Multi-Objective Optimization Methods for Designing Low-Carbon Concrete Mixtures

- Department of Civil, Environmental, and Architectural Engineering, University of Colorado Boulder, Boulder, CO, United States

Concrete mixtures are complex material systems with a multitude of characteristics that decision-makers may deem important. These characteristics can include economic, environmental, mechanical, and durability-related properties of a concrete mixture. However, traditional concrete mixture design typically employs long-standing heuristics, which satisfy requirements for physical characteristics but are unable to minimize specific characteristics, such as the cost or carbon footprint of the concrete mixture. This work considers these performance characteristics by implementing simulation-optimization as a new paradigm for designing concrete mixtures. The utility of the simulation-optimization framework is tested for several concrete design case studies that simultaneously consider compressive strength, embodied carbon, service life, and cost. Results from these scenarios demonstrate that the local conditions of the case study dictate the most important parameters of the simulation-optimization (i.e., relative constituent costs, in situ service-life conditions). Out of all other parameters, constituent cost and service-life conditions impact the set of optimal concrete mixture designs in terms of the types and quantities of mixture ingredients that are utilized. We present a simulation-optimization framework that is demonstrated herein to be a holistic design tool that allows designers to quantify and visualize tradeoffs between critical concrete performance metrics. Such a tool can be used to precision-tailor low-carbon concrete mixtures to the exact preferences of the designer.

Introduction

Concrete is a complex, heterogeneous composite material, and a myriad of properties must be considered in determining appropriate concrete mixture proportions. For instance, for a given application, a concrete mixture must provide sufficient compressive strength, and oftentimes must resist degradation from multiple environmental factors. In addition, due to concerns about climate change, there is increasing pressure for the cement and concrete industry to produce concrete with lower upfront embodied carbon, namely the carbon dioxide emissions associated with manufacture and transportation of concrete (“Making Concrete Change”; Rodgers, 2018). Note that the term “embodied carbon” or “carbon emissions” refers to the carbon dioxide emissions associated with material manufacture. Low-carbon materials, therefore, refer to materials with low carbon dioxide manufacturing emissions. Finally, project budgets and profitability concerns require finding the least expensive concrete that meets all design criteria. Finding a concrete mixture design that can satisfy all of these requirements is thus quite challenging.

The vast majority of current concrete mixture design methodologies, such as the American Concrete Institute’s Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete (ACI 211.1–91), rely on engineering heuristics in order to determine the quantities of each concrete constituent (American Concrete Institute, 1991). Such proportioning methods have the benefit of simplicity but have several disadvantages. First, these heuristics used do not capture the true complexity of the relationship between mixture design and desired properties. For example, in the ACI method, one achieves the appropriate 28-days compressive strength with a heuristic in which the target compressive strength is mapped to the necessary water-to-cement (w/c) ratio. Compressive strength is indeed influenced by the w/c ratio; however, it is also strongly affected by other variables including the total cement content and the type, quantity, and composition of any supplementary cementitious materials (SCMs) (Toutanji et al., 2004; Khatri et al., 1995). Other relationships are similarly simplified, such as the heuristics for slump and durability, meaning that true value of these variables often differs from the target value. Another drawback of traditional concrete design methods is that it is not currently possible to truly optimize (i.e., minimize or maximize) properties of interest, while meeting design considerations related to the fresh-state, hardened-state, durability, economic, and environmental properties of concrete. For instance, traditional mixture design methods lack the ability to identify the mixture design with the lowest cost or lowest embodied carbon, given a set of performance requirements (e.g., required strength, slump, sufficient resistance to chloride-induced corrosion).

To address these challenges, this study proposes multi-objective optimization as a method for designing concrete mixtures with multiple design considerations. Application of multi-objective optimization to concrete mixture design requires the use of property models which link a concrete mixture design to the values of critical concrete properties, such as cost, compressive strength, expected service life, and embodied carbon dioxide emissions of the concrete mixture. Application of this technique to concrete mixture design would enable designers 1) to better predict the properties of a given mixture design with these advanced property models and 2) to simultaneously optimize multiple concrete properties of interest.

The use of multi-objective optimization for proportioning concrete mixtures is relatively underutilized in the literature. What literature exists can be generally grouped into two categories. The first category uses multi-objective optimization to address generalized concrete mixture design using two or three property-related objectives. For instance, Young et al. selected cost and compressive strength as objectives and elected to constrain the optimal solutions by their embodied carbon values. However, a simplified model for embodied carbon was utilized in which the embodied carbon was approximated as a linear function of the quantity of cement; this linear function ignores the impact of other concrete constituents and life cycle stages of concrete manufacturing (e.g., constituent transportation and use phase carbonation) (Young et al., 2019). The outcome of optimizing a design problem is only as good as the property models it uses. The use of more advanced property models for predicting economic, environmental, service life, and mechanical properties may lead to more accurate and trustworthy mix design solutions. The second category of studies in the literature uses multi-objective optimization for analyzing highly specialized concrete applications such as concrete that has very high strength (Baykasoğlu, 2009) or concrete that incorporates uncommon agricultural (Madurwar et al., 2015) or industrial waste products (Promentilla et al., 2017); however, it is difficult to extend such studies to more broad applications since the simulation models they use are developed using specialized datasets.

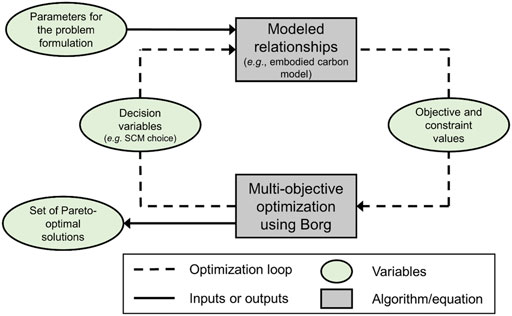

The primary research gap our work addresses is that the existing literature has not considered economic, environmental, mechanical, and durability-related properties simultaneously using multi-objective optimization; this research gap is discussed extensively in (DeRousseau et al., 2018). We seek to expand upon the existing research by incorporating these properties in a simulation-optimization (as illustrated in Figure 1) that can be used for a variety of concrete applications and types. In this framework, concrete properties (i.e., compressive strength, embodied carbon, cost, and service life) are simulated using modeled relationships (i.e., equations or predictive models) that link mixture proportions to material performance. Subsequently, optimal mixture designs are found in an iterative fashion using a state-of-the-art multi-objective evolutionary algorithm called Borg. We apply the simulation-optimization framework to three location-based case studies in order to illustrate how input parameters, such as concrete constituent costs, transportation distances, and chloride exposure conditions affect optimal mixture designs. Three location-based scenarios are selected to represent very different possible design cases in 1) Miami, FL; 2) San Francisco, CA; and 3) Anchorage, AK. The purpose of the case studies is to apply the simulation-optimization framework to possible design situations and to illustrate that resultant optimal mixture designs are highly dependent on input parameters related to individual constituent costs, environmental exposure conditions, temperature, and constituent transportation distances.

FIGURE 1. Conceptualization of the simulation-optimization framework for analyzing each scenario. The Borg MOEA is coupled with the simulation of concrete properties to find Pareto-optimal mixture designs for different scenarios.

