Abstract

High-performance anisotropic bonded magnets need a high volumetric filling fraction of magnetic powder in a polymer binder and good alignment while possessing adequate mechanical properties. The correlation between the degree of alignment (DOA) and the volumetric filling fraction of magnetic powder, the type of binder and the processing parameters have been studied using Nd–Fe–B anisotropic bonded magnets. Thermomagnetic analysis and differential scanning calorimetry results show that the magnetic powder can be well aligned in a bonded magnet under an external magnetic field at a temperature higher than the binders' melting point by 20–60 K, depending on the type of magnetic powder and binder. The DOA results mainly from the interplay between the Zeeman energy (Eapp) and the inter-particle static energy (Estat) in bonded magnets at the chosen alignment temperature and the magnetic fields. A good alignment can be achieved by an alignment magnetic field which is about twice its coercivity in an anisotropic Nd–Fe–B bonded magnet, which is confirmed by our experimental and modeling results.

Export citation and abstract BibTeX RIS

1. Introduction

Nd–Fe–B bonded magnets have been widely applied in data storage and consumer electronic devices [1–4]. To produce bonded magnets, powders are mixed with thermoset or thermoplastic polymers for compression or injection molding methods, respectively. With the appropriate processing design, both compression and injection molding can produce magnets to a near-net shape. Recently, additive manufacturing (AM) has become a promising technique for bonded permanent magnet production [5–12]. As opposed to the conventional subtractive methods of manufacturing, AM has the advantage of components being made near the net shape without tooling requirements and limiting the waste of raw materials.

Like full-density sintered magnets, there are two types of bonded magnets, i.e. isotropic and anisotropic magnets. The magnetic easy axis orients randomly and along a preferential direction in isotropic and anisotropic magnets, respectively. Theoretically, the maximum energy product of anisotropic magnets is four times that of isotropic magnets [13]. There are two main kinds of anisotropic Nd–Fe–B magnetic powders commercially available for producing bonded magnets. One is Magnequench anisotropic (MQA) Nd–Fe–B anisotropic magnetic powder, produced by hot-deformation (or die-upsetting) of powders derived from melt-spun Nd–Fe–B ribbons [14, 15]. The other is Magfine Nd–Fe–B anisotropic magnetic powder, prepared using a hydrogenation–disproportionation–desorption–recombination (HDDR) method [16, 17]. Each particle of the anisotropic magnetic powder of MQA or Magfine Nd–Fe–B contains several million Nd2Fe14B grains. However, the distribution of the magnetic easy axes of Nd2Fe14B grains (or [001] crystallographic orientation) is not completely aligned along a single direction in each particle [15, 18]. The degree of alignment (DOA) is generally evaluated by the remanence ratio (Mr/Ms). The DOA of magnetic powders determines the maximum possible DOA value and maximum energy product of a final bonded magnet. To distinguish between the DOA of Nd–Fe–B particles and that of final bonded magnets, we name the DOA of the magnetic powder as the intrinsic DOA (Φi) and that of the final bonded magnet as the total DOA (Φt) in this paper.

In addition to the performance of the magnetic powder itself, a higher remanent magnetization and energy product can be achieved with a higher loading proportion of magnetic powder and good magnetic alignment in polymer matrix for anisotropic bonded magnets. The magnetic remanence is proportional to the volume fraction of magnetic powder and total DOA of bonded magnets. The maximum energy product is proportional to the square of magnetic remanence or the square of the volume fraction of the magnetic powder. However, the maximum loading fraction of the magnetic powder is limited by the requirement for sufficient mechanical properties of bonded magnets. Typically, in injection molding methods, up to 65 volume % of magnet fractions is filled in a polymer; however, in compression molding methods, up to 80 volume % of magnet fractions is filled [19, 20]. The mechanical properties depend on the type and content of the binder and its distribution in the bonded magnets. The DOA is intimately related to the type of magnetic powder, binder, temperature and applied magnetic field for alignment [21, 22]. To achieve good magnetic and mechanical properties in bonded magnets, establishing optimized processing conditions is very important.

