Abstract

The objective of this study is to experimentally evaluate a new acid combination of HEDP: CH3COOH as a retarded acid to minimize some limitations of high-temperature sandstone acidizing, such as fast acid-rock reaction and secondary precipitation pipeline corrosion. In this work, the acid–base titration, core-powder solubility test, scale deposition test, corrosion rate measurement and corefloods were carried out to evaluate the performances of the acid combination, including acidity characteristics, retarded performance, preventing scale rate, corrosivity and improving permeability. And then the microstructure and mineral content in sandstone samples were observed and analyzed with SEM–EDS. The results of evaluation tests indicated that the new acid combination has excellent performances on retarded rate, preventing scale deposition, permeability enhancement and lower corrosivity, comparing with conventional mud acid. The results of SEM and EDS showed that the microstructure and mineral content of sandstone changed after acid treatment. Compared with mud acid, the new acid system can react more with small particles on sandstone surface and less with the skeleton of samples and the decrease in the contents of Mg, Al, Na, K, Ca and Fe is relatively lower.

Similar content being viewed by others

Introduction

The main purpose of rock matrix acidizing is to eliminate formation damage near the wellbore area during drilling, completion, workover and water injection, thereby restoring or increasing the formation permeability (Zhao et al. 2020; Sidaoui et al. 2016). The ideal acid system can eliminate the damage near the wellbore area and avoid the decline in oil well production caused by secondary precipitation and solid particle migration. Hydrofluoric acid (HF) is the only common cheap acid that can dissolve siliceous minerals. Therefore, any sandstone acid system contains HF in some form (Gomaa et al. 2020; Li et al. 2019; Wilson 2016). The commonly used mud acid, sometimes called sandstone acid, is composed of HF and HCL. In recent years, as much deeper and hotter reservoirs are developed as new reserves, the requirements of high-temperature matrix acidizing are increasing rapidly. At elevated temperatures, conventional mud acid can cause some problems (Shafiq 2019; Shafiq et al. 2017; Zhou 2013) such as rapid acid-rock reaction rates, instability of sensitive clays and high corrosion rate. These problems can lead to ineffective acidizing. Thus, acid systems and procedures should be further improved to meet the requirements of high-temperature acidizing.

To overcome the problems of conventional mud acid in high-temperature sandstone reservoirs, many attempts have been made from acid systems (Li et al. 2015; Shafiq et al. 2013; Zhou 2013; Mahmoud et al. 2011; Thomas et al. 2001; Gdanski 1985). One of these attempts was to develop retarded mud acid systems. At present, there are three main types of retarded mud systems: boric acid (H3BO3), aluminum chloride (AlCl3) and phosphonic acid. However, at elevated temperatures, compared with the conventional mud acids, these retarded mud acid systems still have some problems, such as new precipitations produced. For example, in the H3BO3 system, Thomas et al. (Thomas et al. 2001) pointed out that when H3BO3 reacts with feldspar, KBF4 precipitates are formed. In the AlCl3 system (Gdanski 1985), first AlCl3 reacts with HF to form AlF4 and then as HF is consumed, AlF4 is hydrolyzed to HF. However, this system is very prone to AlF3 precipitation. At a temperature of up to 149 °C (300°F), compared with conventional mud acid, phosphonic retarded mud acid was used to increase the core permeability by 177.9% (Shafiq et al. 2013). Many studies were conducted on various acid combinations as an alternative to conventional mud acid, mainly focusing on the combinations of HF:H3PO4 and HBF4: HCOOH (Shafiq et al. 2017; Shafiq et al. 2013; Thomas et al. 2001). The experimental results indicated that the best acid combination of 3%HF:9%H3PO4 with a permeability increase of 135.32% is better than the conventional mud acid with a permeability increase of 101.76%. Besides, these combinations are less corrosive and allow deep penetration due to slow hydrolytic.

