Abstract

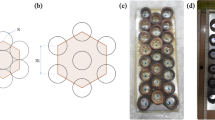

This work investigates a novel concept of sandwich panel composed of discarded polypropylene (PP) bottle caps as circular honeycomb core and skins made with a hybrid glass fibre/silica composite. A full factorial design (DoE) is carried out to identify the effects of the core packing system and the inclusion of silica particles in the composite skins, on the flexural properties of the sandwich panels. Finite element analysis validated by the experimental results is used to investigate and predict the failure mechanisms of these sandwich structures. The DoE reveals that the hexagonal packing of PP bottle caps with the presence of silica in both skins lead to increased mechanical properties, such as core shear stress (0.79 MPa), facing stress (42.56 MPa) and flexural modulus (1589.21 MPa), especially when compared to the orthotropic packing with silica only on the bottom skin which obtained a lower performance of 21.01%, 11.41% and 17.22% for core shear stress, facing stress and flexural modulus, respectively. The findings reveal an alternative upcycling route for discarded polypropylene caps.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Meier, U.: Carbon fibre-reinforced polymers: modern materials in bridge engineering. Struct Eng Int l 2(1), 7–12 (1992). https://doi.org/10.2749/101686692780617020

Safari, H., Karevan, M., Nahvi, H.: Mechanical characterization of natural nano-structured zeolite/polyurethane filled 3D woven glass fibre composite sandwich panels. Polym Test 67, 284–294 (2018). https://doi.org/10.1016/j.polymertesting.2018.03.018

Ullah, Z., Kaczmarczyk, L., Pearce, C.J.: Three-dimensional nonlinear micro/meso-mechanical response of the fibre-reinforced polymer composites. Compos Struct 161, 204–214 (2017). https://doi.org/10.1016/j.compstruct.2016.11.059

Gibson, R.F.: Principles of composite material mechanics, 3rd edn. CRC Press. Boca Raton, FL, USA (2012)

Cao, Y., Cameron, J.: Impact Properties of Silica Particle Modified Glass Fibre Reinforced Epoxy Composite. J Reinf Plast Comp 25(7), 761–769 (2006). https://doi.org/10.1177/0731684406063536

Silva, L.J., Panzera, T.H., Christoforo, A.L.: Micromechanical Analysis of Hybrid Composites Reinforced with Unidirectional Natural Fibres, Silica Microparticles and Maleic Anhydride. Mater Res 15(6), 1003–1012 (2012). https://doi.org/10.1590/S1516-14392012005000134

Torres, R.B., Dos Santos, J.C., Panzera, T.H., Christoforo, A.L., Ribeiro Borges, P.H., Scarpa, F.: Hybrid glass fibre reinforced composites containing silica and cement microparticles based on a design of experiment. Polym Test 57, 87–93 (2017). https://doi.org/10.1016/j.polymertesting.2016.11.012

Santana, P.R.T., Panzera, T.H., Freire, R.T.S., Christoforo, A.L.: Apparent shear strength of hybrid glass fibre reinforced composite joints. Polym Test 64, 307–312 (2017). https://doi.org/10.1016/j.polymertesting.2017.10.022

Ribeiro Júnior, A.L., Gomez, J.E., Hale, D.W., Tonatto, M.L.P., Panzera, T.H., Thomas, C., Scarpa, F.: Evaluation of the stiffening mechanism based on micro-sized particle inclusions in laminated composites. Mater Res 22(4), e20190084 (2019). https://doi.org/10.1590/1980-5373-mr-2019-0084

Bitzer T.: Honeycomb Technology: Materials, Design, Manufacturing, Applications and Testing. Chapman & Hall. London, UK (1997)

Gotkhindi, T.P., Simha, K.R.Y.: In-plane effective shear modulus of generalized circular honeycomb structures and bundled tubes in a diamond array structure. J Mech Sci Technol 101–102, 292–308 (2015). https://doi.org/10.1016/j.ijmecsci.2015.08.009

Oruganti, R.K., Ghosh, A.K.: FEM analysis of transverse creep in honeycomb structures. Acta Mater 56, 726–735 (2008). https://doi.org/10.1016/j.actamat.2007.10.019

Lin, T.C., Chen, T.J., Huang, J.S.: In-plane elastic constants and strengths of circular cell honeycombs. Compos Sci Technol 72, 1380–1386 (2012). https://doi.org/10.1016/j.compscitech.2012.05.009

Chung, J., Waas, A.M.: In-plane elastic properties of circular cell and elliptical cell honeycombs. Acta Mech 144(1–2), 29–42 (2000). https://doi.org/10.1007/BF01181826

Hu, L.L., He, X.L., Wu, G.P., Yu, T.X.: Dynamic crushing of the circular-celled honeycombs under out-of-plane impact. Int J Impact Eng 75, 150–161 (2015). https://doi.org/10.1016/j.ijimpeng.2014.08.008

