Abstract

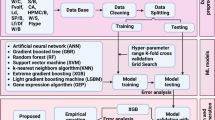

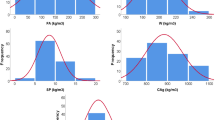

In the present research, the information on compressive strength of self-compacting concrete (SCC) containing rice husk ash (RHA) and calcium carbide waste (CCW) as an admixture cured for 28 days was provided. The research applied feedforward propagation neural network (FFNN), emotional neural network (EANN), and conventional linear regression (LR) in the prediction of compressive in which FFNN, EANN, and LR models were trained on the experimental data obtained from addition of 0%–10% RHA and 0%–20% CCW in the SCC mixtures. The results revealed that inclusion of CCW reduces the workability of SCC mixtures and increases in compressive strength at 28 days were observed for SCC mixture containing 10% RHA and 0% CCW against the reference mixtures. The results also indicated that all the AI models (FFNN, EANN, and LR) performed very well with R2-values higher than 0.8951 in both the testing and training stages. The results showed that EANN-M3, FFNN-M3, and LR-M3 combination has the highest performance evaluation criteria of R2 = 0.9733 and 0.9610, R2 = 0.9440 and 0.9454 and R2 = 0.9117 and 0.9205 in both training and testing stages, respectively. It indicates the proposed models' high accuracy in predicting the compressive strength σ of self-compacting concrete with rice husk ash as cement replacement and calcium carbide waste as supplementary materials. The result also suggested that other models, like emerging algorithms, hybrid models, and optimization methods, could enhance the models’ performance.

Similar content being viewed by others

References

Bouzoubaâ, N.; Lachemi, M.: Self-compacting concrete incorporating high volumes of class F fly ash: Preliminary results. Cem. Concr. Res. 31, 413–420 (2001). https://doi.org/10.1016/S0008-8846(00)00504-4

Pinar, A.; Desmond, F.I.D.; Uwanuakwa, : Intelligent prediction of concrete carboration depth using neural networks. Bull. Transilv. Univ. Brasov, Ser. III Math. Inform. Phys. 9, 99–108 (2016)

Türkel, S.; Kandemir, A.: Fresh and hardened properties of SCC made with different aggregate and mineral admixtures. J. Mater. Civ. Eng. 22, 1025–1032 (2010)

Loukili, A.: Self-compacting concrete. John Wiley & Sons, Hoboken (2013)

Makaratat, N.; Jaturapitakkul, C.; Namarak, C.; Sata, V.: Effects of binder and CaCl2 contents on the strength of calcium carbide residue-fly ash concrete. Cem. Concr. Compos. 33, 436–443 (2010). https://doi.org/10.1016/j.cemconcomp.2010.12.004

Sun, H.; Li, Z.; Bai, J.; Memon, S.A.; Dong, B.; Fang, Y.; Xu, W.; Xing, F.: Properties of chemically combusted calcium carbide residue and its influence on cement properties. Mater. 8, 638–651 (2015). https://doi.org/10.3390/ma8020638

Rattanashotinunt, C.; Thairit, P.; Tangchirapat, W.; Jaturapitakkul, C.: Use of calcium carbide residue and bagasse ash mixtures as a new cementitious material in concrete. Mater. Des. 46, 106–111 (2013)

Hanjitsuwan, S.; Phoo-ngernkham, T.; Li, L.; Damrongwiriyanupap, N.; Chindaprasirt, P.: Strength development and durability of alkali-activated fly ash mortar with calcium carbide residue as additive. Constr. Build. Mater. 162, 714–723 (2018). https://doi.org/10.1016/j.conbuildmat.2017.12.034

Phoo-ngernkham, T.; Phiangphimai, C.; Intarabut, D.; Hanjitsuwan, N.; Damrongwiriyanupap, N.; Li, L.; Chindaprasirt, P.: Low cost and sustainable repair material made from alkali-activated high-calcium fly ash with calcium carbide residue. Constr. Build. Mater. 247, 118543 (2020)

