Abstract

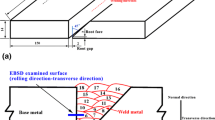

Super duplex stainless steel (UNS S32750) butt joints were prepared using ER2594 and ER2595 electrodes by shielded metal arc welding (SMAW) process. The heat input used during welding was in the range of 0.75–0.81 kJ/mm. Microstructure and texture across the weldments were investigated using optical microscope, scanning electron microscope, and electron backscattered diffraction. The solidification mode in the fusion zone (FZ) was found to be ferritic, and the microstructure mainly consisted of Widmanstatten austenite (WA), grain boundary austenite (GBA), and inter-granular austenite (IGA). The base metal (BM) had ~ 50% ferrite and 50% austenite. The ferrite proportion changed significantly in FZ and heat-affected zone (HAZ) after welding. Austenite in the BM showed strong Brass ({110} < 112 >), Cu ({112} < 111 >), Goss ({110} < 110 >), and S ({123} < 634 >) components, while ferrite showed strong α (RD// < 110 >) and γ (ND// < 111 >) fibres. The texture of ferrite was stronger than that of austenite. The austenite and ferrite in the FZ (cap pass) obeyed Kurdjumov–Sachs (K–S) orientation relationship. Further, the hardness of ER2595 weldments was found to be higher than that of ER2594 weldments.

Similar content being viewed by others

References

Chung H M, Int J Press Vessels Pip 50 (1992) 179.

Johansson J, Odén M, and Zeng X H, Acta Mater 9 (1999) 2669.

Jia N, Peng R L, Wang Y D, Chai G C, Johansson S, Wang G, and Liaw P K, Acta Mater 54 (2006) 3907.

Yang J, Wang Q, and Guan K, Int J Press Vessels Pip 110 (2013) 72.

Lasebikan B A, and Akisanya A R, Int J Press Vessels Pip 119 (2014) 62.

Muthupandi V, Srinivasan P B, Seshadri S K, and Sundaresan S, Mater Sci Eng A 358 (2003) 9.

Dandekar T R, Kumar A, Khatirkar R K, Mahadule D, and Ayyappan G, J Mater Eng Perform 30 (2021) 2916.

Pohl M, Storzand O, and Glogowski T, Mater Charact 58 (2007) 65.

Alvarez-Armas I, Recent Pat Mech Eng 1 (2008) 51.

Luo J, Donga Y, Li L, and Wanga X, J Manuf Process 16 (2013) 144.

Verma J, Taiwade R V, Khatirkar R K, and Kumar A, Mater Trans 57 (2016) 494.

Nilsson J O, Karlsson L, and Andersson J O, Mater Sci Technol 11 (1995) 276.

Liu H Y, Hsieh R I, and Tsai W T, Corros Sci 44 (2002) 2841.

Varbai B, Pickle T, and Májlinger K, Int J Press Vessels Pip 176 (2019) 103952. ISSN 0308–0161.

Nageshand D S, and Datta G L, J Mater Process Technol 123 (2002) 303.

Stephenson N, Weld Met Fabr 55 (1987) 159.

Stephenson N, Weld Met Fabr 55 (1987) 235.

Tavares S S M, Pardal J M, Lima L D, Bastos I N, Nascimento A M, and De Souza J A, Mater Charact 58 (2007) 610.

Hsieh R I, Liouand H Y, and Pan Y T, J Mater Sci Perform 10 (2001) 526.

Dandekar T R, Gupta A, Kumar A, Khatirkar R K, and Vadavadagi B, Mater Res Express 5 (2018) 106506.

Badji R, Bacroix B, and Bouabdallah M, Mater Charact 62 (2011) 833.

Aguiar I V, Escobar D P, Santos D B, and Modenesi P J, Rev Mater 11590 (2015) 212.

Shamanian M, Mohammadnezhad M, Amini M, Zabolian A, and Szpunar J A, JMEPEG 24 (2015) 3118.

