Abstract

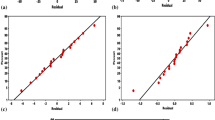

The present study investigates the impact of novel ultrasonic-assisted squeeze casting parameters on the fabrication of AA2014/Al2O3 nanocomposites using the Taguchi Grey response surface methodology. The experiments were carried out using Taguchi's L16 orthogonal array, with five different controllable parameters of ultrasonic-assisted squeeze casting process such as ultrasonic power (1.5–2.25 kW), ultrasonic time (4–16 min.), pouring temperature (700–850 °C may result in premature solidification), squeeze pressure (50–200 MPa) and wt % of reinforcement (1-4). The process's performance measures included hardness, ultimate tensile strength, percentage of elongation and grain size. The microstructure of the nanocomposites was investigated using optical microscopy, high-resolution scanning electron microscopy and X-ray diffraction technique. The multiple responses were converted into a single Grey relational grade, which was then used in modelling and optimization using the response surface methodology. Analysis of variance and 3D surface plots were generated to investigate the most important parameters affecting the quality of AA2014/Al2O3 nanocomposites. The results showed that the optimum parameter settings were ultrasonic power of 2.2489 kW, ultrasonic time of 15.91min, pouring temperature of 700.67 °C, squeeze pressure of 41 MPa and wt % of reinforcement of 1.85. The results of TGRSM demonstrated that ultrasonic power had the strongest correlation with responses, with significant improvements in UTS and grain size. The confirmation experiment revealed an improvement of 0.201 in GRG.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce the current findings cannot be publicly available at this time as the data also form a part of an ongoing study.

References

U. Aybarc, H. Yavuz, D. Dispinar, M.O. Seydibeyoglu, The use of stirring methods for the production of SiC-reinforced aluminum matrix composite and validation via simulation studies. Int. J. Metalcast. 13, 190–200 (2019). https://doi.org/10.1007/s40962-018-0250-3

S. Wetzel, Nano’s Frontier. Mod. Cast. 100(3), 27–30 (2010)

X. Jian, C. Xu, T. Meek, Q. Han, Effect of ultrasonic vibration on the solidification structure of A356 alloy. AFS Trans. 113, 131–138 (2005)

P.C. Lynch, R.C. Voigt, J.C. Furness Jr., D. Paulsen, The effects of non-contact acoustic stimulation on the solidification behavior and microstructure of aluminum alloy A356. AFS Trans. 118, 57–68 (2010)

X. Li, Y. Yang, D. Weiss, Ultrasonic cavitation based dispersion of nanoparticles in aluminum melts for solidification processing of bulk aluminum matrix nanocomposite: theoretical study, fabrication and characterization. AFS Trans. 115, 249–260 (2007)

G. Talla, D.K. Sahoo, S. Gangopadhyay, C.K. Biswas, Modeling and multi-objective optimization of powder mixed electric discharge machining process of aluminum/alumina metal matrix composite. Int. J. Eng. Sci. 18(3), 369–373 (2015). https://doi.org/10.1016/j.jestch.2015.01.007

W. Khalifa, Y. Tsunekawa, M. Okumiya, Ultrasonic grain refining effects in A356 Al-Si cast alloy. AFS Trans. 118, 91–98 (2010)

K. Pasha Bam, Mohamed, Taguchi approach to influence of processing parameters onerosive wear behaviour of Al7034-T6 composites. T. Nonferr. Metal. Soc. 27(10), 2163–2171 (2017). https://doi.org/10.1016/S1003-6326(17)60242-5

S. Thirumalai Kumaran, M. Uthayakumar, S. Aravindan, Analysis of dry sliding friction and wear behaviour of AA6351–SiC–B4C composites using grey relational analysis. Tribol. – Mater. Surf. Interfaces 8(4), 187–193 (2014). https://doi.org/10.1179/1751584X14Y.0000000075

S. Banerjee, P. Sahoo, S. Poria, G. Sutradhar, Nano-indentation and corrosion characteristics of ultrasonic vibration assisted stir-cast AZ31–WC–Graphite nano-composites. Int. J. Metalcast (2020). https://doi.org/10.1007/s40962-020-00538-8

