Abstract

Drucker’s sixth-order yield function for isotropic materials (J Appl Mech 16:349–357, 1949) was extended by Cazacu and Barlat (Math Mech Solids 6:613–630, 2001) for modeling orthotropic sheet metals via a generalization of the two stress invariants according to the theory of representation. The constant c in the original Drucker’s isotropic yield function was found by Dodd and Naruse (Int J Mech Sci 31:511–519, 1989) to be bound between –27/8 and 9/4 per the convexity requirement. In many subsequent modeling applications of orthotropic sheets, the same bound is also tacitly assumed for the constant c used in this class of the generalized Drucker’s yield function CB2001. No actual proof has, however, been presented in the literature that such a bound is indeed absolutely necessary if not sufficient to guarantee the convexity of the orthotropic CB2001 yield function. In this study, the validity of assuming such a convexity bound on the adjustable constant c is examined using a recently proposed numerical convexity certification algorithm. Representative orthotropic CB2001 yield functions whose material parameters have been calibrated and reported in the literature for some 12 FCC, BCC, and HCP sheet metals are evaluated. It is found that a single convexity bound between \(-27/8\) and 9/4 on the constant c does not hold at all for any of those yield functions. This is in contrast to another class of generalized Drucker’s yield function based on linearly transformed stresses where the original convexity bound on the constant c does still hold.

Similar content being viewed by others

Notes

In terms of three principal Cauchy stresses \((\sigma _1,\sigma _2,\sigma _3)\), the corresponding three principal deviatoric stresses (\(s_1, s_2, s_3\)) are simply given, respectively, as \((2\sigma _1-\sigma _2-\sigma _3)/3\), \((2\sigma _2-\sigma _3-\sigma _1)/3\), and \((2\sigma _3-\sigma _1-\sigma _2)/3\).

The parameters (\(a_1, b_1, c_1, g_1\)) and (\(a_2, b_2, c_2, g_2\)) in [34] correspond, respectively, to (\(c_1, c_2, c_3, c_6\)) and (\(d_1, d_2, d_3, d_6\)) in this study.

Alternatively, one can also use any calibrated Drucker’s yield function based on linearly transformed stresses for validating the numerical implementation of the convexity certification algorithm.

Because the as-calibrated Drucker’s yield functions for sheets #2 (AA2090-T3) and #5 (AA6063) are non-convex, one will decrease \(\xi \) from 1 instead to search for its convexity bound of each sheet. Their maximum allowable \(\xi \) values will thus be less than 1, see Table 5.

Abbreviations

- x,y,z :

-

The orthotropic material symmetry axes corresponding to the rolling (RD), transverse (TD), and normal (ND) directions of a thin sheet metal

- \(\sigma _x,\sigma _y,\tau _{xy}\) :

-

Three in-plane Cartesian (two normal and one shear) components of an applied Cauchy stress \(\pmb {\sigma }\) in the orthotropic coordinate system of the sheet metal

- \(\varPhi _{6d}, J_2, J_3, c\) :

-

Drucker’s 1949 isotropic yield function in terms of two stress invariants \(J_2\) and \(J_3\) and one adjustable material constant c with its convexity bound between \(-\,27/8\) and 9/4

- \(\varPhi _6, A_1,\ldots ,A_{16}\) :

-

The complete sixth-order homogeneous polynomial orthotropic yield function in Cartesian plane stress components (\(\sigma _x,\sigma _y,\tau _{xy}\)) and its sixteen material constants

- \(\varPhi _{6cb}, J_{2a}, J_{3a}\) :

-

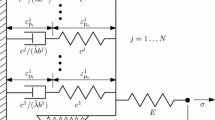

The orthotropic Drucker’s yield function CB2001 in Cartesian plane stress components (\(\sigma _x,\sigma _y,\tau _{xy}\)), with its two generalized stress invariants based on the theory of representation of tensor functions with two different sets of four and six material constants, respectively, per Cazacu and Barlat [10]

- \(\varPhi _{6db}, J_{2b}, J_{3b}\) :

-

The orthotropic Drucker’s yield function in plane stress, with its two generalized stress invariants based on a linearly transformed stress with a set of four material constants per Cazacu and Barlat [10]

- \(\varPhi _{6dc}, J_{2c}, J_{3c}\) :

-

The orthotropic Drucker’s yield function in plane stress, with its second set of two generalized stress invariants based on a second linearly transformed stress with an additional set of four different material constants per Yoshida et al. [34]

References

Ahmadi, A., Olshevsky, A., Parrilo, P., Tsitsiklis, J.: NP-hardness of deciding convexity of quartic polynomials and related problems. Math. Program. Ser. A 137, 453–476 (2013)

Alves, J., Oliveira, M., Menezes, L.: Springback evaluation with several phenomenological yield criteria. In: Martins, R., Fortunato, E., Ferreira, I., Dias, C. (eds.) Advanced Materials Forum II. Materials Science Forum, vol. 455-456, pp. 732–736 (2004)