Nshimiyimana, P.; Messan, A.; Zhao, Z.; Courard, L.: Chemico-microstructural changes in earthen building materials containing calcium carbide residue and rice husk ash. Constr. Build. Mater. 216, 622–631 (2019)

Zareei, S.A.; Ameri, F.; Dorostkar, F.; Ahmadi, M.: Rice husk ash as a partial replacement of cement in high strength concrete containing micro silica: evaluating durability and mechanical properties. Case Stud. Constr. Mater. 7, 73–81 (2017). https://doi.org/10.1016/j.cscm.2017.05.001

Meddah, M.S.; Praveenkumar, T.R.; Vijayalakshmi, M.M.; Manigandan, S.; Arunachalam, R.: Mechanical and microstructural characterization of rice husk ash and Al2O3 nanoparticles modified cement concrete. Constr. Build. Mater. 255, 119358 (2020). https://doi.org/10.1016/j.conbuildmat.2020.119358

Marvila, M.T.; de Azevedo, A.R.G.; Alexandre, J.; Colorado, H.; Pereira Antunes, M.L.; Vieira, C.M.F.: Circular economy in cementitious ceramics: replacement of hydrated lime with a stoichiometric balanced combination of clay and marble waste. Int. J. Appl. Ceram. Technol. 18, 192–202 (2021)

Marvila, M.T.; Alexandre, J.; de Azevedo, A.R.G.; Zanelato, E.B.: Evaluation of the use of marble waste in hydrated lime cement mortar based. J. Mater. Cycles Waste Manag. 21, 1250–1261 (2019)

Zhenyan, L.; Hamid, S.; Zainah, I.; Mahdi, S.; Zamin, J.; Karzan, W.; Thai, P.B.; Tonnizam, M.E.; Majid, K.: Computational and experimental analysis of beam to column joints reinforced with CFRP plates. Steel Compos. Struct. 30, 271–280 (2019). https://doi.org/10.12989/SCS.2019.30.3.271

Shariati, M.; Mafipour, M.S.; Mehrabi, P.; Bahadori, A.; Zandi, A.; Salih, M.N.; Nguyen, H.; Dou, J.; Song, X.; Poi-Ngian, S.: Application of a hybrid artificial neural network-particle swarm optimization (ANN-PSO) model in behavior prediction of channel shear connectors embedded in normal and high-strength concrete. Appl. Sci. 24, 554 (2019). https://doi.org/10.3390/app9245534

Asteris, P.G.; Mokos, V.G.: Concrete compressive strength using artificial neural networks. Neural Comput. Appl. 32, 11807–11826 (2020)

Shariati, M.; Mafipour, M.S.; Mehrabi, P.; Shariati, A.; Toghroli, A.; Trung, N.T.; Salih, M.N.A.: A novel approach to predict shear strength of tilted angle connectors using artificial intelligence techniques. Eng. Comput. (2020). https://doi.org/10.1007/s00366-019-00930-x

Yazdani, M.; Kabirifar, K.; Frimpong, B.E.; Shariati, M.; Mirmozaffari, M.; Boskabadi, A.: Improving construction and demolition waste collection service in an urban area using a simheuristic approach: a case study in Sydney, Australia. J. Clean. Prod. 280, 124138 (2021). https://doi.org/10.1016/j.jclepro.2020.124138

Bingöl, A.F.; Tortum, A.; Gül, R.: Neural networks analysis of compressive strength of lightweight concrete after high temperatures. Mater. Des. 52, 258–264 (2013)

Ramana, K.V.S.; Anita, T.; Mandal, S.; Kaliappan, S.; Shaikh, H.; Sivaprasad, P.V.; Dayal, R.K.; Khatak, H.S.: Effect of different environmental parameters on pitting behavior of AISI type 316L stainless steel: experimental studies and neural network modeling. Mater. Des. 30, 3770–3775 (2009)