In our previous work, we successfully prepared high-performance isotropic and anisotropic Nd–Fe–B bonded magnets using AM technology, and reported the magnetic and mechanical properties [7, 23–25]. As part of our endeavor to advance the AM of high-performance Nd–Fe–B bonded magnets, we study different processing parameters that contribute to the resultant magnetic alignment and hence the magnetic properties of anisotropic Nd–Fe–B bonded magnets. The processing parameters of interest include the powder loading fraction, rheological states of polymer binders, magnetic interaction between the particles, and applied magnetic field during the alignment process. Controlling the resultant hard magnetic properties in anisotropic bonded magnets requires an understanding of the various physics interacting to produce such properties. The goal of this work is to elucidate the physics that drive the orientation of magnetic easy axes to produce high energy density Nd–Fe–B bonded magnets. Ultimately, such understanding can be adopted in various approaches for producing bonded magnets, including injection and compression molding and AM techniques.

2. Experimental methods

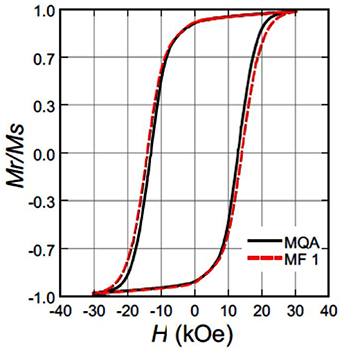

We selected two kinds of anisotropic Nd–Fe–B powders (MQA-38-15 and Magfine-15) to prepare bonded magnets. These are two key types of commercially available anisotropic Nd–Fe–B powders for bonded magnet manufacturing, and will help to ensure that the findings of the present work can have a broader impact. To determine the intrinsic DOA (Φi) of the magnetic powder, we measured the magnetic hysteresis loops. Slightly milled MQA and Magfine Nd–Fe–B powder (less than 0.1 mm) were mixed with paraffin wax, aligned under a magnetic field of 30 kOe at 323 K (the melting point of paraffin wax is 312 K), then cooled in the magnetic field to room temperature. To achieve a high magnetic alignment of the powder, the volume of the magnet powder was about 30% in liquid wax. The observed DOA reflects the degree of c-axis crystal texture of the 2:14:1 phase in the Nd–Fe–B powder, i.e. the intrinsic DOA (Φi). Figure 1 shows the normalized magnetic hysteresis loop. The remanence ratio or intrinsic DOA (Φi) of MQA and Magfine powder are 0.91 and 0.92, respectively. The bonded magnets made with MQA and Magfine are expected to have a total DOA (Φt) less than the corresponding DOA (Φi) values of powder.

Figure 1. Magnetic hysteresis loop of MQA (black solid line, MQA) and Magfine (red dotted line, MF 1) anisotropic Nd–Fe–B magnetic powders.

Download figure:

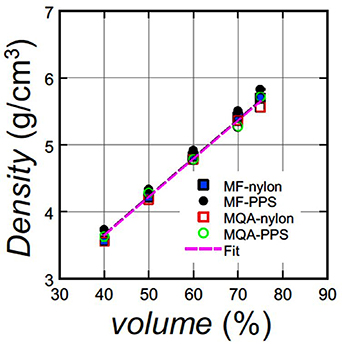

Standard image High-resolution imageTwo types of binders (Nylon-12 and PPS) were selected to fabricate the bonded magnets. Here, different loading fractions of Nd–Fe–B powder were mixed with binders and warm-compacted into bonded magnets with a diameter of 8 mm and a length of 5 mm. For the Nylon-12 and PPS binders, the temperatures of warm compaction were 450 and 550 K, respectively. The relative mass content of the magnetic powder and binder was used to control the volume fraction of the magnetic powders in the bonded magnets. Here, it is assumed that the binders and magnetic powders have their theoretical density and that there is no porosity in the bonded magnets. The correlation between the density of the bonded magnets and the loading fraction of the magnetic powders should be linear. As shown in figure 2, the linear relationship between the density and loading fraction was confirmed for all the bonded magnets with the two types of magnetic powder and the two types of binder.

Figure 2. Correlation between density and loading fraction of magnetic powder in Nylon (circle) and PPS (square) Nd–Fe–B bonded magnets. Open and solid symbols are MQA and Magfine powder, respectively.

