Abstract

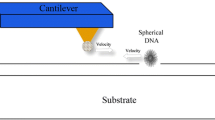

Bio-particles are usually considered as an elastic material, while it has been proven that these particles such as viruses and cells behave more like viscoelastic materials because of the liquid cytoplasm in cells and also the protein capsid around viruses; thus, this property is not ignorable because it leads to a non-precise prediction in simulations. On the other hand, the surface of these particles is usually considered smooth, while the topography shows asperities on them. In this paper, the viscoelastic contact model along with the asperities’ distribution of the bio-particles is considered near reality. Simulation results reveal that the prediction of the viscoelastic contact models is more precise and closer to the experimental data than the elastic state. Using experimental results and applying their effect, asperities’ radii are obtained and comparison shows that the rough viscoelastic theory is more accurate and closer to the experimental data in comparison with viscoelastic models without asperity. The simulation of the first phase of the manipulation, applying three states of the elastic, the viscoelastic, and the rough viscoelastic in addition to a comparison with similar modes, shows that in the particle’s sliding on the substrate, tip sliding on the particle, and the particle rolling modes, the critical force has the highest magnitudes in the rough viscoelastic, the elastic, and the viscoelastic, respectively. However, results for the critical time are different, i.e., the highest critical times are related to the elastic, the viscoelastic, and the rough viscoelastic states, respectively.

Similar content being viewed by others

Notes

Johnson, Kendall, and Roberts.

B. V. Derjaguin, V. M. Muller and Yu. P. Toporov.

Scientific Information Database.

Dulbecco’s Modified Eagle’s Medium.

Phosphate Buffered Saline.

Fetal Bovine Serum.

Root Mean Square.

Abbreviations

- \(\alpha\) :

-

Radius of contact

- \(E\) :

-

Young’s modulus

- \(\nu\) :

-

Poison’s ratio

- \(R\) :

-

Effective radius

- \(E^{*}\) :

-

Effective elastic modules

- \(C\left( t \right)\) :

-

Total creep function

- \(p\) :

-

Pressure on the contact’s surface

- \(dA\) :

-

An element of the area

- \(dw\) :

-

Displacement of the points

- \(\rho\) :

-

Distance between points

- \(\tau\) :

-

Time variation

- \(\delta\) :

-

Indentation depth

- \(F\) :

-

Force

- \(\omega\) :

-

Adhesion energy

- \(\phi \left( \xi \right)\) :

-

Distribution function

- \(\sigma\) :

-

Standard deviation in the distribution function

- \(\mu\) :

-

Average of asperities’ height in the distribution function

- \(R_{{\text{p}}}\) :

-

Particle’s radius

- \(R_{{\text{t}}}\) :

-

Tip’s radius

References

Perotti, L.E., Dharmavaram, S., Klug, W.S., Marian, J., Rudnick, J., Bruinsma, R.F.: Useful scars: physics of the capsids of archaeal viruses. Phys. Rev. E (2016). https://doi.org/10.1103/PhysRevE.94.012404

Yang, W.: The contact problem for viscoelastic bodies (1966). Accessed 30 Jan 2021. [Online]

Barthel, E.: Adhesive elastic contacts: JKR and more. J. Phys. D Appl. Phys. (2008). https://doi.org/10.1088/0022-3727/41/16/163001

Kendall, K.: Surface energy and the contact of elastic solids. Proc. R. Soc. Lond. A 324(1558), 301–313 (1971). https://doi.org/10.1098/rspa.1971.0141

Hui, C.Y., Baney, J.M., Kramer, E.J.: Contact mechanics and adhesion of viscoelastic spheres. Langmuir 14(22), 6570–6578 (1998). https://doi.org/10.1021/la980273w

Zhai, M., McKenna, G.B.: Viscoelastic modeling of nanoindentation experiments: a multicurve method. J. Polym. Sci. Part B Polym. Phys. 52(9), 633–639 (2014). https://doi.org/10.1002/polb.23470

Rabinovich, Y.I., Adler. J.J., Ata, A., Singh, R.K., Moudgil, B.M.: Adhesion Between Nanoscale Rough Surfaces: I. Role of Asperity Geometry. Elsevier (2000). Accessed 30 Jan 2021

Meine, K., Kloß, K., Schneider, T., Spaltmann, D.: The influence of surface roughness on the adhesion force. Surf. Interface Anal. 36(8), 694–697 (2004). https://doi.org/10.1002/sia.1738

Greenwood, J.A., Williamson, J.B.P.: Contact of nominally flat surfaces. Proc. R. Sot. Lond. 5(1442), 300–319 (1967)