Sirohi S, Pandey C, and Goyal A, Fusion Eng Des 159 (2020) 111935.

Sirohi S, Pandey C, and Goyal A, Int J Press Vessels Pip 188 (2020) 104179.

Shamanian M, Kangazian J, and Szpunar J, Weld World (2021).

Kangazian J, and Shamanian M, Mater Charact 155 (2019) 109802.

Parmar R S, Welding Engineering & Technology, Khanna Publisher, New Delhi (2002)

Standard practice for preparation of metallographic specimens, E3–95, ASTM, PA, USA (1995).

ASM handbook, Metallographic and Microstructures, ASM International, Materials Park, OH (2004).

OIM, Analysis Version 7.2, TexSEM Laboratories Inc, Draper (2013).

Schwartz A J, Kumar M, Adams B L, and Field D P, Electron Backscatter Diffraction in Materials Science, Springer, US, (2009).

Chen L, Tan H, Wang Z, Li J, and Jiang Y, Corros Sci 58 (2012) 168.

Nowacki J, and Łukojć A, J Mater Process Technol 164–165 (2005) 1074.

Perren R A, Suter T, Solenthaler C, Gullo G, Uggowitzer P J, Bohni H, and Speidel M O, Corros Sci 43 (2001) 727.

Eghlimi A, Shamanian M, and Raeissi K, Surf Coat Technol 244 (2014) 45.

Yang Y, Yan B, Li J, and Wang J, Corros Sci 53 (2011) 3756.

Badji R, Chauveau T, and Bacroix B, Mater Sci Eng A 575 (2013) 94.

Souza Jr C M, Abreu H F G, Tavares S S M, and Rebello J M A, Mater Charact 59 (2008) 1301.

Puthuparambil Madhavan A, Paulraj S, and Sivanandam A, Friction 2 (2014) 82.

Unnikrishnan R, Satish Idury K S N, Ismail T P, Bhadauria A, Shekhawat S K, Rajesh Z K, Khatirkar K, Sanjay G, and Sapate G, Mater Charact 93 (2014) 10.

Gerber P H, Tarasiuk J, Chauveau T, and Bacroix B, Acta Mater 51 (2003) 6359.

Wu S H, Huang J C, and Wang Y N, Metall Mater Trans A 35 (2004) 2455.

Etter A L, Baudin T, Mathon M H, Swiatnicki W, and Penelle R, Scr Mater 54 (2006) 683.

Herrera C, Ponge D, and Raabe D, Steel Res Int 79 (2008) 482.

Nelson T W, Lippold J C, and Mills M J, Weld J 78 (1999) 329.

Brytan Z, and Niagaj J, Chiang Mai J Sci 40 (2013) 923.

ORTtools v1.0.2. https://github.com/frankNiessen/ORTools/.

Bachmann F,Hielscher R, and Schaeben H, Trans Tech Publ 5 (2010) 39.

MATLAB, Natick, The Mathwork Inc, Massachusetts (2019).

Karlsson L, and Börjesson J, Sci Technol Weld Joining 19 (2014) 318.

Monlevade E F, and Falleiros I G S, Metall Mater Trans A 37 (2006) 939.

Tseng C M, Liouand HY, and Tsai W T, Sci Eng A 344 (2003) 190.

Rawers J, and Gruijicic M, Mater Sci Eng A 207 (1996) 188.

Acknowledgment

The authors are thankful to Director, VNIT Nagpur, for providing necessary facilities and constant encouragement to publish this paper. The authors would like to acknowledge the use of National Facility for Texture and OIM (A DST-IRPHA project), IIT, Bombay for EBSD measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dandekar, T.R., Gupta, A., Khatirkar, R.K. et al. Evolution of Microstructure and Texture in UNS S32750 Super Duplex Stainless Steel Weldments. Trans Indian Inst Met 74, 2267–2283 (2021). https://doi.org/10.1007/s12666-021-02274-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02274-x