Download figure:

Standard image High-resolution imagePrior to magnetic alignment, the magnetic hysteresis loops of the as-prepared magnets with randomly oriented particles were measured at 300 K. To magnetically align the Nd–Fe–B powder in the as-prepared bonded magnets, a post-compaction magnetic field alignment was performed with an applied external magnetic field of up to 30 kOe. The samples were heated in magnetic fields from 300 to 530 K (Nylon-12) or 630 K (PPS) with a dwell time of 15 min at 530 K or 630 K, and then cooled down to 300 K. Further details have been reported in [24]. After each alignment process, the magnetic hysteresis loops were measured again at 300 K. All the magnetic hysteresis loops were measured using a Quantum Design Versalab VSM magnetometer. The total DOAs (Φt) were determined using the remanent magnetization ratio of the bonded magnets after magnetic alignment. To determine the melting point of the binder in the bonded magnets, differential scanning calorimetry (DSC) measurements were performed using a NETZSCH STA449F3 Jupiter thermal analyzer.

3. Results and discussion

3.1. Effect of loading fraction on magnetic alignment and hard magnetic properties

Figure 3(a) displays a typical magnetic hysteresis loop of an MQA Nd–Fe–B Nylon bonded magnet with a magnetic powder loading fraction of 75 vol%. After magnetic alignment (at 30 kOe), the magnetic remanence increases from 4.0 to 8.2 kGs, while the intrinsic coercivity Hci changes from 9.8 to 10.8 kOe. The enhancement in remanence is due to the magnetic alignment of the easy axis of the magnetic powder in bonded magnets. The alignment-induced enhancement of coercivity is ascribed to the coercivity being mainly controlled by the nucleation of reversal magnetic domains in MQA–Nd–Fe–B powders [26]. Further, the inductive coercivity increases from 2.9 to 5.9 kOe (figure 3(b)), resulting from the increase in remanence Br. The maximum energy product increases from 2.9 to 13 MGOe. As shown in figure 3(c), the magnetization has a jump at a temperature of 490–500 K during annealing under external applied fields. This temperature is slightly higher than the melting point of Nylon-12 (450 K), which means the binder (Nylon-12) is melted and in a low-viscosity state. The low viscosity of the binder reduces the friction between binder and particle and facilitates the magnetic powder alignment under the magnetic field. This is a necessary condition to achieve alignment of magnetic particles in Nd–Fe–B bonded magnets during the magnetic alignment process (see details on sample and measurement in the section 'Experimental method'). Similar situations are observed with Nd–Fe–B bonded magnets with the PPS binder (see figure S1 in the supplemental materials, available online at stacks.iop.org/JPD/54/315004/mmedia).

Figure 3. (a) Magnetic hysteresis plots, J–H (black and red lines are non-aligned and aligned samples, respectively); (b) B–H curves (black) and energy product (red); solid and dashed lines are non-aligned and aligned samples, respectively; (c) magnetization vs. temperature plot, J–T for the heating and cooling profiles. All data are for 75 vol% MQA Nd–Fe–B nylon bonded magnets.

Download figure:

Standard image High-resolution imageThe magnetic remanence depends on the filling fraction of magnetic powder and their alignment in bonded magnets. The relationship can be expressed as

where Br, f and Φp are the remanence of bonded magnets, volume fraction of magnetic powder, and DOA of the magnetic particle in the bonded magnet, respectively. Mr0 is the remanence of the magnetic powder, which is determined by its intrinsic DOA (Φi) and saturation magnetization (Ms0), i.e. Mr0= Φi× Ms0. The observed total DOA (Φt) of the bonded magnet is contributed by the intrinsic DOA, Φi, (i.e. the degree of c-axis crystal texture of the 2:14:1 phase of Nd–Fe–B) and the extrinsic DOA, Φp, (i.e. the degree of particle alignment induced by an external magnetic field). Equation (1) can be rewritten as

