Abstract

To retrieve the fuel debris in Fukushima Daiichi Nuclear Power Plants (1F), it is essential to infer the fuel debris distribution. In particular, the molten metal spreading behavior is one of the vital phenomena in nuclear severe accidents because it determines the initial condition for further accident scenarios such as molten core concrete interaction (MCCI). In this study, the fundamental molten metal spreading experiments were performed with different outlet diameters and sample amounts to investigate the effect of the outlet for spreading-solidification behavior. In the numerical analysis, the moving particle full-implicit method (MPFI), which is one of the particle methods, was applied to simulate the spreading experiments. In the MPFI framework, the melting-solidification model including heat transfer, radiation heat loss, phase change, and solid fraction-dependent viscosity was developed and implemented. In addition, the difference in the spreading and solidification behavior due to the outlet diameters was reproduced in the calculation. The simulation results reveal the detailed solidification procedure during the molten metal spreading. It is found that the viscosity change and the solid fraction change during the spreading are key factors for the free surface condition and solidified materials. Overall, it is suggested that the MPFI method has the potential to simulate the actual nuclear melt-down phenomena in the future.

Similar content being viewed by others

Abbreviations

- A :

-

Surface area of particle

- C ps :

-

Specific heat for solid/(J·(kg·K)−1)

- C pl :

-

Specific heat for liquid/(J·(kg·K)−1)

- D :

-

Nozzle diameter/mm

- M :

-

Molten metal amount/g

- MPFI:

-

Moving particle Full-implicit method

- MPS:

-

Moving particle Semi-implicit method

- Nu :

-

Nusselt number

- P :

-

Pressure/Pa

- Pr :

-

Prandtl number

- Q :

-

Heat source/J

- Re :

-

Reynolds number

- T :

-

Temperature/°C

- T e :

-

Environment temperature/°C

- T m :

-

Melting temperature/°C

- T s :

-

Stainless steel temperature/°C

- X :

-

Falling height/mm

- a :

-

Parameter for surface tension calculation

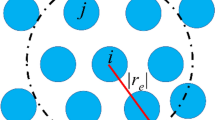

- d ij :

-

Distance between particle i and particle j/m

- g :

-

Gravity acceleration/(m·s−2)

- h :

-

Enthalpy/J

- h 1 :

-

Liquefying enthalpy/J

- h 0 :

-

Solidifying enthalpy/J

- k :

-

Thermal conductivity/(W·(m·K)−1)

- q radiation :

-

Heat flux from radiation/(W·m−2)

- r e :

-

Effective radius/m

- t :

-

Time/s

- u :

-

Fluid velocity/(m·s−1)

- w ij :

-

Weight function

- γ :

-

Solid fraction

- η :

-

Emissivity

- κ :

-

Compressibility/(N·m−2)

- μ 0 :

-

Initial viscosity/(Pa·s)

- μ 1 :

-

Viscosity/(Pa·s)

- ρ :

-

Density/(kg·m−3)

- σ :

-

Stephan-Boltzmann constant

- ω :

-

Angular velocity/(rad·s−1)

References

TEPCO. Unit 3 Primary Containment Vessel Internal Investigation. 2017, available at the website of http://tepco.co.jp

TEPCO. Fukushima Daiichi Nuclear Power Station Unit 2 primary containment vessel internal investigation results. 2018, available at the website of http://tepco.co.jp

Pellegrini M, Dolganov K, Herranz E, et al. Benchmark study of the accident at the Fukushima Daiichi NPS: best-estimate case comparison. Nuclear Technology, 2016, 196(2): 198–210

Sehgal B R. Nuclear Safety in Light Water Reactors-severe Accident Phenomenology. USA: Academic Press, 2012

Veteau J M, Wittmaack R. CORINE experiments and theoretical modelling. In: Van Goetem G, Balz W, Della Loggia E, eds. FISA 95 EU Research on Severe Accidents, Office Official Publ. Luxembourg: Europ. Communities, 1996, 271–285

Green G A, Finrock C, Klages J, et al. Experimental studies on melt spreading, bubbling heat transfer, and coolant layer boiling. In: Proceedings of 16th Water Reactor Safety Meeting, Gaithersburg, MD, USA, 1988

Dinh T N, Konovalikhin M J, Sehgal B R. Core melt spreading on a reactor containment floor. Progress in Nuclear Energy, 2000, 36(4): 405–468

Suzuki H, Matsumoto T, Sakaki I, et al. Fundamental experiment and analysis for melt spreading on concrete floor. In: Proceedings 2nd ASME/JSME International Conference 1, San Francisco, USA, 1993, 403–407

Eppinger B, Fieg G, Schuetz W, Stegmaier U. KATS experiments to simulate corium spreading in the EPR core catcher concept. In: Proceedings of the 9th International Conference on Nuclear Engineering (ICONE-9), Nice Acropolis, France, 2001, 32068804

Alsmeyer H, Cron T, Messemer G, et al. ECOKATS-2: a large scale experiment on melt spreading and subsequent cooling by top flooding. In: Proceedings ICAPP’04 (International Congress Advances in Nuclear Power Plants), Pittsburg, USA, 2004

Alsmeyer H, Crin T, Foit J J, et al. Test report of the melt spreading tests ECOKATS-V1 and ECOKATS-1. Constract FIKS — CT 1999 — 003. Ex-vessel core melt stabilization research. Karlsruhe: Wissenschaftliche Berichte, 2004, SAM-ECOSTAR-D15/FZKA 7064

Steinwarz W, Alemberti A, Häfner W, et al. Investigations on the phenomenology of ex-vessel core melt behavior (COMAS). Nuclear Engineering and Design, 2001, 209(1–3): 139–146

