Abstract

Machining robots are expected to significantly change existing production systems in the near future. The quality of the machining process with robots is mainly governed by the accuracy and stiffness of the robots. Therefore, a precision reducer for the robot joint is an important component that governs the accuracy of machining robots. This paper presents a review of rigid precision reducers for machining robots. Initially, an overview of the machining robots and their features is introduced. The importance of a precision reducer as a component of a robot for machining is explored. A cycloid reducer is the best candidate among precision reducers, considering both the structural compliance and kinematic accuracy of the machining robots. This is followed by reviews of various cycloid reducers and their operating principles. The design issues of the cycloid reducer for performance improvement are then presented. Additionally, the methodology and analysis to assess the performance of the cycloid reducers are discussed. The machining and fault detection of a cycloid reducer are briefly addressed. Finally, other applications of cycloid reducers are introduced.

Similar content being viewed by others

References

Davis, J., Edgar, T., Porter, J., Bernaden, J., & Sarli, M. (2012). Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Computers and Chemical Engineering, 47, 145–156.

Park, K. T., Kang, Y. T., Yang, S. G., et al. (2020). Cyber physical energy system for saving energy of the dyeing process with industrial internet of things and manufacturing big data. International Journal of Precision Engineering and Manufacturing-Green Technology, 7, 219–238. https://doi.org/10.1007/s40684-019-00084-7

Lee, J., Bagheri, B., & Kao, H.-A. (2015). A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manufacturing letters, 3, 18–23.

Sim, H. S. (2019). Big data analysis methodology for smart manufacturing systems. International Journal of Precision Engineering and Manufacturing, 20, 973–982. https://doi.org/10.1007/s12541-019-00136-7

Lee, J. Y., Yoon, J. S., & Kim, B. (2017). A big data analytics platform for smart factories in small and medium-sized manufacturing enterprises: An empirical case study of a die casting factory. International Journal of Precision Engineering and Manufacturing, 18, 1353–1361. https://doi.org/10.1007/s12541-017-0161-x

Tao, F., Qi, Q., Wang, L., & Nee, A. Y. C. (2019). Digital twins and cyber-physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering, 5(4), 653–661. https://doi.org/10.1016/j.eng.2019.01.014

Gupta, N., Tiwari, A., Bukkapatnam, S. T. S., & Karri, R. (2020). Additive manufacturing cyber-physical system: Supply chain cybersecurity and risks. IEEE Access, 8, 47322–47333. https://doi.org/10.1109/ACCESS.2020.2978815

Mehrpouya, M., Dehghanghadikolaei, A., Fotovvati, B., Vosooghnia, A., Emamian, S. S., & Gisario, A. (2019). The potential of additive manufacturing in the smart factory industrial 4.0: A review. Applied Science, 9, 3865.

Temoelman, E., Shercliff, H., & Ninaber van Eyben, B. (2014). Additive Manufacturing. In E. Tempelman, H. Shercliff, & B. N. V. Eyben (Eds.), Manufacturing and design (pp. 187–200). Butterworth-Heinemann.

Jamie, D. (2018). 3D printing vs CNC machining: Which is best for prototyping? https://www.3dnatives.com/en/3d-printing-vs-cnc-160320184/#!

Pereira, T., Kennedy, J. V., & Potgieter, J. (2019). A comparison of traditional manufacturing vs additive manufacturing, the best method for the job. Procedia Manufacturing, 30, 11–18.

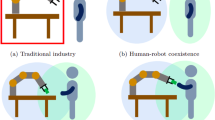

Demir, K. A., Doven, G., & Sezen, B. (2019). Industry 5.0 and human-robot co-working. Procedia Computer Science, 158, 688–695.

Zhu, D., Feng, X., Xu, X., Yang, Z., Li, W., Yan, S., & Ding, H. (2020). Robotic grinding of complex components: A step towards efficient and intelligent machining—Challenges, solutions, and applications. Robotics and Computer-Integrated Manufacturing, 65, 101908.

Ji, W., & Wang, L. (2019). Industrial robotic machining: A review. International Journal of Advanced Manufacturing Technology, 103, 1239–1255.

