Abstract

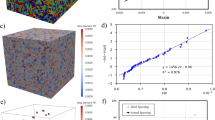

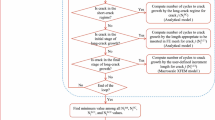

The relative fatigue resistance of different polycrystalline microstructures can be evaluated using fatigue indicator parameters (FIPs) that serve as surrogate measures for the fatigue crack formation driving force. This typically requires simulating many grains/phases to capture sufficient microstructure heterogeneity. Thus, the concept of a representative volume element (RVE) for fatigue-related properties has remained computationally prohibitive and elusive. Alternatively, ensembles of statistical volume elements (SVEs) can be simulated to build up the extreme value fatigue response. A crucial consideration in these types of crystal plasticity finite element method (CPFEM) simulations is the nature of applied boundary conditions. Fatigue crack formation has been experimentally observed to occur either at or near the free surface or throughout the specimen volume, depending on the material microstructure, surface conditions, and the fatigue regime (e.g., low cycle, transition, or high cycle fatigue). The recently developed open-source PRISMS-Fatigue framework (Yaghoobi et al. in NPJ Comput Mater 7:38, 2021) enables the simulation of very large microstructures that may be used to study fatigue RVE characteristics. The available multi-point constraints in PRISMS-Fatigue impose periodic boundary conditions that can appropriately distinguish between the bulk and surface driving forces for fatigue crack formation. We demonstrate the efficacy of these multi-point constraints in microstructure-sensitive CPFEM simulations and compare the extreme value fatigue crack driving force response using various boundary conditions, microstructures, and crystallographic textures. The effects of applied boundary conditions on different mechanical responses such as the macroscopic stress–strain response, local measures of plastic slip, and corresponding FIPs are studied. The results provide guidance for microstructure-sensitive crystal plasticity fatigue studies and demonstrate the advanced capabilities of PRISMS-Fatigue to model large volumes of material microstructure.

Similar content being viewed by others

Data Availability

The microstructures, CPFEM input files, PRISMS-Plasticity raw simulation results, and individual plots are available on Materials Commons at https://doi.org/10.13011/m3-mhgc-ec71. The two Python scripts necessary to reproduce the results of this article are available at https://github.com/prisms-center/Fatigue.

Code Availability

PRISMS-Plasticity and PRISMS-Fatigue are open-source computer codes available for download at https://github.com/prisms-center/plasticity and https://github.com/prisms-center/Fatigue, respectively. In addition to written tutorials available in the GitHub repositories, a series of video tutorials totaling nearly two and three hours of content are available at https://www.youtube.com/playlist?list=PL4yBCojM4Swqy4FRteqxHWSiM1uiOOesj and https://www.youtube.com/playlist?list=PL4yBCojM4Swo3CvlA57syFrzk3p1mugP5, respectively.

References

McDowell DL (1996) Basic issues in the mechanics of high cycle metal fatigue. Int J Fract 80:103

McDowell DL (2007) Simulation-based strategies for microstructure-sensitive fatigue modeling. Mater Sci Eng A 468–470:4

McDowell DL, Dunne FPE (2010) Microstructure-sensitive computational modeling of fatigue crack formation. Int J Fatigue 32:1521

Przybyla CP, McDowell DL (2011) Simulated microstructure-sensitive extreme value probabilities for high cycle fatigue of duplex Ti–6Al–4V. Int J Plast 27:1871

Hallberg H, Ås SK, Skallerud B (2018) Crystal plasticity modeling of microstructure influence on fatigue crack initiation in extruded Al6082-T6 with surface irregularities. Int J Fatigue 111:16

Le Pécheur A, Curtit F, Clavel M, Stephan JM, Rey C, Bompard P (2012) Polycrystal modelling of fatigue: pre-hardening and surface roughness effects on damage initiation for 304l stainless steel. Int J Fatigue 45:48

Prithivirajan V, Sangid MD (2020) Examining metrics for fatigue life predictions of additively manufactured IN718 via crystal plasticity modeling including the role of simulation volume and microstructural constraints. Mater Sci Eng A 783:139312

