Abstract

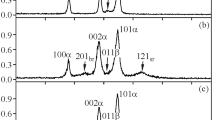

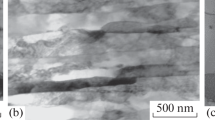

Interaction of Ti–C with titanium alloys of α + β and pseudo α classes and formation of the reaction layer at the interface have been investigated. We used titanium α + β alloys VT6 (Ti–Al–V) and VT8 (Ti–Al–Mo–Si) as well as pseudo α alloy VT20 (Ti–Al–Zr–Mo–V). The structure and composition of the interfaces were investigated by means of TEM in the scanning beam mode and energy dispersive spectroscopy. It was ascertained that, already at the stage of production of the samples by thermal diffusion joining, interphase chemical interaction and formation of the reaction layers occurred. The reaction layer consists of distinct regions of small crystals (nanocrystals of TiC of 10–50 nm in size) and large grains of Ti8C5 100–500 nm in size. Most of the reaction layer consists of large grains of Ti8C5. It is found that the average thickness of the reaction layer varies depending on the Ti alloy type and is ~0.89 μm (VT6 alloy), ~0.97 μm (VT8 alloy), and ~0.51 μm (VT20 alloy). Additional heat treatment of the samples leads to increasing thickness of the reaction layer in all Ti–C/Ti alloy systems due to the growth of large grains of titanium carbide.

Similar content being viewed by others

REFERENCES

Kablov, E.N., Innovations of VIAM as part of implementing the Strategic Directions of Development of Materials and Technologies of Their Processing for the Period up to 2030, Aviats. Mater. Tekhnol., 2015, no. 1, pp. 3–33. https://doi.org/10.18577/2071-9140-2015-0-1-3-33

Stoyakina, E.A., Kurbatkina, E.I., Simonov, V.N., Kosolapov, D.V., and Gololobov, A.V., Mechanical properties of aluminum-matrix composite materials reinforced with SiC particles, depending on the matrix alloy (review), Tr. VIAM, 2018, no. 2 (62), pp. 62–73. https://doi.org/10.18577/2307-6046-2018-0-2-8-8

Kablov, E.N., New generation materials – the basis of innovation, technological leadership and national security of Russia, Intellekt Tekhnol., 2016, no. 2 (14), pp. 16–21.

Sidorov, D.V., Serpova, V.M., and Shavnev, A.A., Manufacture methods and application fields of high-strength fibrous composite materials reinforced with silicon carbide fiber, Vse Mater. Entsikloped. Sprav., 2018, no. 3, pp. 15–22.

Apukhtina, T.L., Shcherbakova, G.I., Sidorov, D.V., Varfolomeyev, M.S., Sidorov, D.G., and Drachev, A.I., Reinforcing silicon carbide fibers with protective glass-ceramic coatings, Inorg. Mater., 2015, vol. 51, no. 8, pp. 806–810.

Serpova, V.M., Kosolapov, D.V., Zhabin, A.N., and Shavnev, A.A., Methods for forming semi-finished products for the production of continuous fiber reinforced metal matrix composites (review), Tr. VIAM, 2017, no. 7, pp. 69–78. https://doi.org/10.18577/2307-6046-2017-0-7-8-8

Kablov, E.N., Ospennikova, O.G., and Svetlov, I.L., Highly efficient cooling of GTE hot section blades, Aviats. Mater. Tekhnol., 2017, no. 2, pp. 3–14. https://doi.org/10.18577/2071-9140-2017-0-2-3-14

Sidorov, D.V. and Shcherbakova, G.I., High-tech composite components and special fibers for a wide range of applications, Khim. Tekhnol., 2016, vol. 17, no. 4, pp. 183–192.

Sidorov, D.V., Serpova, V.M., and Shavnev, A.A., Interaction of titanium alloys and fibers of silicon carbide in metallic composite materials of Ti–SiCf system, Khim. Tekhnol., 2018, vol. 19, no. 8, pp. 339–344.

Wakelkamp, W., van Loo, F., and Metselaar, R., Phase relation in the Ti–Si–C system, J. Eur. Ceram. Soc., 1991, vol. 8, pp. 135–139.

Kiparisov, S.S., Levinskii, Yu.V., and Petrov, A.P., Karbid titana: Svoistva, poluchenie, primenenie (Titanium Carbide: Preparation, Properties, and Applications), Moscow: Metallurgiya, 1987.

Gusev, A.I., Phase equilibria, phases, and chemical compounds in the Ti–C system, Russ. Chem. Rev., 2002, vol. 71, no. 6, pp. 439–463.

Baik, K. and Grant, P., Chemical interaction between sigma 1140+SiC fiber and Ti-6Al-4V, Scripta Mater., 2001, vol. 44, pp. 607–612.

Wang, J., Ni, Y., and Lu, C., A new method of fabrication of TiC by employing pyrolytic carbon black and titanium, Int. J. Refract. Met. Hard Mater., 2014, vol. 45, pp. 137–140.

Lipatnikov, V.N., Zueva, L.V., Gusev, A.I., and Kottar, A., Disorder-order phase transformations and electrical resistivity of nonstoichiometric titanium carbide, Phys. Solid State, 1998, vol. 40, no. 7, pp. 1211–1218.

ACKNOWLEDGMENTS

This study was prepared within the framework of implementation of complex research field 12.1: Metallic Composite Materials (MCM) Reinforced with Particles and Fibers of High-Melting Compounds (“Strategic Directions for the Development of Materials and Technologies for Their Processing for the Period up to 2030”).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by K. Gumerov

Rights and permissions

About this article

Cite this article

Sidorov, D.V., Serpova, V.M., Zavodov, A.V. et al. Investigation of the Interphase Interaction at the Interface in the Ti–C System with Domestic Titanium Alloys of the α + β and Pseudo α Classes. Inorg. Mater. Appl. Res. 12, 846–850 (2021). https://doi.org/10.1134/S2075113321030357

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113321030357