Abstract

Micro-seismic events within a mine have the potential to disturb planned daily operations as unpredictable events can lead to safety concerns. Mines are typically large-scale underground endeavours which cannot easily be modelled on the macro scale. One increasingly popular technique for simulating activity in mines is the material point method (MPM) which is a numerical algorithm designed for analysing large deformations. One attraction of the MPM over many other numerical strategies is that it does not require repeated remeshing of the underlying computational grid but this means that the MPM is not particularly suited to analysis of small-scale events. In an effort to address this dichotomy, in this work we propose an adaptation to the regular grid used in MPM together with a novel time-stepping strategy. This assists greatly in the solution of large modeling problems typical of those arising in mining contexts. We present a new approach of extracting mining induced micro-seismic events from a numerical model by converting simulated plastic strain to seismic potency with the elastoplastic Coulomb criterion used to describe tensile and shear fracturing. Our results are benchmarked against a standard geotechnical problem in order to validate our formulation. The potential practical usefulness of the model is demonstrated by applying it to a real case study consisting of 4 months of recorded micro-seismic events taken from a mine in Tasmania.

Similar content being viewed by others

Availability of Data and Material

Mine seismic data is the property of the mine and will not be shared.

Code Availability

Not applicable.

Abbreviations

- L :

-

Three-dimensional grid cell length

- \(L_i\) :

-

Level i grid cell size

- t :

-

Time

- \(\Delta {t}\) :

-

Time step

- \(S_l\) :

-

Shape functions used to interpolate values between MPM particles and grid nodes

- \(G_l\) :

-

Derivatives of shape functions \(S_i\)

- \(C_L\) :

-

A list of sorted grid cells ranging from \(L_n\) to \(L_0\)

- \(m_l\) :

-

Mass of node l

- \(\mathbf{v} _l\) :

-

Velocity of node l

- \(\mathbf{v} _p\) :

-

Velocity of particle p

- \(\mathbf{f} _l\) :

-

Force acting on node l

- \(\sigma _p\) :

-

Stress of particle p

- \(\sigma _\mathrm{{r}}\) :

-

Radial stress

- \(\sigma _\theta\) :

-

Tangential stress

- \(\sigma _\infty\) :

-

Uniform applied stress in Kirces test

- d :

-

Radius of opening in Kirches test

- \(V_p\) :

-

Particle volume l

- \(\mathbf{b}\) :

-

External body forces acting on a particle

- \(m_p\) :

-

Mass of particle p

- \(\mathbf{a} _p\) :

-

Acceleration of node l

- \(\mathbf{f} _\mathrm{{d}}\) :

-

Damping force to remove energy from the MPM system

- \(\mathbf{x} _p\) :

-

Position of particle p

- \(\dot{\varepsilon }_{p}\) :

-

Strain increment of particle p

- \(\Delta \sigma {_p}^\mathrm{{p}}\) :

-

Stress drop of particle p due to constitutive relation

- P :

-

Seismic potency

- \(\bar{u}\) :

-

Average slip calculated over seismic source area

- \(A_\mathrm{{s}}\) :

-

Seismic source area

- \(P_\mathrm{{s}}\) :

-

Seismic potency of a single dislocation seismic source

- \(\Delta \varepsilon\) :

-

Strain change

- \(\Delta \sigma\) :

-

Stress change

- \(\mu\) :

-

Rigidity of rock mass

- \(V_\mathrm{{s}}\) :

-

Seismic source volume

- \(\Delta \varepsilon ^\mathrm{{p}}\) :

-

Plastic strain change

- V :

-

Volume

- \(\sigma _1\) :

-

Major principal stress

- \(\sigma _2\) :

-

Intermediate principal stress

- \(\sigma _3\) :

-

Minor principal stress

- \(P^\mathrm{{T}}\) :

-

Total potency of a group of failed particles

- \(P_{ij}\) :

-

Major principal stress

- \(\Delta \varepsilon ^\mathrm{{p}}_{ij}\) :

-

Tensor of plastic strain change

- \(X_{ij}\) :

-

Arbitrary tensor in closeness test

- \(Y_{ij}\) :

-

Arbitrary tensor in closeness test

- D :

-

Mine datum (depth from surface)

- \(\alpha\) :

-

A constant scaling factor ranging between 0 and 1 to account for a proportion of aseismic potency

- b :

-

Power-law exponent in Gutenberg–Richter law

- a :

-

A constant in the Gutenberg–Richter law

- N :

-

Number of events in Gutenberg–Richter law

References

Al-Kafaji I (2013) Formulation of a dynamic material point method (MPM) for geomechanical problems. Ph.D. thesis, University of Stuttgart. https://doi.org/10.18419/opus-496

Anderson L, Anderson SM (2007) Material-point method analysis of bending in elastic beams. In: The eleventh international conference on civil, structural and environmental engineering computing, vol 1. Aalborg University, pp 1–30

Bardenhagen S, Kober E (2004) The generalized interpolation material point method. Comput Model Eng Sci 5(6):477–495

Brebbia C (1973) The boundary element method for engineers. Pentech Press Limited, London