In addition, the role of HCl in matrix acidizing is to minimize secondary precipitation (Gomaa et al. 2015). However, HCl should be carefully used due to corrosion of pipeline, crude oil sludging, secondary precipitation and fine particle migration (Gdanski 1996; Shuchart et al. 1996). Attempts have been made to minimize the potential problems associated with HCl in acid systems and procedures. One of these attempts was to use organic acids as an alternative to HCl because of the less corrosive and retarded rate of organic acids. The widely used organic acids are acetic acid and formic acid. Several studies (Li et al. 2019; Yang et al. 2012; Al-Harbi et al. 2011) have indicated the excellent advantages of organic-HF acids in sandstone acidizing. Especially, organic acids are useful for sensitive clays such as illite and zeolite. From the aspect of improving treatment procedures, a single-stage sandstone acidizing is developed to reduce HCl requirements, the treatment complexity and the overall treatment rig time (Gomaa et al. 2015). The conventional acidizing procedure mainly includes three main steps: pre-flush, main acid stage and after-flush (Gidley et al. 1996; Sutton et al. 1972). In single-stage sandstone acidizing, the acid system is injected into formations in one step instead of three steps. Chike et al. (2004) first proposed a one-step acidizing process. Since then, Uchendu et al. (2006) developed a one-step acid system containing HV chelating agent and successfully applied it to sandstone reservoirs in Niger Delta and gas wells on the Indian coast. After continuous development, many researchers (Zhao et al. 2020; Zhao et al. 2017; Zhou 2013; Liu et al.2013) developed different one-step acid systems, such as H3BO3 retarded mud acid, organic-HF acid and chelating acid.

Up to now, many studies have been carried out highlighting the importance of acidizing in sandstone reservoirs (Shafiq et al. 2017). A few studies have been reported on different sandstone reservoirs at elevated temperatures. And the current acid combinations still have some limitations at high temperatures such as fast acid-rock reaction rate, short acid penetration distance, instability of clays and pipeline corrosion (Abaa et al. 2017; Barri et al. 2016; Gomaa et al. 2013; Thomas et al. 2001). Thus, it is very significant to develop economical acid combinations, which can minimize the limitations at high temperatures. In this work, based on the advantages of organic phosphonic acid and organic acid systems, a new acid combination of HEDP: CH3COOH selected as the research objective, it was carried out studies on acidity characteristics, dissolution rate of core-powder, retarded performance, corrosivity, preventing scale deposition, improving permeability and the microstructures and mineral contents of sandstone samples before and after acid treatment. Based on experimental results, an economical and effective one-step retarded acid system was proposed.

Experiment program

Materials

The natural sandstone core was sampled from G6 Block in Jiangsu Oilfield, China. The Bentonite for drilling mud was chosen to represent clay sample, which is mainly montmorillonite. 1-hydroxyethylidene-1,1-diphoshonic acid (HEDP) and amino trim-ethylene phosphonic acid (ATMP) and 36 wt%HCl solution were provided by Taihe Water Treatment Technologies Co., Ltd., Shandong. CH3COOH, NH4HF2, HF, NaCl, CaCl2, NaSiO3, FeCl3, AlCl3(AR grade) were purchased from West Asia chemical reagent.

Test apparatus

The main apparatuses included a PHS-3B universal pH meter with an accuracy of ± 0.05pH, an oven WGL-30B with a temperature range of 5–300 °C and a BSA124S electronic balance with a precision of ± 0.1 mg, a KYKY-EM6200 type SEM equipped with EDS instrument for microstructure observation and acidizing physics simulation apparatus.

Test methods

The sample solubility test: core-powder samples were dissolved in the acid system at the weight ratio of 1:20, that is 5 g core-powder samples were weighed into 250 mL plastic beakers and 100 mL of acid solution was added into each beaker and then leave them at 90 °C water bath for 4 h. After the reaction, the suspension was filtered by using 0.2 μm filter paper. The filtered solids were dried in an oven at 105 °C for 2 to 3 h. And then the filtered solids were weighed.

SEM–EDS was used to obtain the microstructure and mineral content of the clay and sandstone samples before and after acid treatment. Results in this paper are presented in the form of average values.

Results and discussion

Screening phosphonic acid

Due to the cost of acid systems, two cheap phosphonic acids (ATMP and HEDP) commonly used are selected as the test objects. At room temperature, the acidity curves of three acid solutions (ATMP, HEDP and HCl) with a concentration of 3 wt% were determined through the acid solution titrated by 1 mol/L NaOH solution, respectively. In the titration process, the changes of pH values of the three acid solutions were recorded with the increase of alkali addition, shown in Fig. 1.

