Abstract

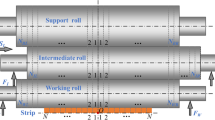

In the routine roll shifting mode, work rolls of the continuous variable crown (CVC) hot strip mill are always in repeated shifting positions, which affects the uniform wear of work rolls. As an available solution to the above problem, a new random shifting mode for CVC work rolls has been developed in this paper. According to the relationship between shifting position and bending force, the new CVC shifting mode shifts work rolls in a random pattern within the limits by randomly changing the bending force, so that the roll shifting is dispersed and the strip shape remains good. The Light Gradient Boosting Machine (LightGBM) algorithm is applied to build the prediction models of CVC shifting to accurately express the relationship between shifting position and bending force. Random search and Bayesian optimization are used to optimize the LightGBM models, respectively. By comparison, LightGBM with Bayesian optimization is recommended to predict roll shifting, which is more accurate and efficient than using random search. The new CVC shifting mode has been implemented by an off-line application in the 1780 mm hot rolling line. The results reveal that the proposed CVC shifting mode can well disperse roll shifting positions and accurately control strip shape.

Similar content being viewed by others

Data availability

My manuscript has no associated data in data repositories and the data was collected from a 1780 mm hot steel strip rolling line in China and will not be deposited in a repository.

Code availability

The calculation program was self-coded and run on JetBrains PyCharm Community Edition 2019.1 x64.

Change history

13 July 2021

A Correction to this paper has been published: https://doi.org/10.1007/s00170-021-07508-2

Abbreviations

- AE:

-

absolute error

- AI:

-

artificial intelligence

- ASR:

-

asymmetry self-compensating work roll

- CSP:

-

compact strip production

- CVC:

-

continuously variable crown

- EFB:

-

exclusive feature bundling

- EI:

-

expected improvement

- FEM:

-

finite element method

- GBDT:

-

gradient boosting decision tree

- GOSS:

-

gradient-based one-side sampling

- GP:

-

gaussian process

- HSS:

-

high-speed steel

- K-WRS:

-

Kawasaki steel work-roll shifting

- LightGBM:

-

Light Gradient Boosting Machine

- MAE:

-

mean absolute error

- MNMSE:

-

mean of negative mean square error

- MSE:

-

mean square error

- RBF:

-

radial basis function

- SFR:

-

schedule-free rolling

- SMS:

-

Schloemann-Siemag

References

Lu C, Tieu AK, Jiang ZY (2002) A design of a third-order CVC roll profile. J Mater Process Technol 125:645–648. https://doi.org/10.1016/S0924-0136(02)00373-4

He AR, Kong FF, Shao J (2015) Novel curved roll contour technology for profile control in hot strip mills. Ironmak Steelmak 42(1):55–62. https://doi.org/10.1179/1743281214Y.0000000200

Zheng XT, Zhang J, Li HB, Li HH, Su Y, Su H (2012) The partial high point and the influence to the hot strip profile control. Appl Mech Mater 152:1143–1148. https://doi.org/10.4028/www.scientific.net/AMM.152-154.1143

Cao JG, Chai XT, Li YL, Kong N, Jia SH, Zeng W (2018) Integrated design of roll contours for strip edge drop and crown control in tandem cold rolling mills. J Mater Process Technol 252:432–439. https://doi.org/10.1016/j.jmatprotec.2017.09.038

Moazeni B, Salimi M (2015) Investigations on relations between shape defects and thickness profile variations in thin flat rolling. Int J Adv Manuf Technol 77(5–8):1315–1331. https://doi.org/10.1007/s00170-014-6544-6

Zhang GM, Xiao H, Wang CH (2006) Three-dimensional model for strip hot rolling. J Iron Steel Res Int 13(1):23–26. https://doi.org/10.1016/S1006-706X(06)60020-4

Xu LJ, Xing JD, Wei SZ, Zhang YZ, Long R (2006) Investigation on wear behaviors of high-vanadium high-speed steel compared with high-chromium cast iron under rolling contact condition. Mater Sci Eng A-Struct Mater Prop Microstruct Process 434(1-2):63–70. https://doi.org/10.1016/j.msea.2006.07.047

Andersson M, Finnström R, Nylen T (2004) Introduction of enhanced indefinite chill and high speed steel rolls in European hot strip mills. Ironmak Steelmak 31(5):383–388. https://doi.org/10.1179/030192304225018208

Tieu AK, Jiang ZY, Lu C (2002) A 3D finite element analysis of the hot rolling of strip with lubrication. J Mater Process Technol 125:638–644. https://doi.org/10.1016/S0924-0136(02)00371-0

Azushima A, Xue WD, Yoshida Y (2007) Lubrication mechanism in hot rolling by newly developed simulation testing machine. CIRP Ann-Manuf Technol 56(1):297–300. https://doi.org/10.1016/j.cirp.2007.05.069

John S, Sikdar S, Mukhopadhyay A, Pandit A (2006) Roll wear prediction model for finishing stands of hot strip mill. Ironmak Steelmak 33(2):169–175. https://doi.org/10.1179/174328106X80091

