Abstract

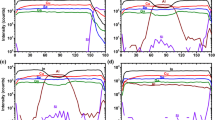

The structural and nanomechanical properties of Cu(InxGa1–x)Se2 films deposited on Si(100) substrate at different temperatures (25°C to 500°C) by one-step radiofrequency magnetron sputtering are discussed. X-ray diffraction analysis revealed a dominant (112) diffraction peak. The surface morphology was examined by field-emission scanning electron microscopy and atomic force microscopy. The film composition was examined by electron probe microanalysis. The Cu/(In + Ga) and Ga/(In + Ga) ratios were 0.9 and 0.3, respectively. Nanoindentation conducted in conjunction with scanning electron microscopy revealed that the films suffered severe delamination-type fracture due to poor adhesion to the Si substrate. The hardness of the films was not influenced by the substrate temperature except for the film grown at 500°C. The hardness was greatly affected at depths greater than the thickness of the film due to its poor adhesion. At deep indents, the hardness results agreed closely with that of the Si substrate.

Similar content being viewed by others

References

C.A. Wolden, J. Kurtin, J.B. Baxter, I. Repins, S.E. Shaheen, J.T. Torvik, A.A. Rockett, V.M. Fthenakis, and E.S. Aydil, J. Vac. Sci. Technol. A 29, 030801. (2011).

M. Nakamura, K. Yamaguchi, Y. Kimoto, Y. Yasaki, T. Kato, and H. Sugimoto, IEEE J. Photovolt. 9(6), 1863–1867. https://doi.org/10.1109/JPHOTOV.2019.2937218 (2019).

M.A. Green, E.D. Dunlop, J. Hohl-Ebinger, M. Yoshita, N. Kopidakis, and X. Hao, Prog. Photovolt. Res. Appl. 28, 629–638. https://doi.org/10.1002/pip.3303 (2020).

A. Chirilă, P. Reinhard, F. Pianezzi, P. Bloesch, A.R. Uhl, C. Fella, L. Kranz, D. Keller, C. Gretener, and H. Hagendorfer, Nat. Mater. 12, 1107–1111. (2013).

W. Li, L. Yao, K. Li, X. Li, B. Yang, S. Xu, S. Shi, C. Yi, M. Chen, Y. Feng, and A.C.S. Appl, Energy Mater. 3, 4201–4207. (2020).

P.S. Suryavanshi, H. Khunt, B. Rehani, and C.J. Panchal, Mater. Today Proc. 4, 12500–12504. (2017).

S. Shirakata, Y. Kannaka, H. Hasegawa, T. Kariya, and S. Isomura, Jpn. J. Appl. Phys. 38, 4997–5002. (1999).

R.N. Bhattacharya, J.F. Hiltner, W. Batchelor, M.A. Contreras, R.N. Noufi, and J.R. Sites, Thin Solid Films 361, 396–399. (2000).

A. Bouloufa, K. Djessas, and D. Todorovic, Mater. Sci. Semicond. Process. 12, 82–87. (2009).

J.A. Frantz, J.D. Myers, R.Y. Bekele, V.Q. Nguyen, B.M. Sadowski, S.I. Maximenko, M.P. Lumb, R.J. Walters, and J.S. Sanghera, IEEE J. Photovolt. 6, 1036–1050. (2016).

U.C. Matur, and N. Baydogan, J. Nanoelectron. Optoelectron. 12, 352–358. (2017).

M. Singh, P. Prasher, and K. Suganuma, Nano-Structures Nano-Objects 11, 129–134. (2017).

T.-Y. Lin, C.-H. Chen, W.-C. Huang, W.-H. Ho, Y.-H. Wu, and C.-H. Lai, Nano Energy 19, 269–278. (2016).

L. Oliveira, T. Todorov, E. Chassaing, D. Lincot, J. Carda, and P. Escribano, Thin Solid Films 517, 2272–2276. (2009).

K. Kushiya, Solar Energy Mater Solar Cells 93, 1037–1041. (2009).

K. Ellmer, J. Hinze, and J. Klaer, Thin Solid Films 413, 92–97. (2002).

J.C. Park, M. Al-Jassim, S.W. Shin, J.H. Kim, and T.W. Kim, Ceram. Int. 45, 4424–4430. (2019).