Subrin, K., Sabourin, L., Cousturier, R., Gogu, G., & Mezouar, Y. (2013). New redundant architectures in machining: Serial and parallel robots. Procedia Engineering, 63, 158–166.

Kim, S. H., Nam, E., Ha, T. I., et al. (2019). Robotic machining: A review of recent progress. International Journal of Precision Engineering and Manufacturing, 20(9), 1629–1642.

Iglesias, I., Sebastian, M. A., & Ares, J. E. (2015). Overview of the state of robotic machining: Current situation and future potential. Procedia Engineering, 132, 911–917.

Chen, Y., & Dong, F. (2013). Robot machining: Recent development and future research issues. International Journal of Advanced Manufacturing Technology, 66, 1489–1497.

Pandremenos, J., Doukas, C., Stavropoulos, P., & Chryssolouris, G. (2011). Machining with robots: A critical review. In Proceedings of DET2011 (pp. 1–9).

Schneider, U., Ansaloni, M., Drust, M., Leali, F., & Verl, A. (2013). Experimental investigation of sources of error in robot machining. In International workshop on robotics in smart manufacturing (WRSM 2013) (pp. 14–26).

Zhang, T., Yu, Y., Yang, L., Xiao, M., & Chen, S. (2020). Robot grinding system trajectory compensation based on co-kriging method and constant-force control based on adaptive iterative algorithm. International Journal of Precision Engineering and Manufacturing. https://doi.org/10.1007/s12541-020-00367-z

Schneider, U., Drust, M., Ansaloni, M., Lehmann, C., Pellicciari, M., Leali, F., Gunnink, J. W., & Verl, A. (2014). Improving robotic machining accuracy through experimental error investigation and modular compensation. International Journal of Advanced Manufacturing Technology, 95, 83–89.

Kuka. (2020). Milling robot. https://www.kuka.com/en-my/products/process-technologies/milling.

DePree, J., Gesswein, C. (2008). "Robot machining white paper project", Halcon development, Robotic Industries Association. https://www.robotics.org/robotics/halcyon-development-ria.

Klimchik, A., Ambiehl, A., Garnier, S., Furet, B., & Pashkevich, A. (2017). Efficiency evaluation of robots in machining applications using industrial Performance measure. Robotics and Computer-Integrated Manufacturing, 48, 12–29.

Belaganger-Barrette, M. (2014). Machining with industrial robots. https://blog.robotiq.com/bid/73008/Machining-with-Industrial-Robots.

Matsuoka, S., Shimizu, K., Yamazaki, N., & Oki, Y. (1999). High-speed end milling of an articulated robot and its characteristics. Journal of Materials Processing Technology, 95, 83–89.

Kim, K., Lee, S., Kim, K., et al. (2010). Development of the end-effector measurement system for a 6-axis welding robot. International Journal of Precision Engineering and Manufacturing, 11, 519–526.

Chen, X., Zhang, Q., & Sun, Y. (2019). Model-based compensation and pareto-optimal trajectory modification method for robotic applications. International Journal of Precision Engineering and Manufacturing, 20, 1127–1137.

Verl, A., Valente, A., Melkote, S., Brecher, C., Ozturk, E., & Tunc, L. T. (2019). Robots in machining. CIRP Annuals Manufacturing Technology, 68, 799–822.

Erkaya, S. (2012). Investigation of joint clearance effects on welding robot manipulator. Robotics and Computer-Integrated Manufacturing, 28, 449–457.

Oh, Y. T. (2011). Influence of joint angular characteristics on the accuracy of industrial robots. Industrial Robot: An International Journal, 38(4), 406–418.

Giberti, H., Cinquenmani, S., & Legnani, G. (2010). Effect of transmission mechanical characteristics on the choice of a motor-reducer. Mechatronics, 20, 604–610.

Garcia, P. L., Crispel, S., Saerens, E., Verstraten, T., & Lefeber, D. (2020). Compact gearboxes for modern robotics: A review. Frontiers in Robotics and AI, 7(103), 1–19.

Harmonic Drive, “Improve the productivity of your factory automation systems with lightweight gears and actuators”, 800-921-3332. www.harmonicdrive.net.