As seen in Fig. 1, the acidity curve of HCl has only one mutation point and the mutation part of the curve is very steep, almost straight, indicating that HCl is a strong monobasic acid and H+ in the solution is in a fully ionized state. The acidity curves of ATMP and HEDP have multiple mutation points, indicating that ATMP and HEDP are polybasic weak acids and can gradually release H+ with the consumption of partially ionized H+ in the solution. Thus, it shows that ATMP and HEDP solutions are better-buffering ones, but HCl does not have buffering properties. In addition, with the addition of alkali, the acidity curve of HEDP changes more smoothly than that of ATMP, indicating that HEDP has better-buffering properties than ATMP. As mentioned in the literature (Jiang et al. 2013), the corrosion inhibition rate of HEDP for carbon steel is greater than that of ATMP. In the following work, HEDP was screened as one component of a new acid combination.

Performance evaluation

In this work, the experimental temperature is 90 °C, the mud acid formula is 3 wt% HF + 12 wt%HCl and the HEDP retarded acid formula is 3 wt% HEDP + 4 wt% NH4HF2 + 6 wt% CH3COOH.

Dissolution rate of core-powder

The acid mixtures contained 4 wt%NH4HF2, 6 wt% CH3COOH and different concentrations of HEDP. To investigate the HEDP concentration effect on the dissolution rate of core-powder, the concentration increased from 0 to 6 wt%, experimental results are shown in Fig. 2.

As seen in Fig. 2, the dissolution rate of core-powder decreases with the increase of the HEDP concentration. When the HEDP concentration range is 2 wt% to 6 wt%, the dissolution rate changes around 21 wt% to 23 wt %. Compared with the blank acid sample (organic-HF acid), HEDP can reduce the dissolution rate of core-powder by 35.1%, indicating that HEDP can retard the acid-rock reaction and effectively expand the distance of acid treatment.

Retarded performance

The solubility tests of mud acid and HEDP retarded acid system were carried out for sandstone core and clay samples, respectively. The experimental results are shown in Fig. 3.

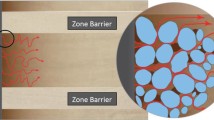

As are shown in Fig. 3, with the reaction time increases, the dissolution rate first increases rapidly and then levels off. Meanwhile, the acid-rock reaction rate of the mud acid is faster than that of the HEDP retarded acid system. This shows that the new acid system has better retarded performance. Also, it can be noticed that, when the dissolution rate of acid-rock reaches the equilibrium value, the value of the mud acid is greater than that of the new acid system. For example, for clay samples, after 1 h of reaction, the dissolution rate of the mud acid and the new acid solution rise dramatically to 70.7 wt% and 34.1 wt%, respectively. Compared with the mud acid, the reaction rate is reduced by 52%. This phenomenon can be explained as follows (shown in Fig. 4): In the acid solution, HEDP can be partially ionized to generate organic phosphonate and H+. The organic phosphonate and aluminum-containing minerals (such as plagioclase and montmorillonite) can form a layer of aluminum silicate-phosphonate film on the rock surface through electrostatic action. This film can prevent further reaction of HF with core minerals and control the dissolution rate, which allows deeper penetration into the formation (Zhao et al. 2017; Liu et al. 2013).

Preventing scale deposition

Firstly, 3 solutions were prepared as follows: No. 1: the solution composition is 1 mol/L NaCl + 1 mol/L CaCl2; No. 2: the solution composition is mol/L NaSiO3; No. 3: the solution composition is 1 mol/L FeCl3 + 1 mol/L AlCl3. And then 4 acid solutions were prepared as follows: mud acid, organic acid(6 wt%HCl + 8 wt%CH3COOH + 3 wt%HF), fluoboric acid(6wt%HBF4 + 3wt%HF) and HEDP retarded acid. Secondly, the 50 mL solutions were mixed with the same volume of different acids in plastic bottles, respectively. And then the plastic bottles were put in a 90 °C water bath for 2 h. Finally, the precipitations of three solutions were determined through the titration of 1 mol/L NaOH solution, respectively. The experimental results are shown in Fig. 5.

