Abstract

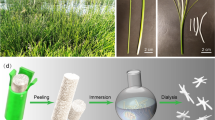

The replacement of synthetic foam materials using natural biological ones is of great significance for saving energy/resources and reducing environmental pollutions. Here we characterized the microstructure and mechanical properties of natural cornstalk pith, which has a large annual output yet lacks an effective exploitation, and evaluated its feasibility for applications as a substitute for synthetic foam materials. The cornstalk pith was revealed to be a cellular material composed of closed cells elongated along the growth direction of corn plant and reinforced by well-aligned vascular bundles penetrating the foam matrix. The compressive behavior is featured by a stable stress plateau which is favorable for energy absorption with its mechanical properties largely dependent on the hydration state and loading configuration. In particular, the initial dimension and mechanical properties of cornstalk pith can be effectively recovered after deformation simply by hydration treatment owing to swelling effect caused by the turgor pressure from osmosis. The cornstalk pith demonstrates an outstanding combination of low density and high energy absorption efficiency among various foam materials, specifically with its plateau stress and energy absorption comparable or even superior to those of some typical synthetic foam materials. These along with the huge resources and good biodegradability make it a promising natural energy absorbing cellular material for replacing synthetic counterparts.

Similar content being viewed by others

References

Gibson L J, Ashby M F. Celluar Solids: Structure and Properties. Cambridge University Press, Cambridge, UK, 1999, 1, 2–99.

Ashby M F, Mehl Medalist R F. The mechanical properties of cellular solids. Metallurgical Transactions A, 1983, 14, 1755–1769.

Gautam R, Bassi A S, Yanful E K. A review of biodegradation of synthetic plastic and foams. Applied Biochemistry and Biotechnology, 2007, 141, 85–108.

Free C M, Jensen O P, Mason S A, Eriksen M, Williamson N J, Boldgiv B. High-levels of microplastic pollution in a large, remote, mountain lake. Marine Pollution Bulletin, 2014, 85, 156–163.

Agrawal A, Kaur R, Walia R S. PU foam derived from renewable sources: Perspective on properties enhancement: An overview. European Polymer Journal, 2017, 95, 255–274.

Webb H K, Arnott J, Crawford R J, Ivanova E P. Plastic degradation and its environmental implications with special reference to poly (ethylene terephthalate). Polymers, 2012, 5, 5010001.

Yang W Q, Dong Q Y, Liu S L, Xie H H, Liu L L, Li J H. Recycling and disposal methods for polyurethane foam wastes. Procedia Environmental Sciences, 2012, 16, 167–175.

Al-Salem S M, Lettieri P, Baeyens J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Management, 2009, 29, 2625–2643.

Fratzl P, Weinkamer R. Nature’s hierarchical materials. Progress in Materials Science, 2007, 52, 1263–1334.

Gibson L J, Ashby M F, Harley B A. Cellular Materials in Nature and Medicine. Cambridge University Press, Cambridge, UK, 2010, 1, 8–12.

Sullivan T N, Pissarenko A, Herrere S A, Kisailus D, Lubarda V A, Meyers M A. A lightweight, biological structure with tailored stiffness: The feather vane. Acta Biomaterialia, 2016, 41, 27–39.

Wang Z, Tan Y T, Yang Y L, Zhao X N, Liu Y, Niu L Y, Tichnell B, Kong L B, Kang L, Liu Z, Ran F. Pomelo peels-derived porous activated carbon microsheets dual-doped with nitrogen and phosphorus for high performance electrochemical capacitors. Journal of Power Sources, 2017, 378, 499–510.

Li H Z, Li X D. The art of curved reinforcing in biological armors — seashells. Journal of Bionic Engineering, 2019, 16, 711–718.

Chen P Y, McKittrick J, Meyers M A. Biological materials: Functional adaptations and bioinspired designs. Progress in Materials Science, 2012, 57, 1492–1704.

Meyers M A, McKittrick J, Chen P Y. Structural biological materials: Critical mechanics-materials connections. Science, 2013, 339, 773–779.

Liu Z Q, Zhang Z F, Ritchie R O. Structural orientation and anisotropy in biological materials: Functional designs and mechanics. Advance Functional Materials, 2020, 30, 1908121.

Wegst U G K, Bai H, Saiz E, Tomsia A P, Ritchie R O. Bioinspired structural materials. Nature Materials, 2015, 14, 23–26.