Prokopovich, P., Starov, V.: Adhesion Models: From Single to Multiple Asperity Contacts. Elsevier, Amsterdam (2011). https://doi.org/10.1016/j.cis.2011.03.004

Prokopovich, P., Perni, S.: Multiasperity contact adhesion model for universal asperity height and radius of curvature distributions. Langmuir 26(22), 17028–17036 (2010). https://doi.org/10.1021/la102208y

Li, Q., Rudolph, V., Peukert, W.: London-van der Waals Adhesiveness of Rough Particles. Elsevier (2006). Accessed 30 Jan 2021. [Online]

Particle Technology no. (1971). https://doi.org/10.1002/0471238961.partpark.a01.pub2

Hui, C.Y., Lin, Y.Y., Baney, J.M.: Mechanics of tack: viscoelastic contact on a rough surface. J. Polym. Sci. Part B Polym. Phys. 38(11), 1485–1495 (2000). https://doi.org/10.1002/(SICI)1099-0488(20000601)38:11%3c1485::AID-POLB80%3e3.0.CO;2-1

Tiwari, A., et al.: The effect of surface roughness and viscoelasticity on rubber adhesion. Soft Matter 13(19), 3602–3621 (2017). https://doi.org/10.1039/c7sm00177k

Hodges, C.S., Looi, L., Cleaver, J.A.S., Ghadiri, M.: Use of the JKR model for calculating adhesion between rough surfaces. Langmuir 20(22), 9571–9576 (2004). https://doi.org/10.1021/la035790f

Motaghi, A., Korayem, M.H., Zakeri, M.: Dynamic modeling of 2D nano-manipulation based on AFM in liquid environment.In: 2010 17th Iranian Conference of Biomedical Engineering (ICBME) (2010) [Online]. https://ieeexplore.ieee.org/abstract/document/5705009/. Accessed 30 Jan 2021

Korayem, M.H., Saraee, M.B., Mahmoodi, Z., Dehghani, S.: Modeling and simulation of three dimensional manipulations of biological micro/nanoparticles by applying cylindrical contact mechanics models by means of AFM. J. Nanoparticle Res. 17(11), 1–17 (2015). https://doi.org/10.1007/s11051-015-3240-x

Korayem, M.H., Mirmohammad, S.A., Saraee, M.B.: Investigating the effect of surface roughness on the critical sliding and rolling forces of cylindrical nanoparticles based on the multi-asperity contact models. Appl. Phys. A Mater. Sci. Process. 120(4), 1511–1528 (2015). https://doi.org/10.1007/s00339-015-9348-0

Saraee, M.B., Korayem, M.H.: Dynamic Modeling and Simulation of 3D Manipulation on Rough Surfaces Based on Developed Adhesion Models. Springer (2017). Accessed 30 Jan 2021

Korayem, M.H., Rastegar, Z., Taheri, M., Rastegar, Z., Taheri, M.: Application of Johnson–Kendall–Roberts model in nanomanipulation of biological cell: air and liquid. IET 7(6), 576–580 (2012). https://doi.org/10.1049/mnl.2012.0292

Gascoyne, P.R.C., Shim, S.: Isolation of circulating tumor cells by dielectrophoresis. Cancers (Basel) 6(1), 545–579 (2014). https://doi.org/10.3390/cancers6010545

Korayem, M.H., Mahmoodi, Z., Taheri, M., Saraee, M.B.: Three-dimensional modeling and simulation of the AFM-based manipulation of spherical biological micro/nanoparticles with the consideration of contact mechanics theories. Proc. Inst. Mech. Eng. Part K J. Multi-body Dyn. 229(4), 370–382 (2015). https://doi.org/10.1177/1464419314567551

Geltmeier, A., et al.: Characterization of dynamic behaviour of MCF7 and MCF10A cells in ultrasonic field using modal and harmonic analyses. PLoS ONE (2015). https://doi.org/10.1371/journal.pone.0134999

Dimitriadis, E.K., Horkay, F., Maresca, J., Kachar, B., Chadwick, R.S.: Determination of Elastic Moduli of Thin Layers of Soft Material Using the Atomic Force Microscope. Elsevier (2002). Accessed 30 Jan 2021. [Online]. https://www.sciencedirect.com/science/article/pii/S0006349502756208

Korayem, M.H., Hoshiar, A.K.” Dynamic 3D modeling and simulation of nanoparticles manipulation using an AFM nanorobot. search.proquest.com, Accessed 30 Jan 2021s

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Korayem, M.H., Mozafari, M., Sooha, Y.H. et al. Development and application of rough viscoelastic contact models in the first phase of 3D manipulation for biological micro-/nanoparticles by AFM. Arch Appl Mech 91, 3739–3753 (2021). https://doi.org/10.1007/s00419-021-01967-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-021-01967-5