As are shown in Fig. 5, the preventing scale rate of HEDP retarded acid on CaF2, Na2SiF6, metal hydroxide precipitations are up to 72 wt%, comparing with that of mud acid. The performance of preventing scale deposition is in order as follows; HEDP retarded acid > organic acid > HBF4 > mud acid. The new acid system has an excellent ability to prevent scale deposition.

Corrosivity

According to the requirements of acidizing, the acid system should have a lower rate of corrosion to reduce the damage of pipelines during the long-term acid injection process. N80 steel samples were placed in HEDP retarded acid solutions with different acid-to-water ratios at 90 °C for 24 h, respectively. The corrosion rate results are listed in Table 1.

As illustrated in Table 1, a temperature of 90 °C, the corrosion rates of the HEDP acid system to N80 steel sheet are 2.18 g/(m2·h), 1.72 g/(m2·h) and 1.38 g/(m2·h) under the conditions of the acid-to-water ratios of 1:2,1:4 and 1:6, respectively. The corrosion rates are smaller than the first-level standard (less than 4 g/(m2·h)) of the petroleum industry in China. This indicates HEDP retarded acid system has a lower rate of corrosion and reduces the requirement of corrosion inhibition agents.

Coreflood

At a temperature of 90 °C, the HEDP retarded acid system was selected as a one-step sandstone acid system for testing. The nature core samples were taken from Block G6 in Jiangsu Oilfield, China. After injection 5 wt%NH4Cl at a rate of 2 cm3/min to measure the initial permeability, 8 pore volumes (PV) of the HEPD retarded acid system were injected as the one-step sandstone acid and, finally, followed by 5wt%NH4Cl. The coreflood results are shown in Fig. 6.

Figure 6 shows the pressure drop during the acidizing process for different stages. The experiment started with injecting 2.2 PV of 5 wt%NH4Cl. The original permeability of the core was 18.8 × 10–3 μm2. Following the NH4Cl solution stage, the HEPD retarded acid system was injected for 8 PV and the pressure drop firstly was increased from 0.85 MPa to 1.21 MPa and then decreased to 1.01 MPa. And then white bubbles in the effluent were observed. It is most probably a result of the Jamin effect caused by producing gas between acid and clay minerals such as carbonate in the core. After that, the pressure drop was decreased rapidly to 0.6 MPa. And then the decrease in the pressure drop was slowed upon reaching 0.46 MPa. At the end of the experiment, 82% permeability enhancement was calculated. After the experiment, the end face of the core is good and no collapse. It was clear that the HEDP retarded acid system has a better ability to enhance permeability.

Change in microstructure

KYKY-EM6200 SEM equipped with EDS instrument at 20 kV and 2 kx was used to study the influence of different acid systems on the microstructure of sandstone samples at the temperature of 90 °C for 2 h, shown in Fig. 7. Image a is the untreated sandstone sample's SEM; image b is the treated sandstone sample’s SEM with an HEDP retarded acid system. Image c is the treated sandstone sample’s SEM with a mud acid system.

Figure 7 shows that the surface of the untreated core is covered by some small particles. After the acid solution treatment, most of the small particles are completely dissolved, especially in image c. In image c, some uneven ravines are formed on the rock surface, which indicates that the mud acid reacts with these small particles as well as the skeleton structure of sandstone, which is a general reaction. Therefore, compared with the mud acid, the HEDP retarded acid system can react more with these small particles and less with the sandstone skeleton, which has a certain selectivity. It was clear that the HEDP retarded acid system can easily remove formation damage and reduce the acid damage to the sandstone skeleton.

To accurately obtain EDS data representing the whole samples, multi-spectral analyses were performed at different locations and the average mass and atomicity percentage of the main elements are shown in Table 2. The data difference was mainly caused by the inhomogeneity of the samples.