Zhang Y C, Huang W, Hayashi C, Gatesy J, McKittrick J. Microstructure and mechanical properties of different keratinous horns. Journal of the Royal Society Interface, 2018, 15, 20180093.

Huang W, Zahera A, Jung J Y, Espinosa H D, Mckittrick J. Hierarchical structure and compressive deformation mechanisms of bighorn sheep (Ovis canadensis) horn. Acta Biomaterialia, 2017, 64, 1–14.

Weinkamer R, Fratzl P. Mechanical adaptation of biological materials: The examples of bone and wood. Materials Science and Engineering: C, 2011, 31, 1164–1173.

Emadian S M, Onay T T, Demirel B. Biodegradation of bioplastics in natural environments. Waste Management, 2017, 59, 526–536.

Ma C, Zhang S, Dong R D, Wang M, Jia W D, Lu Z G. Corn stalk fiber-based biomass brick reinforced by compact organic inorganic calcification composites. ACS Sustainable Chemistry & Engineering, 2018, 6, 2086–2093.

Jiang D P, Ge X M, Lin L, Zhang T, Liu H, Hu J J, Zhang Q G. Continuous photo-fermentative hydrogen production in a tubular photobioreactor using corn stalk pith hydrolysate with a consortium. International Journal of Hydrogen Energy, 2020, 45, 3776–3784.

Liu Y C, Xie J, Wu N, Ma Y H, Menon C, Tong J. Characterization of natural cellulose fiber from corn stalk waste subject to different surface treatments. Cellulose, 2019, 26, 4707–4719.

Chen J X, Elbashiry E M A, Yu T, Ren Y Z, Guo Z S, Liu S Y. Research progress of wheat straw and rice straw cement-based building materials in China. Magazine of Concrete Research, 2018, 70, 84–95.

Yu Y, Ren Y Z, Guo Z S, Chen X, Chen J X, Elbashiry E M A. Progress of research into cotton straw and corn straw cement-based building materials in China. Advances in Cement Research, 2018, 30, 93–102.

Chen J X, Zhang X M, Okabe Y, Saito K, Guo Z S, Pan L C. The deformation mode and strengthening mechanism of compression in the beetle elytron plate. Materials and Design, 2017, 131, 481–486.

Chen J X, Zhang X M, Okabe Y, Xie J, Xu M Y. Beetle elytron plate and the synergistic mechanism of a trabecular honeycomb core structure. Science China Technological Sciences, 2019, 62, 87–93.

Chen J X, Hao N, Pan L C, Hu L P, Du S C, Fu Y Q. Characteristics of compressive mechanical properties and strengthening mechanism of grid beetle elytron plates. Journal of Materials Science, 2020, 55, 8541–8552.

Sadighi Mojtaba, Salami S J. An investigation on low-velocity impact response of elastomeric & crushable foams. Central European Journal of Engineering, 2012, 2, 627–637.

Yonezu A, Hirayama K, Kishida H, Chen X. Characterization of the compressive deformation behavior with strain rate effect of low-density polymeric foams. Polymer Testing, 2016, 50, 1–8.

Li Y, Ren H F, Ragauskas A J. Rigid polyurethane foam reinforced with cellulose whiskers: Synthesis and characterization. Nano Micro Letters, 2010, 2, 89–94.

Wang B Q, Peng Z L, Zhang Y, Zhang Y X. Compressive response and energy absorption of foam EPDM. Journal of Applied Polymer Science, 2007, 105, 3462–3469.

Tondi G, Pizzi A, Du G, Fierro V, Celzard A. Tannin-based rigid foams: A survey of chemical and physical properties. Bioresource Technology, 2009, 100, 5162–5169.

Ozturk U E, Anlas G. Energy absorption calculations in multiple compressive loading of polymeric foams. Materials & Design, 2009, 30, 15–22.

Maiti S K, Gibson L J, Ashby M F. Deformation and energy absorption diagram for cellular solids. Acta Metallurgica, 1984, 32, 1963–1975.

Liu Z Q, Jiao D, Meyers M A, Zhang Z F. Structure and mechanical properties of naturally occurring lightweight foam-filled cylinder — the peacock’s tail coverts shaft and its components. Acta Biomaterialia, 2015, 15, 137–151.

Zhang X X, Li J H, Yu Z X, Yu Y, Wang H K. Compressive failure mechanism and buckling analysis of the graded hierarchical bamboo structure. Journal of Materials Science, 2017, 52, 6999–7007.

