Abstract

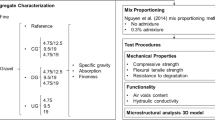

An improved design method of pervious concrete was proposed to lower the deviation between the designed and actual porosity and maintain both mechanical property and permeability of pervious concrete. The improved design method is mainly based on the optimal volume ratio of paste to aggregate (VRPA), which was determined by testing the average thickness of cement paste coating aggregate. The performances of pervious concrete designed by the traditional method and the improved one were compared. The results show that with the increase of designed porosity, the reduction of compressive strength and flexural strength of pervious concrete designed by the improved method is significantly smaller than those designed by the traditional one. The maximum deviation between the designed and actual porosity of the pervious concrete by the improved method is only 1.54%, which is far less than 8.7% obtained by the traditional one. Micro-structural analysis shows that the porous distribution of pervious concrete designed by improved method exhibits better uniformity.

摘要

为了减小透水混凝土设计孔隙率与实际孔隙率的偏差, 保持其良好的力学性能和渗透性, 提出 了一种改进的透水混凝土设计方法。改进后的透水混凝土设计方法主要是基于最优浆骨比(VRPA)的参 数提出来的, 而最优浆骨比是通过测试包裹集料水泥浆体的平均厚度来确定的。通过对比两种传统方 法设计透水混凝土性能, 发现随着设计孔隙率的增加, 采用改进方法设计的透水混凝土的抗压强度和 抗折强度折减量明显小于传统设计方法设计的透水混凝土的折减量。采用改进方法制备的透水混凝土 孔隙率设计值与实际值的最大偏差仅为1.54%, 远小于采用传统方法的最大偏差8.7%。微观结构分析 表明, 采用改进方法设计的透水混凝土中孔隙分布具有较好的均匀性。

Similar content being viewed by others

References

HO H L, HUANG R, HWANG L C, LIN W T, HSU H M. Waste-based pervious concrete for climate-resilient pavements [J]. Materials, 2018, 11(6): 900–916. DOI: https://doi.org/10.3390/ma11060900.

HASEBACH L M, VALAVALA S, MONTES F. Permeability predictions for sand clogged portland cement pervious concrete pavement systems [J]. Journal of Environment Management, 2005, 81: 42–49. DOI: https://doi.org/10.1016/j.jenvman.2005.09.01.

ZHOU H, LI H, ABDELHADY A, LIANG X, WANG H B, YANG B. Experimental investigation on the effect of pore characteristics on clogging risk of pervious concrete based on CT scanning [J]. Construction and Building Materials, 2019, 212(10): 130–139. DOI: https://doi.org/10.1016/j.conbuildmat.2019.03.310.

WANG Yue, YAN Bin, LI Cheng-lin. Review on preparation and properties of permeable concrete [J]. Bulletin of the Chinese Ceramic Society, 2017, 36(3): 864–869. DOI: https://doi.org/10.16552/j.cnki.issn1001-1625.2017.03.018. (in Chinese)

YANG J, JIANG G L. Experimental study on properties of pervious concrete pavement materials [J]. Cement and Concrete Research, 2003, 33(3): 381–386. DOI: https://doi.org/10.1016/S0008-8846(02)00966-3.

CHEN J, WANG H, XIE P, NAJM H. Analysis of thermal conductivity of porous concrete using laboratory measurements and microstructure models [J]. Construction and Building Materials, 2019, 218: 90–98. DOI: https://doi.org/10.1016/j.conbuildmat.2019.05.120.

NOVO A V, BAYON J R, CASTRO-FRESNO D, RODRIGUEZ-HERNANDEZ J. Temperature performance of different pervious pavements: Rainwater harvesting for energy recovery purposes [J]. Water ResourcesManagement, 2013, 15(27): 5003–5016. DOI: https://doi.org/10.1017/s11269-013-0270-y.

HESAMI S, AHMADI S, NEMATZADEH M. Effects of rice husk ash and fiber on mechanical properties of pervious concrete pavement [J]. Construction and Building Materials, 2014, 53(4): 680–691. DOI: https://doi.org/10.1016/j.conbuildmat.2013.11.070.

WANG Hong-yu, WU Hao, MA Hong-wei, WANG Peng, LING Li. Study on waterlogging reduction effect of three types of permeable pavements in sponge city construction [J]. China Water and Wastewater, 2019, 35(12): 44–48. (in Chinese)

FU Fang-hua, ZHU Xiang, LIU Xiao-bing, QIAN Hai-yan, LU Xiao-jun. Ecological study on pervious concrete [J]. Concrete, 2012, 6: 13–16. DOI: https://doi.org/10.3969/j.issn.1002-3550.2012.06.005. (in Chinese)

JIAO Kai, CHEN Chen, LI Lei, SHI Xun, MA Zong-yuan. Performance of pervious concrete based on orthogonal experimental design [J]. Bulletin of the Chinese Ceramic Society, 2019, 38(6): 1839–1844. DOI: https://doi.org/10.16552/j.cnki.issn1001-1625.2019.06.033. (in Chinese)

YU F, SUN D, HU M, WANG J. Study on the pores characteristics and permeability simulation of pervious concrete based on 2D/3D CT images [J]. Construction and Building Materials, 2019, 200(10): 687–702. DOI: https://doi.org/10.1016/j.conbuildmat.2018.12.135.

