Abstract

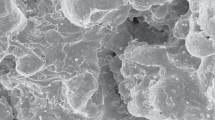

Porous coatings are actively used in engineering practice. The porous coating determines the reliability of the operation of the intraosseous implant and the heat transfer process when the aggregate state of the refrigerant is changed. The choice of method for quantitative analysis of porosity is determined by the structure of the coating. In this study, plasma coatings sprayed from powders were analyzed. A porosity of 10.3% inside the alumina coating was analyzed by mercury porosimetry. The main volume of the porosity of the coating is formed by pores ranging in size from 0.13 to 0.36 μm; their share in the total volume is 68.29%. The remaining volume is distributed in sizes of 0.04–0.12 mm, 0.58–4.66 mm, and 5.66–18.2 mm. Microtomography makes it possible to get a more complete general idea of the macro- and microstructure of coatings, establishing the mechanisms of its formation, and to obtain data on the real shape of the pores. A quantitative description of the visible pores of three-dimensional capillary-porous 3CaO⋅Al2O3 coatings in the form of ridges and depressions was determined by raster image analysis using special STIMAN programs. The porosity of this coating is 39.7% of the distribution over four pore groups: 0.74–3.56, 4.34–11.57, 14.08–55.65, 67.73–267.71 mm.

Similar content being viewed by others

REFERENCES

Berndt, C.C., Hasan, F., Tietz, U., and Schmitz, K.P., A review of hydroxyapatite coatings manufactured by thermal spray, in Advances in Calcium Phosphate Biomaterials, Besim, Ben-Nissan, Ed., Berlin–Heidelberg: Springer, 2014, pp. 267–329.

Gross, K.A., Walsh, W., and Swarts, E., Analysis of retrieved hydroxyapatite-coated hip prostheses, J. Therm. Spray Technol., 2004, vol. 13, no. 2, pp. 190–199.

Heimann, R.B., Plasma-sprayed bioactive ceramic coatings with high resorption resistance based on transition metal-substituted calcium hexaorthophosphates, Materials, 2019, vol. 12, no. 13, art. ID 2059. https://doi.org/10.3390/ma12132059

Dorozhkin, S.V., Functionalized calcium orthophosphates (CaPO4) and their biomedical applications, J. Mater. Chem. B, 2019, vol. 7, no. 47, pp. 7471–7489. https://doi.org/10.1039/c9tb01976f

Surtaev, A., Kuznetsov, D., Serdyukov, V., Pavlenko, A., Kalita, V., Komlev, D., Ivannikov, A., and Radyuk, A., Structured capillary-porous coatings for enhancement of heat transfer at pool boiling, Appl. Therm. Eng., 2018, vol. 133, pp. 532–542. https://doi.org/10.1016/j.applthermaleng.2018.01.051

Pavlenko, A.N., Tsoi, A.N., Surtaev, A.S., Kuznetsov, D.V., Kalita, V.I., Komlev, D.I., Ivannikov, A.Yu., and Radyak, A.A., Experimental study of rewetting of a superheated plate with structured capillary-porous coating by flowing liquid film, High Temp., 2018, vol. 56, no. 3, pp. 404–409.

Kalita, V.I., Komlev, D.I., Komlev, V.S., and Radyuk, A.A., The shear strength of three-dimensional capillary-porous titanium coatings for intraosseous implants, Mater. Sci. Eng., C, 2016, vol. 60, pp. 255–259.

Bulygina, L.G., Sokolov, V.N., Chernov, M.S., Razgulina, O.V., and Yurkovets, D.I., Analysis of the soil structure by the scanning electron microscope—X-ray computed microtomograph system (SEM-mCT), Geoekol. Inzhen. Geol. Gidrogeol. Geokriol., 2014, no. 5, pp. 450–456. https://elibrary.ru/item.asp?id=22390922.

Kalita, V.I., Sokolov, V.N., and Paramonov, V.A., Three-dimensional capillary-porous coatings, Fiz. Khim. Obrab. Mater., 2000, no. 4, pp. 55–61.

Kalita, V.I. and Komlev, D.I., Plazmennye pokrytiya s nanokristallicheskoi i amorfnoi strukturoi (Plasma Coatings with Nanocrystalline and Amorphous Structure), Moscow: Biblioteka, 2008.

Siebert, B., Funke, C., Vasen, R., and Stover, D., Changes in porosity and Young’s modulus due to sintering of plasma sprayed thermal barrier coatings, J. Mater. Process. Technol., 1999, vols. 92–93, pp. 217–223.

Qiua, S.-Y., Liu, Y.-C., Guo, H.-B., Huang, C.-G., Ma, Y., and Wu, C.-W., Effect of splat-interface discontinuity on effective thermal conductivity of plasma sprayed thermal barrier coating, Ceram. Int., 2020, vol. 46, pp. 4824–4831. https://doi.org/10.1016/j.ceramint.2019.10.215

Kalita, V.I., Radyuk, A.A., Komlev, D.I., Ivannikov, A.Yu., Komlev, V.S., and Demin, K.Yu., The boundary between the hydroxyapatite coating and titanium substrate, Inorg. Mater.: Appl. Res., 2017, vol. 8, no. 3, pp. 444–451.

Kalita, V.I., Komlev, D.I., Ivannikov, A.Yu., Radyuk, A.A., Komlev, V.S., Mamonov, V.I., Sevast’ianov, M.A., and Baikin, A.S., The shear strength of Ti–HA composite coatings for intraosseous implants, Inorg. Mater.: Appl. Res., 2017, vol. 8, no. 2, pp. 296–304. https://doi.org/10.1134/S2075113317020083

Mamayev, A.I., Mamayeva, V.A., Kalita, V.I., Komlev, D.I., Radyuk, A.A., Ivannikov, A.Yu., Mikhaylova, A.B., Baikin, A.S., Sevostyanov, M.A., and Amel’chenko, N.A., Shear strength of the cylindrical titanium implant-plastic system, Inorg. Mater.: Appl. Res., 2018, vol. 9, no. 5, pp. 855–860. https://doi.org/10.1134/S2075113318050209

Sesso, M.L., Berndt, C.C., and Wong, Y.C., Effect of plasma spray parameters on thermal barrier coating formation and microstructural properties, Proc. Int. Thermal Spray Conf. & Exposition (ITSC 2013): Innovative Coating Solutions for the Global Economy (Busan, Republic of Korea, May 13–15, 2013), Lima, R.S., Ed., ASM Int., pp. 577–582.

Funding

This work was supported by the Russian Science Foundation, project no. 20-19-00671. The studies were carried out using a LEO-1450VP scanning electron microscope and a Yamato TDM 1000H-II computerized X-ray microtomograph (Japan), purchased at the expense of the Development Program of Moscow University.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Sh. Galyaltdinov

Rights and permissions

About this article

Cite this article

Sokolov, V.N., Chernov, M.S., Kalita, V.I. et al. The Structure and Porosity of Plasma Coatings. Inorg. Mater. Appl. Res. 12, 718–726 (2021). https://doi.org/10.1134/S2075113321030369

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113321030369