Abstract

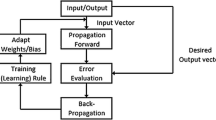

Carbonation is one of the most aggressive phenomena affecting reinforced concrete structures and causing their degradation over time. Once reinforcement is altered by carbonation, the structure will no longer fulfill service requirements. For this purpose, the present work estimates the lifetime of fly ash concrete by developing a carbonation depth prediction model that uses an artificial neural network technique. A collection of 300 data points was made from experimental results available in the published literature. Backpropagation training of a three-layer perceptron was selected for the calculation of weights and biases of the network to reach the desired performance. Six parameters affecting carbonation were used as input neurons: binder content, fly ash substitution rate, water/binder ratio, CO2 concentration, relative humidity, and concrete age. Moreover, experimental validation carried out for the developed model shows that the artificial neural network has strong potential as a feasible tool to accurately predict the carbonation depth of fly ash concrete. Finally, a mathematical formula is proposed that can be used to successfully estimate the service life of fly ash concrete.

Similar content being viewed by others

References

Dhir R K, Hewlett P C, Chan Y N. Near surface characteristics of concrete: Prediction of carbonation resistance. Magazine of Concrete Research, 1989, 41(148): 137–143

Tuutti K. Corrosion of Steel in Concrete. Stockholm: Swedish Cement and Concrete Research Institute, 1982

Elhassane J. Reliability assessment of the impact of climatic factors on the corrosion of reinforced concrete beams Application to the Lebanese case. Dissertation for the Doctoral Degree. Clermont Ferrand: Blaise Pascal-Clermont II University, 2010 (in French)

Papadakis V, Fardis M, Vayenas C. Hydration and carbonation of pozzalanic cements. ACI Materials Journal, 1992, 89(2): 119–130

Baroghel-Bouny V. Design of concrete for a given service life of structures—Control of durability with regard to the corrosion of reinforcements and alkali-reaction—State of the art and guide for the implementation of an approach performance based on sustainability indicators. Paris: French Association of Civil Engineering, 2004 (in French)

Fagerlund G. Service life of structures. In: Proceedings of Symposium of Quality Control of Concrete Structures. Stockholm: Swedish C & CRI, 1979, 3: 199–215

Niu D T, Chen Y Q, Yu S. Model and reliability analysis for carbonation of concrete structures. Journal of Xi’an University of Architecture and Technology, 1995, 27(4): 365–369

Liang M T, Wang K L, Liang C H. Service life prediction of reinforced concrete structures. Cement and Concrete Research, 1999, 29(9): 1411–1418

Cho H C, Lee D H, Ju H, Kim K S, Kim K H, Monteiro P J M. Remaining service life estimation of reinforced concrete buildings based on fuzzy approach. Computers and Concrete, 2015, 15(6): 879–902

Schubert P. Carbonation behavior of mortars and concrete made with fly ash. ACI Special Publications, 1987, SP-100: 1945–1962

Park G K. Durability and carbonation of concrete. Magazine of Korean Concrete Institute, 1995, 7: 74–81

Mindess S, Young J F, Darwin D. 2nd ed. Concrete. New Jersey: Prentice Hall, 2002

Burden D. The durability of concrete containing high levels of fly ash. Dissertation for the Doctoral Degree. Fredericton: New Brunswick University, 2006

Younsi A. Carbonation of concretes with high rates of substitution of cement by mineral additions. Dissertation for the Doctoral Degree. La Rochelle: La Rochelle University, 2011 (in French)

Chaussadent T. State of play and reflection on the carbonation of reinforced concrete. Studies and Research of Bridges and Roads Laboratories. Paris: Central Laboratory of Roads and Bridges, 1999 (in French)

Borges P H R, Costa J O, Milestone N B, Lynsdale C J, Streatfield R E. Carbonation of CH and C-S-H in composite cement pastes containing high amounts of BFS. Cement and Concrete Research, 2010, 40(2): 284–292

Bier T A. Influence of the type of cement and curing on carbonation progress and pore structure of hydrated cement pastes. In: Materials Research Society Symposium Proceedings. USA: Cambridge University Press, 1986, 85–123