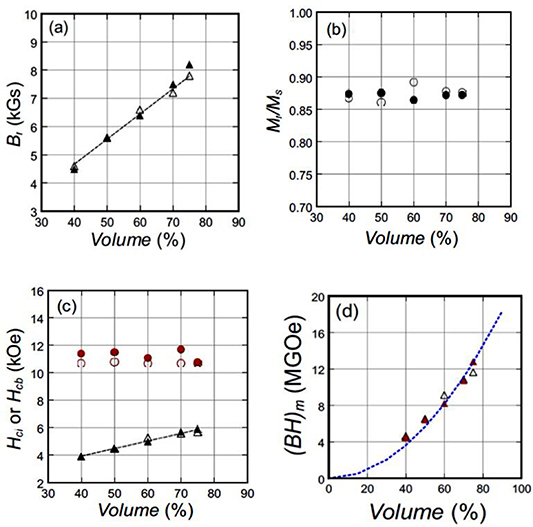

We have investigated the loading fraction of Nd–Fe–B on the alignment and magnetic properties of bonded magnets. As shown in figure 4, the magnetic remanence Br increases almost linearly while the remanence ratio Mr /Ms remains almost unchanged with the increasing loading volume fractions from 40% to 75% in the aligned Nd–Fe–B bonded magnets. The ratio of Mr /Ms or Φt is about 0.88 in both the Nylon and PPS bonded magnets, and the derived Φp is 0.97 based on formula (2). In other words, the magnetic powders have been aligned by 97% under an external applied magnetic field of 30 kOe (Φp= 0.97). As seen from equation (2), the remanence Br is directly proportional to the filling fraction of the magnetic powder having a fixed value of Φt (∼0.88) in the bonded magnets prepared here. The intrinsic coercivity Hci remains almost unchanged with the increasing loading fraction of Nd–Fe–B powders (figure 4(c)). The inductive coercivity Hcb increases at higher contents of Nd–Fe–B powders, which is ascribed to the higher remanence of the bonded magnet with the larger filling fraction of Nd–Fe–B powders. If the demagnetization curve M–H has ideal squareness, i.e. the value of Hcb is the same as that of Br, the maximum energy product (BH)max equals ¼(Br)2. It is expected that the value of (BH)max increases parabolically with Br or the filling fraction volume. However, the volume fraction dependence of (BH)max deviates slightly from a parabolic curve since the real magnet lacks the perfect squareness of the M–H curve (figure 4(d)).

Figure 4. Dependence of magnetic properties on filling fraction for bonded magnets made with MQA Nd–Fe–B powders in nylon (solid symbol) and PPS (open symbol): (a) magnetic remanence; (b) magnetic remanence ratio; (c) intrinsic (circle) and inductive (triangle) coercivity; and (d) maximum energy product.

Download figure:

Standard image High-resolution imageFigure 5 shows the magnetic hysteresis loop of Magfine (HDDR) Nd–Fe–B bonded magnets. The remanence increases with the magnetic alignment and results in a maximum energy product of about 13 MGOe. Different from the MQA bonded magnets (figure 3), the intrinsic coercivity remains unchanged for non-aligned and aligned samples. The result confirms that the domain wall pinning plays an important role in the magnetization reversal process [27]. It should be noted that the magnetic alignment occurs at a temperature range between 475 and 485 K (figure 5(b)), less than that for MQA Nd–Fe–B nylon bonded magnets by about 15 K (figure 3(c)). This is partially ascribed to the different morphology of Magfine and MQA Nd–Fe–B powder (supplementary material, figure S2). The Magfine particle has an irregular sphere-like shape while MQA powder has a plate-like morphology. For the same viscosity of melted binders, the sphere-like particles are easier to move or rotate than plate-like ones. The correlation between the magnetic alignment temperature and types of magnetic powder will be discussed in section 3.2.

Figure 5. (a) Magnetic hysteresis plots, J–H (black and red lines are non-aligned and aligned samples, respectively); and (b) magnetization vs. temperature plot, J–T, for the heating and cooling profiles. All data are for 75 vol% Magfine Nd–Fe–B nylon bonded magnets.