Methods

Problem Formulation

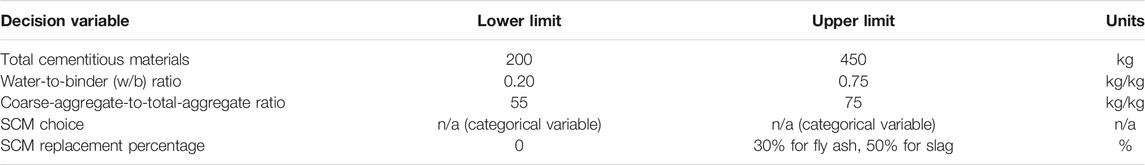

To conduct multi-objective optimization, one must define the problem formulation, which is composed of decisions, objectives, constraints, and modeled relationships for the problem. Decisions are a set of variables (

Each of the decision variables allow for the calculation of the quantities of each mixture ingredient (i.e., cement, fly ash, slag, water, coarse aggregate, fine aggregate, water-reducer, air-entraining admixture), and the absolute volume method is used to quantify the mixture ingredient quantities from the decision variables (American Concrete Institute, 1991). Table 1 provides the allowable range of values for the decision variables, which are selected using engineering judgement and the limits imposed to avoid issues associated with degradation or concrete setting. For instance, limits are placed on the w/b ratio to avoid segregation and bleeding (for high w/b values) and to ensure full cement hydration (for low w/b values). Similarly, to avoid low values of early-age strength, limits are placed on the maximum percent replacement that is allowed for fly ash and slag, which are 30 and 50%, respectively, (Alabama Standard Specifications, 2012).

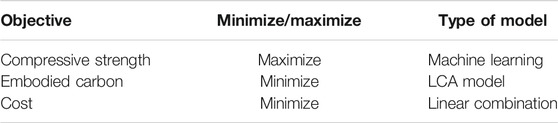

Objectives (

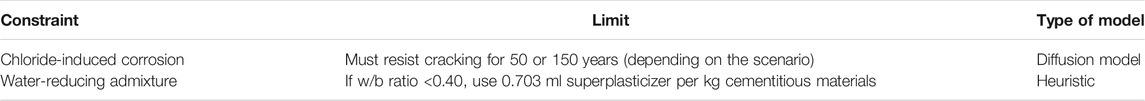

Constraints place limits on the values of the decisions or objectives of the problem. The difference between constraints and objectives is distinct; a constraint must be met for the design to be successful. In contrast, an objective is a design target where a lower value (or higher) is considered better. This analysis poses a constraint on concrete service life and requires that concrete must resist corrosion for a set number of years as specified in Table 3). Note that for the case studies proposed in Case Studies, the dominant degradation mechanism is assumed to be chloride-induced corrosion. An additional constraint relates to water-reducing admixture dosage, which is required when the w/b ratio is less than 0.40 so that the concrete remains workable (Domone, 1998).

Lastly, the modeled relationships are equations (i.e., models) that relate the decision variables to quantifiable values of the objectives and constraints. This analysis employs four modeled relationships which have been developed in other research for quantifying compressive strength, embodied carbon, cost, and chloride-induced corrosion. These modeled relationships are further discussed in Modeled Relationships.

Multi-Objective Optimization With Evolutionary Algorithms

Assuming minimization of all objectives, multi-objective optimization is formalized as the equations below (Coello et al., 2007).

Minimize:

Subject to:

and:

where each f(x) is an objective to be optimized and x is the n-dimensional decision space.

To search for the Pareto-optimal solutions, this analysis uses a multi-objective evolutionary algorithm (MOEA) called Borg, which was selected due to its auto-adaptive features and high performance on challenging multi-objective problems. (Reed et al., 2013; Zatarain; Salazar and Jazmin, 2016). For each function evaluation, Borg stochastically generates and evaluates a new solution (i.e., potential mixture design). A solution is non-dominated if none of the objectives can be improved in value without degrading one or more of the other objective values when compared to other existing solutions. During the search, the goal is to continue finding non-dominated solutions until a close approximation to the set of Pareto-optimal solutions is found. In this study, each scenario involved 50,000 function evaluations and incorporated five random seeds. Using some number of random seeds greater than one ensures that solutions were not an artifact of Borg’s initial parameterization.

Modeled Relationships

In the following sections, each of the modeled relationships for calculating cost, compressive strength, embodied carbon, and chloride-induced corrosion are discussed in detail. Note that the cost, compressive strength, and embodied carbon models require the mass of the mixture ingredients as input variables. To calculate these values, we use the absolute volume method (American Concrete Institute, 1991) applied to the decision variables, since the decision variables are quantities such as the w/b ratio and SCM replacement percentage.

Cost Model

To quantify the cost of a unit volume of concrete, the costs of each mixture ingredient are simply summed as shown in Eq. 4, where Ctotal is the total cost of 1 m3 of concrete, Ci are the costs per tonne of each mixture ingredient, and xi are the quantities of each mixture ingredient per unit of concrete (tonne/m3). This linear cost model is adapted by identifying unit costs of each individual mixture constituent in bulk in the location of each case study. The cost coefficients also include cost of transportation to the ready-mix plant. However, additional costs due to construction, maintenance, and end-of-life are not included here because it is assumed that for a given application, these costs will be equivalent for all alternatives. Note that the simulation-optimization framework allows for mixture constituent costs to vary geographically, which is one reason why the set of Pareto-optimal solutions varies for each case study.

Compressive Strength Model

The 28-days compressive strength of concrete is a critical design parameter for reinforced concrete structures. Accurate numerical estimation of the 28-days compressive strength of concrete is desirable because more precise prediction provides assurance of concrete quality, reduces the number of concrete batches that are needed to be tested to meet strength targets, and enables a reduction in factors of safety.

In this study, we utilize a validated machine learning model for predicting the 28-days compressive strength, which was formulated by the authors and reported in (Mikaela DeRousseau et al.). In the study it was found that the random forest model performs best compared to all other models tested in a machine learning pipeline in terms of root mean squared error, mean absolute error, and coefficient of determination. Consequently, this Python-based model is utilized in the simulation-optimization framework as the objective function for compressive strength. The inputs to the random forest model are quantities of the mixture ingredients, which are within the bounds of ingredient quantities found in the training data. Since the decision variables are quantities such as the w/b ratio, c/a ratio, percent replacement of SCMs, etc., we use the absolute volume method to calculate the quantity of mixture ingredients and subsequent compressive strength prediction (Wilson and Kosmatka, 2011). Choosing compressive strength as an objective rather than a constraint allows us to quantify tradeoffs made with the other objectives for each incremental increase in compressive strength.

Embodied Carbon Model

The purpose of the upfront embodied carbon model is to quantify the embodied carbon emissions for a functional unit of concrete as a function of the mixture ingredient quantities. The embodied carbon model accounts for the life cycle modules of A1-A3 and B1 (i.e., emissions from raw material supply, transport, manufacturing of products, and concrete carbonation). In this study, we utilize a model formulated and published by the authors in (MA DeRousseau et al., 2019) in which the embodied carbon was modeled as the sum of the material processing, transportation, and manufacturing emissions, minus the sum of the emissions due to carbonation during use and end-of-life for all ingredients for 1 m3 of concrete, as shown in Eq. 5.