Ginzburg VB (1993) High-quality steel rolling: theory and practice. CRC Press, Boca Raton

Wang XD, Li F, Li BH, Dong LJ, Zhang BH (2012) Design and application of an optimum backup roll contour configured with CVC work roll in hot strip mill. ISIJ Int 52(9):1637–1643. https://doi.org/10.2355/isijinternational.52.1637

Li GT, Gong DY, Lu X, Wang ZH, Zhang DH (2019) Design of a kind of backup roll contour used in four-high CVC hot strip mill. ISIJ Int 59(3):504–513. https://doi.org/10.2355/isijinternational.ISIJINT-2018-674

Wei GC, Cao JG, Zhang J, Hao JW, Chen G (2007) Optimization and application of CVC work roll contour on 2250 hot strip mills. J Cent South Univ (Sci Technol) 38(5):937–942

Li YL, Cao JG, Qiu L, Yang GH, He AR, Zhou YZ (2018) Research on ASR work roll contour suitable for all width electrical steel strip during hot rolling process. Int J Adv Manuf Technol 97(9):3453–3458. https://doi.org/10.1007/s00170-018-2198-0

Li WG, Liu XH, Guo ZH, Huang JP (2012) Roll shifting strategy with varying stroke and step in hot strip mill. J Cent South Univ 19(5):1226–1233. https://doi.org/10.1007/s11771-012-1133-z

Li WG, Guo ZH, Yi J, Liu XH (2012) Optimization of roll shifting strategy of alternately rolling in hot strip mill. J Iron Steel Res Int 19(5):37–42. https://doi.org/10.1016/S1006-706X(12)60097-1

Li WG (2013) Simulation-based multi-objective optimization for roll shifting strategy in hot strip mill. J Cent South Univ 20(5):1226–1234. https://doi.org/10.1007/s11771-013-1606-8

Yamaguchi S, Miyake M, Kimura K, Jinnouchi T (2017) Work roll shifting method by optimum calculation of work roll profile in hot strip rolling. Procedia Eng 207:1320–1325. https://doi.org/10.1016/j.proeng.2017.10.890

Yang GH, Cao JG, Zhang J, Song P, Yan TL, Rao KF (2012) Profile and flatness control technology with a long shifting stroke on wide non-oriented electrical steel sheets. J Iron Steel Res Int 19(1):31–35. https://doi.org/10.1016/S1006-706X(12)60043-0

Cao JG, Liu SJ, Zhang J, Song P, Yan TL, Zhou YZ (2011) ASR work roll shifting strategy for schedule-free rolling in hot wide strip mills. J Mater Process Technol 211(11):1768–1775. https://doi.org/10.1016/j.jmatprotec.2011.05.025

Cao JG, Xiong HT, Huang XH, Zhao QF, Li YN, Liu SQ (2020) Work roll shifting strategy of uneven "cat ear" wear control for profile and flatness of electrical steel in schedule-free rolling. Steel Res Int 91(9):1900662. https://doi.org/10.1002/srin.201900662

Shang F, Li HB, Kong N, Zhang J, Hu C, Chen L, Zhang C, Chen JF (2016) CVC cyclical shifting mode and its working characteristics for the mills of CSP. Int J Adv Manuf Technol 87(5-8):1907–1916. https://doi.org/10.1007/s00170-016-8602-8

Shang F, Li HB, Kong N, Zhang J, Hu C, Zhang C, Chen JF, Mitchell DRG (2017) Improvement in continuously variable crown work roll contour under CVC cyclical shifting mode. Int J Adv Manuf Technol 90(9):2723–2731. https://doi.org/10.1007/s00170-016-9587-z

Nie ZG, Lin T, Jiang HL, Kara LB (2021) TopologyGAN: Topology optimization using generative adversarial networks based on physical fields over the initial domain. J Mech Des 143(3):031715. https://doi.org/10.1115/1.4049533

Jiang HL, Nie ZG, Yeo R, Farimani AB, Kara LB (2021) StressGAN: A generative deep learning model for 2D stress distribution prediction. J Appl Mech 88(5):051005. https://doi.org/10.1115/1.4049805

Wang ZH, Liu YM, Gong DY, Zhang DH (2018) A new predictive model for strip crown in hot rolling by using the hybrid AMPSO-SVR-based approach. Steel Res Int 89(7):1800003. https://doi.org/10.1002/srin.201800003

Huang ZW, Zhu JM, Lei JT, Li XR, Tian FQ (2019) Tool wear predicting based on multi-domain feature fusion by deep convolutional neural network in milling operations. J Intell Manuf 31(4):953–966. https://doi.org/10.1007/s10845-019-01488-7

Machado MR, Karray S, de Sousa IT (2019) LightGBM: An effective decision tree gradient boosting method to predict customer loyalty in the finance industry. 14th International Conference on Computer Science & Education (ICCSE). https://doi.org/10.1109/ICCSE.2019.8845529