Metha P K, Monteiro P J M. Concrete, Microstructure, Properties and Materials. New York: McGraw-Hill, 2006

Atis C D. Accelerated carbonation and testing of concrete made with fly ash. Construction & Building Materials, 2003, 17(3): 147–152

Ogha H, Nagataki S. Prediction of carbonation depth of concrete with fly ash. In: 3rd International Conference on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete. Trodheim: American Concrete Institute, ACI SP-114, 1989, 275–294

Marques P F, Chastre C, Nunes Â. Carbonation service life modelling of RC structures for concrete with Portland and blended cements. Cement and Concrete Composites, 2013, 37: 171–184

Thomas M D A, Matthews J D. Carbonation of fly ash concrete. Magazine of Concrete Research, 1992, 44(160): 217–228

Khunthongkeaw J, Tangtermsirikul S, Leelawat T. A study on carbonation depth prediction for fly ash concrete. Construction & Building Materials, 2006, 20(9): 744–753

Anitescu C, Atroshchenko E, Alajlan N, Rabczuk T. Artificial neural network methods for the solution of second order boundary value problems. Computer Materials Continua, 2019, 59(1): 345–359

Guo H, Zhuang X, Rabczuk T. A deep collocation method for the bending analysis of kirchhoff plate. Computer, Materials and Continua, 2019, 59(2): 433–456

Yan L, Zhao S, Yi C. The forecast of carbonation depth of concrete based on RBF neural network. In: Second International Symposium of Intelligent Information Technology Application IITA’08. Shanghai: IEEE, 2008, 3: 544–548

Lu C, Liu R. Predicting carbonation depth of prestressed concrete under different stress states using artificial neural network. Advances in Artificial Neural Systems, 2009, 5: 1–8

Narui B, Guoli Y, Hui Z. Prediction of concrete carbonization depth based on DE-BP neural network. In: Third international symposium on intelligent information technology application. Nanchang: IEEE, 2009, 240–243

Luo D, Niu D, Dong Z. Application of neural network for concrete carbonation depth prediction. In: Proceedings of 4th International Durability Conference of Concrete Structures. West Lafayette: Purdue University, 2014

Taffese W Z, Sistonen E, Puttonen J. CaPrM: Carbonation prediction model for reinforced concrete using machine learning methods. Construction & Building Materials, 2015, 100: 70–82

Kellouche Y, Boukhatem B, Ghrici M, Tagnit Hamou A. Exploring the major factors affecting fly-ash concrete carbonation using artificial neural network. Neural Computing & Applications, 2019, 31(S2): 969–988

Felix E F, Possan E, Carrazedo R. Analysis of training parameters in the ANN learning process to mapping the concrete carbonation depth. Journal of Building Pathology and Rehabilitation, 2019, 4(1): 1–13

Akpinar P, Uwanuakwa I D. Investigation of the parameters influencing progress of concrete carbonation depth by using artificial neural networks. Materiales de Construcción, 2020, 70(337): 209

Benítez P, Rodrigues F, Talukdar S, Gavilán S, Varum H, Spacone E. Analysis of correlation between real degradation data and a carbonation model for concrete structures. Cement and Concrete Composites, 2019, 95: 247–259

Hecht-Nielsen R. Theory of the backpropagation neural network. In: Neural network for Perception: Computation, Learning, Architectures. ACM, 1992, 2, 65–93

Geoffrey H. Training and Neural Networks. Paris, 1992, 181: 124–132 (in French)

Sulapha P, Wong S F, Wee T H, Swaddiwudhipong S. Carbonation of concrete containing mineral admixtures. Journal of Materials in Civil Engineering, 2003, 15(2): 134–143

Sisomphon K, Franke L. Carbonation rates of concretes containing high volume of pozzolanic Materials. Cement and Concrete Research, 2007, 37(12): 1647–1653

Lammertijn S, de Belie N. Porosity, gas permeability, carbonation and their interaction in high-volume fly ash concrete. Magazine of Concrete Research, 2008, 60(7): 535–545

Jiang L, Liu Z, Ye Y. Durability of concrete incorporating large volumes of low-quality fly ash. Cement and Concrete Research, 2004, 34(8): 1467–1469

