Abstract

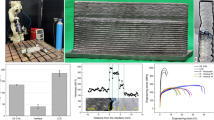

Integration of two metallurgically distinct materials (bimetallic) is an inevitable advancement in the automotive and marine field. In this context, this study investigates the fabrication, characterization, and properties of solid–liquid compound cast aluminum alloy AA5052 and ferrous alloy (mild steel and galvanized iron) based bimetallic materials. Microstructural evolution, microhardness, and tensile strength of the developed bimetallic material are investigated. The results show that the formation of cracks at the interface in AA5052/Mild Steel caused the joint failure in the course of preliminary testing. In AA5052/Galvanized Iron, the growth of intermetallics at the oxide-free steel surface results in a shear strength of 19.9 MPa. XRD analysis attests to the presence of brittle intermetallics and Al bond at the interface of AA5052/Galvanized Iron bimetallic material, which in turn confirms the development of a metallurgical.

Graphic abstract

Similar content being viewed by others

References

L.H. Shah, M. Ishak, Mater. Manuf. Process. 29, 928 (2014)

M. Lee, S.-H. Jung, J. Weld. Join. 34, 19 (2016)

G. Ghongade, P.K. Kota, V.V. Ramalingam, G. Myilsamy, Mater. Today Proc. (2020). https://doi.org/10.1016/j.matpr.2020.09.694

R. Padmanaban, V. Balusamy, K.N. Nouranga, J. Eng. Sci. Technol. 10, 790 (2015)

A.J. Alex, V.V. Ramalingam, R. Padmanaban, G. Myilsamy, Mater. Today Proc. 22, 3340 (2020)

A.J. Alex, V.V. Ramalingam, R. Padmanaban, G. Myilsamy, Aust. J. Mech. Eng. (2020). https://doi.org/10.1080/14484846.2020.1756184

A. Hbbani, J.M. Paiva, Bimetallic engineering applications and machinability challenges, Paper presented at the 7th International Conference on Virtual Machining Process Technology (VMPT), McMaster University, Hamilton, Cannada, 7-9 May 2018

J.-M. Kim, K. Shin, J.-S. Shin, Metals 10, 759 (2020)

K.-I. Mori, Y. Abe, Int. J. Lightweight Mater. Manuf. 1, 1 (2018)

M. Piekarczyk, R. Grec, Arch. Civ. Eng. 58, 309 (2012)

T. Senthil Kumar, V. Balasubramanian, M.Y. Sanavullah, S. Babu, J. Mater. Sci. Technol. 23, 223 (2007)

V.V. Ramalingam, P. Ramasamy, M.D. Kovukkal, G. Myilsamy, Met. Mater. Int. 26, 409 (2020)

Q. Wen, W. Li, V. Patel, Y. Gao, A. Vairis, Met. Mater. Int. 26, 1830 (2020)

B. Bagheri, M. Abbasi, A. Abdollahzadeh, H. Omidvar, Met. Mater. Int. 26, 1562 (2020)

P. Gao, Y. Zhang, K.P. Mehta, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00759-w

G.H.S.F.L. Carvalho, I. Galvão, R. Mendes, R.M. Leal, A. Loureiro, J. Mater. Process. Tech. 283, 116707 (2020)

A. Ismail, W. Bahanan, P.B. Hussain, A.M. Saat, N.B. Shaik, Processes 8, 824 (2020)

T. Das, R. Das, J. Paul, J. Manuf. Process. 53, 260 (2020)

P. Wang, X. Chen, Q. Pan, B. Madigan, J. Long, Int. J. Adv. Manuf. Tech. 87, 3081 (2016)

P.K.S. Srujan, H.K. Kaka, V.V. Ramalingam, P.K. Kota, R. Padmanaban, G. Myilsamy, AIP Conf. Proc. 2128, 030006 (2019)

M. Ramadan, N. Fathy, K.S. Abdel Halim, A.S. Alghamdi, Int. J. Adv. Appl. Sci. 6, 75 (2019)

Y.Y. Kang, G.W. Zhang, H. Xu, J.W. Niu, Conf. Proc.: J Phys.: Conf. Ser. 1507 (2020). https://doi.org/10.1088/1742-6596/1507/4/042008

G.R. Zare, M. Divandari, H. Arabi, Mater. Sci. Technol. 29, 190 (2013)

