’s Sullivan Concentrator. In 13th CMP annual meeting. Ottawa, CIM, Montreal (pp. 300–310).

Acknowledgments

This research would not have been possible without the financial assistance and research training scholarship, provided to the corresponding author by the University of Queensland. Also, the authors would like to express their deep gratitude to the three anonymous referees for their useful and insightful comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sotoudeh, F., Nehring, M., Kizil, M. et al. A New Mathematical Formulation for Underground Cut-off Grade Determination in the Presence of Pre-concentration Systems. Nat Resour Res 30, 3241–3259 (2021). https://doi.org/10.1007/s11053-021-09892-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-021-09892-8