G. Cao, H. Konishi, X. Li, Recent developments on ultrasonic cavitation based solidification processing of bulk Magnesium nanocomposites. Int. J. Metalcast 2, 57–65 (2008). https://doi.org/10.1007/BF03355422

A. Khandelwal, K. Mani, N. Srivastava, R. Gupta, G.P. Chaudhari, Mechanical behavior of AZ31/Al2O3 magnesium alloy nanocomposites prepared using ultrasound assisted stir-casting. Compos. Part B-Eng. 123, 64–73 (2017). https://doi.org/10.1016/j.compositesb.2017.05.007

M. Habibnejad-Korayem, R. Mahmudi, W.J. Poole, Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles. Mat. Sci. Eng.-A 519(1–2), 198–203 (2009). https://doi.org/10.1016/j.msea.2009.05.001

H. Choi, W. Cho, X.C. Li, Semi-solid mixing for fabrication of A206/Al2O3 master nanocomposites. AFS Transactions 121, 159–164 (2013)

Y. Sun, H. Choi, X.C. Li, Composition optimization for A206/Al2O3 nanocomposite. AFS Transactions 121, 205–215 (2013)

S. Bin, S. Xing, N. Zhao, L. Li, Influence of technical parameters on strength and ductility of AlSi9Cu3 alloys in squeeze casting. T. Nonferr. Metal. Soc. 23(4), 977–982 (2013). https://doi.org/10.1016/S1003-6326(13)62555-8

P. Loganathan, A. Gnanavelbabu, K. Rajkumar, Influence of ZrB2/hBN particles on the wear behaviour of AA7075 composites fabricated through stir followed by squeeze cast technique. P. I. Mech. Eng. J.-J. Eng. 235(1), 149–160 (2020). https://doi.org/10.1177/1350650120929501

R. Ahmad, D.T. Gethin, R.W. Lewis, Design element concept of squeeze casting process. Appl. Math. Model 36(10), 4760–4788 (2012). https://doi.org/10.1016/j.apm.2011.12.012

T. Lu, W. Chen, B. Li, M. Mao, Z. Li, Y. Liu, S. Scudino, Influence mechanisms of Zr and Fe particle additions on the microstructure and mechanical behavior of squeeze-cast 7075Al hybrid composites. J. Alloy Compd. 798, 587–596 (2019). https://doi.org/10.1016/j.jallcom.2019.05.301

A. Gnanavelbabu, K. Rajkumar, Experimental characterization of dimensional and surface alternation of straight and angular cutting on self-lubricating composite: A wire EDM approach. Arab. J. Sci. Eng. 45, 5859–5872 (2020). https://doi.org/10.1007/s13369-020-04596-2

D. Yuan, X. Yang, S. Wu, S. Lü, K. Hu, Development of high strength and toughness nano-SiCp/A356 composites with ultrasonic vibration and squeeze casting. J. Mater. Process Tech. 269, 1–9 (2019). https://doi.org/10.1016/j.jmatprotec.2019.01.021

A. Hussain, A.I. Mourad, Conventional stir casting versus ultrasonic assisted stir casting process: Mechanical and physical characteristics of AMCs. J. Alloy Compd. 805, 502–508 (2019). https://doi.org/10.1016/j.jallcom.2019.07.076

C. Allen, Q. Han, Grain refinement of pure aluminum using ultrasonics. Int. J. Metalcast 5, 69–70 (2011). https://doi.org/10.1007/BF03355511

X. Liu, S. Jia, L. Nastac, Ultrasonic cavitation-assisted molten metal processing of cast A356-nanocomposites. Int. J. Metalcast 8, 51–58 (2014). https://doi.org/10.1007/BF03355591

A. Gnanavelbabu, K.T. Sunu Surendran, P. Loganathan, E. Vinothkumar, Effect of ageing temperature on the corrosion behaviour of UHTC particulates reinforced magnesium composites fabricated through ultrasonic assisted squeeze castingprocess. J. Alloy Compd. 856, 158–173 (2020). https://doi.org/10.1016/j.jallcom.2020.158173