W. Jiang, H. Jiang, G. Li, F. Guan, J. Zhu, Z. Fan, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-019-00606-7

G. Li, W. Jiang, F. Guan, J. Zhu, Z. Zhang, Z. Fan, J. Mater. Process. Tech. 288, 116874 (2021)

A.O. Bakke, L. Arnberg, J.-O. Løland, S. Jørgensen, J. Kvinge, Y. Li, J. Alloy. Compd. 849, 156685 (2020)

G. Liu, Q. Wang, T. Liu, B. Ye, H. Jiang, W. Ding, Mater. Sci. Eng. A 696, 208 (2017)

W. Jiang, G. Li, Y. Wu, X. Liu, Z. Fan, J. Mater. Process. Tech. 258, 239 (2018)

M. Salimi, M. Malekan, B. Nami, H. Hoseiny, J. Mater. Res. 32, 874 (2017)

J. Shin, T. Kim, K. Lim, H. Cho, D. Yang, C. Jeong, S. Yi, J. Alloy. Compd. 778, 170 (2019)

Y. Tanaka, M. Kajihara, J. Mater. Sci. 45, 5676 (2010)

K. Zhang, X. Bian, Y. Li, Y. Liu, C. Yang, J. Mater. Res. 28, 3279 (2013)

V.N. Yeremenko, Y.V. Natanzon, V.I. Dybkov, J. Mater. Sci. 16, 1748 (1981)

W. Jiang, Z. Fan, C. Li, J. Mater. Process. Tech. 226, 25 (2015)

N. Takata, M. Nishimoto, S. Kobayashi, M. Takeyama, Intermetallics 67, 1 (2015)

H. Springer, A. Kostka, J.F. dos Santos, D. Raabe, Mater. Sci. Eng. A 528, 4630 (2011)

T.-S. Shih, S.-H. Tu, Mater. Sci. Eng. A 454-455, 349 (2007)

X. Li, A. Scherf, M. Heilmaier, F. Stein, J. Phase Equilib. Diff. 37, 162 (2016)

M. Kajihara, Mater. Trans. 47, 1480 (2006)

H. He, W. Gou, S. Wang, Y. Hou, C. Ma, P.F. Mendez, Int. J. Mater. Res. 110, 194 (2019)

M. Potesser, T. Schoeberl, H. Antrekowitsch, J. Bruckner, in EPD Congress 2006, ed. by S.M. Howard et al. San Antonio, Texas, USA, March 12-16, 2006 (TMS, Warrendale, 2006), p. 167

J. Grin, U. Burkhardt, M. Ellner, K. Peters, Z. Kristallogr. Cryst. Mater. 209, 479 (1994)

K. Chandrappa, A. Kumar, K. Shubham, IOP Conf. Ser. Mat. Sci. 402, 012124 (2018)

H. Nakajima, JOM 49, 15 (1997)

H. Springer, A. Kostka, E.J. Payton, D. Raabe, A. Kaysser-Pyzalla, G. Eggeler, Acta Mater. 59, 1586 (2011)

M. Kab, S. Mendil, K. Taibi, Metallogr. Microstruct. Anal. 9, 476 (2020)

K. Bhanumurthy, W. Krauss, J. Konys, Fusion Sci. Technol. 65, 262 (2014)

Acknowledgements

The authors are thankful to the Department of Science and Technology and Quantum Heat Treaters Pvt. Ltd., for their financial support to carry out this investigation through a research project titled “Development, Field Trials, Pilot Production, and Technology Demonstration of Sintered Braked Pads with Improved Performance for Wind Turbine Applications Suitable to India Specific Wind Characteristics” (DST/TDT/AMT/2017/002(G)). The authors thank the Ministry of Human Resource Department (MHRD, Government of India) and Center of Excellence in Advanced Materials and Green Technologies (CoE – AMGT, Amrita Vishwa Vidyapeetham) for providing access to X-ray diffractometer and field-emission scanning electron microscope analytical facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kota, P.K., Myilsamy, G. & Ramalingam, V.V. Metallurgical Characterization and Mechanical Properties of Solid–Liquid Compound Casting of Aluminum Alloy: Steel Bimetallic Materials. Met. Mater. Int. 28, 1416–1422 (2022). https://doi.org/10.1007/s12540-021-00979-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-00979-8