Abstract

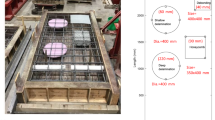

An automated system with two optimized modular devices is presented—MULTITEST-MC010 for research of ferromagnetic materials with the methods for measuring magnetic noise and magneto acoustic emission of Barkhausen and MULTITEST—CD010 for research of mechanical engineering materials with the methods of velocity measurement of longitudinal waves C and attenuation coefficient δ of ultrasound. The main approaches and principles for the automated data processing of complex non-destructive testing are presented, as well as the setup of the modular devices of the automated system. For approbation of the system the influence of the heat treatment (hardness) in structural steel 40X on the non-destructive information parameters of the magnetic noise and the magneto acoustic emission—magnetic noise voltage EBN and voltage of the magneto acoustic emission EMAE was studied. The mechanical properties in foundry cast iron samples with complex measurement of the information parameters EBN, EMAE C, by simultaneous use of the two modular devices of the system were also studied. The possibility for the complex application of these parameters for non-destructive testing of the mechanical properties after heat treatment in structural steel 40X and the tensile strength in cast iron specimens has been proven.

Similar content being viewed by others

REFERENCES

Afifi, A., and Azen, S., Statistical Analysis. A Computer oriented Approach, New York: Academic Press, 1982.

Shibata, M., and Ono, K., Magneto mechanical acoustic emission – A new method for non-destructive stress measurement, Int. Conf. NDT, London, 1981.

Velev, G., Georgiev, G., and Dimitrov, D., Patent RB N 85497, 2019.

Velev, G., and Latkovski, V., A method of ultrasonic study of materials, Tech. Acoust., 2003, vol. 3.

Velev, G., Latkovski, V., and Mitutsova, L., Non-destructive analysis of ferromagnetic materials by means of Barkhäusen effect methods, Slov. Akad. Dubnica, 2004, pp. 635–638.

Gorkunov, E., Subachev, Yu., Povolotskaya, A., and Zadvorkin, S. M., The influence of elastic deformations on the hysteresis properties of a two-layer ferromagnet composed of components with magnetostrictions of opposite signs, Russ. J. Nondestr. Test., 2014, vol. 50, no. 8, pp. 469–480.

Kostin, V., Vasilenko, O., Filatenkov, D., Chekasina, Yu., and Serbin, E., Magnetic and magnetoacoustic testing parameters of the stressed–strained state of carbon steels that were subjected to a cold plastic deformation and annealing, Russ. J. Nondestr. Test., 2015, vol. 51, No. 8, pp. 624–632.

Dzudzev, B., Angelov, V., Zlatkov, M., and Kostadinov, P., Testing of automatized system for complex non-destructive study of metallic materials, Mach. Technol. Mater., 2019, no. 6, pp. 273–276.

Ivanova, Y., Non-destructive monitoring of tensile of mild steel samples by magnetic Barkhäusen and ultrasonic methods, MATEC Web Conf., 2018, vol. 145, article ID 05007. https://doi.org/10.1051/matecconf/201814505007

Ronggao, C., Li, Sh., Wang, Z., and Wang, X., A modified residual stress dependent Jile–Atherton hysteresis model, J. Magn. Magn. Mater., 2018, vol. 465, pp. 578–584.

Gorkunov, E., Povolotskaya, A., Zadvorkin, S., Putilova, E., Mushnikov, A., Bazulin, E., and Vopilkin, A., Some features in the behavior of magnetic and acoustic characteristics of hot-rolled 08G2B steel under cyclic loading, Russ. J. Nondestr. Test., 2019, vol. 55, pp. 827–836.

Rabung, M., Amiri, M., Becker, M., Kopp, M., Tschuncky, R., Veile, I., Weber, F., Weikert-Müller, M., and Szielasko, K., Nondestructive Characterization of Residual Stress Using Micromagnetic and Ultrasonic Techniques, in New Challenges in Residual Stress Measurements and Evaluation, Casavola, C., Ed., London: IntechOpen, 2020.https://doi.org/10.5772/intechopen.90740

Funding

This work was implemented under project M27/7 from 2018, funded by the Research Fund of the Ministry of Education and Science.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Velev, B.G., Ivanov, I.S. & Kamenov, V.V. Automated System for Complex Non-Destructive Testing of the Structure and Mechanical Properties of Mechanical Engineering Materials. Russ J Nondestruct Test 57, 203–211 (2021). https://doi.org/10.1134/S1061830921030074

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830921030074