D. Gao, Z. Li, Q. Han, Q. Zhai, Effect of ultrasonic power on microstructure and mechanical properties of AZ91 alloy. Mat. Sci. Eng.-A 502(1–2), 2–5 (2009). https://doi.org/10.1016/j.msea.2008.12.005

S.H. Mousavi Anijdan, M. Sabzi, The effect of pouring temperature and surface angle of vortex casting on microstructural changes and mechanical properties of 7050Al-3 wt% SiC composite. Mat. Sci. Eng.-A 737, 230–235 (2018). https://doi.org/10.1016/j.msea.2018.09.057

G. Chen, M. Yang, Y. Jin, H. Zhang, F. Han, Q. Chen, Z. Zhao, Ultrasonic assisted squeeze casting of a wrought aluminum alloy. J. Mater. Process Tech. 266, 19–25 (2019). https://doi.org/10.1016/j.jmatprotec.2018.10.032

P. Vijian, V.P. Arunachalam, Optimization of squeeze casting process parameters using Taguchi analysis. Int. J. Adv. Manuf. Tech. 33(11–12), 1122–1127 (2007). https://doi.org/10.1007/s00170-006-0550-2

H. Su, W. Gao, Z. Feng, Z. Lu, Processing, microstructure and tensile properties of nano-sized Al2O3 particle reinforced aluminum matrix composites. Mater. Design 36, 590–596 (2012). https://doi.org/10.1016/j.matdes.2011.11.064

N. Srivastava, G.P. Chaudhari, M. Qian, Grain refinement of binary Al-Si, Al-Cu and Al-Ni alloys by ultrasonication. J. Mater. Process Tech. 249, 367–378 (2017). https://doi.org/10.1016/j.jmatprotec.2017.06.024

M.H. Sarfraz, M. Jahanzaib, W. Ahmed, S. Hussain, Multi-response parametric optimization of squeeze casting process for fabricating Al 6061-SiC composite. Int. J. Adv. Manuf. Tech. 102(1–4), 759–773 (2019). https://doi.org/10.1007/s00170-018-03278-6

R. Soundararajan, A. Ramesh, N. Mohanraj, N. Parthasarathi, An investigation of material removal rate and surface roughness of squeeze casted A413 alloy on WEDM by multi response optimization using RSM. J. Alloy Compd. 685, 533–545 (2016). https://doi.org/10.1016/j.jallcom.2016.05.292

A. Maleki, B. Niroumand, A. Shafyei, Effects of squeeze casting parameters on density, macrostructure and hardness of LM13 alloy. Mat. Sci. Eng.-A 428(1–2), 135–140 (2006). https://doi.org/10.1016/j.msea.2006.04.099

A. Jahangiri, S.P.H. Marashi, M. Mohammadaliha, V. Ashofte, The effect of pressure and pouring temperature on the porosity, microstructure, hardness and yield stress of AA2024 aluminum alloy during the squeeze casting process. J. Mater. Process Tech. 245, 1–6 (2017). https://doi.org/10.1016/j.jmatprotec.2017.02.005

P. Madhukar, N. Selvaraj, C.S.P. Rao, G.B. Veeresh Kumar, Tribological behavior of ultrasonic assisted double stir casted novel nano-composite material (AA7150-hBN) using Taguchi technique. Compos. Part B-Eng. 175, 107–136 (2019). https://doi.org/10.1016/j.compositesb.2019.107136

P. Senthil, K.S. Amirthagadeswaran, Optimization of squeeze casting parameters for non symmetrical AC2A aluminium alloy castings through taguchi method. J. Mech. Sci. Tech. 26(4), 1141–1147 (2012). https://doi.org/10.1007/s12206-012-0215-z

R.J. Wang, W.F. Tan, D.W. Zhou, Effects of squeeze casting parameters on solidification time based on neural network. Int. J. Mater. Prod. Tec. 46(2/3), 124–140 (2013). https://doi.org/10.1504/IJMPT.2013.056302