In this equation, ci are the embodied carbon coefficients for each constituent due to material processing (in kgCO2e/tonne), xi is the quantity of each mixture ingredient, di is the transportation distance for each mixture constituent, t is the transportation emissions factor (in kgCO2e/tonne/km) for the method of transportation, m is the embodied carbon associated with concrete manufacturing (in kgCO2e/m3), and s is the quantity of CO2 sequestered during the use and end-of-life stages of a concrete in kgCO2e/m3 of concrete, which is a function of the quantity and CaO content of cementitious materials in the concrete and therefore dependent on the SCM content. Subsequently, this model is used for quantifying concrete embodied carbon in the simulation-optimization framework where minimizing embodied carbon is an objective.

DeRousseau et al. (MA DeRousseau et al., 2020) analyze the variability in emissions using statistical distributions and the mean values of the life cycle inventory distributions in the study are utilized, except for transportation distance. For transportation distances, we use values relevant for each case study location as inputs for calculating embodied carbon.

Chloride-induced Corrosion Model

Chloride-induced corrosion occurs when chloride ions from the environment (often due to de-icing salts or proximity to marine environments), diffuse into concrete. When a high enough concentration of chloride ions reaches the concrete reinforcement, the reinforcement corrodes, which produces expansive rust products and subsequent concrete cracking and spalling.

Modeling of chloride-induced corrosion has been discussed extensively in the literature (Srubar, 2015; Sohanghpurwala, 2006; Liu and Weyers, 1998; Bentz, 2003; Cusson et al., 2003). In previous research, expected service life (ts) with regard to corrosion-induced cracking (t) can be estimated using a two-part damage model first proposed by Tuutti in which the time to rebar cracking is the sum of the time to corrosion initiation plus the time to concrete cracking (Tuutti, 1982). Life-365™ is advanced chloride corrosion modeling software, which accounts for both time and temperature-dependent changes in the rate of chloride diffusion. In addition, it uses the Crank-Nicolson finite difference method to solve for t. In this study, we utilize the same methodology as Life-365™ in the simulation-optimization framework (Ehlen et al., 2009). For a full discussion of the service life model equations and parameters used in this analysis, see the Supplementary Information.

Case Studies

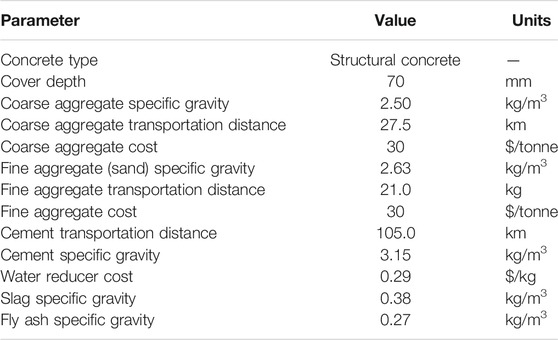

In this work, we apply the simulation-optimization framework described in the previous section to three case studies to illustrate how it can be applied to specific concrete design problems. For comparability, certain aspects of the problem formulation are kept constant among all three case studies, including the decision variables, objectives, and constraints described in Problem Formulation. In addition, we assume a set of input parameters representing the constituent qualities (e.g., aggregate size, specific gravity) and the concrete design (e.g., rebar cover depth). These parameters are consistent for all case studies and provided in Table 4.

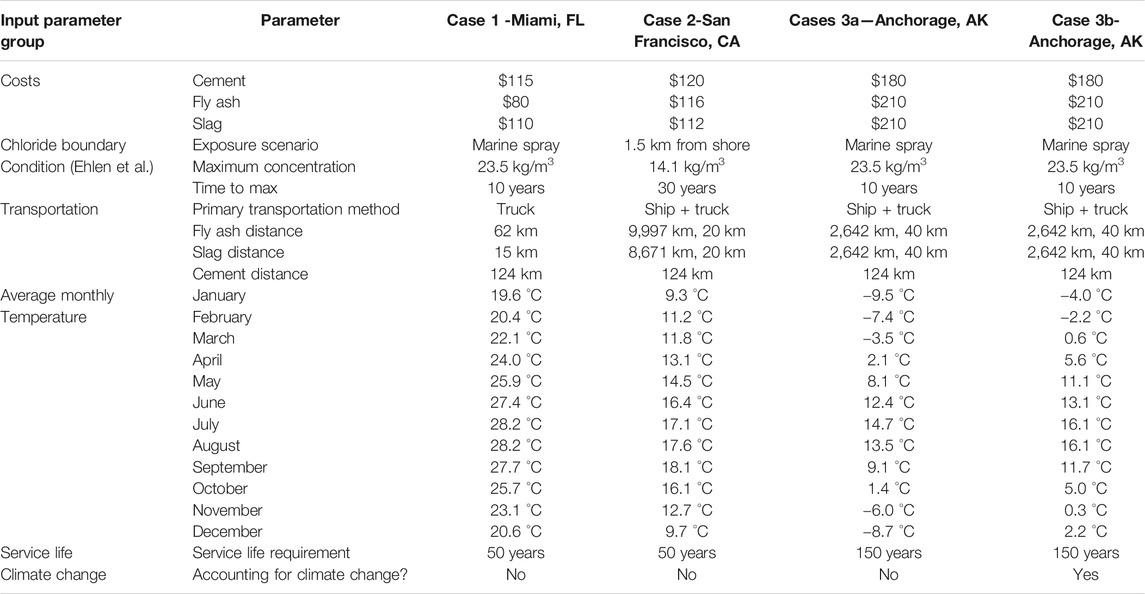

Other parameters, deemed the variable input parameters, are different for each case study, because they reflect three different location-based concrete design scenarios. The variable input parameters include: the relative costs of ingredients, transportation distances, chloride exposure conditions, and monthly average temperatures. These parameters all vary based on project location, with the potential to impact the set of optimal mixture designs. Table 5 provides a summary of the variable input parameters that change between each of the case studies, which are based in Miami, FL; San Francisco, CA; and Anchorage, AK. Cost parameters were estimated via expert interviews and transportation distances were estimated based on the existence of local material production. Note that monthly average temperature data for Anchorage is reported in the table along with the predicted monthly average temperature for the 150th year of service life to simulate climate change effects, as discussed for Case 3b in the following section (Alaska Regional Climate Projections, 2009). Table 6 provides a qualitative summary of these parameters.

For the Miami case study (Case 1), the purpose is 1) to investigate a concrete design scenario in which there is a high chloride exposure condition and low cost of SCMs and 2) to determine how the Pareto-optimal results are determined by this design scenario. For instance, due to high chloride exposure, it is expected that the Pareto-optimal solutions may exhibit relatively high SCM replacement percentages or low w/b ratios in order to generate concrete mixes that resist chloride diffusion for 50 years. Specifically, the concrete structure being analyzed is assumed to be near the coastline with exposure to marine spray, which involves a maximum chloride boundary condition of 23.5 kg/m3 and a 10-years ramp up to this value (see supplementary information) (Ehlen et al.). This case study is considered a high chloride exposure scenario. In addition, temperatures in Miami are relatively high, which facilitates rapid chloride diffusion. In Miami, fly ash is significantly cheaper than slag or cement at a price of $80 per tonne. Slag is $110 per tonne, while cement is $120 per tonne. Transportation of fly ash and slag is highly local as is shown in Table 5, meaning that emissions due to transportation of SCMs will be low compared to other case studies.