It is observed that the contents of Mg, Al, Na, K, Ca and Fe decreased in the samples after the treatment of acid solutions. Compared with the mud acid, the decrease in the content of the above cations for HEDP retarded acid system is relatively lower. This means that the reaction degree of minerals such as calcite or chlorite is relatively low. From the elemental analysis of all the sandstone samples, there was no peak of F element in these spectra proving no AlF3 precipitate under the test conditions. This phenomenon can be explained by preventing aluminum precipitation due to the high content of CH3COOH in the acid systems in this study.

Conclusions

In this work, the main conclusions of this study are as follows:

-

1.

The acidity characteristics of HCl, ATMP and HEDP indicated that ATMP or HEDP solution is a buffer, but HCl does not have buffering properties. And HEDP has better-buffering properties than ATMP.

-

2.

Evaluation results showed that the new acid system has better performances with a retarded rate of 52%, a preventing scale deposition rate of up to 72 wt% and lower corrosivity of less than 2.18 g/(m2·h), compared with the conventional mud acid. The results of coreflood showed that the core permeability can be enhanced by 82% with the new acid system.

-

3.

The results of SEM and EDS showed that the microstructure and mineral content of sandstone changed after acid treatment. Compared with the mud acid, the new acid system can react more with small particles on the sandstone surface and less with the sample skeleton and the decrease in the contents of Mg, Al, Na, K, Ca and Fe is relatively lower.

-

4.

Based on experimental results, a new economic and effective single-step retarded acid system is suggested: 3 wt%HEDP + 4 wt%NH4HF2 + 6 wt% CH3COOH.

References

Abaa K, Thaddeus I M, Adewumi M (2017) Effect of acoustic stimulation on aqueous phase trapping in low-permeability sandstones. J. Energy Resour. Technol. 139(6). https://doi.org/10.1115/1.4037156.

Al-Harbi BG, Al-Khaldi MH, Al-Dossary KA (2011) Interactions of organic-HF systems with aluminosilicates: lab testing and field recommendations. SPE European Formation Damage Conference, Noordwijk. https://doi.org/10.2118/144100-MS

Barri A, Mahmoud M, Elkatatny S (2016) Evaluation of rock mechanical properties alteration during matrix stimulation with chelating agents. J. Energy Resour. Technol. 138(3). https://doi.org/10.1115/1.4032546.

Chike U, Awoleke O, Linus N (2004) Solvent/acid blend provides economic single step matrix acidizing success for fines and organic damage removal in sandstone reservoirs: A Niger-delta case study. SPE Annual Technical Conference and Exhibition, Houston. https://doi.org/10.2118/90798-MS

Gdanski R (1996) Kinetics of tertiary reaction of HF on alumino-silicates. SPE Formation Damage Control Symposium, Lafayette. .https://doi.org/10.2118/31076-MS.

Gdanski RD (1985) AlCl3 retards HF acid for more effective stimulation. Oil & Gas J. January 83:111–115.

Gidley JL, Brezovec EJ, King GE (1996) An improved method for acidizing oil wells in sandstone formations. SPE Prod Facil 11:4–10. https://doi.org/10.2118/26580-PA

Gomaa I, Mahmoud M (2020) Stimulating illitic sandstone reservoirs using in-situ generated HF with the aid of thermochemicals. J Petrol Sci Eng 190:107089. https://doi.org/10.1016/j.petrol.2020.107089

Gomaa AM, Stolyarov S, Cutler J (2015) Retarded HF system to deeply stimulate sandstone formation and eliminate the need for preflush and post-flush acid stages: experimental and field cases. The 2015 International Petroleum Technology Conference, Doha. https://doi.org/10.2523/IPTC-18571-MS

Gomaa AM, Cutler J, Qu Q, et al (2013) An effective single-stage acid system for sandstone formations. SPE European Formation Damage Conference and Exhibition, Noordwijk.