Prasannavenkatesan R, Zhang J, McDowell DL, Olson GB, Jou H-J (2009) 3d modeling of subsurface fatigue crack nucleation potency of primary inclusions in heat treated and shot peened martensitic gear steels. Int J Fatigue 31:1176

Salajegheh N, McDowell DL (2014) Microstructure-sensitive weighted probability approach for modeling surface to bulk transition of high cycle fatigue failures dominated by primary inclusions. Int J Fatigue 59:188

Stopka KS, McDowell DL (2020) Microstructure-sensitive computational multiaxial fatigue of Al 7075-T6 and duplex Ti-6Al-4V. Int J Fatigue 133:105460

Castelluccio GM, McDowell DL (2016) Microstructure-sensitive small fatigue crack growth assessment: effect of strain ratio, multiaxial strain state, and geometric discontinuities. Int J Fatigue 82:521

Castelluccio GM, McDowell DL (2014) Mesoscale modeling of microstructurally small fatigue cracks in metallic polycrystals. Mater Sci Eng A 598:34

Yaghoobi M et al (2019) Prisms-plasticity: an open-source crystal plasticity finite element software. Comput Mater Sci 169:109078

Roters F et al (2019) DAMASK – the Düsseldorf advanced material simulation kit for modeling multi-physics crystal plasticity, thermal, and damage phenomena from the single crystal up to the component scale. Comput Mater Sci 158:420

Dawson PR, Boyce DE (2015) Fepx-finite element polycrystals: theory, finite element formulation, numerical implementation and illustrative examples. arXiv preprint arXiv: 1504.03296

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117:1

Gaston D, Newman C, Hansen G, Lebrun-Grandié D (2009) Moose: a parallel computational framework for coupled systems of nonlinear equations. Nucl Eng Des 239:1768

DeWitt S, Rudraraju S, Montiel D, Andrews WB, Thornton K (2020) Prisms-pf: a general framework for phase-field modeling with a matrix-free finite element method. NPJ Comput Mater 6:29

Yaghoobi M, Stopka KS, Lakshmanan A, Sundararaghavan V, Allison JE, McDowell DL (2021) Prisms-fatigue computational framework for fatigue analysis in polycrystalline metals and alloys. NPJ Comput Mater 7:38

Aagesen LK et al (2018) Prisms: an integrated, open-source framework for accelerating predictive structural materials science. JOM 70:2298

Przybyla CP, McDowell DL (2010) Microstructure-sensitive extreme value probabilities for high cycle fatigue of Ni-base superalloy IN100. Int J Plast 26:372

Przybyla CP, McDowell DL (2012) Microstructure-sensitive extreme-value probabilities of high-cycle fatigue for surface vs. Subsurface crack formation in duplex Ti–6Al–4V. Acta Mater 60:293

Przybyla CP, Musinski WD, Castelluccio GM, McDowell DL (2013) Microstructure-sensitive HCF and VHCF simulations. Int J Fatigue 57:9

Przybyla CP, Prasannavenkatesan R, Salajegheh N, McDowell DL (2010) Microstructure-sensitive modeling of high cycle fatigue. Int J Fatigue 32:512

Stopka KS, Gu T, McDowell DL (2020) Effects of algorithmic simulation parameters on the prediction of extreme value fatigue indicator parameters in duplex Ti–6Al–4V. Int J Fatigue 141:105865

Stopka KS, McDowell DL (2020) Microstructure-sensitive computational estimates of driving forces for surface versus subsurface fatigue crack formation in duplex Ti–6Al–4V and Al 7075–T6. JOM 72:28

Stopka KS, Whelan G, McDowell DL (2019) Society of the advancement of material and process engineering (SAMPE, 2019), Charlotte, NC

Gu T, Stopka KS, Xu C, McDowell DL (2020) Prediction of maximum fatigue indicator parameters for duplex Ti–6Al–4V using extreme value theory. Acta Mater 188:504

Muth A, John R, Pilchak A, Kalidindi SR, McDowell DL (2020) Analysis of fatigue indicator parameters for Ti–6Al–4V microstructures using extreme value statistics in the HCF regime. Int J Fatigue 145:106096