T. Varol, A. Canakci, S. Ozsahin, Prediction of effect of reinforcement content, flake size and flake time on the density and hardness of flake AA2024-SiC nanocomposites using neural networks. J. Alloy Compd. 739, 1005–1014 (2018). https://doi.org/10.1016/j.jallcom.2017.12.256

G.C.M. Patel, P. Krishna, M.B. Parappagoudar, Squeeze casting process modeling by a conventional statistical regression analysis approach. Appl. Math. Model 40(15–16), 6869–6888 (2016). https://doi.org/10.1016/j.apm.2016.02.029

G.C.M. Patel, A.K. Shettigar, P. Krishna, M.B. Parappagoudar, Back propagation genetic and recurrent neural network applications in modelling and analysis of squeeze casting process. Appl. Soft Comput. 59, 418–437 (2017). https://doi.org/10.1016/j.asoc.2017.06.018

G.C.M. Patel, A.K. Shettigar, M.B. Parappagoudar, A systematic approach to model and optimize wear behaviour of castings produced by squeeze casting process. J. Manuf. Process 32, 199–212 (2018). https://doi.org/10.1016/j.jmapro.2018.02.004

A. Gnanavelbabu, K.T. Sunu Surendran, S. Kumar, Influence of ultrasonication power on grain refinement, mechanical properties and wear behaviour of AZ91D/nano-Al2O3 composites. Mater. Express (2020). https://doi.org/10.1088/2053-1591/ab64d7

A. Singh, N. Bala, Synthesis and comparative sliding wear behavior of stir cast Mg and Mg/Al2O3 metal matrix composites. Mater. Express (2019). https://doi.org/10.1088/2053-1591/ab10d3

M.E. Moussa, M.A. Waly, M. Amin, Effect of high intensity ultrasonic treatment on microstructural modification and hardness of a nickel-aluminum bronze alloy. J. Alloy Compd. 741, 804–813 (2018). https://doi.org/10.1016/j.jallcom.2018.01.218

Q. Gao, S. Wu, S. Lü, X. Xiong, R. Du, An. Ping, An Improvement of particles distribution of in-situ 5 vol% TiB2 particulates reinforced Al-4.5Cu alloy matrix composites with ultrasonic vibration treatment. J. Alloy Compd. 692, 1–9 (2017). https://doi.org/10.1016/j.jallcom.2016.09.013

D. Sameer Kumar, K.N.S. Suman, C. Tara Sasanka, K. Ravindra, P. Poddar, S.B. Venkata Siva, Microstructure, mechanical response and fractography of AZ91E/Al2O3(p) nano composite fabricated by semi solid stir casting method. J. Magnes. Alloy 5(1), 48–55 (2017). https://doi.org/10.1016/j.jma.2016.11.006

L. Hao, X. Yang, S. Lü, X. Fang, S. Wu, Influence of squeeze casting pressure and heat treatment on microstructure and mechanical properties of Mg94Ni2Y4 alloy with LPSO structure. Mat. Sci. Eng.-A 707, 280–286 (2017). https://doi.org/10.1016/j.msea.2017.09.060

S. Zhu, T. Luo, Y. Li, Y. Yang, Characterization the role of squeezing pressure on microstructure, tensile properties and failure mode of a new Mg-6Zn-4Al-0.5Cu magnesium alloy. J. Alloy Compd. 718, 188–196 (2017). https://doi.org/10.1016/j.jallcom.2017.05.115

H.S. Xue, Z.H. Xing, W. Zhang, G. Yang, F.S. Pan, Effects of ultrasonic treatment on microstructure and mechanical properties of Mg-6Zn-0.5Y-2Sn alloy. T. Nonferr. Metal Soc. 26(7), 1826–1834 (2016). https://doi.org/10.1016/S1003-6326(16)64263-2

I. Tzanakis, G.S.B. Lebon, D.G. Eskin, K. Pericleous, Investigation of the factors influencing cavitation intensity during the ultrasonic treatment of molten aluminium. Mater. Design 90, 979–983 (2016). https://doi.org/10.1016/j.matdes.2015.11.010