In the San Francisco case study (Case 2), the purpose is to investigate a scenario in which the availability of SCMs is low. San Francisco has a high demand but a low local supply of SCMs, which drives up the cost of fly ash and slag to that of cement. In addition, in this scenario, we mimic the low supply of fly ash and slag by assuming that these materials are imported from international suppliers (Indian Bureau of Mines, 2010; The Morning Call, 2017). Thus, the carbon dioxide emissions contributed by fly ash and slag is expected to be higher compared to the Miami case study. In addition, the concrete building is assumed to be 1.5 km from the coast and thus receives a mild chloride exposure boundary condition of 14.1 kg/m3 and a 10-years ramp up to this value (Ehlen et al.). San Francisco also has lower average temperatures than Miami. Consequently, less rapid chloride diffusion is expected over 50 years.

Finally, in the Anchorage scenario (Case 3), the goal is to investigate the impact of accounting for the predicted increase in average temperatures related to climate change over a longer service life. In this case study, we analyze the Pareto optimal concrete mixture designs for a scenario in which historical monthly average temperatures are used (Case 3a) compared to a scenario that uses predictions for increases in monthly average temperature using a regional climate prediction model for Alaska (Case 3b) (Alaska Regional Climate Projections, 2009). Note that temperatures linearly increase from 2020 to the predicted temperature for 2,100 in the diffusion model and continue to increase linearly throughout the 150-years service life. Since the diffusion model accounts for monthly average temperatures as an input to calculate the rate of chloride diffusion, the expected increased temperatures due to climate change will increase chloride diffusion rates compared to the “base case” This specific temperature data is included in Table 5. We hypothesize that increases in temperature will increase chloride diffusion rates and cause more rapid chloride-induced corrosion. In this case study, the concrete structure is assumed to be on the coast exposed to a marine spray exposure condition (i.e., 23.5 kg/m3, 10-years ramp up period). As seen in Table 5 the high costs and transportation distances for SCMs are due to the lack of local supply.

Results

As anticipated, the Pareto-optimal solutions for each case study vary significantly due to the different design parameters in each location. In the parallel axis plots, values of the objectives and the decision variables are provided to illustrate their connection. All three objectives are oriented such that preferred values of each objective are in the downward direction.

Case 1: Miami, Florida

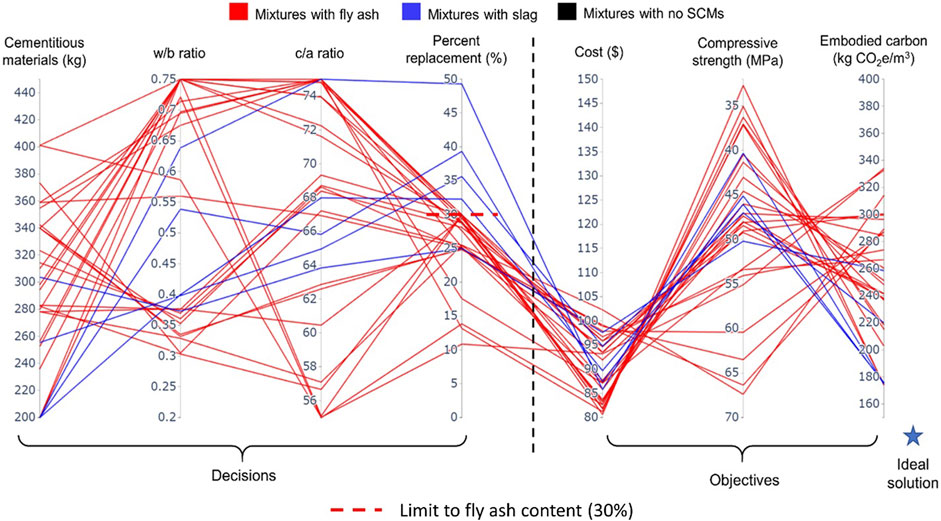

In the Miami scenario, we seek to determine the set of viable mixture designs for a severe chloride exposure condition in a SCM market with low costs and transportation distances. Figure 2 illustrates the full set of Pareto-optimal designs solutions for this case study with a 50-years service life constraint. In the figure, red lines indicate a solution in which fly ash is used, blue lines indicate a solution that uses slag, and black lines indicate a solution that uses no SCMs.

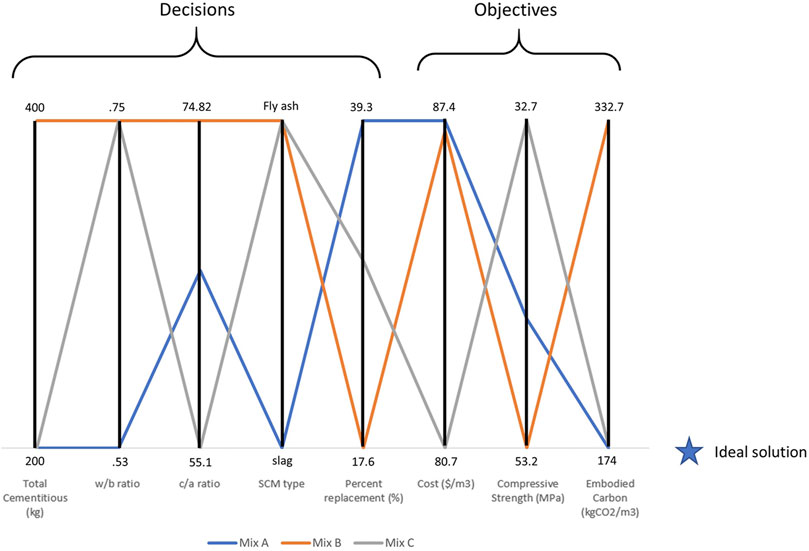

FIGURE 2. Selection of three possible mix designs to illustrate trade-offs.Set of optimal mixture designs for Miami case study.

In Figure 3, the four axes on the left represent the decision variables and the three axes on the right represent the objectives. The axes for the objectives are oriented such that the preferred direction is down. Note that there is no preferred direction for the decisions. In addition, each solution is represented with a line connecting all the axes. Finally, crossed lines indicate a conflict between objectives for those two solutions. In other words, a lower magnitude of one objective (better performance) is related to a higher magnitude of a second objective (worse performance). As an example, the crossed lines between, the cost and compressive strength objectives indicate that for a given solution, better performance with respect to one of the objectives will mean worse performance in the other.