Hill R (1963) Elastic properties of reinforced solids: some theoretical principles. J Mech Phys Solids 11:357

Kanit T, Forest S, Galliet I, Mounoury V, Jeulin D (2003) Determination of the size of the representative volume element for random composites: statistical and numerical approach. Int J Solids Struct 40:3647

Przybyla CP (2010) PhD dissertation, School of Materials Science and Engineering, Georgia Institute of Technology

Zhang C et al (2015) Effect of realistic 3d microstructure in crystal plasticity finite element analysis of polycrystalline Ti–5Al–2.5Sn. Int J Plast 69:21

Lim H, Battaile CC, Bishop JE, Foulk JW (2019) Investigating mesh sensitivity and polycrystalline RVEs in crystal plasticity finite element simulations. Int J Plast 121:101

Kapoor K, Sangid MD (2018) Initializing type-2 residual stresses in crystal plasticity finite element simulations utilizing high-energy diffraction microscopy data. Mater Sci Eng A 729:53

Hennessey C, Castelluccio GM, McDowell DL (2017) Sensitivity of polycrystal plasticity to slip system kinematic hardening laws for Al 7075-T6. Mater Sci Eng A 687:241

Yaghoobi M, Allison JE, Sundararaghavan V (2020) Multiscale modeling of twinning and detwinning behavior of HCP polycrystals. Int J Plast 127:102653

Ganesan S et al (2021) The effects of heat treatment on the response of WE43 Mg alloy: crystal plasticity finite element simulation and SEM-DIC experiment. Int J Plast 137:102917

Voyiadjis GZ, Yaghoobi M (2019) Size effects in plasticity: from macro to nano. Academic Press, London, pp 191–232

Groeber M, Ghosh S, Uchic MD, Dimiduk DM (2008) A framework for automated analysis and simulation of 3d polycrystalline microstructures.: Part 1: statistical characterization. Acta Mater 56:1257

Groeber M, Ghosh S, Uchic MD, Dimiduk DM (2008) A framework for automated analysis and simulation of 3d polycrystalline microstructures. Part 2: synthetic structure generation. Acta Mater 56:1274

Groeber MA, Jackson MA (2014) DREAM.3D: a digital representation environment for the analysis of microstructure in 3D. Integr Mater Manuf Innov 3:56

Yeratapally SR, Glavicic MG, Hardy M, Sangid MD (2016) Microstructure based fatigue life prediction framework for polycrystalline nickel-base superalloys with emphasis on the role played by twin boundaries in crack initiation. Acta Mater 107:152

Ozturk T et al (2015) Simulation domain size requirements for elastic response of 3d polycrystalline materials. Modell Simul Mater Sci Eng 24:015006

Ozturk D, Shahba A, Ghosh S (2016) Crystal plasticity Fe study of the effect of thermo-mechanical loading on fatigue crack nucleation in titanium alloys. Fatigue Fract Eng Mater Struct 39:752

Ozturk T, Rollett AD (2018) Effect of microstructure on the elasto-viscoplastic deformation of dual phase titanium structures. Comput Mech 61:55

Mandal S, Lao J, Donegan S, Rollett AD (2018) Generation of statistically representative synthetic three-dimensional microstructures. Scripta Mater 146:128

Donegan SP, Rollett AD (2015) Simulation of residual stress and elastic energy density in thermal barrier coatings using fast Fourier transforms. Acta Mater 96:212

Kakandar E, Barrios A, Michler J, Maeder X, Pierron ON, Castelluccio GM (2020) A computational and experimental comparison on the nucleation of fatigue cracks in statistical volume elements. Int J Fatigue 137:105633

Kasemer M, Echlin MP, Stinville JC, Pollock TM, Dawson P (2017) On slip initiation in equiaxed α/β Ti-6Al-4V. Acta Mater 136:288

Chatterjee K, Echlin MP, Kasemer M, Callahan PG, Pollock TM, Dawson P (2018) Prediction of tensile stiffness and strength of Ti-6Al-4V using instantiated volume elements and crystal plasticity. Acta Mater 157:21