M.F. Qi, Y.L. Kang, B. Zhou, G.M. Zhu, H.H. Zhang, Y.D. Li, Effects of pouring temperature and cylinder temperature on microstructures and mechanical properties of rheomoulding AZ91D alloy. T. Nonferr. Metal Soc. 25(9), 2884–2892 (2015). https://doi.org/10.1016/S1003-6326(15)63914-0

Y. Zhang, G. Wu, W. Liu, L. Zhang, S. Pang, Y. Wang, W. Ding, Effects of processing parameters and Ca content on microstructure and mechanical properties of squeeze casting AZ91-Ca alloys. Mat. Sci. Eng. A 595, 109–117 (2014). https://doi.org/10.1016/j.msea.2013.12.014

T. Liu, Q. Wang, Y. Sui, Q. Wang, W. Ding, An investigation into aluminum-aluminum bimetal fabrication by squeeze casting. Mater. Design 68, 8–17 (2015). https://doi.org/10.1016/j.matdes.2014.11.051

X.J. Wang, N.Z. Wang, L.Y. Wang, X.S. Hu, K. Wu, Y.Q. Wang, Y.D. Huang, Processing, microstructure and mechanical properties of micro-SiC particles reinforced magnesium matrix composites fabricated by stir casting assisted by ultrasonic treatment processing. Mater. Design 57, 638–645 (2014). https://doi.org/10.1016/j.matdes.2014.01.022

Y.S. Yang, J.C. Wang, T. Wang, C.M. Liu, Z.M. Zhang, Effects of ultrasonic treatment on microstructures of AZ91 alloy. T. Nonferr. Metal Soc. 24(1), 76–81 (2014). https://doi.org/10.1016/S1003-6326(14)63030-2

Z.H. Guo, H. Hou, Y.H. Zhao, S.W. Qu, Optimization of AZ80 magnesium alloy squeeze cast process parameters using morphological matrix. T. Nonferr. Metal Soc. 22(2), 411–418 (2012). https://doi.org/10.1016/S1003-6326(11)61192-8

G.C. Manjunath Patel, P. Krishna, M.B. Parappagoudar, Modelling and multi-objective optimisation of squeeze casting process using regression analysis and genetic algorithm. Aust J Mech Eng 14(3), 182–198 (2016)

J.G. Jung, J.M. Lee, Y.H. Cho, W.H. Yoon, Combined effects of ultrasonic melt treatment, Si addition and solution treatment on the microstructure and tensile properties of multicomponent Al-Si alloys. J. Alloy Compd. 693, 201–210 (2017). https://doi.org/10.1016/j.jallcom.2016.09.006

R. Adalarasan, M. Santhanakumar, M. Rajmohan, Optimization of laser cutting parameters for Al6061/SiCp/Al2O3 composite using grey based response surface methodology (GRSM). Meas. 73, 596–606 (2015). https://doi.org/10.1016/j.measurement.2015.06.003

U. Aybarc, O. Ertugrul, M.O. Seydibeyoglu, Effect of Al2O3 particle size on mechanical properties of ultrasonic-assisted stir-casted Al A356 matrix composites. Int. J. Metalcast (2020). https://doi.org/10.1007/s40962-020-00490-7

H. Puga, S.D. Tohidi, V.H. Carneiro, J. Meireless, M. Prokic, Ceramic sonotrodes for light alloy melt treatment. Int. J. Metalcast. (2020). https://doi.org/10.1007/s40962-020-00476-5

J. Barbosa, H. Puga, Ultrasonic melt treatment of light alloys. Int. J. Metalcast. 13, 180–189 (2019). https://doi.org/10.1007/s40962-018-0248-x

Acknowledgement

The authors gratefully acknowledge the financial support by Science and Engineering Research Board (SERB), Government of India, through the grant number: EEQ/2017/000382.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gnanavelbabu, A., Surendran, K.T.S. & Kumar, S. Process Optimization and Studies on Mechanical Characteristics of AA2014/Al2O3 Nanocomposites Fabricated Through Ultrasonication Assisted Stir–Squeeze Casting. Inter Metalcast 16, 759–782 (2022). https://doi.org/10.1007/s40962-021-00634-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00634-3