WANG Cong-feng, LIU De-fu. High-permeable concrete mix design optimization and application [J]. Sichuan Building Science, 2011, 37(5): 237–239. DOI: CNKI:SUN:ACZJ.0.2011-05-066. (in Chinese)

ZHAO Jing, HU Li-guo, ZHANG Chang-fu. Experiment study on pervious concrete mix ratio design [J]. Journal of Dalian Jiaotong University, 2014, 35(1): 57–59. DOI: https://doi.org/10.3969/j.issn.1673-9590.2014.01.014. (in Chinese)

CHEN Chao, WANG Yi-heng, CHEN Qin, HUA Xin. Mix design and test methods of pervious concrete [J]. World of Building Materials, 2018, 39(2): 18–22. DOI: https://doi.org/10.3963/j.issn1674-6066.2018.02.005. (in Chinese)

DEA O, NEITHALATH N. Compressive response of pervious concretes proportioned for desired porosities [J]. Construction and Building Materials, 2011, 25(11): 4181–4189. DOI: https://doi.org/10.1016/j.conbuildmat.2011.04.055.

YAHIA A, KABAGIRE K D. New approach to proportion pervious concrete [J]. Construction and Building Materials, 2014, 62: 38–46. DOI: https://doi.org/10.1016/j.conbuildmat.2014.03.025.

IBRAHIM A, MAHMOUD E, YAMIN M, PATIBANDLA V C. Experimental study on portland cement pervious concrete mechanical and hydrological properties [J]. Construction and Building Materials, 2014, 50(2): 524–529. DOI: https://doi.org/10.1016/j.conbuildmat.2013.09.022.

LUND M S M, HANSEN K K, BRINCKER R, JENSEN A H, AMADOR S D R. Evaluation of freeze-thaw durability of pervious concrete by use of operational modal analysis [J]. Cement and Concrete Research, 2018, 106: 57–64. DOI: https://doi.org/10.1016/j.cemconres.2018.01.021.

KAROLINA R, HANDANA M A P, ZULFIKAR. Preliminary study of pervious concrete with the addition chemical admixture Type B. [J]. AIP Conference Proceedings, 2017, 1903(1): 1–5. https://doi.org/10.1063/1.5011517.

XU Ren-chong, GUI Miao-miao, LIU Jun-xiu, CHEN Qingji, GONG Ming-zi. Study on parameters selection and design method of pervious concrete mix proportion [J]. Concrete, 2011(8): 116–119. DOI: CNKI:SUN:HLTF.0.2011-08-039. (in Chinese)

JIANG Zheng-wu, SUN Zhen-ping, WANG Pei-ming. Effects of some factors on properties of porous pervious concrete [J]. Journal of Buliding Materials, 2005(5): 50–56. DOI: CNKI:SUN:JZCX.0.2005-05-008. (in Chinese)

GAO Xiao-jian, CHEN Tie-feng, SU An-shuang. Research progress on preparation method and properties of pervious concrete [J]. Hydro Science and Cold Zone Engineering, 2018, 1(6): 22–27. DOI: CNKI:SUN:SLTD.0.2018-06-009. (in Chinese)

NGEYEN D H, SEBAIBI N, BOUTOUIL M, LELEYTERB L, BARAUDB F. A modified method for the design of pervious concrete mix [J]. Constr Build Mater, 2014, 73: 271–282. DOI: https://doi.org/10.1016/j.conbuildmat.2014.09.088.

XIE Xiao-geng. Mixture proportioning, structural design and preparation of pervious concrete based on strength and permeability [D]. Guangzhou, China: South China University of Technology, 2018. DOI: CNKI:CDMD:2.1018.872465. (in Chinese)

LI Yan-Kun, HU Xiao-Bo, QJ Chen, HU Xiang, QU Ming-Hui. Designing of pervious concrete mixture proportion by surrounding model [J]. Concrete, 2008(9): 29–32. DOI: https://doi.org/10.3969/j.issn.1002-3550.2008.09.010. (in Chinese)

YUAN Xiao-lu. Effect of mineral admixtures and additives on the fluidity and its loss of cement paste and cement mortar [D]. Chongqing, China: Chongqing University, 2005. https://doi.org/10.7666/d.d019687. (in Chinese)

ZHAO Su, WU Jiao-ying, FU Er-kang. Influence of Fluidity of cement paste on synthesis conditions of polycarboxylate superplasticizer [J]. Concrete, 2012(5): 46–49, 51. DOI: https://doi.org/10.3969/j.issn.1002-3550.2012.05.014. (in Chnese)

HAN Jian-guo, YAN Pei-yu. A survey of testing and evaluation methods for flexural toughness of concrete [J]. China Concrete, 2010(11): 44–47. DOI: CNKI:SUN:JZSJ.0.2010-11-010. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Projects(51978346, 51778302) supported by the National Natural Science Foundation of China; Project(202002N3117) supported by the Ningbo Science and Technology Project, China

Contributors

BA Ming-fang provided the concept, conducted the literature reviews and edited the draft of manuscript. QI Xin-yu conducted the experiments and wrote the first draft of the manuscript. ZHEN Yu-hang and HUANG Guo-yang cooperated with QI Xin-yu for the experiments and analysis. HE Zhi-min advised some experimental methods. LIU Jun-zhe designed the experimental program.

Conflict of interest

BA Ming-fang, QI Xin-yu, ZHEN Yu-hang, HUANG Guo-yang, HE Zhi-min and LIU Jun-zhe declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ba, Mf., Qi, Xy., Zheng, Yh. et al. Improved designed method of pervious concrete based on optimal volume ratio of paste to aggregate. J. Cent. South Univ. 28, 1534–1545 (2021). https://doi.org/10.1007/s11771-021-4713-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4713-y

Key words

- pervious concrete

- absolute volume method

- volume ratio of paste to aggregate

- mechanical properties

- porous structures

- permeability