Abstract

With increasing requirements of continuous arc additive remanufacturing for robots in mold repair, the alloy and slag systems in the traditional flux-cored wire have to be further improved. Especially in order to realize welding automation, the content of slag must be cut down to decrease the time of removing the slag during the deposition. In this paper, Al–Mg and ferrotitanium are used as deoxidizer to make up the side effect caused by lessening the slag. Six kinds of micro-slag gas-shielded flux-cored wires with different content of deoxidizer based on the commercial cored wire RMD535 were developed. The effect of deoxidizer on microstructure and mechanical properties of micro-slag gas-shielded flux-cored wires were studied. The results demonstrated that the microstructure of deposited metal was mainly composed of acicular ferrite and proeutectoid ferrite. With the increase of deoxidizer content, the toughness increases and then decrease, reaching the maximum of 33.45 J and 35.02 J at Ag–Mg alloy and ferrotitanium content of 1.2% and 1.8%. The hardness is constantly increasing. Six kinds of welding wire had different properties, mainly because of the different characteristics of the inclusions in the deposited metal. The spherical inclusion was the result of deoxidation by Al–Mg alloy or ferrotitanium and the diameter in range of 0.4–0.8 μm were effective for acicular ferrite nucleation. However, inclusions predominantly TiOX were more effective than that of Al2O3 in the same size. The present work provided an effective way to improve the impact toughness of deposited metal by the control of deoxidizer content.

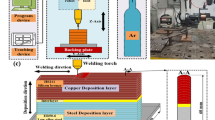

Graphical abstract

Similar content being viewed by others

References

J. Wang, Y.W. Chung, Encyclopedia of Tribology (Springer, Bsoston, 2013), pp. 1620–1625

S.S. Babu, Curr. Opin. Solid St. M. 8, 267 (2004)

D.J. Abson, R.J. Pargeter, Int. Met. Rev. 31, 141 (1986)

Y. Chu, W. Li, Y. Ren, L. Zhang, Metall. Mater. Trans. B 50, 2047 (2019)

T. Hermenegildo, T. Santos, E. Torres, C. Afonso, A. Ramirez, Met. Mater. Int. 24, 1120 (2018)

Y. Wang, W. Yang, L. Zhang, Steel Res. Int. 90, 19 (2019)

L.R. Jacobo, R. García-Hernández, V.H. López-Morelos, A. Contreras, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00805-7

J. Sarkar, P. Modak, S.B. Singh, D. Chakrabarti, Mater. Chem. Phys. 257, 257 (2021)

K. Park, S.W. Hwang, J.H. Ji, C.H. Lee, Met. Mater. Int. 17, 349 (2011)

D.S. Sarma, A.V. Karasev, P.G. Jonsson, ISIJ Int. 49, 1063 (2009)

Z. Zhang, R.A. Farrar, Mater. Sci. Technol. 12, 237 (2013)

H. Nako, Y. Okazaki, ISIJ Int. 55, 250 (2015)

J.C. Gonzalez, C.L. Llorente, H. Biloni, Can. Metall. Quart. 25, 319 (1986)

T.L. Zhang, Z.X. Li, S.D. Kou, H.Y. Jing, G.D. Li, H.J. Kin, Mater. Sci. Eng. A 628, 332 (2015)

Y.C. Cai, R.P. Liu, Y.H. Wei, Z.G. Cheng, Mater. Design 62, 83 (2014)

Y. Huang, G. Cheng, S. Li, W. Dai, Steel Res. Int. 89, 1800371 (2018)

W. Xin, J. Zhang, G. Luo, R. Wang, Q. Meng, B. Song, Metall. Res. Technol. 115, 419 (2018)

C. Yang, Y. Luan, D. Li, Y. Li, J. Mater. Sci. Technol. 35, 1298 (2019)

Q. Ren, L.F. Zhang, Y.B. Liu, L.X. Cui, W. Yang, J. Mater. Res. Technol. 9, 8197 (2020)

W.Y. Zhang, Welding Metallurgy (Basic Principles) (China Machine Press, Beijing, 2003)

C.B. Gui, P.A. Wu, A.L. Wang, Trans. China Weld. Inst. 26, 54 (2005)

J.H. Shim, Y.J. Oh, J.Y. Suh, Y.W. Cho, J.D. Shim, J.S. Byun, D.N. Lee, Acta Mater. 49, 2115 (2001)

J.S. Byun, J.H. Shim, Y.W. Cho, D.N. Lee, Acta Mater. 51, 1593 (2003)

J. Jang, J.E. Indacochea, J. Mater. Sci. 22, 689 (1987)

S. Balos, L. Sidjanin, M. Dramicanin, D. Labus, B. Pilic, M. Jovicic, Met. Mater. Int. 22, 509 (2016)

D. You, S.K. Michelic, P. Presoly, J. Liu, C. Bernhard, Metals 7, 460 (2017)

S. Yi, C.X. Liu, Z.S. Yan, H.J. Li, J. Mater. Sci. Technol. 34, 737 (2018)

A.L.V. da Costa Silva, J. Mater. Res. Technol. 8, 2408 (2019)

Y. Tian, X.N. Xu, Q.B. Ye, R.D.K. Misra, Z.D. Wang, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00714-9

I.S. Bott, P.R. Rios, Scripta Mater. 38, 1269 (1998)

R. Kiessling, N. Lange, Non-Metallic Inclusions in Steel, Part III (The Iron and Steel Institute Publication, London, 1968)

J.M. Gregg, H.K.D.H. Bhadeshia, Acta Mater. 45, 739 (1997)

K. Seo, K. Kim, H.J. Kim, H. Ryoo, G.M. Evans, C. Lee, Met. Mater. Int. 26, 1226 (2020)

J. Tian, T. Qu, D. Wang, H. Wang, Z. Xu, E. Xinrui, Arch. Metall. Mater. 63, 1599 (2018)

R.A. Ricks, P.R. Howell, G.S. Barritte, J. Mater. Sci. 17, 732 (1982)

Acknowledgements

The authors gratefully acknowledge a project funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xie, W.P., Liu, R.P., Wang, H. et al. Effect of Deoxidizer on Microstructure and Mechanical Properties of Micro-Slag Gas-Shielded Flux-Cored Wire. Met. Mater. Int. 28, 1184–1194 (2022). https://doi.org/10.1007/s12540-021-00981-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-00981-0