Cundall P (2009) FLAC 3D user guide, 2009, 1st edn. ITASCA

Davis S, Frolich C (1991) Single-link cluster analysis, synthetic earthquake catalogues, and aftershock identification. Geophys J Int 104(2):289–306

Ester M, Kriegel HP, Sander J, Xu X (1996) A density-based algorithm for discovering clusters a density-based algorithm for discovering clusters in large spatial databases with noise. In: Proceedings of the second international conference on knowledge discovery and data mining, AAAI Press, KDD’96, pp 226–231. http://dl.acm.org/citation.cfm?id=3001460.3001507

Fairhurst C (1964) On the validity of the ‘Brazilian’ test for brittle materials. Int J Rock Mech Min Sci Geomech Abstr 1(4):535–546

Gao M (2017) An adaptive generalized interpolation material point method for simulating elastoplastic materials. ACM Trans Graph (TOG) 36(6):1–12

Hamad F (2014) Formulation of a dynamic material point method and applications to soil-water-geotextile systems. Ph.D. thesis, University of Stuttgart

Hughes T (1987) The finite element method: linear static and dynamic finite element analysis, vol 1. Prentice Hall, New Jersey

Itasca (2019) Fast Lagrangian analysis of continua. https://www.itascacg.com/software/FLAC. Accessed Feb 2021

Itasca (2021) Distinct element modelling of joint or blocky material. https://www.itascacg.com/software/3DEC. Accessed Feb 2021

Lian Y, Zhang X, Zhang F, Cui X (2014) Tied interface grid material point method for problems with localized extreme deformation. Int J Impact Eng 70(1):50–61

Lian Y, Zhang X, Zhang F, Cui X, Huang Y (2015) A mesh-grading material point method and its parallelization for problems with localized extreme deformation. Comput Methods Appl Math Eng 289(1):291–315

Liao Z, Zhu J, Tang C (2019) Numerical investigation of rock tensile strength determined by direct tension, Brazilian and three-point bending tests. Int J Rock Mech Min Sci 115(1):21–32

Linkov A (2005) Numerical modeling of seismic and aseismic events in geomechanics. J Min Sci 41(1):14–26

MacQueen J (1967) Some methods for classification and analysis of multivariate observations. In: Proceedings of the fifth Berkeley symposium on mathematical statistics and probability. Statistics, vol 1. University of California Press, Berkeley, California, pp 281–297. https://projecteuclid.org/euclid.bsmsp/1200512992. Accessed Feb 2021

Madariaga R (1979) On the relation between seismic moment and stress drop in the presence of stress and strength heterogeneity. J Geophys Res 84(B5):2243–2250

Malovichko D, Basson G (2014) Simulation of mining induced seismicity using Salamon–Linkov method. In: Hudyma M, Potvin Y (eds) Proceedings of the seventh international conference on deep and high stress mining, Australian Centre for Geomechanics, Perth

Mendecki A (2016) Mine seismology reference book: seismic hazard, 1st edn. Institute of Mine Seismology. ISBN 978-0-9942943-0-2

Michael A (1984) Determination of stress from slip data: faults and folds. J Geophys Res 90(B13):11517–11526

Michael A (1987) Use of focal mechanisms to determine stress: a control study. J Geophys Res 92(B1):357–368

Nairn J (2003) Material point method calculations with explicit cracks. Comput Model Eng Sci 4(6):649–663

Pantev I (2016) Contact modelling in the material point method. MSc Thesis. Delft University of Technology, Geoscience & Engineering

Ryder J, Jager A (2002) A textbook on rock mechanics for tabular hard rock mines. Safety in Mines Research Advisory Committee (SIMRAC), Johannesburg, p 489

Salamon M (1993) Keynote address: Some applications of geomechanical modelling in rockburst and related research. In: Young BP (ed) 3rd international symposium on rockbursts and seismicity in mines. Rotterdam, pp 297–309

Simulia (2019) Abaqus finite element analysis. http://www.3ds.com. Accessed Feb 2021

Steffen M, Wallstedt P, Guilkey J, Kirby R, Berzins M (2008) Examination and analysis of implementation choices within the material point method. Comput Model Eng Sci 31(2):107–127

Sulsky D, Chen Z, Scheyer H (1994) A particle method for history-dependent materials. Comput Methods Appl Mech Eng 118(1):179–196

Wang B, Vardon P, Hicks M, Chen Z (2015) Development of an implicit material point method for geotechnical applications. Comput Geotech 71:159–167

Wei J, Zhu W, Guan K, Zhou J, Song J (2019) An acoustic emission data-driven model to simulate rock failure process. Rock Mech Rock Eng 53:1605–1621

Acknowledgements

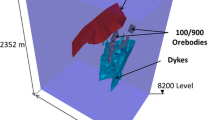

We are indebted to Kevin Stacey from Renison Bell mine for allowing us to use and show the mine data. We are also grateful to the referees whose numerous suggestions led to substantial improvements to this paper. We are indebted to the editors for their guidance and advice.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by GB. The first draft of the manuscript was written by GB and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Basson, G., Bassom, A.P. & Salmon, B. Simulating Mining-Induced Seismicity Using the Material Point Method. Rock Mech Rock Eng 54, 4483–4503 (2021). https://doi.org/10.1007/s00603-021-02522-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-021-02522-y