Looking at the objective space, there is a conflict between compressive strength and the other two objectives (i.e., cost, embodied carbon), as anticipated. High compressive strength concrete mixtures also exhibit high costs and high embodied carbon values; the reverse is also true. Cost and embodied carbon tend to not conflict; in other words, low-cost solutions tend to also have low embodied carbon, given that an increase in Portland cement is the main driver for an increase in both cost and embodied carbon. Other research and industry groups have noted these tradeoffs previously (Fantilli et al., 2009). In terms of decision variables, the low-cost solutions tend to be associated with a high w/b ratio, high SCM replacement percentages, and low total quantity of cementitious materials. High strength solutions are associated with the opposite. Low embodied carbon mixtures are most greatly affected by the overall quantity of Portland cement, so low total cementitious content and high SCM replacement percentages can provide low embodied carbon. Looking at the decision variable space, it is apparent that the respective limits on fly ash and slag (30 and 50%) are both reached. Recall from Table 5 that fly ash is 27% cheaper than slag and 33% cheaper than cement in the Miami scenario; the low cost of fly ash likely contributes to its usage in the concrete mixtures with the lowest cost. Alternatively, note that the mixture with the lowest embodied carbon utilizes slag; this result is due to the fact that a higher slag replacement is allowed (up to 50%). Finally, note that all mixtures utilize some level of SCM. We hypothesize that this result is due to the existence of severe chloride exposure conditions and inexpensive, local SCMs, which are well known to densify concrete microstructures and improve the chloride resistance of concrete via the pozzolanic reaction.

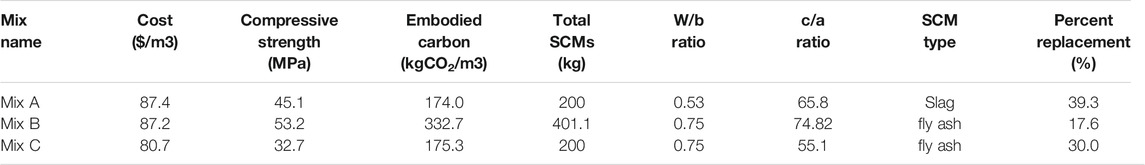

In Figure 2 (and subsequently listed in Table 7) we illustrate via three examples how a concrete designer might use these results to select a Pareto-optimal concrete based on preferences for the project. First, suppose that a concrete designer deemed the embodied carbon objective as the most critical. In this case, Mix A would be selected because it is a mixture that satisfies the problem formulation constraints and has the minimum possible embodied carbon. Second, suppose that the concrete designer required a 50 MPa mixture and that the most important objective was to minimize cost. In this case, Mix B would be optimal because it satisfies the requirement for compressive strength and among the remaining feasible solutions, mix B has the lowest cost. Third, consider a case where the most critical objective is cost. In this case, Mix C would be selected because it has the absolute lowest cost among the set of Pareto-optimal solutions. It is important to note that, due to the inherent tradeoffs between these objectives, that choosing a solution with a ‘desirable’ value for one objective means that one (or more) of the other objectives necessarily becomes less desirable.

Case 2: San Francisco, California

The goal of this case study was to elucidate optimal mixture designs for a case study location that has 1) a mild chloride exposure condition and 2) high costs and transportation distances for SCMs. Figure 4 illustrates the set of optimal solutions for this case study. One key result from this scenario is that none of the optimal mixture designs reach the maximum allowable SCM replacement percentages. Moreover, unlike the Miami case studies, there are several solutions which utilize less than 10% SCM replacement for both fly ash and slag and several that use no SCMs whatsoever. These results are likely due to two compounding factors. First, fly ash and slag are nearly the same cost as cement and have high transportation emissions, which reduces their utility for reducing cost or embodied carbon. Second, Case 1 does not incentivize the use of SCMs as much as Case 2 due to the mild chloride exposure conditions.

Furthermore, we see that the objective values of the solutions can be broadly classified into two groups. The first group includes solutions that use fly ash, which tend to have relatively high embodied carbon, high strength, and high cost. Looking at the corresponding decision variables, these solutions use relatively higher quantities of total cementitious materials. In the other group are mixtures that use lower quantities of cementitious materials and either slag or no SCMs. In the objective space, these variables tend to be low cost and low embodied carbon, but also lower strength than the group of solutions that use fly ash. These trends are significantly different than the trends seen in the Miami case study, in which most Pareto-optimal solutions employed fly ash replacement. We hypothesize that the comparably high cost of both fly ash and slag in this case study incentivized the smaller quantities of SCM replacement.

Another outcome that was unexpected is that the Pareto-optimal mixture design with the lowest embodied carbon does not utilize SCMs whatsoever in this case study. We hypothesize that this result is due to the fact that this mixture design uses the lowest allowable quantity of total cementitious materials and because (compared to the other case studies) fly ash and slag are actually associated with high embodied carbon emissions due to the assumed transportation distances.