Download figure:

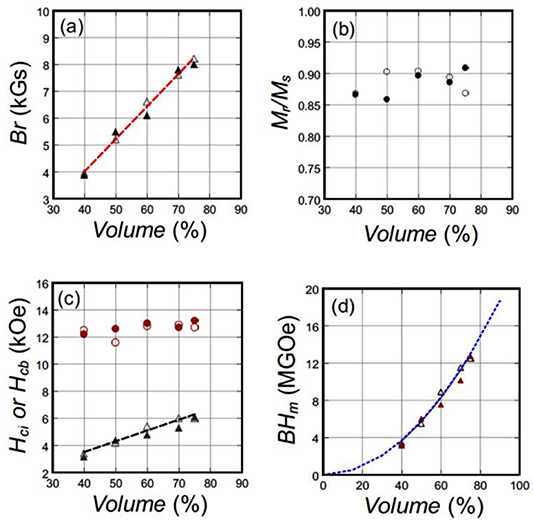

Standard image High-resolution imageFigure 6 displays the effect of the loading fraction of Magfine powders on the magnetic properties of the bonded magnets. The magnetic remanence Br increases linearly with the filling fraction of Nd–Fe–B powder for both Nylon and PPS bonded magnets. For all the Magfine bonded magnets, the remanence ratio Mr /Ms is about 0.89 and comparable to that of the MQA bonded magnets (0.88). The magnetic alignment of the particles is very similar for both types of anisotropic Nd–Fe–B powder under processing conditions and achieves a particle DOA Φp = 0.97. Similar to MQA bonded magnets, the inductive coercivity and energy product of Magfine bonded magnets increases almost linearly and parabolically with the loading fraction of magnetic powders, respectively.

Figure 6. Dependence of magnetic properties on filling fraction for bonded magnets made with Magfine Nd–Fe–B powders in nylon (solid symbol) and PPS (open symbol): (a) magnetic remanence; (b) magnetic remanence ratio; (c) intrinsic (circle) and inductive (triangle) coercivity; and (d) maximum energy product.

Download figure:

Standard image High-resolution image3.2. Effect of temperature on magnetic alignment

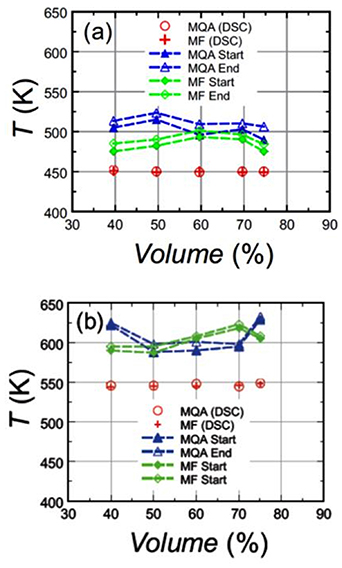

In nylon and PPS bonded magnets, the magnetic powder was bonded to achieve a near-net shape and mechanical integrity. To align the magnetic particles with the externally applied magnetic field, the binder should be in a low-viscosity state to facilitate the rotation of magnetic particles. The magnetic alignment must be done at temperatures slightly above the melting point of the binder. To understand the effect of temperature on magnetic alignments, we have measured the melting point of the binder in bonded magnets with different loading fractions of magnetic powders using DSC (see supplementary materials figures S3 and S4 for the DSC curves of nylon and PPS bonded magnets, respectively). The starting temperature and ending temperature for magnetic alignment were derived from thermal magnetization curves in bonded magnets during the post-compaction magnetic alignment process.

Figure 7 displays the binder melting temperature and magnetic alignment temperature in anisotropic Nd–Fe–B nylon and PPS bonded magnets. The binder melting temperature is the same in bonded magnets with MQA and Magfine magnetic powders and remains almost unchanged with different loading fractions of Nd–Fe–B magnetic powders. However, the magnetic alignment temperature is different for the different types of magnetic powders. As shown in figure 7(a), the starting and ending magnetic alignment temperatures of MQA are higher than that of Magfine in nylon bonded magnets by about 10–20 K. This means that the MQA powder is more difficult to align than Magfine powders in nylon bonded magnets, i.e. MQA powder needs a higher temperature to facilitate magnetic alignment. This is contrary to expectation because the MQA magnetic powder has a slightly lower coercivity than Magfine powder (figure 1), indicating that the response to magnetic alignment should be less in MQA at a fixed applied magnetic field and viscous state of the binder. Further, comparing figures 3(c) and 5(b), the magnetization of the MQA powder is higher than that of the Magfine powder by about 15% at around 450–500 K, under the applied alignment magnetic field of 30 kOe. In other words, the driving force for magnetic alignment of MQA powder is slightly higher than that for Magfine powders, which, again, indicates that MQA should be easier to align. One reason for the difficulty in the magnetic alignment of MQA powder is related to the different morphology of Magfine and MQA powders, as discussed in section 3.1. The irregular sphere-like Magfine particles are easier to rotate than the plate-like MQA powder in binders with similar viscosity. This morphological difference is likely a reflection of the methods via which each of the powders was made.