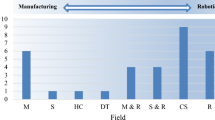

PhamAhn, A. D. H. J. (2018). High precision reducers for industrial robots driving 4th industrial revolution: State of arts, analysis, design, performance evaluation, and perspective. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(4), 519–533.

Qin, Z., et al. (2018). A review of recent advances in design optimization of gearbox. International Journal of Precision Engineering and Manufacturing, 19(11), 1753–1762.

Yang, C., Hu, Q., Liu, Z., et al. (2020). Analysis of the partial axial load of a very thin-walled spur-gear (flexspline) of a harmonic drive. International Journal of Precision Engineering and Manufacturing, 21, 1333–1345. https://doi.org/10.1007/s12541-020-00333-9

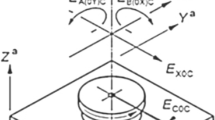

Meng, Y., Wu, C., & Ling, L. (2007). Mathematical modeling of the transmission performance of 2K-H pin cycloid planetary mechanism. Mechanism and Machine Theory, 42(7), 776–790.

Yu, D. (1987). KHV planetary gearing. Gear Technology, 4(6), 21–31.

Wang, Y., Qian, Q., Chen, G., Jin, S., & Chen, Y. (2017). Multi-objective optimization design of cycloid pin gear planetary reducer. Advances in Mechanical Engineering, 9(9), 1–10. https://doi.org/10.1177/1687814017720053

Sun, Z., & Han, L. (2019). A new numerical force analysis method of CBR reducer with tooth modification. Journal of Physics: Conference Series, 1187, 032053.

Bao, J., & He, W. (2015). Parametric design and efficiency analysis of the output-pin-wheel cycloid transmission. International Journal of Control and Automation, 8(8), 349–362.

Gear materials. https://khkgears.net/new/gear_knowledge/gear_technical_reference/gear_materials.html.

Ovako, Material data sheet -20MnCr5. https://steelnavigator.ovako.com/steel-grades/20mncr5/.

Lauer, D. A. (2013). Gear Lubrication. In Q. J. Wang & Y. W. Chung (Eds.), Encyclopedia of tribology (pp. 1495–1501). Boston: Springer. https://doi.org/10.1007/978-0-387-92897-5_19

Ken bannister. (2017). Understand motor and gearbox lubrication. https://www.efficientplantmag.com/2017/01/understand-motor-gearbox-lubrication/.

Botsiber, D. W., & Kingston, L. (1956). Design and performance of the cycloid reducer. Machine Designs, 28, 65–69.

Blanche, J. G., & Yang, D. C. H. (1989). Cycloid drives with machining tolerances. ASME Journal of Mechanisms, Transmissions, 111, 337–344.

Litvin, F. L., & Feng, P.-H. (1996). Computerized design and generation of cycloidal gearings. Mechanism and Machine Theory, 31(7), 891–911. https://doi.org/10.1016/0094-114x(95)00115-f

Hsieh, C.-F. (2014). Dynamics analysis of cycloidal speed reducers with pinwheel and nonpinwheel designs. Journal of Mechanical Design, 136(9), 091008. https://doi.org/10.1115/1.4027850

Hu, Y., Li, G., Zhu, W., & Cui, J. (2020). An elastic transmission error compensation method for rotary vector speed reducers based on error sensitivity analysis. Applied Science, 10, 481.

Shin, J. H., & Kwon, S. M. (2006). On the lobe profile design in a cycloid reducer using instant velocity center. Mechanism and Machine Theory, 41, 596–616.

Tran, T. L., Pham, A. D., & Ahn, H. J. (2016). Lost motion analysis of one stage cycloid reducers considering tolerances. International Journal of Precision Engineering and Manufacturing, 17(8), 1009–1016.