Banabic, D., Cazacu, O., Barlat, F., Comsa, D., Wagner, S., Siegert, K.: Description of anisotropic behaviour of AA3103-0 aluminium alloy using two recent yield criteria. J. Phys. IV 105, 297–304 (2003)

Barlat, F., Brem, J., Yoon, J.W., Chung, K., Dick, R.E., Lege, D., Pourboghrat, F., Choi, S.H., Chu, E.: Plane stress yield function for aluminum alloy sheets—part 1: theory. Int. J. Plast. 19, 1297–1319 (2003)

Barlat, F., Lege, D.J., Brem, J.C.: A six-component yield function for anisotropic materials. Int. J. Plast. 7(5), 693–712 (1991)

Barlat, F., Yoon, J.W., Cazacu, O.: On linear transformations of stress tensors for the description of plastic anisotropy. Int. J. Plast. 23(3), 876–896 (2007)

Barros, P.D., Alves, J.L., Oliveira, M.C., Menezes, L.F.: Modeling of tension-compression asymmetry and orthotropy on metallic materials: numerical implementation and validation. Int. J. Mech. Sci. 114, 217–232 (2016). https://doi.org/10.1016/j.ijmecsci.2016.05.020

Barros, P.D., Alves, J.L., Oliveira, M.C., Menezes, L.F.: Study on the effect of tension-compression asymmetry on the cylindrical cup forming of an AA2090-T3 alloy. Int. J. Solids Struct. 151, 135–144 (2018)

Carrell, J.B.: Fundamentals of Linear Algebra, pp. 363–364 (2005). http://www.math.ubc.ca/~carrell/NB.pdf. Accessed 21 May 2021

Cazacu, O., Barlat, F.: Generalization of Drucker’s yield criterion to orthotropy. Math. Mech. Solids 6(6), 613–630 (2001). https://doi.org/10.1177/108128650100600603

Cazacu, O., Barlat, F.: Application of the theory of representation to describe yielding of anisotropic aluminum alloys. Int. J. Eng. Sci. 41(12), 1367–1385 (2003). https://doi.org/10.1016/S0020-7225(03)00037-5

Dodd, B., Naruse, K.: Limitation on isotropic yield criterion. Int. J. Mech. Sci. 31, 511–519 (1989)

Drucker, D.: Relations of experiments to mathematical theories of plasticity. J. Appl. Mech. 16, 349–357 (1949)

Hill, R.: The Mathematical Theory of Plasticity. Clarendon Press, Oxford (1950)

Karafillis, A.P., Boyce, M.C.: A general anisotropic yield criterion using bounds and a transformation weighting tensor. J. Mech. Phys. Solids 41(12), 1859–1886 (1993)

Khalfallah, A., Alves, J.L., Oliveira, M.C., Menezes, L.F.: Influence of the characteristics of the experimental data set used to identify anisotropy parameters. Simul. Model. Pract. Theory 53, 15–44 (2015). https://doi.org/10.1016/j.simpat.2015.02.007

Khalfallah, A., Oliveira, M.C., Alves, J.L., Menezes, L.F.: Constitutive parameter identification of CB2001 yield function and its experimental verification using tube hydroforming tests. Int. J. Mech. Sci. 185, 105868 (2020)

Khalfallah, A., Oliveira, M.C., Alves, J.L., Zribi, T., Belhadjsalah, H., Menezes, L.F.: Mechanical characterization and constitutive parameter identification of anisotropic tubular materials for hydroforming applications. Int. J. Mech. Sci. 104, 91–103 (2015). https://doi.org/10.1016/j.ijmecsci.2015.09.017

Lou, Y., Yoon, J.W.: Anisotropic behavior in plasticity and ductile fracture of an aluminum alloy. Key Eng. Mater. 651–653, 163–168 (2015)

Lou, Y., Yoon, J.W.: Anisotropic yield function based on stress invariants for bcc and fcc metals and its extension to ductile fracture criterion. Int. J. Plast. 101, 125–155 (2018)

Osgood, W.: Combined-stress tests on 24s-t aluminum alloy tubes. J. Appl. Mech. Trans. ASME 69, A-147 (1947)

Padmanabhan, R., Oliveira, M.C., Baptista, A.J., Alves, J.L., Menezes, L.F.: Numerical study on the influence of initial anisotropy on optimal blank shape. Finite Elem. Anal. Des. 45(2), 71–80 (2009). https://doi.org/10.1016/j.finel.2008.07.012

Prates, P.A., Oliveira, M.C., Fernandes, J.V.: On the equivalence between sets of parameters of the yield criterion and the isotropic and kinematic hardening laws. Int. J. Mater. Form 8, 505–515 (2015)

Reis, L.C., Prates, P.A., Oliveira, M.C., Santos, A.D., Fernandes, J.V.: Anisotropy and plastic flow in the circular bulge test. Int. J. Mech. Sci. 128, 70–93 (2017). https://doi.org/10.1016/j.ijmecsci.2017.04.007