Figure 7. The binder melting temperature (circle and plus symbols are MQA and Magfine bonded magnets, respectively); starting magnetic alignment temperature (solid symbol) and ending magnetic alignment temperature (open symbol) as a function of loading fraction of bonded magnets made with Nd–Fe–B magnetic powders in nylon (a) and PPS- (b). Triangle and diamond symbols represent MQA and Magfine bonded magnet samples, respectively.

Download figure:

Standard image High-resolution imageIn contrast, the difference between the starting and ending magnetic alignment temperatures is only about 3–5 K for both the MQA and Magfine powders in PPS bonded magnets (figure 7(b)). A possible reason is that the temperature dependence of viscosity for PPS is different from that of Nylon-12 [28, 29]. As the temperature reaches the critical point, the viscosity of PPS is relatively low, so that both MQA and Magfine powder can be easily rotated in a narrow temperature range (3–5 K). On the other hand, the relatively wider temperature range (10–15 K) needed to complete the magnetic alignment of magnetic powder in Nylon-12 indicates a slower change in viscosity compared to PPS. Further work is needed to clarify the correlation between magnetic alignment and the viscosity of binders.

3.3. Magnetic energy variation during post-compaction magnetic alignment process

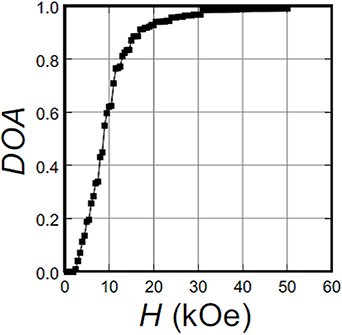

During the magnetic alignment process, there are three main types of competing interaction [30, 31]. Firstly, the Zeeman energy due to the interaction between the external applied magnetic field and magnetic powder (Eapp) is the driving force to align magnetic particles. Secondly, the inter-particle magneto-static energy (Estat) promotes the random distribution of the magnetization direction of the different magnetic powders and discourages the magnetic alignment. Thirdly, the interaction between the magnetic particle and binder (Ebind) prevents the particles from moving or rotating. However, Ebind depends on the temperature. When the processing temperature is higher than the melting point of the binder, the interaction between the particle and binder is very weak. The spatial distribution of the direction of the magnetic easy axes for the magnetic particles (i.e. DOA) is determined by the balance between the Zeeman energy (Eapp) and the inter-particle static energy (Estat) in bonded magnets, when Ebind is negligible (e.g. near the melting temperature of the binder). We considered these two contributions to simulate the relationship between the DOA and magnetic alignment field Happ during the magnetic alignment process in anisotropic Nd–Fe–B bonded magnets. The achieved DOA results from the minimization of the total magnetic energy (Etot):

During the magnetic alignment process, the coercive Nd–Fe–B magnetic powders are magnetized and display net magnetization. Estat increases while Eapp reduces with the increasing net magnetization under a fixed DOA and an external applied field. If the increased part of Estat is compensated by the reduction in Eapp (i.e. ignoring the particle–binder interaction at alignment temperature), the magnetic particle will rotate to reduce the angle between its effective easy magnetization axis (EMA) and the direction of the alignment field and continue until the distribution of magnetic particles reaches a new balance. Further increase in the alignment magnetic field reduces the angle between the EMA of the magnetic powder and the direction of the applied field, i.e. an enhancement of the DOA. The DOA has been calculated as a function of the alignment field. In the numerical implementation, we fix the particle but rotate the direction of its EMA in response to the externally applied alignment magnetic field, which are mathematically equivalent. The room temperature magnetic properties of anisotropic Nd–Fe–B powder are selected as the starting point. The coercivity and remanence are 15 kOe and 12.5 kGs, respectively (see figure 1).

