Abstract

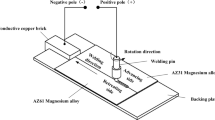

Friction Stir Welding (FSW) has great potential over fusion welding for joining dissimilar alloys. However, formation of intermetallic compounds (IMCs) Al12Mg17 and Al3Mg2 in FSW of Al/Mg alloys is almost unavoidable and problematic for the research community. Such IMCs in the form of continuous layer provide easy crack propagation path which increases brittleness and reduces the joint strength of the weld. To improve the material flow behavior and reducing brittleness, accurate and precise attempts were taken to join two dissimilar alloys i.e. Al 7075 and Mg AZ31 with the incorporation of cadmium interlayer first time. Tool rotational speed of 1300 rpm and traverse speed of 20 mm/min were maintained throughout the welding process. Various phase formation and their distribution in the nugget zone has been studied in details by using optical microscopy, SEM–EDS and XRD. The supersaturated solid solution (SSSS) of Mg in Al, and a thin layer of Al3Mg2 and small particles (~ 1 µm) of Al12Mg17 have been observed in the stir zone. During processing Cd reacted with Mg and formed CdMg and CdMg3 which have been distributed in the upper-middle portion of Mg region as intercalated lamellar structure. Formation of these compound provided micro-mechanical interlocking. Further, Al material has been found to be deposited into the Mg region in the form of elongated balloon which provided anchoring effect due to mechanical interlocking. The maximum tensile strength achieved is 129 MPa which is higher than the previously reported dissimilar FSW of Al 7xxx series alloy with Mg alloy. Fractographic study of the dissimilar FSW tensile sample was carried out to understand crack propagation path and scope for further improvement in the weld joint strength.

Graphic abstract

Similar content being viewed by others

References

J. Verma, R.V. Taiwade, S.G. Sapate, A.P. Patil, A.S. Dhoble, J. Mater. Eng. Perform. 26, 4738 (2017)

Z. Liu, S. Ji, X. Meng, J. Mater. Eng. Perform. 27, 1404 (2018)

R.S. Mishra, Z.Y. Ma, Mater. Sci. Eng. R Rep. 50, 1 (2005)

V.P. Singh, S.K. Patel, A. Ranjan, B. Kuriachen, J. Mater. Res. Technol. 9, 6217 (2020)

R.P. Mahto, S. Anishetty, A. Sarkar, O. Mypati, S.K. Pal, J.D. Majumdar, Met. Mater. Int. 25, 752 (2019)

D. Bernard, D.G. Hattingh, W.E. Goosen, M.N. James, High speed friction stir welding of 5182-H111 Alloy: Temperature and microstructural insights into deformation mechanisms. Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00622-y

A. Masoudian, A. Tahaei, A. Shakiba, F. Sharifianjazi, J.A. Mohandesi, T. Nonferr Metal. Soc. 24, 1317 (2014)

T. Rosendo, B. Parra, M.A.D. Tier, A.A.M. da Silva, J.F. dos Santos, T.R. Strohaecker, N.G. Alcantara, Mater. Design 32, 1094 (2011)

S.A. Khodir, T. Shibayanagi, Mater. Sci. Eng. B 148, 82 (2008)

N. Shanmuga Sundaram, N. Murugan, Mater. Design 31, 4184 (2010)

A. Razal Rose, K. Manisekar, V. Balasubramanian, T. Nonferr. Metal. Soc. 21, 974 (2011)

K. Singh, G. Singh, H. Singh, J. Magnes. Alloy. 6, 399 (2018)

A.S. Zoeram, S.H.M. Anijdan, H.R. Jafarian, T. Bhattacharjee, Mater. Sci. Eng. A 687, 288 (2017)

Y. Chen, Q. Ni, L. Ke, T. Nonferr. Metal. Soc. 22, 299 (2012)

M.-J. Hsieh, R.-T. Lee, Y.-C. Chiou, J. Mater. Process. Tech. 240, 118 (2017)

R. Ramesh, I. Dinaharan, R. Kumar, E.T. Akinlabi, Mater. Sci. Eng. A 687, 39 (2017)

A. Yazdipour, A. Heidarzadeh, J. Alloy. Compd. 680, 595 (2016)

Q. Zheng, X. Feng, Y. Shen, G. Huang, P. Zhao, J. Alloy. Compd. 686, 693 (2016)

A. Karimnejad, M. Ashjani, A. Heidarzadeh, T. Saeid, Structure modification of a rheocast aluminum–zinc alloy by friction stir butt welding: Microstructural evolution. Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00643-7

J. Yan, Z. Xu, Z. Li, L. Li, S. Yang, Scripta Mater. 53, 585 (2005)

A.H. Baghdadi, N.F.M. Selamat, Z. Sajuri, IOP Conf. Ser. Mat. Sci. 238, 012018 (2017)