Naragani D et al (2017) Investigation of fatigue crack initiation from a non-metallic inclusion via high energy X-ray diffraction microscopy. Acta Mater 137:71

Sangid MD, Ravi P, Prithivirajan V, Miller NA, Kenesei P, Park J-S (2020) ICME approach to determining critical pore size of IN718 produced by selective laser melting. JOM 72:465

Humphreys FJ, Hatherly M (2004) In: Humphreys FJ, Hatherly M (eds) Recrystallization and related annealing phenomena (second edition). Elsevier, Oxford

Ramesh Narayanan P, Suwas S, Sreekumar K, Sinha PP, Ranganathan S (2012) Evolution of crystallographic texture in cold rolled Al–Zn–Mg alloys used in space applications. Mater Sci Forum 702–703:315

Fintová S, Kuběna I, Trško L, Horník V, Kunz L (2020) Fatigue behavior of AW7075 aluminum alloy in ultra-high cycle fatigue region. Mater Sci Eng A 774:138922

Shahzad M, Chaussumier M, Chieragatti R, Mabru C, Rezai Aria F (2010) Influence of surface treatments on fatigue life of Al 7010 alloy. J Mater Process Technol 210:1821

Zuo JH, Wang ZG, Han E (2008) Effect of microstructure on ultra-high cycle fatigue behavior of Ti–6Al–4V. Mater Sci Eng A 473:147

Ravi Chandran KS, Jha SK (2005) Duality of the s–n fatigue curve caused by competing failure modes in a titanium alloy and the role of Poisson defect statistics. Acta Mater 53:1867

Szczepanski CJ, Jha SK, Larsen JM, Jones JW (2008) Microstructural influences on very-high-cycle fatigue-crack initiation in Ti-6246. Metall Mater Trans A 39:2841

Bouchedjra M, Kanit T, Boulemia C, Amrouche A, Belouchrani MEA (2018) Determination of the RVE size for polycrystal metals to predict monotonic and cyclic elastoplastic behavior: statistical and numerical approach with new criteria. Eur J Mech A Solids 72:1

Fatemi A, Socie DF (1988) A critical plane approach to multiaxial fatigue damage including out-of-phase loading. Fatigue Fract Eng Mater Struct 11:149

Castelluccio GM, McDowell DL (2012) Assessment of small fatigue crack growth driving forces in single crystals with and without slip bands. Int J Fract 176:49

Castelluccio GM, McDowell DL (2015) Microstructure and mesh sensitivities of mesoscale surrogate driving force measures for transgranular fatigue cracks in polycrystals. Mater Sci Eng A 639:626

Le Biavant K, Pommier S, Prioul C (2002) Local texture and fatigue crack initiation in a Ti-6Al-4V titanium alloy. Fatigue Fract Eng Mater Struct 25:527

Castillo E (2012) Extreme value theory in engineering. Elsevier Science, Amsterdam

Priddy MW, Paulson NH, Kalidindi SR, McDowell DL (2017) Strategies for rapid parametric assessment of microstructure-sensitive fatigue for HCP polycrystals. Int J Fatigue 104:231

Acknowledgements

KSS and DLM are grateful for the support from the Office of Naval Research under grant number N00014-18-1-2784. MY and JEA are grateful for the support from the U.S. Department of Energy, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering under Award #DE-SC0008637 as part of the Center for PRedictive Integrated Structural Materials Science (PRISMS Center) at University of Michigan. This work used the Extreme Science and Engineering Discovery Environment (XSEDE), which is supported by National Science Foundation grant number ACI-1548562, through the allocation TG-MSS160003. This research was supported in part through research cyberinfrastructure resources and services provided by the Partnership for an Advanced Computing Environment (PACE) at the Georgia Institute of Technology, Atlanta, Georgia, USA.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Stopka, K.S., Yaghoobi, M., Allison, J.E. et al. Effects of Boundary Conditions on Microstructure-Sensitive Fatigue Crystal Plasticity Analysis. Integr Mater Manuf Innov 10, 393–412 (2021). https://doi.org/10.1007/s40192-021-00219-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-021-00219-2