Jiang S, Xu JW (2013) Studies on the corrosion inhibition performance and mechanism of organic phosphonate on the carbon steel. Shangdong Chem Ind 42(12):9–11

Li J, Yuan SX, Song J et al (2019) Study and application on the novel organic mud acidizing technology. Mod Chem Res 16:73–75

Li NY, Zhang Q, Wang YQ et al (2015) A new multichelating acid system for high-temperature sandstone reservoirs. J Chem, Article ID. https://doi.org/10.1155/2015/594913

Liu PL, Sun G, Li NY et al (2013) Novel retarded acid performance research of high temperature sandstone reservoir. Drill Fluid & Comp Fluid 30(03):76–78

Mahmoud MA, Nasr-El-Din HA, Wolf CDe, et al (2011) Sandstone Acidizing using a new class of chelating agents. SPE International Symposium on Oilfield Chemistry, Woodland. https://doi.org/10.2118/139815-MS

Shafiq MU, Chong YJ, Mahmud HKB et al (2019) Application of emulsified acids on sandstone formation at elevated temperature conditions: an experimental study. J Petrol Explor Prod Technol 9(2):1323–1329. https://doi.org/10.1007/s13202-018-0567-8

Shafiq MU, Mahmud HB (2017) Sandstone matrix acidizing knowledge and future development. J Petrol Explor Prod Technol 7(4):1205–1216. https://doi.org/10.1007/s13202-017-0314-6

Shafiq MU, Kyaw A, Shuker MT (2013) A comprehensive research to find suitable acid for sandstone acidizing. Adv Mater Res 788:274–280.

Shuchart CE, Gdanski RD (1996) Improved success in acid stimulations with a new organic-HF system. The European Petroleum Conference, Milan. https://doi.org/10.2118/36907-MS

Sidaoui Z, Sultan A (2016) Formulating a stable emulsified acid at high temperatures: stability and rheology study. The International Petroleum Technology Conference, Bangkok. https://doi.org/10.2523/iptc19012-ms

Stolyarov S, Alam A (2013) Overcoming challenges while acidizing sandstone formation successfully in the gulf of Cambay offshore India. SPE North Africa Technical Conference and Exhibition, Cairo. https://doi.org/10.2118/164631-MS

Sutton GD, Lasater RM (1972) Aspects of acid additive selection in sandstone acidizing. The Fall Meeting of the Society of Petroleum Engineers of AIME, San Antonio. https://doi.org/10.2118/4114-MS

Thomas RL, Nasr-El-Din HA, Lynn JD et al (2001) Precipitation during the acidizing of a HT/HP illitic sandstone reservoir in eastern Saudi Arabia: a laboratory study. SPE Annual Technical Conference and Exhibition, New Orleans. https://doi.org/10.2118/71690-MS

Uchendu CV, Nwoke LA, Akinlade O et al (2006) A new approach to matrix sandstone acidizing using a single step HF system: A Niger-delta case study. SPE Annual Technical Conference and Exhibition, San Antonio. https://doi.org/10.2118/103041-MS

Wilson A (2016) Sandstone-acidizing system eliminates need for preflush and post-flush stages. J Pet Technol 68:59–60. https://doi.org/10.2118/0616-0059-JPT

Yang F, Nasr-El-Din HA, Al-Harbi BM (2012) Acidizing sandstone reservoirs using HF and Formic acids. SPE International Symposium and Exhibition on Formation Damage, Lafayette. https://doi.org/10.2118/150899-MS

Zhao LQ, Chen X, Shan JC et al (2020) Research and application of chelating acid blocking removal system for injection wells. J Southwest Petrol U (sci & Tech Edit) 42(03):123–131

Zhao LQ, Pan YY, Liu YG et al (2017) Research and performance evaluation on an HA integrated acid system for sandstone acidizing. Nature G Ind 37(09):57–62

Zhou L, Nasr-El-Din HA (2013) Acidizing sandstone formations using a sandstone acid system for high temperatures. SPE European Formation Damage Control Conference & Exhibition, Noordwijk. https://doi.org/10.2523/165084-MS

Funding

This study was supported by the Natural Science Foundation of Guangxi Province (Grant number: 2018JJA120001) and the High-level Talent Foundation of Beibu Gulf University (Grant Number: 18KYQD52).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there are no conflicts of interest regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, F. Experimental study of one-step economical retarded sandstone acid. J Petrol Explor Prod Technol 11, 2991–2997 (2021). https://doi.org/10.1007/s13202-021-01213-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-021-01213-2