Case 3: Anchorage, Alaska

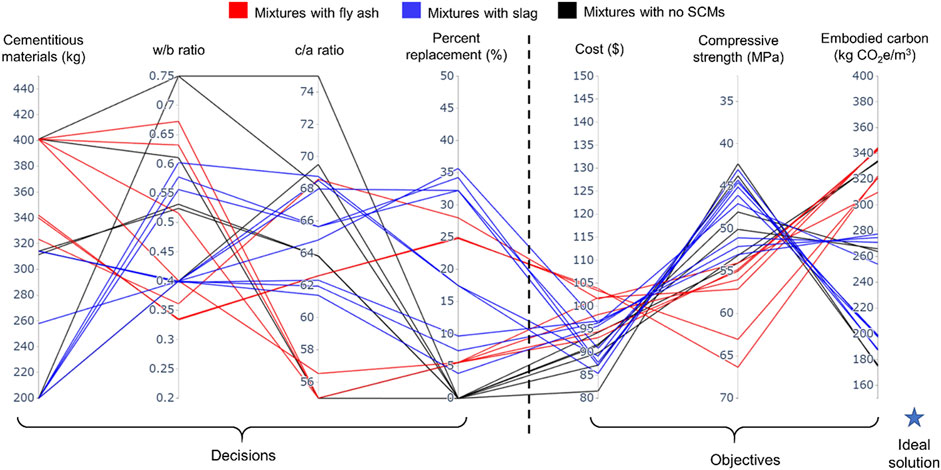

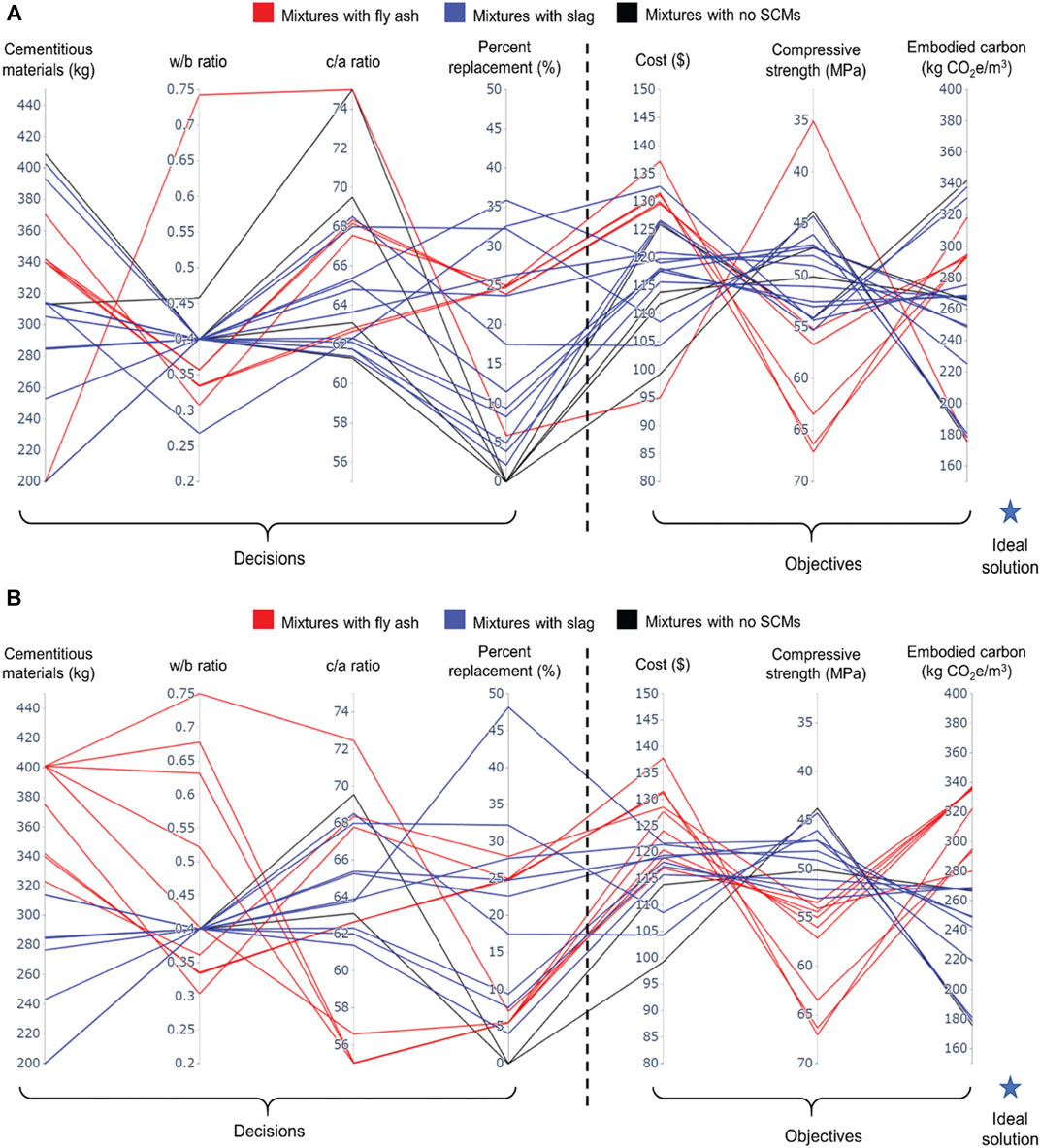

The purpose of the Anchorage case study was to investigate whether accounting for increased average temperatures due to climate change alters the set of Pareto-optimal mixture designs. In Case 3a we use historical monthly average temperatures to quantify chloride ingress. In Case 3b, we employ predicted average temperatures for Anchorage using the regional climate model discussed in Case Studies. Since increased temperatures cause increased rates of diffusion, it was expected that climate change will cause a more rapid violation of the service life constraint in Case 3b.

Figure 5Areports the set of optimal mixture designs for the Case 3a. Notably, the total costs of these mixtures are significantly higher than that of the Miami and San Francisco scenarios, due to the high costs of cement, fly ash, and slag in the Anchorage market. Regarding the decision variables, we see that the limits to fly ash and slag replacement are not reached—a result attributable to the fact that slag and fly ash are 10% more expensive than cement. Also note the existence of several concrete mixture designs that use only cement—again, an interesting, but expected, finding in this market where the cost of cement is less than either fly ash or slag.

FIGURE 5. Pareto-optimal solutions for (A) Case 3a and (B) Case 3b, which illustrates the importance of climate change accounting regarding prevention of corrosion in chloride-laden conditions.

It appears that the more severe service life condition in Case 3b (due to temperature rise) has caused a change in the set of optimal mixture designs. Figure 5B illustrates the set of optimal mixture designs when higher average temperatures are considered. Looking at the objective space, we see that the MOEA was unable to find a 35 MPa mixture that was feasible and non-dominated because this solution uses a high w/b ratio and low quantity of total cementitious materials. In addition, several solutions which used only cement have become infeasible due to the service life constraint. Despite the fact that cement is the least expensive cementitious material in Case 3b, the amount of SCM use tends to increase due to the need to prevent accelerated corrosion that can arise from increased temperatures.

Furthermore, it was found that an increase in the required durability of a concrete appears to shift the balance between fly ash and slag utility for this case study. Concrete mixture designs with compressive strengths around the 55 MPa utilize fly ash instead of slag (or only cement) in order to meet the increased durability requirement. We see that these mixtures use high cementitious materials quantities, which leads to high values of embodied carbon, and moderately high cost. These results point to the sensitivity of the optimal solutions for a given case study to increased temperatures. However, it should be noted that this sensitivity will be different for every design scenario.

Discussion

General Trends

Due to their advantages for strengthening and densifying concrete, SCMs (especially fly ash) are commonly used in scenarios where prevention of chloride-induced corrosion is necessary. For instance, in the two scenarios with extreme chloride exposure conditions (Miami and Anchorage) Miami case study, there is a prevalence of optimal mixture designs that employ SCMs. Furthermore, comparing Case 3a to Case 3b, we see that the increased durability concerns caused several concrete mixtures without SCMs to become infeasible, despite the cost premium for SCMs compared to cement in the Anchorage market.

Furthermore, we see a trend in the decision variables that are used to design high-strength mixtures. In all cases, fly ash is the SCM selected for high strength mixtures; specifically, all cases use fly ash to design mixtures above 55 MPa. High strength concrete mixtures also used high quantities (>340 kg) of cementitious materials in all these cases. Relatively low w/b ratios were also seen to be an important factor for designing high strength concrete (0.30–0.55).

Another general trend is that the mixtures with the lowest embodied carbon contained slag, which was observed in all case study examples. This phenomenon is likely because slag replacement was defined to be as high as 50%, compared to 30% for fly ash. This low-carbon trend was consistent, regardless of whether slag was more expensive or had higher transportation emissions than fly ash. Of course, this result would change if the allowable replacement percentages were increased for fly ash. Low-cost concrete mixtures tended to use low quantities of total cementitious materials; however, these mixtures were not consistent for all scenarios in terms of fly ash or slag use because of the changing relative cost of cementitious materials. It was found that both embodied carbon and cost conflict with the compressive strength objective in all scenarios.

Future Opportunities

In the section that follows, we outline four ways that this research could be advanced. First, the service life modeling should be expanded. Recall that in this study, service life is predicted for concretes in chloride-laden environments. Although chloride-induced corrosion is the costliest degradation mechanism in the U.S., there are other types of concrete degradation mechanisms, which may be dominant under certain conditions. For instance, when concrete is exposed to water containing sulfate ions (e.g., from drainage, sewers), sulfate ions diffuse into concrete, react with cement hydration products, and cause cracking. Other degradation mechanisms can include freeze-thaw damage, alkali-silica reaction, alkali-carbonate reaction, delayed-ettringite formation, among many others. Equations should be incorporated in the simulation-optimization framework for modeling these mechanisms and how they are affected by the quantity and types of mixture constituents used. Simulating multiple degradation mechanisms will also provide concrete designers with information about which mechanism is expected to cause degradation first. For example, if a concrete is placed in an environment in which both freeze-thaw conditions and chloride-exposure conditions occur, modeling of both degradations can help determine which mechanism is the most critical.