Słoński, M.: A comparison of model selection methods for compressive strength prediction of high-performance concrete using neural networks. Comput. Struct. 88, 1248–1253 (2010)

Correia, S.L.; Partala, T.; Loch, F.C.; Segadães, A.M.: Factorial design used to model the compressive strength of mortars containing recycled rubber. Compos. Struct. 92, 2047–2051 (2010)

Deshpande, N.; Londhe, S.; Kulkarni, S.: Modeling compressive strength of recycled aggregate concrete by artificial neural network, model tree and non-linear regression. Int. J. Sustain. Built Environ. 3, 187–198 (2014)

Alkroosh, I.S.; Sarker, P.K.: Prediction of the compressive strength of fly ash geopolymer concrete using gene expression programming. Comput. Concr. 24, 295–302 (2019)

Sadrmomtazi, A.; Sobhani, J.; Mirgozar, A.M.: Modeling compressive strength of EPS lightweight concrete using regression, neural network and ANFIS. Constr. Build. Mater. 42, 205–216 (2013)

Chopra, P.; Sharma, R.K.; Kumar, M.: Prediction of compressive strength of concrete using artificial neural network and genetic programming. Mater. Sci. Eng. Adv. (2016). https://doi.org/10.1155/2016/7648467

Chang, W.; Zheng, W.: Estimation of compressive strength of stirrup-confined circular columns using artificial neural networks. Struct. Concr. 20, 1328–1339 (2019)

Hammoudi, A.; Moussaceb, K.; Belebchouche, C.; Dahmoune, F.: Comparison of artificial neural network (ANN) and response surface methodology (RSM) prediction in compressive strength of recycled concrete aggregates. Constr. Build. Mater. 209, 425–436 (2019)

Tuntisukrarom, K.; Cheerarot, R.: Prediction of Compressive Strength Behavior of Ground Bottom Ash Concrete by an Artificial Neural Network. Adv. Mater. Sci. Eng. 2020 (2020). https://doi.org/10.1155/2020/2608231

Nikoo, M.; Moghadam, F.T.; Sadowski, L.: Prediction of concrete compressive strength by evolutionary artificial neural networks. Adv. Mater. Sci. Eng. 2015 (2015). https://doi.org/10.1155/2015/849126

Banu, S.S.; Kartikeyan, J.; Jayabalan, P.: Influence of using agro-waste as a partial replacement in cement on the compressive strength of concrete–A statistical approach. Constr. Build. Mater. 250, 118746 (2020)

Naderpour, H.; Nagai, K.; Fakharian, P.; Haji, M.: Innovative models for prediction of compressive strength of FRP-confined circular reinforced concrete columns using soft computing methods. Compos. Struct. 215, 69–84 (2019)

Azimi-Pour, M.; Eskandari-Naddaf, H.: ANN and GEP prediction for simultaneous effect of nano and micro silica on the compressive and flexural strength of cement mortar. Constr. Build. Mater. 189, 978–992 (2018)

Onyari, E.K.; Ikotun, B.D.: Prediction of compressive and flexural strengths of a modified zeolite additive mortar using artificial neural network. Constr. Build. Mater. 187, 1232–1241 (2018)

ASTM C150/C150M-20: Standard specification for portland cement ASTM international west Conshohocken, (2000).

ASTM C188–17: Standard test method for density of hydraulic cement, ASTM international, West Conshohocken, PA, (2017).

ASTM C136/C136M-19: Standard, Standard test method for sieve analysis of fine and coarse aggregates, ASTM international, West Conshohocken, PA, (2019).

ASTM C29/C29M-17: Standard test method for bulk density (“Unit Weight”) and voids in aggregate ASTM international west Conshohocken, PA, (2017).

ASTM C127- 15: Standard test method for relative density (Specific Gravity) and absorption of coarse aggregate, ASTM international west Conshohocken, PA, (2015).