S. Ji, Z. Li, L. Zhang, Z. Zhou, P. Chai, Mater. Design 103, 160 (2016)

S.A. Khodir, T. Shibayanagi, Mater. Trans. 48, 2501 (2007)

A.D. D’Souza, S.S. Rao, M.A. Herbert, Met. Mater. Int. 26, 1394 (2020)

S. Babu, K. Elangovan, V. Balasubramanian, M. Balasubramanian, Met. Mater. Int. 15, 321 (2009)

K.K. Mugada, K. Adepu, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00623-x

U. Suhuddin, V. Fischer, F. Kroeff, J.F. dos Santos, Mater. Sci. Eng. A 590, 384 (2014)

A. Kostka, R.S. Coelho, J.F. dos Santos, A.R. Pyzalla, Scripta Mater. 60, 953 (2009)

J. Mohammadi, Y. Behnamian, A. Mostafaei, H. Izadi, T. Saeid, A.H. Kokabi, A.P. Gerlich, Mater. Charact. 101, 189 (2015)

H. Shi, K. Chen, Z. Liang, F. Dong, T. Yu, X. Dong, L. Zhang, A. Shan, J. Mater. Sci. Technol. 33, 359 (2017)

Y. Zhao, Z. Lu, K. Yan, L. Huang, Mater. Design 65, 675 (2015)

Q. Wang, Z. Zhao, Y. Zhao, K. Yan, C. Liu, H. Zhang, Mater. Design 102, 91 (2016)

F. Heirani, A. Abbasi, M. Ardestani, J. Manuf. Process. 25, 77 (2017)

Y.B. Tan, X.M. Wang, M. Ma, J.X. Zhang, W.C. Liu, R.D. Fu, S. Xiang, Mater. Charact. 127, 41 (2017)

A. Abdollahzadeh, A. Shokuhfar, J.M. Cabrera, A.P. Zhilyaev, H. Omidvar, J. Mater. Process. Tech. 263, 296 (2019)

Z. Liu, X. Meng, S. Ji, Z. Li, L. Wang, J. Manuf. Process. 31, 552 (2018)

A. Abdollahzadeh, A. Shokuhfar, J.M. Cabrera, A.P. Zhilyaev, H. Omidvar, J. Manuf. Process. 34, 18 (2018)

P. Gao, Y. Zhang, K.P. Mehta, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00759-w

L.H. Shah, N.H. Othman, A. Gerlich, Sci. Technol. Weld. Joi. 23, 256 (2018)

D. Hernández-García, R. Saldaña-Garcés, F. García-Vázquez, E.J. Gutiérrez-Castañeda, R. Deaquino-Lara, D. Verdera, MRS Adv. 2, 4055 (2017)

D. Li, Z.-Q. Cui, Q.-X. Yang, B. Sun, M.-H. Sun, J. Shanghai Jiaotong Univ. (Sci.) 17, 679 (2012)

M. Tabasi, M. Farahani, M. K. Besharati Givi, M. Farzami, A. Moharami, Int. J. Adv. Manuf. Tech. 86, 705 (2016)

W. Guo, G. You, G. Yuan, X. Zhang, J. Alloy. Compd. 695, 3267 (2017)

S. Niu, S. Ji, D. Yan, X. Meng, X. Xiong, J. Mater. Process. Tech. 263, 82 (2019)

Z. Liang, G. Qin, P. Geng, F. Yang, X. Meng, J. Manuf. Process. 25, 153 (2017)

Z. Moser, W. Gasior, J. Wypartowicz, L. Zabdyr, The Cd-Mg (Cadmium-Magnesium) system. Bulletin of Alloy Phase Diagrams 5, 23 (1984). https://doi.org/10.1007/BF02868720

F. Liu, Y. Liu, Y. Wu, Sci. Technol. Weld. Joi. 22, 719 (2017)

R. Mola, A. Dziadoń, Arch. Foundry Eng. 8, 127 (2008)

Acknowledgement

The authors would like to thank Director NIT Raipur, India for providing necessary facilities, contingency grant and constant encouragement for publication of the research work. The authors would also like to thank Mr. V. K. Ingole (Technical staff, Department of Metallurgical and Materials Engineering, NIT Raipur) for his help in characterization of welded specimens.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dewangan, S.K., Tripathi, M.K. & Manoj, M.K. Material Flow Behavior and Mechanical Properties of Dissimilar Friction Stir Welded Al 7075 and Mg AZ31 Alloys Using Cd Interlayer. Met. Mater. Int. 28, 1169–1183 (2022). https://doi.org/10.1007/s12540-021-00980-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-00980-1