Z. Yu, Y. Yan, S. Li, Y. Zhang, C. Yan, L. Liu, Y. Zhang, and Y. Zhao, Appl. Surf. Sci. 264, 197–201. (2013).

G. Pürçek, E. Bacaksız, and İ Miskioğlu, J. Mater. Process. Technol. 198, 202–206. (2008).

T. Nakada, Electron. Mater. Lett. 8, 179–185. (2012).

R.L. Garris, S. Johnston, J.V. Li, H.L. Guthrey, K. Ramanathan, and L.M. Mansfield, Solar Energy Mater. Solar Cells 174, 77–83. (2018).

R. Mohan and R. Paulose, Photoenergy Thin Film Mater. 157–192. (2019).

H. Shaban, S.A. Gad, B.A. Mansour, S.H. Moustafa, and T.A. Hameed, J. Inorg. Organometall. Polym. Mater. (2019).

L.C. Andreani, P.A. Kowalczewski, C.I. Mura, M. Patrini, M. Acciarri, S. Binetti, A. Sassella, and S. Marchionna, Towards CIGS Solar Cells with Reduced Film Thickness: A Study of Optical Properties and of Photonic Structures for Light Trapping, pp. 2334.

K. Tapily, J.E. Jakes, D.S. Stone, P. Shrestha, D. Gu, H. Baumgart, and A.A. Elmustafa, J. Electrochem. Soc. 155, H545. (2008).

M.A. Al Mamun, A.H. Farha, Y. Ufuktepe, H.E. Elsayed-Ali, and A.A. Elmustafa, J. Mater. Res. 27, 1725. (2012).

M.A. Hafez, M.A. Mamun, A.A. Elmustafa, and H.E. Elsayed-Ali, J. Phys. D Appl. Phys. 46, 175301. (2013).

Y. Ufuktepe, A.H. Farha, S.-I. Kimura, T. Hajiri, F. Karadağ, M.A. Al Mamun, A.A. Elmustafa, G. Myneni, and H.E. Elsayed-Ali, Mater. Chem. Phys. 141, 393–400. (2013).

Y. Ufuktepe, A.H. Farha, S.I. Kimura, T. Hajiri, K. Imura, M.A. Mamun, F. Karadag, A.A. Elmustafa, and H.E. Elsayed-Ali, Thin Solid Films 545, 601–607. (2013).

G.M. Pharr, Mater. Sci. Eng. A 253, 151–159. (1998).

J.R. Mohamed, C. Sanjeeviraja, and L. Amalraj, J. Asian Ceram. Soc. 4, 191–200. (2016).

S. Chaisitsak, A. Yamada, and M. Konagai, Jpn. J. Appl. Phys. 41, 507–513. (2002).

Y. Yan, F. Jiang, L. Liu, Z. Yu, Y. Zhang, and Y. Zhao, Electron. Mater. Lett. 12, 59–66. (2016).

W. Chen, W. Cao, T.A. Hameed, S. Marsillac, and H.E. Elsayed-Ali, J. Mater. Sci. Mater. Electron. 26, 1743–1747. (2014).

L. Zhang, Q. He, W.-L. Jiang, F.-F. Liu, C.-J. Li, and Y. Sun, Solar Energy Mater Solar Cells 93, 114–118. (2009).

H. Wang, Y. Zhang, X.L. Kou, Y.A. Cai, W. Liu, T. Yu, J.B. Pang, C.J. Li, and Y. Sun, Semicond. Sci. Technol. 25, 055007. (2010).

T.A. Hameed, S.H. Moustafa, H. Shaban, and B.A. Mansour, Opt. Mater. 109, 110308. (2020).

T.A. Hameed, W. Cao, E.M. Abdelrazek, I.K. El Zawawi, B.A. Mansour, and H.E. Elsayed-Ali, J. Mater. Sci. Mater. Electron. 27, 3209–3216. (2015).

T.A. Hameed, W. Cao, B.A. Mansour, I.K. Elzawaway, E.-M.M. Abdelrazek, and H.E. Elsayed-Ali, J. Vac. Sci. Technol. A 33, 031201. (2015).

A. Karimi, Y. Wang, T. Cselle, and M. Morstein, Thin Solid Films 420, 275–280. (2002).

Acknowledgements

This material is based on work supported by the Air force Office of Scientific Research and the National Science Foundation under grant no. MRI-0821180. T.A.H. was supported by the National Research Center, Egypt.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hameed, T.A., Mamun, M.A.A., Cao, W. et al. Structural and Nanomechanical Properties of Cu (InxGa1–x)Se2 Thin Films Fabricated by One-Step Sputtering. JOM 73, 2790–2797 (2021). https://doi.org/10.1007/s11837-021-04764-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04764-1