Mirarabi, A.; Nassery, H.R.; Nakhaei, M.; Adamowski, J.; Akbarzadeh, A.H.; Alijani, F.: Evaluation of data-driven models (SVR and ANN) for groundwater-level prediction in confined and unconfined systems. Environ. Earth Sci. 78, 1–15 (2019). https://doi.org/10.1007/s12665-019-8474-y

Mehr, A.D.; Kahya, E.; Olyaie, E.: Streamflow prediction using linear genetic programming in comparison with a neuro-wavelet technique. J. Hydrol. 505, 240–249 (2013). https://doi.org/10.1016/j.jhydrol.2013.10.003

Gaya, M.S.; Abdul Wahab, N.; Sam, Y.M.; Samsudin, S.I.: anfis modelling of carbon and nitrogen removal in domestic wastewater treatment plant. J. Teknol. (2014). https://doi.org/10.11113/jt.v67.2839

Malik, A.; Bhagwat, A.: Modelling groundwater level fluctuations in urban areas using artificial neural network. Groundw. Sustain. Dev. 12, 100484 (2020). https://doi.org/10.1016/j.gsd.2020.100484

Khashman, A.: A modified backpropagation learning algorithm with added emotional coefficients. IEEE Trans. Neural Netw. 19, 1896–1909 (2008). https://doi.org/10.1109/TNN.2008.2002913

Choubin, B.; Khalighi-Sigaroodi, S.; Malekian, A.; Kişi, O.: Multiple linear regression, multi-layer perceptron network and adaptive neuro-fuzzy inference system for forecasting precipitation based on large-scale climate signals. Hydrol. Sci. J. 61, 1001–1009 (2016). https://doi.org/10.1080/02626667.2014.966721

Bilgili, M.: Prediction of soil temperature using regression and artificial neural network models. Meteorol. Atmos. Phys. 110, 59–70 (2010). https://doi.org/10.1007/s00703-010-0104-x

Yetilmezsoy, K.; Ozkaya, B.; Cakmakci, M.: Artificial intelligence-based prediction models for environmental engineering. Neural Net. World 21, 193–218 (2011)

Ozturk, S.; Enez, K.: Determination of the perceptions of secondary education students towards environment and nature. J. Envrion. Prot. Ecol. 16, 723–732 (2015)

Abrahão, R.; Carvalho, M.; Da Silva, W.R.; Machado, T.T.V.; Gadelha, C.L.M.; Hernandez, M.I.M.: Use of index analysis to evaluate the water quality of a stream receiving industrial effluents. Water SA. 33, 459–465 (2007)

Liu, Y.; Hou, D.; Bao, J.; Qi, Y.: Multi-step ahead time series forecasting for different data patterns based on LSTM recurrent neural network. In: Proc. - 2017 14th Web Inf. Syst. Appl. Conf. WISA 2017. 2018-Janua 305–310 (2018).

Zhang, P.G.: Time series forecasting using a hybrid ARIMA and neural network model. Neurocomputing 50, 159–175 (2003). https://doi.org/10.1016/S0925-2312(01)00702-0

Sammen, S.S., Ehteram, M,; Abba, SI,; Abdulkadir, RA,; Ahmed, AN.; El-Shafie, A.: A new soft computing model for daily streamflow forecasting. Stoch. Environ. Res. Risk Assess. (2021). https://doi.org/10.1007/s00477-021-02012-1

Acknowledgements

The authors acknowledge the Department of Civil Engineering Laboratory, Bayero University Kano-Nigeria, for their support throughout this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haruna, S.I., Malami, S.I., Adamu, M. et al. Compressive Strength of Self-Compacting Concrete Modified with Rice Husk Ash and Calcium Carbide Waste Modeling: A Feasibility of Emerging Emotional Intelligent Model (EANN) Versus Traditional FFNN. Arab J Sci Eng 46, 11207–11222 (2021). https://doi.org/10.1007/s13369-021-05715-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05715-3