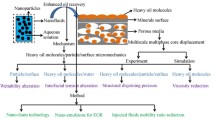

Self-suspension systems for fracturing technology has proved to provide great convenience when used in oilfield operation. However, most fracturing fluid systems contain mainly cationic surfactants, which can easily cause reservoir damage, solution residue, and poor temperature resistance. In the case of the cationic-surfactant fracturing system, the fluid sand carrying capacity is not high enough to change the formation pressure, and the failure of the self-suspension ability leads to a decline in well production capacity and other problems. In this paper, we have proposed an architecture model of a self-suspension solution containing nano-particles, including the model of nano-particle monolayer adsorption on the proppant surface and the three-dimensional network-structure model of nano-particle adsorption on micelles in the solution. The rheological properties, temperature resistance, viscoelasdcity, sand-suspending capacity, gel-breaking properties, and core damage of the modified solution are tested and evaluated. The viscosity and temperature resistance, enhanced sand suspension, and sand-carrying capacity are verified by field application experiments. The results show that the modified fluid system has obvious advantages over traditional fracturing fluid systems and can eliminate the shortcomings of conventional fracturing. The proposed nanoparticle self-suspension solution technology helps to overcome construction difficulties and to reduce engineering costs and environmental pollution, as well as to increase production of the oil wells. The experimental validation results prove that the proposed fluid system can be successfully applied in complex oilfield formations.

Similar content being viewed by others

References

R. Z. Jiang, T. X. Jiang, Y. L. Wang, et. al., “Present development and prospecting of hydraulic fracturing technology,” Drill. Prod. Technol, 26(4), 52-53 (2004).

K J. Liu, J. T. Zhang, B. C. Yin, et. al, “Current situation and prospect of hydraulic fracturing proppant,” Drill. Prod. Technol., 26(4), 31-32 (2003).

G. Q. Dong, J. D. Lu, F. C. Yang, et. al., “The main measures to improve the development effect of low permeability small fault block oilfield,” Inn. Mon. Petrochem. Technol., 25(3), 158-160 (1999).

Y. X. Liu, B. F. Wang, and J. K. Liu, “Experimental study on water sensitive damage of fracturing fluid to low permeability gas reservoirs,” Pet. Drill. Technol., 41(1), 70-72 (2013).

D. Li, J. W. Bai, C. Y. Zhang, et. al., “Research and application of low damage fracturing technology in low-permeability tight sandstone gas reservoirs,”.J. Pet. Nat. Gas, 35(1), 149-151 (2013).

Q. C. Lin, S. C. Zhang, and Z. F. Pan, “Turing stimulation for Jurassic low permeable gas reservoirs in West Sichuan,” Nat. Gas Ind., 25(7), 86-88 (2005).

J. Chen, “Research progress of clean fracturing fluid abroad,” J. Southwest Pet. Univ. (Nat. Sci. Ed), 24(25), 65-67 (2002).

B. Yang, C. Yang, W. Wu, et. al., “Development and application of a new type of clean fracturing fluid (VES-SL),”J Shengli Oilfield Work. Univ., 6(3), 52-53 (2007).

Y. W. Liu, D. P. Gao, Q. Li, et. al., “Mechanical frontiers in shale-gas development,”Adv. Mech., 49(1), 201901-201909(2019).

V. Rocca, M. Cocuzza, et. al., “Current and future nanotech applications in the oil industry,” Am. J. Appl. Sci.,9(6), 784-793 (2012).

T. Huang and J. B. Crews, “Nanotechnology applications in viscoelastic surfactant stimulation fluids,” SPE Prod. Oper., 23(4), 512-517 (2008).

M. E. Helgeson, T. K. Hodgdon, E. W. Kler, et. al., “Formation and rheolgy of viscoelastic “double networks” in wormlike micelle-nanoparticle mixtures,”Langmuir, 26(11), 8049-8060 (2010).

A. Qajar, X. Zheng, A. J. Worthen, et. al., “Modeling fracture propagation and cleanup for dry nanoparticle-stabilized-foam fracturing fluids,”J Pet. Sci. Eng., 146, 210-221 (2016).

B. D. Ma, “Mechanism of surfactant improving oilfield wastewater recycling efficiency,” Dissertation, Shandong University (2014).

S. Pal, A. S. Patra, S. Ghorai, et. al., “Modified guar gum/SiO2: development and application of a novel hybrid nanocomposite as a flocculent for the treatment of wastewater,” Environ. Sci.: Water Res. Technol., 1, 84-95 (2015).

R. P. Mahoney, D. S. Thorne, M. K. Melling. et. al., “Self-suspension proppant for hydraulic fracturing,” USA Patent 201380030270.0 (2013).

S. ZhangD. SunX. nougat. al., “Aqueous foams stabilized with particles and nonionic surfactants,” Colloids Surf. A: Physicochem. Eng. Asp., 324(1), 1-8 (2008).

J. C. Zhang, J. C. Xue, and X. W. Liu, “A self-suspension proppant for water fracturing and a preparation method thereof,” China Patent 201510266248.7 (2013).

F. Q. Dong and G. J. Wu, “Studies on sensitive chitosan-polyether hydrogel,”Mater. Rep., 24(8), 37-40 (2010).

T. Hang, J. B. Crews, and G Agrawal, “Nanoparticle pseudocrosslinked micellar fluids: Optimal solution for fluid-loss control with internal breaking,” SPE International Symposium and Exhibition on Formation Damage Control, Luisiana, USA, SPE 128067 (2010).

P. Z. Zheng, C. F. Du, W. G. Shen, et. al., “Volumetric studies on aqueous solutions of dodecyltrimethylammonium bromide and 1-dodecyl-3-methylimidazolium bromide,” 16th Chinese Chemical Society Conference on Colloids and Interface Chemistry: Theoretical Issues in Colloids and Interface Chemistry, China (2017).

R. P. Mahoney, D. Soane. and K. P. Kincaid, “Self-susupending proppant,” SPE Hydraulic Fracturing Tedchnology Conference. 4-6 February, the Woodlands, Texas, USA (2013).

E. Sourtiji, D. D. Ganji. M. Gorji-Bandpy, and S. M. Seyyedi, “Numerical study of periodic natural convection in a nanoflnid-filled enclosure due to transitional temperature of heat source,” Powder Technol., 259, 64-73 (2014).

C. T. Nguyen, F. Desgnnges, G. Roy, N. Galanis, T. Mare, S. Boucher, et. al., “Temperature and particle-size dependent viscosity data for water-based nanofluids — hysteresis phenomenon,” Int. J. Heat Fluid Flow, 28,1492-1506 (2007).

F. Selimefendigil and H. F. Öztop, “Numerical investigation and reduced order model of mixed convection at a backward facing step with a rotating cylinder subjected to nanofluid,” Comput. Fluids, 109, 27-37 (2015).

R. P. Mahoney, D. S. Thorne, M. K. Helling, et. al., “Self-suspension proppant for hydraulic fracturing,” USA Patent 201280042615.X (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologtva Topliv i Mosel, No. 2, pp. 79 — 91, March —April, 2021.

Rights and permissions

About this article

Cite this article

Liu, J., Li, J., Zhao, W. et al. Modeling and Experimental Study of Self-Suspension Fracking Liquid Containing Nanoparticles. Chem Technol Fuels Oils 57, 335–357 (2021). https://doi.org/10.1007/s10553-021-01253-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-021-01253-8