Second, future work should also consider how other types of SCMs besides fly ash and slag (e.g., silica fume, metakaolin) impact simulated concrete properties. Novel supplementary cementitious materials have been the subject of increased research (Juenger and Maria, 2019) given global decarbonization and decommissioning of coal-fired power plants that produce large quantities of beneficial fly ash at a time in which the demand for SCMs continues to increase. However, to integrate alternative SCMs into this simulation-optimization framework, first the impact of the type and quantity of each SCM on cost, compressive strength, embodied carbon, and service life must be modeled. These additional models will need to be developed using machine learning, life cycle assessment, and physics-based service life modeling. Similarly, incorporating models that assess the impacts of adding multiple SCMs to concrete mixtures (i.e., ternary blends) would be beneficial for deciding what SCMs to use for different types of mixture design priorities (Khan, 2012). The use of alternative SCMs would have similarly beneficial impacts on compressive strength and service life do to their pozzolanic nature (Behnood and Ziari, 2008).

Thrd, as a greater variety of SCMs and degradation mechanisms are incorporated into the simulation-optimization framework, more data will be needed for modeling these relationships. For instance, the development of machine learning models for predicting compressive strength requires broad sampling of the predictor variable space to make accurate predictions. Future research should aim to develop publicly available databases that contain mixture design information such as the quantities and properties of the mixture constituents, as well as resultant properties of the mixture such as compressive strength and slump. As an example of this kind of database, the University of California Irvine’s Machine Learning Repository houses a dataset of 1,000 concrete mixture designs and the resultant compressive strength (UCI Machine Learning Repository, 2020). This dataset should be expanded to include mixture design information including other types of SCMs and constituent material properties.

Last, it would be beneficial for the optimization analyses to directly consider uncertainty for each constraint and objective. Currently, the compressive strength and embodied carbon models quantify the average error, but the only way for concrete designers to use this uncertainty information is to build safety factors into final mixture designs. A direct method for considering uncertainty could involve a technique called many objective robust decision making in which multi-objective optimization is used to determine a set of Pareto-optimal solutions; then these solutions are evaluated under a variety of scenarios to determine which solutions perform well (i.e., are robust) under many circumstances (Kasprzyk and Nataraj, 2013; Kasprzyk and Reed, 2012; Kasprzyk, Nataraj, et al.).

Conclusion

This study presents the formulation and implementation of a simulation-optimization framework in Python that integrates predictive property models to design optimal concrete mixtures under many design scenarios. The simulation-optimization framework developed primarily improves upon the existing literature because it enables designers to find optimal concrete mixture designs while simultaneously considering environmental, economic, durability, and hardened-state performance.

The utility of the simulation-optimization framework was tested for several concrete design case studies (based in Miami, San Francisco, and Anchorage) and the objectives of compressive strength, embodied carbon, and cost were optimized. Results from these scenarios demonstrate that the local conditions of the case study dictate the most important parameters of the simulation-optimization (i.e., relative constituent costs, in situ service-life conditions). Out of all other input parameters, constituent cost and service-life conditions most greatly impact the set of optimal concrete mixture designs in terms of the types and quantities of mixture ingredients that are utilized. For instance, high costs for SCMs produced Pareto-optimal mixture designs with significantly lower SCM replacement percentages. Similarly, more aggressive chloride exposure conditions caused optimal concrete mixtures to have lower w/b ratios and higher SCM replacement percentages to densify the concrete and meet the service life requirement. The highly varying solution sets for the case studies illustrate that the simulation-optimization framework can be utilized to quantify and visualize tradeoffs between critical concrete performance metrics. Such a tool can be used to tailor low-carbon concrete mixtures to the exact preferences of the designer.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author Contributions

MD, JK, and WS contributed conceived and designed study. MD conducted the study and wrote the first draft of the article. All authors contributed to article editing. All authors approved the submitted version.

Funding

This research was made possible the Department of Civil, Environmental, and Architectural Engineering, the College of Engineering and Applied Sciences, and the Living Materials Laboratory (LMLab) at the University of Colorado Boulder, with support from the National Science Foundation (Award No. CMMI-1562557). This work represents the views of the authors and not necessarily those of the sponsors.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Acknowledgments

Publication of this article was funded by the University of Colorado Boulder Libraries Open Access Fund.

Supplementary Material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fmats.2021.680895/full#supplementary-material

References

American Concrete Institute (1991). ACI 211.1 - Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. Farmington Hills, MI: American Concrete Institute.

Alabama Standard Specifications (2012). 2012 Edition - Portland Cement Concrete Pavement, Section 450. Alabama Department of Transportation. Available at: https://www.dot.state.al.us/conweb/pdf/Specifications/2012%20GASP%20Summary/12-0152.pdf (Accessed May 12, 2020).

Alaska Regional Climate Projections (2009). Alaska Regional Climate Projections. Fairbanks, AK: University of Alaska FairbanksAvailable at: https://www.uaf.edu/files/snre/MP_09_04.pdf.

Baykasoğlu, A., and Özbay, E. (2009). Prediction and Multi-Objective Optimization of High-Strength Concrete Parameters via Soft Computing Approaches. Expert Syst. Appl. 36 (3), 6145–6155. doi:10.1016/j.eswa.2008.07.017

Behnood, A., and Ziari, H. (2008). Effects of Silica Fume Addition and Water to Cement Ratio on the Properties of High-Strength Concrete after Exposure to High Temperatures. Cement Concrete Composites 30 (2), 106–112. doi:10.1016/j.cemconcomp.2007.06.003

Bentz, E. C. (2003). Probabilistic Modeling of Service Life for Structures Subjected to Chlorides. Mater. J. 100 (5), 391–397. doi:10.14359/12814

Coello, C. A., Lamont, G. B., and Van Veldhuizen, D. A. (2007). Evolutionary Algorithms for Solving Multi-Objective Problems. New York, NY: Springer, Vol. 5.

Cusson, D., Lounis, Z., and Daigle, L. (2011). Durability Monitoring for Improved Service Life Predictions of Concrete Bridge Decks in Corrosive Environments. Computer-Aided Civil Infrastructure Eng. 26 (7), 524–541. doi:10.1111/j.1467-8667.2010.00710.x

DeRousseau, M. A., Arehart, J. H., Kasprzyk, J. R., and Srubar, W. V. (2020). Statistical Variation in the Embodied Carbon of Concrete Mixtures. J. Clean. Prod. 275, 123088. doi:10.1016/j.jclepro.2020.123088

DeRousseau, M. A., Kasprzyk, J. R., and Srubar, W. V. (2018). Computational Design Optimization of Concrete Mixtures: A Review. Cement Concrete Res. 109, 42–53. doi:10.1016/j.cemconres.2018.04.007

DeRousseau, M. A., Laftchiev, E., Kasprzyk, J. R., Rajagopalan, B., and Srubar III, W. V. (2019). A Comparison of Machine Learning Methods for Predicting the Compressive Strength of Field-Placed Concrete. Construction Building Mater. 228, 116661. doi:10.1016/j.conbuildmat.2019.08.042

Domone, P. (1998). The Slump Flow Test for High-Workability Concrete 11Communicated by C.D. Pomeroy. Cement Concrete Res. 28 (2), 177–182. doi:10.1016/S0008-8846(97)00224-X

Ehlen, M. A., Michael, D. A. T., and Evan, C. B. (2009). Life-365 Service Life Prediction ModelTM Version 2.0. Concrete Int. 31 (5), 41–46.