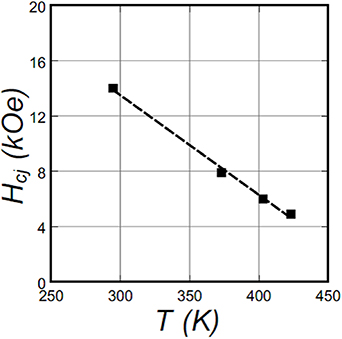

As shown in figure 8, the DOA increases slowly at a low external field (<5 kOe), then increases rapidly and reaches a value of 0.9 at the external field of 15 kOe (the same as the coercivity). When the external applied field reaches twice that of the coercivity (∼30 kOe), perfect alignment is achieved (DOA = 1.0). Further, the coercivity decreases almost linearly with the temperature, which reduces the required magnetic field strength for alignment. For example, the coercivity of Magfine powder is around 4.5 kOe at ∼425 K (figure 9). In other words, an external field of 10 kOe is enough to fully align Magfine or MQA Nd–Fe–B powder in bonded magnets above 425 K. The numerical calculations confirm that the DOA is 0.99 under an alignment field of 10 KOe for magnetic powder with a coercivity of 4.5 kOe and a remanence of 12 kGs. In our previous work [12], an alignment field of 10 kOe achieved a complete alignment of MQA Nd–Fe–B powder in Nylon-12 bonded magnets (30 vol% binder) with an alignment temperature of 550 K, in qualitative agreement with the modeling results.

Figure 8. Effect of applied field on DOA of anisotropic MQA Nd–Fe–B bonded magnets.

Download figure:

Standard image High-resolution imageFigure 9. Temperature dependence of coercivity in anisotropic Magfine Nd–Fe–B bonded magnets.

Download figure:

Standard image High-resolution imageThis finding is important for integrating alignment magnetic field sources into AM systems in order to print and align at the same time, especially considering that 90% of alignment can be achieved with a <5 kOe external magnetic field at 425 K. The reason is that it is much easier to incorporate an alignment field source if the required magnetic field strength is low. This means that a sufficient magnetic field for alignment during AM could be supplied with sintered magnets, even with the sintered magnet positioned far enough to shield it from thermal demagnetization.

4. Conclusion

In summary, the magnetic alignment of anisotropic Nd–Fe–B bonded magnets depends on the binder type, thermo-magnetic properties of the magnetic powder, and alignment magnetic field. When the binder is in a molten state, the magnetic powder can be aligned in bonded magnets by an external field. The DOA is determined by the balance between the Zeeman energy (Eapp) and the inter-particle static energy (Estat) in bonded magnets around the melting temperature of the binders. Almost complete alignment can be achieved by applying a magnetic field which is twice the coercivity in anisotropic Nd–Fe–B bonded magnets. It is expected that similar behavior can be achieved with other anisotropic bonded magnets. To achieve good alignment in anisotropic bonded magnets with selective binders, the temperature dependence of coercivity of the selected magnetic powder determines the minimum value of the necessary alignment magnetic field.

Acknowledgments

This work was supported by the Critical Materials Institute (CMI), an Energy Innovation Hub funded by the US Department of Energy (DOE), Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office. This work was performed in part at Ames Laboratory, operated for the U.S. Department of Energy by the Iowa State University of Science and Technology under Contract No. DE-AC02-07CH11358.This manuscript has been authored in part by UT-Battelle, LLC, under contract DE-AC05-00OR22725 with the US Department of Energy.

The US government retains and the publisher, by accepting the article for publication, acknowledges that the US government retains a nonexclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for US government purposes. The DOE will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (https://energy.gov/downloads/doe-public-access-plan).

Data availability statement

The data that support the findings of this study are available upon reasonable request from the authors.