Huang W, Restrepo D, Zavattieri P, Jung J Y, Su F Y, Liu Z Q, Ritchie R O, McKittrick J, Kisailun D. Mustiscale toughening mechanisms in biological materials and bioinspried designs. Advanced Materials, 2019, 31, 1901561.

Sullivan T N, Zhang Y L, Zavattieri P D, Meyers M A. Hydration-induced shape and strength recovery of the feather. Advanced Functional Materials, 2018, 28, 1801250.

Quan H C, Kisailus D, Meyers M A. Hydration-induced reversible deformation of biological materials. Nature Reviews Matetials, 2021, 6, 264–283.

Liu Z Q, Jiao D, Zhang Z F. Remarkable shape memory effect of a natural biopolymer in aqueous environment. Biomaterials, 2015, 65, 13–21.

Beverte I. Deformation of polypropylene foam Neopolen® P in compression. Journal of Cellular Plastics, 2004, 40, 191–204.

Zhang G Q, Wang B, Ma L, Wu L Z, Pan S D, Yang J S. Energy absorption and low velocity impact response of polyurethane foam filled pyramidal lattice core sandwich panels. Composite Structures, 2014, 108, 304–310.

Ouellet S, Cronin D, Worswick M. Compressive response of polymeric foams under quasi-static, medium and high strain rate conditions. Polymer Testing, 2006, 25, 731–743.

Luong D D, Pinisetty D, Gupta N. Compressive properties of closed-cell polyvinyl chloride foams at low and high strain rates: Experimental investigation and critical review of state of the art. Composites Part B: Engineering, 2013, 44, 403–416.

Gibson L J. The mechanical behaviour of cancellous bone. Journal of Biomechanics, 1985, 18, 317–328.

Chen Y X, Zhang K T, Yuan F C, Zhang T T, Weng B B, Wu S S, Huang A Y, Su N, Guo Y. Properties of two-variety natural luffa sponge columns as potential mattress filling materials. Materials, 2018, 11, 541.

Trim M W, Horstemeyer M F, Rhee H, Kadiri H E, Williams L N, Liao J, Walters K B, McKittrick J, Park S J. The effects of water and microstructure on the mechanical properties of bighorn sheep (Ovis canadensis) horn keratin. Acta Biomaterialia, 2011, 7, 1228–1240.

Zhang Y C, Huang W, Hayashi C, Gatesy J, McKittrick J. Microstructure and mechanical properties of different keratinous horns. Journal of the Royal Society Interface, 2018, 15, 20180093.

Avalle M, Belingardi G, Montanini R. Characterization of polymeric structural foams under compressive impact loading by means of energy-absorption diagram. International Journal of Impact Engineering, 2001, 25, 455–472.

Liu Z Q, Weng Z Y, Zhai Z, Huang N, Zhang Z J, Tan J, Jiang C B, Jiao D, Tan G Q, Zhang J, Jiang X, Zhang Z F, Ritchie R O. Hydration-induced nano- to micro-scale self-recovery of the tooth enamel of the giant panda. Acta Biomaterialia, 2018, 81, 267–277.

Liu Z Q, Jiao D, Weng Z Y, Zhang Z F. Structure and mechanical behaviors of protective armored pangolin scales and effects of hydration and orientation. Journal of the Mechanical Behavior of Biomedical Materials, 2016, 56, 165–174.

Zhu D J, Zhang C H, Liu P, Jawad A L. Comparison of the morphology, structures and mechanical properties of teleost fish scales collected from New Zealand. Journal of Bionic Engineering, 2019, 16, 328–336.

Acknowledgment

The authors are grateful for the financial support by National Key R&D Program of China under Grant Number 2020YFA0710404, the National Natural Science Foundation of China under grant number 51871216, the LiaoNing Revitalization Talents Program, the State Key Laboratory for Modification of Chemical Fibers and Polymer Materials at Donghua University, the Opening Project of Jiangsu Province Key Laboratory of High-End Structural Materials under grant number hsm1801, the Lu Jiaxi International Team Program supported by the K.C. Wong Education Foundation and CAS, and the Youth Innovation Promotion Association CAS.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, L., Liu, Z., Jiao, D. et al. Natural Cornstalk Pith as an Effective Energy Absorbing Cellular Material. J Bionic Eng 18, 600–610 (2021). https://doi.org/10.1007/s42235-021-0045-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-021-0045-8