Soare, S., Yoon, J.W., Cazacu, O.: On the use of homogeneous polynomials to develop anisotropic yield functions with applications to sheet forming. Int. J. Plast. 24(6), 915–944 (2008)

Tong, W.: Application of Gotoh’s orthotropic yield function for modeling advanced high-strength steel sheets. ASME J. Manuf. Sci. Eng. 138, 094502-1–094502-5 (2016)

Tong, W.: Generalized fourth-order Hill’s 1979 yield function for modeling sheet metals in plane stress. Acta Mech. 227(10), 2719–2733 (2016)

Tong, W.: Algebraic convexity conditions for Gotoh’s non-quadratic yield function. ASME J. Appl. Mech. 85, 074501-1–074501-7 (2018)

Tong, W.: Calibration of a complete homogeneous polynomial yield function of six degrees for modeling orthotropic steel sheets. Acta Mech. 229, 2495–2519 (2018). https://doi.org/10.1007/s00707-018-2113-7

Tong, W.: On the certification of positive and convex Gotoh’s fourth-order yield function. J. Phys. Conf. Ser. 1063, 012093012093 (2018)

Tong, W., Alharbi, M.: Comparative evaluation of non-associated quadratic and associated quartic plasticity models for orthotropic sheet metals. Int. J. Solids Struct. 128, 133–148 (2017)

Tong, W., Alharbi, M., Sheng, J.: On the new shear constraint for plane-stress orthotropic plasticity modeling of sheet metals. Exp. Mech. 60, 889–905 (2020). https://doi.org/10.1007/s11340-020-00596-3

van den Boogaard, A., Havinga, G., Belin, A., Barlat, F.: Parameter reduction for the yld2004-18p yield criterion. Int. J. Mater. Form 9(2), 175–178 (2016). https://doi.org/10.1007/s12289-015-1221-3

Yoshida, F., Hamasaki, H., Uemori, T.: A user-friendly 3D yield function to describe anisotropy of steel sheets. Int. J. Plast. 45, 119–139 (2013)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A The compact polynomial form of the generalized Drucker’s yield function CB2001

Recall that the generalized Drucker’s yield function \(\varPhi _{6cb}(\sigma _x,\sigma _y,\tau _{xy})\) of Eq. (4) can be written into a complete homogeneous sixth-order polynomial in plane stress \(\varPhi _{6}(\sigma _x,\sigma _y,\tau _{xy})\) of a compact form Eq. (3). Here, we list the 16 polynomial coefficients (\(A_1,\ldots ,A_{16}\)) in terms of the 11 material constants (\(a_1\), \(a_2\), \(a_3\), \(a_4\), \(b_1\), \(b_2\), \(b_3\), \(b_4\), \(b_5\), \(b_{10},c\)) appearing in \(\varPhi _{6cb}(\sigma _x,\sigma _y,\tau _{xy})\) with \(c^*=c/27\):

Similar results of the 16 polynomial coefficients for both generalized Drucker’s yield functions \(\varPhi _{6db}\) and \(\varPhi _{6dc}\) in terms of the material constants \((c_1,c_2,c_3,c_6)\) and \((d_1,d_2,d_3,d_6)\) in the linearly transformed stresses along with the constant c have already been given in the appendix of [34].

Appendix B Transversely isotropic Drucker’s yield function

The Drucker’s yield function has been specified for transversely isotropic sheets in [11] using the generalized \(J^T_2\) and \(J^T_3\) with transverse isotropy. These two stress invariants can be written in terms of two principal stresses \((\sigma _1, \sigma _2)\) in plane stress as

where \(h_1, h_2, g_1\), and \(g_2\) are the four material constants. The 10 materials constants that appeared in the orthotropic stress invariants \(J_{2a}\) and \(J_{3a}\) of Eq. (5) are given in terms of these four material constants as

Appendix C The relation between two formulations of the generalized Drucker’s yield function

The generalized Drucker’s yield function \(\varPhi _{6db}\) based on one linearly transformed stress can be rewritten into the form of the generalized Drucker’s yield function \(\varPhi _{6cb}\) by setting \(J_{2a}=J_{2b}\) and \(J_{3a}=J_{3b}\). The ten material constants (\(a_1,\ldots ,b_{10}\)) of the latter can be obtained in terms of the four material constants (\(c_1,c_2,c_3,c_6\)) of the former as

However, the generalized Drucker’s yield function \(\varPhi _{6dc}\) based on two linearly transformed stresses may not be rewritten into the form of the generalized Drucker’s yield function \(\varPhi _{6cb}\) as \(J^3_{2a} \ne J^3_{2b} + J^3_{2c}\) and \(J^2_{3a} \ne J^2_{3b} + J^2_{3c}\) in general.

Rights and permissions

About this article

Cite this article

Tong, W., Yang, SY. On the convexity bound of the generalized Drucker’s yield function CB2001 for orthotropic sheets. Acta Mech 232, 3259–3275 (2021). https://doi.org/10.1007/s00707-021-03006-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-021-03006-4