Chen, B., Zhong, H., Liu, J., Li, C., & Fang, T. (2012). Generation and investigation of a new cycloid drive with double contact. Mechanism and Machine Theory, 49, 270–283. https://doi.org/10.1016/j.mechmachtheory.2011.10.001

Li, T., Li, J., Deng, X., Tian, M., & Li, Y. (2020). Meshing contact analysis of cycloidal-pin gear in RV reducer considering the influence of manufacturing error. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 42, 133. https://doi.org/10.1007/s40430-020-2208-7

Hwang, Y.-W., & Hsieh, C.-F. (2007). Determination of surface singularities of a cycloidal gear drive with inner meshing. Mathematical and Computer Modelling, 45(3–4), 340–354. https://doi.org/10.1016/j.mcm.2006.05.010

Wang, J., Gu, J., & Yan, Y. (2016). Study on the relationship between the stiffness of RV reducer and the profile modification method of cycloid-pin wheel. Intelligent Robotics and Applications-ICIRA, 2016, 722–735.

Li, T., An, X., Deng, X., Li, J., & Li, Y. (2020). A new tooth profile modification method of cycloidal gears in precision reducers for robots. Applied Science, 10, 1266.

Ren, Z. Y., Mao, S. M., Guo, W. C., & Guo, Z. (2017). Tooth modification and dynamic performance of the cycloidal drive. Mechanical Systems and Signal Processing, 85, 857–866.

Bo, W., Jiaxu, W., Guangwu, Z., Rongsong, Y., Hongjun, Z., & Tao, H. (2015). Mixed lubrication analysis of modified cycloidal gear used in the RV reducer. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 230(2), 121–134. https://doi.org/10.1177/135065011559330

Sun, X., & HanMaLiWang, L. K. L. J. (2018). Lost motion analysis of CBR reducer. Mechanism and Machine Theory, 120, 89–106.

Lin, W.-S., Shih, Y.-P., & Lee, J.-J. (2014). Design of a two-stage cycloidal gear reducer with tooth modifications. Mechanism and Machine Theory, 79, 184–197. https://doi.org/10.1016/j.mechmachtheory.2014.04.009

Zang, T., Li, X., Wang, Y., & Sun, L. (2020). A semi-analytical load distribution model for cycloid drives with tooth profile and longitudinal modifications. Applied Sciences, 10, 4859.

Sensinger, J. W. (2010). Unified approach to cycloid drive profile, stress, and efficiency optimization. Journal of Mechanical Design, 132(2), 024503. https://doi.org/10.1115/1.4000832

Wang, H., Shi, Z.-Y., Yu, B., & Xu, H. (2019). Transmission performance analysis of RV reducers influenced by profile modification and load. Applied Science, 9, 4099.

Sun, X., Han, L. J., & Wang. (2019). Design and transmission error analysis of CBR reducer. Journal of Mechanical Design, 141, 082301-1–82310.

Hsieh, C. F. (2014). The effect on dynamics of using a new transmission design for eccentric speed reducers. Mechanism and Machine Theory, 80, 1–16.

Pham, A. D., & Ahn, H. J. (2017). Efficiency analysis of a cycloid reducer considering tolerance. Journal of Friction and Wear, 38(6), 490–496.

Hsieh, C. F. (2015). Traditional versus improved designs for cycloidal speed reducers with a small tooth difference: The effect on dynamics. Mechanism and Machine Theory, 86, 15–35.

Kumar, N. (2015). Investigation of a driven-train dynamics of mechanical transmissions incorporating cycloidal drives. Ph.D. thesis, Queensland University of Technology, Brisbane.

Kosse, V. (2007). Using hysteresis loop and torsional shock load to acess damping and efficiency of cycloid drives. In Proceedings of 14th international congress on sound & vibration (ICSV14) (pp. 1–8).

Yoshioka, T., Hirano, Y., & Ohishi, K. (2014). Vibration suppressing control method of angular transmission error of cycloid gear for industrial robots. In Proceedings of 2014 international power electronics conference (pp. 1956–1961).

Bednarczyk, S., Jankowski, L., & Krawczyk, J. (2019). The influence of eccentricity changes on power losses in cycloidal gearing. Tribologia, 3, 19–29.

Xu, L. X., & Yang, Y. H. (2016). Dynamic modeling and contact analysis of cycloid-pin gear mechanism with a turning arm cylindrical roller bearing. Mechanism and Machine Theory, 104, 327–349.