Tromm W, Foit J J, Magallon D. Dry and wet spreading experiments with prototypic materials at the FARO facility and the theoretical analysis, 2000, Germany. FZKA, 2000, 6475: 178–188

Journeau C, Boccaccio E, Brayer C, et al. Ex-vessel corium spreading: results from the VULCANO spreading tests. Nuclear Engineering and Design, 2003, 223(1): 75–102

Alsmeyer H, Albrecht G, Fieg G, et al. Controlling and cooling core melts outside the pressure vessel. Nuclear Engineering and Design, 2000, 202(2–3): 269–278

Ogura T, Matsumoto T, Miwa S, et al. Experimental study on molten metal spreading and deposition behaviors. Annals of Nuclear Energy, 2018, 118: 353–362

Matsumoto T, Sakurada K, Miwa S, et al. Scaling analysis of the spreading and deposition behaviors of molten-core-simulated metals. Annals of Nuclear Energy, 2017, 108: 79–88

Ogura T, Matsumoto T, Miwa S, et al. Experimental study on molten metal spreading and deposition behaviors on wet surface. Progress in Nuclear Energy, 2018, 106: 72–78

Sahboun N, Miwa S, Sawa K, et al. A molten metal jet impingement on a flat spreading surface. Journal of Nuclear Science and Technology, 2020, 57(9): 1111–1120

Yokoyama R, Suzuki S, Okamoto K, et al. Scale effect of amount of molten corium and outlet diameters on corium spreading. Progress in Nuclear Energy, 2020, 130: 103535

TEPCO. Locating fuel debris inside the unit 3 reactor using a muon measurement technology at Fukushima Daiichi nuclear power station. 2017-9-28, available at the website of http://tepco.co.jp

Huppert H. The propagation of two-dimensional and axisymmetric viscous gravity currents over a rigid horizontal surface. Journal of Fluid Mechanics, 1982, 121: 43–58

Foit J J. Spreading under variable viscosity and time-dependent boundary conditions: estimate of viscosity from spreading experiments. Nuclear Engineering and Design, 2004, 227(2): 239–253

Farmer T, Sienicki J, Chu C, et al. The MELTSPREAD-1 computer code for the analysis of transient spreading and cooling of high temperature melts. Report EPRITR-103413,1993

Wittmaack R. Coreflow: a code for the numerical simulation of free-surface flow. Nuclear Technology, 1997, 119(2): 158–180

Spindler B, Veteau J M. The simulation of melt spreading with THEMA code. Nuclear Engineering and Design, 2006, 236(4): 415–424

Allelein H, Breest A, Spengler C. Simulation of core melt spreading with LAVA: theoretical background and status of validation. In: Proceedings of the OECD Workshop on Ex-vessel Debris Cool-ability, Karlsruhe, Germany, 1999, FZKA6747

Koshizuka S, Oka Y. Moving particle semi-implicit method for fragmentation of incompressible fluid. Nuclear Science and Engineering, 1996, 123(3): 421–434

Kawahara T, Oka Y. Ex-vessel molten core solidification behavior by moving particle semi-implicit method. Journal of Nuclear Science and Technology, 2012, 49(12): 1156–1164

Li G, Oka Y, Furuya M. Experimental and numerical study of stratification and solidification/melting behaviors. Nuclear Engineering and Design, 2014, 272: 109–117

Chai P, Erkan N, Kondo M, et al. Experimental research and numerical simulation of moving molten metal pool. Mechanical Engineering Letters, 2015, 1: Paper No.15-00367

Yamaji A, Li X. Development of MPS method for analyzing melt spreading behavior and MCCI in severe accident. Journal of Physics: Conference Series, 2016, 739: 012002

Chai P, Kondo M, Erkan N, et al. Numerical simulation of MCCI based on MPS method with different types of concrete. Annals of Nuclear Energy, 2017, 103: 227–237

Jubaidah D G, Duan G, Yamaji A, et al. Investigation on corium spreading over ceramic and concrete substrates in VULCANO VE-U7 experiment with moving particle semi-implicit method. Annals of Nuclear Energy, 2020, 141: 107266

Kondo M. A physically consistent particle method for incompressible fluid flow calculation. Computational Particle Mechanics, 2021, 8(1): 69–86

Kondo M, Ueda S, Okamoto K. Melting simulation using a particle method with angular momentum conservation. In: Proceedings of the 2017 25th International Conference on Nuclear Engineering, Shanghai, China, 2017

Monaghan J J. Simulating free surface flows with SPH. Journal of Computational Physics, 1994, 110(2): 399–406

Spencer D B, Mehrabian R, Flemings M C. Rheological behavior of Sn-15 Pct Pb in the crystallization range. Metallurgical and Materials Transactions B, Process Metallurgy and Materials Processing Science, 1972, 3(7): 1925–1932

Joly P A, Mehrabian R. The rheology of a partially solid alloy. Journal of Materials Science, 1976, 11(8): 1393–1418

Ramacciotti M, Journeau C, Sudreau F, et al. Viscosity models for corium melts. Nuclear Engineering and Design, 2001, 204(1–3): 377–389

Kondo M. Development of surface tension model with many-body potential. In: International Conference on Particle-based Methods — Fundamentals and Applications (Particles 2017), Hannover, Germany, 2017, 461–470

Acknowledgements

This study was partially supported by the Mitsubishi Heavy Industry (MHI).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yokoyama, R., Kondo, M., Suzuki, S. et al. Analysis of molten metal spreading and solidification behaviors utilizing moving particle full-implicit method. Front. Energy 15, 959–973 (2021). https://doi.org/10.1007/s11708-021-0753-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-021-0753-0