Rozière E, Loukili A, Cussigh F. A performance-based approach for durability of concrete exposed to carbonation. Construction & Building Materials, 2009, 23(1): 190–199

Xu H, Chen Z Q, Li S B, Huang W, Ma D. Carbonation test study on low calcium fly ash concrete. Applied Mechanics and Materials, 2010, 34–35(35): 327–331

Das B, Pandey S P. Influence of fineness of fly ash on the carbonation and electrical conductivity of concrete. Journal of Materials in Civil Engineering, 2011, 23(9): 1365–1368

Zhang P, Li Q. Effect of fly ash on durability of high-performance concrete composites. Research Journal of Applied Sciences, Engineering and Technology, 2013, 6(1): 7–12

van den Heede P, de Belie N. Service life based global warming potential for high-volume fly ash concrete exposed to carbonation. Construction & Building Materials, 2014, 55: 183–193

Hamdia K M, Zhuang X, Rabczuk T. An efficient optimization approach for designing machine learning models based on genetic algorithm. Neural Computing & Applications, 2021, 33(6): 1923–1933

Quan H Z, Kasami H. Experimental study on durability improvement of fly ash concrete with durability improving admixture. The Scientific World Journal, 2014, 1–11

Gao Y, Cheng L, Gao Z, Guo S. Effects of different mineral admixtures on carbonation resistance of lightweight aggregate concrete. Construction & Building Materials, 2013, 43: 506–510

Huang C H, Geng G L, Lu Y S, Bao G, Lin Z R. Carbonation depth research of concrete with low-volume fly ash. Applied Mechanics and Materials, 2012, 155–156: 984–988

Chen S, Sun W, Zhang Y, Guo F. Carbonation depth prediction of fly ash concrete subjected to 2- and 3-dimensional CO2 attack. Frontiers of Architecture and Civil Engineering in China, 2008, 2(4): 395–400

Papadakis V. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cement and Concrete Research, 2000, 30(2): 291–299

Khunthongkeaw J, Tangtermsirikul S. Model for simulating carbonation of fly ash concrete. Journal of Materials in Civil Engineering, 2005, 17(5): 570–578

Shi H S, Xu B W, Zhou X C. Influence of mineral admixtures on compressive strength, gas permeability and carbonation of highperformance concrete. Construction & Building Materials, 2009, 23(5): 1980–1985

Saetta A V, Schrefler B A, Vitaliani R V. The carbonation of concrete and the mechanism of moisture heat and carbon dioxide flow through porous materials. Cement and Concrete Research, 1993, 23(4): 761–772

Saetta A V, Schrefler B A, Vitaliani R V. Schrefler B A, Vitaliani R V. 2-D Model for carbonation and moisture-heat flow in porous materials. Cement and Concrete Research, 1995, 25(8): 1703–1712

Saetta A V, Vitaliani R V. Experimental investigation and numerical modeling of carbonation process in reinforced concrete structures. Cement and Concrete Research, 2005, 35(5): 958–967

Kellouche Y. Prediction of the service-life of concrete structures based on cement additives. Dissertation for the Doctoral Degree. Chlef: University of Hassiba Benbouali, 2018 (in French)

Sabet B, Jong H C. Effect of preconditioning of concrete under accelerated test. In: Proceedings of the 31st Conference on Our World in Concrete and Structures. Singapore: CI Premier Pte Ltd, 2006

Czarnecki L, Woyciechowski P. Modelling of concrete carbonation: Is it a process unlimited in time and restricted in space? Bulletin of Polish Academy of Sciences, Technical Sciences, 2015, 63(1): 1–12

Acknowledgements

This research was sponsored by the General Directorate for Scientific Research and Technological Development (DGRSDT) of the Algerian Minister of Higher Education and Scientific Research. The authors would like to thank the entire team of the alternative materials laboratory at Sherbrook University, especially Dr. Arezki Taghnit-Hamou, who welcomed us to his laboratory, and Dr. Ablam Zidol, for his help in carrying out the experimental program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kellouche, Y., Ghrici, M. & Boukhatem, B. Service life prediction of fly ash concrete using an artificial neural network. Front. Struct. Civ. Eng. 15, 793–805 (2021). https://doi.org/10.1007/s11709-021-0717-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-021-0717-9