Xu, L. X., Chen, B. K., & Li, C. Y. (2019). Dynamic modelling and contact analysis of bearing-cycloid-pinwheel transmission mechanisms used in joint rotate vector reducers. Mechanism and Machine Theory, 137, 432–458.

Dion, J. L., Pawelshi, Z., Chianca, V., Zdzinnicki, Z., Peyret, N., Uszpolewicz, G., Ormezowski, J., & Mitukiewicz, G. (2020). Theoretical and experimental study for an improved cycloid drive model. Journal of Applied Mechanics, 87, 011002-1–11013.

Bao, J., He, W., Qiao, S., & Johnson, P. (2020). Optimum design of parameters and contact analysis of cycloid drive. Journal of Computational Methods in Sciences and Engineering, 21, 71–83.

Tsai, Y. T., & Lin, K. H. (2020). Dynamic analysis and reliability evaluation for an eccentric speed reducer based on fem. Journal of Mechanics, 36(3), 395–403. https://doi.org/10.1017/jmech.2019.52

Yu, H. L., Yi, J. H., Hu, X., & Shi, P. (2013). Study on teeth profile modification of cycloid reducer based on non-Hertz elastic contact analysis. Mechanics Research Communications, 48, 87–92.

Yang, Y., Chen, C., & Wang, S. (2018). Response sensitivity to design parameters of RV reducer. Chinese Journal of Mechanical Engineering, 31, 49. https://doi.org/10.1186/s10033-018-0249-y

Neagoe, M., Diaconescu, D., Pascalse, L., & Saulescu, R. (2007). On the efficiency of a cycloidal planetary reducer with a modified structure. International Conference on Economic Engineering and Manufacturing Systems ICEEMS, 8(3), 544–549.

Ahn, H. J., Choi, B. M., Lee, Y. H., & Pham, A. D. (2021). Impact analysis of tolerance and contact friction on a RV reducer using FE method. International Journal of Precision Engineering and Manufacturing. https://doi.org/10.1007/s12541-021-00537-7

Zang, Y., He, W., Wang, X., & Luo, Y. (2019). Transmission error simulation analysis for RV reducer with orthogonal experiment method. Intelligent Robotics and Applications-ICIRA, 2019, 629–641.

Kim, K. H., Lee, C. S., & Ahn, H. J. (2009). Torsional rigidity of a cycloid drive considering finite bearing and Hertz contact stiffness. International Power Transmission and Gearing Conference, 6, 125–130.

Olejarczyk, K., Wikło, M., & Kołodziejczyk, K. (2019). The cycloidal gearbox efficiency for different types of bearings—Sleeves vs. needle bearings. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 233(21–22), 7401–7411. https://doi.org/10.1177/0954406219859903

Liu, Z., Zhang, T., Wang, Y., et al. (2019). Experimental studies on torsional stiffness of cycloid gear based on machining parameters of tooth surfaces. International Journal of Precision Engineering and Manufacturing, 20(6), 1017–1025. https://doi.org/10.1007/s12541-019-00108-x

Pham, A. D., Tran, T. L., & Ahn, H. J. (2017). Hysteresis curve analysis of a cycloid reducer using non-linear spring with a dead zone. International Journal of Precision Engineering and Manufacturing, 18(3), 375–380.

Gorla, C., Davoli, P., Rosa, F., Longoni, C., Chiozzi, F., & Samarani, A. (2008). Theoretical and experimental analysis of a cycloidal speed reducer. Journal of Mechanical Design, 130(11), 112604-112604–8.

Mihailidis, A., Athanasopoulos, E., & Agouridas, K. (2016). EHL film thickness and load dependent power loss of cycloid reducers. Proceedings of the Institution of Mechanical Engineers, Part C, 230(7–8), 1303–1317.