Cabrera, N.O., Alcock, B., Peijs, T.: Design and manufacture of all-PP sandwich panels based on co-extruded polypropylene tapes. Compos Part B Eng 39, 1183–1195 (2008). https://doi.org/10.1016/j.compositesb.2008.03.010

Riccio, A., Raimondo, A., Saputo, S., Sellitto, A., Battaglia, M., Petrone, G.: A numerical study on the impact behaviour of natural fibres made honeycomb cores. Compos Struct 202, 909–916 (2018). https://doi.org/10.1016/j.compstruct.2018.04.062

Oliveira, P.R., Bonnaccorsi, A.M.S., Panzera, T.H., Christoforo, A.L., Scarpa, F.: Sustainable sandwich composite structures made from aluminium sheets and disposed bottle caps. Thin-Walled Struct 2017(120), 38–45 (2017). https://doi.org/10.1016/j.tws.2017.08.013

Oliveira, P.R., Panzera, T.H., Freire, R.T.S., Scarpa, F.: Sustainable sandwich structures made from bottle caps core and aluminium skins: A statistical approach. Thin-Walled Struct 130, 362–371 (2018). https://doi.org/10.1016/j.tws.2018.06.003

De. Jesus, M.M., Gato, L.B.L., Oliveira, P.R., Ribeiro Filho, S.L.M., Tonatto, M.L.P., Panzera, T.H., Scarpa, F.: Recycled polyethylene bottle caps as sandwich panel circular honeycomb: experimental and numerical approach. Polym. Compos. 2020, 1–14 (2020). https://doi.org/10.1002/pc.25742

ASTM, C393 / C393M-16: Standard test method for core shear properties of sandwich constructions by beam flexure, West Conshohocken, PA: ASTM International (2016)

ASTM, D3039 / D3039M-17: Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials, West Conshohocken, PA: ASTM International (2017)

ASTM, D695: Standard test method for compressive properties of rigid plastics, West Conshohocken, PA: ASTM International (2011)

ASTM, D790/15 - Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials, West Conshohocken, PA: ASTM International (2015)

ASTM, D7250/D7250M-16, Standard Practice for Determining Sandwich Beam Flexural and Shear Stiffness, West Conshohocken, PA: ASTM International (2016)

Montgomery DC, 2008. Design and Analysis of Experiments, 5th Edition. John Wiley & Sons. New York, NY; USA

Minitab 17 Statistical Software: Computer software, Minitab, Inc, State College, PA, USA (2010). 〈www.minitab.com〉

Dutra, J.R., Ribeiro Filho, S.L.M., Christoforo, A.L., Panzera, T.H., Scarpa, F.: Investigations on sustainable honeycomb sandwich panels containing eucalyptus sawdust. Piassava and cement particles, Thin-Walled Struct 143, 106–191 (2019). https://doi.org/10.1016/j.tws.2019.106191

Delucis R.A., Tonatto, M.L.P., Trindade, R.S., Amico, S.C.: In situ L-RTM manufacturing of sandwich panels with PET foam core reinforced by polymeric pins. J Sandw Struct Mater 1-14 (2019). https://doi.org/10.1177/1099636219830145

Barbero, E.J.: Introduction to Composite Materials Design, 2nd edn. CRC Press. Boca Raton, FL, USA (2011)

Dryden, J.R., Shinozaki, D.M., Slywuck, M.: Inhornogeneous plasticity in polypropylene spherulites. Polymer 32(15), 2760–2765 (1991). https://doi.org/10.1016/0032-3861(91)90105-R

Dadej, K., Surowska, B.: Analysis of cohesive zone model parameters on response of glass epoxy composite in mode II interlaminar fracture toughness test. Compos Theory Pract 16(3): 180–188 (2010). Available at https://www.semanticscholar.org/paper/Analysis-of-cohesive-zone-model-parameters-on-of-in-Dadej-Surowska/eab7d94ab1480caae516c3427a1215febc804ea0

Gholami, M., Alashti, R.A., Fathi, A.: Optimal design of a honeycomb core composite sandwich panel using evolutionary optimization algorithms. Compos Struct 139, 254–262 (2016). https://doi.org/10.1016/j.compstruct.2015.12.019

Missoum, S., Lacaze, S., Amabili, M., Alijani, F.: Identification of material properties of composite sandwich panels under geometric uncertainty. Compos Struct 2017(179), 695–704 (2017). https://doi.org/10.1016/j.compstruct.2017.07.020

Acknowledgements

The authors acknowledge the Brazilian Research Agencies, CAPES (MSc scholarship), CNPq (PQ—309885/2019-1) and FAPEMIG (PPM-IX) for the financial support provided.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interests

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gato, L.B.L., Ribeiro Filho, S.L.M., Panzera, T.H. et al. Sandwich Structures Made of Discarded Bottle Caps Core and Hybrid Glass Fibre Composite Skins. Appl Compos Mater 28, 1427–1449 (2021). https://doi.org/10.1007/s10443-021-09922-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-09922-x