Fantilli, A. P., Mancinelli, O., and Chiaia, B. (2019). The Carbon Footprint of Normal and High-Strength Concrete Used in Low-Rise and High-Rise Buildings. Case Stud. Construction Mater. 11, e00296. doi:10.1016/j.cscm.2019.e00296

Jazmin, Z. S., Patrick, M. R., Jonathan, D. H., Matteo, G., and Andrea, C. (2016). A Diagnostic Assessment of Evolutionary Algorithms for Multi-Objective Surface Water Reservoir Control. Adv. Water Resour. 92, 172–185. doi:10.1016/j.advwatres.2016.04.006

Juenger, M. C. G., Snellings, R., and Bernal, S. A. (2019). Supplementary Cementitious Materials: New Sources, Characterization, and Performance Insights. Cement Concrete Res. 122, 257–273. doi:10.1016/j.cemconres.2019.05.008

Kasprzyk, J. R., Nataraj, S., Reed, P. M., and Lempert, R. J. (2013). Many Objective Robust Decision Making for Complex Environmental Systems Undergoing Change. Environ. Model. Softw. 42, 55–71. doi:10.1016/j.envsoft.2012.12.007

Kasprzyk, J. R., Reed, P. M., Characklis, G. W., and Kirsch, B. R. (2012). Many-objective De Novo Water Supply Portfolio Planning under Deep Uncertainty. Environ. Model. Softw. 34, 87–104. doi:10.1016/j.envsoft.2011.04.003

Khan, M. I. (2012). Predicting Properties of High Performance Concrete Containing Composite Cementitious Materials Using Artificial Neural Networks. Automat. Construct. 22, 516–524. doi:10.1016/j.autcon.2011.11.011

Khatri, R. P., Sirivivatnanon, V., and Gross, W. (1995). Effect of Different Supplementary Cementitious Materials on Mechanical Properties of High Performance Concrete. Cement Concrete Res. 25 (1), 209–220. doi:10.1016/0008-8846(94)00128-L

Liu, T., and Weyers, R. W. (1998). Modeling the Dynamic Corrosion Process in Chloride Contaminated Concrete Structures. Cement and Concrete Research 28 (3), 365–379. doi:10.1016/S0008-8846(98)00259-2

Madurwar, M., Sakhare, V., and Ralegaonkar, R. (2015). Multi Objective Optimization of Mix Proportion for a Sustainable Construction Material. Proced. Eng. 118, 276–283. doi:10.1016/j.proeng.2015.08.427

Promentilla, M. A. B., Kalaw, M. E., Nguyen, H. T., Aviso, K. B., and Tan, R. R. (2017). A Fuzzy Programming Approach to Multi-Objective Optimization for Geopolymer Product Design. Computer Aided Chem. Eng. 40, 1015–1020. doi:10.1016/b978-0-444-63965-3.50171-9

Reed, P. M., Hadka, D., Herman, J. D., Kasprzyk, J. R., and Kollat, J. B. (2013). Evolutionary Multiobjective Optimization in Water Resources: The Past, Present, and Future. Adv. Water Resour. 51, 438–456. doi:10.1016/j.advwatres.2012.01.005

Rodgers, L. (2018). The Massive CO2 Emitter You May Not Know about. BBC News. Available at: https://www.bbc.com/news/science-environment-46455844 (Accessed April 18, 2020).

Sohanghpurwala, A. A. (2006). Manual on Service Life of Corrosion-Damaged Reinforced Concrete Bridge Superstructure Elements. Report 558. Washington, D.C.: National Cooperative Highway Research Program. Available at: https://www.nap.edu/read/13934/chapter/1.

Srubar, W. V. (2015). Stochastic Service-Life Modeling of Chloride-Induced Corrosion in Recycled-Aggregate Concrete. Cement Concrete Composites 55 (Jan), 103–111. doi:10.1016/j.cemconcomp.2014.09.003

The Morning Call (2017). Despite Glut of Coal Ash, U.S. Is Importing it from Other CountriesAssociated PressAvailabe at: https://www.mcall.com/business/mc-despite-glut-of-coal-ash-u-s-is-importing-it-from-other-countries-20170323-story.html (Accessed June 4, 2020).

Toutanji, H., Delatte, N., Aggoun, S., Duval, R., and Danson, A. (2004). Effect of Supplementary Cementitious Materials on the Compressive Strength and Durability of Short-Term Cured Concrete. Cement Concrete Res. 34 (2), 311–319. doi:10.1016/j.cemconres.2003.08.017

UCI Machine Learning Repository (2020). UCI Machine Learning Repository: Concrete Compressive Strength Data Set. Irvine, CA. Available at: https://archive.ics.uci.edu/ml/datasets/Concrete+Compressive+Strength (Accessed Oct 31, 2018).

Wilson, M. L., and Kosmatka, S. H. (2011). Design and Control of Concrete Mixtures. 15 edition. Skokie, IL: Portland Cement Assn.

Young, B. A., Hall, A., Pilon, L., Gupta, P., and Sant, G. (2019). Can the Compressive Strength of Concrete Be Estimated from Knowledge of the Mixture Proportions?: New Insights from Statistical Analysis and Machine Learning Methods. Cement Concrete Res. 115, 379–388. doi:10.1016/j.cemconres.2018.09.006

Keywords: concrete, multi-objective optimization, embodied carbon, low-carbon concrete, modeling

Citation: DeRousseau M, Kasprzyk J and Srubar W (2021) Multi-Objective Optimization Methods for Designing Low-Carbon Concrete Mixtures. Front. Mater. 8:680895. doi: 10.3389/fmats.2021.680895

Received: 16 March 2021; Accepted: 23 June 2021;

Published: 26 July 2021.

Edited by:

Brant Walkley, The University of Sheffield, United KingdomReviewed by:

Marlon Augusto Longhi, Federal University of Rio Grande do Sul, BrazilXinyuan Ke, University of Bath, United Kingdom

Maria Criado, Instituto de Ciencias de la Construcción Eduardo Torroja (IETCC), Spain

Jiri Klemes, Brno University of Technology, Czechia

Copyright © 2021 DeRousseau, Kasprzyk and Srubar. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: M.A. DeRousseau, mikaela.derousseau@colorado.edu

M.A. DeRousseau

M.A. DeRousseau J.R. Kasprzyk

J.R. Kasprzyk  W.V. Srubar

W.V. Srubar