Sun XL, Liu MX, Sima ZQ (2020) A novel cryptocurrency price trend forecasting model based on LightGBM. Financ Res Lett 32:101084. https://doi.org/10.1016/j.frl.2018.12.032

Chen C, Zhang QM, Ma Q, Yu B (2019) LightGBM-PPI: Predicting protein-protein interactions through LightGBM with multi-information fusion. Chemom Intell Lab Syst 191:54–64. https://doi.org/10.1016/j.chemolab.2019.06.003

Gao HS, Ye ZYF, Dong J, Gao HL, Yu H, Li HF, Ouyang DF (2020) Predicting drug/phospholipid complexation by the lightGBM method. Chem Phys Lett 747:137354. https://doi.org/10.1016/j.cplett.2020.137354

Niu S (2019) A Method for Three-Dimensional Deformation Predictions in the Rolling of Steel Strips. Metall Mater Trans B Process Metall Mater Process Sci 50(4):1581–1587. https://doi.org/10.1007/s11663-019-01571-7

Li YL, Cao JG, Qiu L, Kong N, He AR, Zhou YZ (2019) Effect of strip edge temperature drop of electrical steel on profile and flatness during hot rolling process. Adv Mech Eng 11(4):1–11. https://doi.org/10.1177/1687814019840471

Sun WQ, Li B, Shao J, He AR (2016) Research on crown and flatness allocation strategy of hot rolling mills. Int J Simul Model 15(2):327–340. https://doi.org/10.2507/IJSIMM15(2)CO6

Kitagoh K, Shimoda N, Kubo N (2012) Development of practical shape models and control system for strips. IFAC Proceedings Volumes 45(23):38–43. https://doi.org/10.3182/20120910-3-JP-4023.00027

Furumoto H, Kanemori S, Takeguchi T (2017) Reduction of off-centering at tail end caused by unstable work roll position with mill stabilizing device in hot rolling. Procedia Eng 207:1373–1378. https://doi.org/10.1016/j.proeng.2017.10.899

Ke GL, Meng Q, Finley T, Wang TF, Chen W, Ma WD, Ye QW, Liu TY (2017) Lightgbm: A highly efficient gradient boosting decision tree. Adv Neural Inf Proces Syst 30

Friedman JH (2001) Greedy function approximation: a gradient boosting machine. Ann Stat 29(5):1189–1232. https://doi.org/10.1214/aos/1013203451

Breiman L, Friedman JH, Stone CJ, Olshen RA (1984) Classification and regression trees. CRC press, Boca Raton

Bergstra J, Bengio Y (2012) Random search for hyper-parameter optimization. J Mach Learn Res 13:281–305

Chen HZ, Liu ZY, Cai K, Xu LL, Chen A (2018) Grid search parametric optimization for FT-NIR quantitative analysis of solid soluble content in strawberry samples. Vib Spectrosc 94:7–15. https://doi.org/10.1016/j.vibspec.2017.10.006

Shahriari B, Swersky K, Wang ZY, Adams RP, de Freitas N (2015) Taking the human out of the loop: A review of Bayesian optimization. Proc IEEE 104(1):148–175. https://doi.org/10.1109/JPROC.2015.2494218

Brochu E, Cora VM, de Freitas N (2010) A tutorial on Bayesian optimization of expensive cost functions, with application to active user modeling and hierarchical reinforcement learning. arXiv preprint arXiv:10122599. https://arxiv.org/abs/1012.2599. Accessed 12 December 2010

Mockus J, Tiesis V, Zilinskas A (1978) The application of Bayesian methods for seeking the extremum. Towards Global Optim 2:117–129

Greenhill S, Rana S, Gupta S, Vellanki P, Venkatesh S (2020) Bayesian optimization for adaptive experimental design: A review. IEEE Access 8:13937–13948. https://doi.org/10.1109/ACCESS.2020.2966228

Peng KX, Zhong H, Zhao L, Xue K, Ji YD (2014) Strip shape modeling and its setup strategy in hot strip mill process. Int J Adv Manuf Technol 72(5–8):589–605. https://doi.org/10.1007/s00170-014-5649-2

Acknowledgements

This work was supported by National Key R&D Program of China (2017YFB0304100), National Natural Science Foundation of China (51704067, 51774084, 51634002).

Funding

This work was supported by National Key R&D Program of China (2017YFB0304100), National Natural Science Foundation of China (51704067, 51774084, 51634002)

Author information

Authors and Affiliations

Contributions

All authors contributed to the study of this paper. Guangtao Li: Software, Methodology, Formal analysis, Data Curation, Conceptualization, Writing–original draft. Dianyao Gong: Methodology, Conceptualization, Writing–review & editing, Supervision. Junfang Xing: Data collection. Dianhua Zhang: Investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: The original article contained symbol mistakes regarding formulas (10) and (11).

Rights and permissions

About this article

Cite this article

Li, G., Gong, D., Xing, J. et al. Optimization of CVC shifting mode for hot strip mill based on the proposed LightGBM prediction model of roll shifting. Int J Adv Manuf Technol 116, 1491–1506 (2021). https://doi.org/10.1007/s00170-021-07395-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07395-7