Abstract

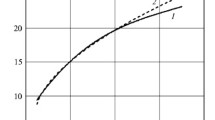

A method is proposed to model the radiant heat exchange in heating units. Studies are performed on a fire stand and an experimental installation to determine the amount of heat transferred to the heated medium in tubular furnaces and radiation recuperators after the deposition of high-emissivity-factor coatings onto heat-absorbing surfaces. After coating deposition, the heat absorption by the medium to be heated in tubular furnaces is shown to increase by 16–17% and that in radiation recuperators, by 20% at temperatures of 300–600°C.

Similar content being viewed by others

REFERENCES

A. G. Radyuk and A. E. Titlyanov, “Application of heat-resistant coatings for the protection of materials and equipment during high-temperature heating,” Tekhnol. Metal., No. 1, 12–17 (2015).

S. S. Solntsev, “High-temperature composite materials and coatings based on glass and ceramics for aerospace equipment,” Ross. Khim. Zh. 54 (1), 25–33 (2010).

R. A. Latypov, E. V. Ageev, G. R. Latypova, A. Yu. Altukhov, and E. V. Ageeva, “Properties of the coatings fabricated by plasma-jet hard-facing by dispersed mechanical engineering wastes,” Russ. Metall. (Metally), 2018 (6), 573–575 (2018).

R. A. Latypov, E. V. Ageeva, and G. R. Latypova, “Properties of the composite galvanic coatings fabricated using the dispersed wastes of ShKh15 steel,” Russ. Metall. (Metally), 2019 (6), 632–635 (2019).

K. Yu. Frolenkov, “Heat-resistant glass-ceramic coatings for protection from high-temperature gas corrosion of low-alloy steels,” Fizikokhim Poverkhn. Zashch. Mater. 45 (4), 415–421 (2009).

V. V. Chernov, O. V. Klenina, and R. A. Latypov, “Role of the emissivity factor of brickwork in the radiant heat exchange of fuel furnaces,” Ogneupory Tekhn. Keram., No. 10, 14–17 (2015).

V. V. Chernov and V. I. Dudin, “Development of compositions of high-temperature coatings with a high emissivity factor for the intensification of radiant heat transfer,” Elektrometallurgiya, No. 2, 33–37 (2019).

I. I. Ponikarov and M. G. Gainullin, Machines and Apparatuses of Chemical Production and Oil and Gas Processing (Al’fa-M, Moscow, 2006).

V. V. Chernov, “Optimization of compositions of high-temperature coatings with a high emissivity factor for the intensification of radiant heat transfer in thermal units,” Elektrometallurgiya, No. 2, 19–24 (2020).

B. P. Teben’kov, Recuperators for Industrial Furnaces (Metallurgiya, Moscow, 1975).

Calculations of Metallurgical Furnaces: A Handbook, Ed. by V. I. Timoshpol’skii and V. I. Gubinskii (Teplotekhnik, Moscow, 2009), Vol. 1; (Teplotekhnik, Moscow, 2011), Vol. 2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Chernov, V.V., Andreeva, L.P. Heat Exchange in Heating Units When High-Emissivity-Factor Coatings on Heat-Absorbing Surfaces Are Used. Russ. Metall. 2021, 685–688 (2021). https://doi.org/10.1134/S0036029521060112

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521060112