Baron, P., Kočiško, M., Dobránsky, J., Pollák, M., & Cmorej, T. (2015). Research and correlation of diagnostic methods for assessment of the state of oil filling in cycloid gearbox. Advances in Materials Science and Engineering, 2015, 1–9. https://doi.org/10.1155/2015/597841

Wang, S., Tan, J., Gu, J., & Huang, D. (2020). Study on torsional vibration of RV reducer based on time-varying stiffness. Journal of Vibration Engineering and Technologies. https://doi.org/10.1007/s42417-020-00211-8

Chen, C., & Yang, T. (2017). Structural characteristics of rotate vector reducer free vibration. Shock and Vibration, 4214370, 1–14. https://doi.org/10.1155/2017/4214370

Li, T., Li, J., Deng, X., Tian, M., & Li, Y. (2020). Quantitative correction method for the grinding errors of cycloidal gears in precision reducer. Journal of Advanced Mechanical Design, Systems, and Manufacturing, 14(4), 1–14.

Gu, L., Xu, J., & Luo, S. (2016). The design of new cycloid gear with variable cross section and the research of end milling in five-axis machine tool. Manufacturing Technology, 16(3), 497–502.

Maeng, S., Lee, P. A., Kim, B. H., et al. (2020). An analytical model for grinding force prediction in ultra-precision machining of WC with PCD micro grinding tool. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-020-00199-2

Chu, X., Xu, H., Wu, X., Tao, J., & Shao, G. (2018). The method of selective assembly for the RV reducer based on genetic algorithm. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 232(6), 921–929. https://doi.org/10.1177/0954406217700179

Bai, B., Li, Z., & Zhang, J. (2019). Failure rate prediction and reliability assessment of RV reducer. In International conference on quality, reliability, risk, maintenance, and safety engineering (QR2MSE) (pp. 364–371).

Kim, Y., et al. (2020). Phase-based time domain averaging (PTDA) for fault detection of a gearbox in an industrial robot using vibration signals. Mechanical Systems and Signal Processing, 138(106544), 1–19.

Zhang, Y., et al. (2019). Industrial robot rotate vector reducer fault detection based on hidden Markov models. In IEEE international conference on robotics and biomimetics (ROBIO) (pp. 3013–3018).

An, H., Liang, W., Zhang, Y., Li, Y., Liang, Y., & Tan, J. (2017). Rotate vector reducer crankshaft fault diagnosis using acoustic emission techniques. In 5th International conference on enterprise systems (ES). https://doi.org/10.1109/es.2017.55.

Lee, K., Hong, S., & Oh, J. (2020). Development of a lightweight and high-efficiency compact cycloidal reducer for legged robots. International Journal of Precision Engineering and Manufacturing, 21(3), 415–425. https://doi.org/10.1007/s12541-019-00215-9

Yamato, H., Ogihara, K., et al. (2020). A partner robot transforming to a vehicle: CanguRo-design, development and evaluation of its in-wheel drive unit with cycloid gear. In Proceedings of 2020 IEEE/SICE international symposium on system integration (pp. 1205–1211).

FuRo (2007). CanguRo: intelligent robot–transformable and ridable. https://furo.org/en/works/canguro/canguro.html.

Spinea, Spinea–Excellence in motion: Applications-medial. https://www.spinea.com/en/industries/medical.

Lee, S., & Baek, S. W. (2020). A study on the improvement of the cam phase control performance of an electric continuous variable valve timing system using a cycloid reducer and BLDC motor. Microsystem Technology, 26, 59–70. https://doi.org/10.1007/s00542-019-04411-5

Kia Motor. (2015). Kia Stinger: Engine control system/E-CVVT motor. http://www.kstinger.com/e_cvvt_motor-464.html.

Austin, M. (2019). How Hyundai’s new, more fuel-efficient CVVD engine technology works. https://www.caranddriver.com/news/a28284180/hyundai-cvvd-car-engine-technology-explained/.

Spinea, Spinea–Excellence in motion: Applications-defence and security. https://www.spinea.com/en/industries/defense-and-security.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper is an invited paper (Invited Review).

Rights and permissions

About this article

Cite this article

Pham, AD., Ahn, HJ. Rigid Precision Reducers for Machining Industrial Robots. Int. J. Precis. Eng. Manuf. 22, 1469–1486 (2021). https://doi.org/10.1007/s12541-021-00552-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-021-00552-8