Abstract

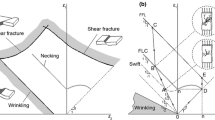

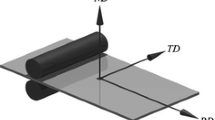

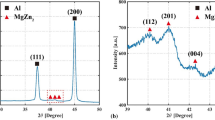

In this work, formabilities of aluminum sheet alloy grade AA5052-H32 were investigated under consideration of the anisotropic behavior of material. Experimental tensile tests and modified Marciniak in-plane stretch-forming tests of sheet samples with varying shapes were performed for different sample orientations. The critical fracture strains at various states of stress were gathered by means of a digital image correlation (DIC) technique. Then, the Lou-Huh ductile fracture criterion was applied in combination with the Hill’48 and Yld2000-2d yield criteria for generating the fracture loci (FLs) of examined sheet. Hereby, material parameters of the fracture model were calibrated by the tensile tests of pure shear, uniaxial tension and plane strain samples. It was found that the Yld2000-2d-based fracture model could more accurately predict the experimental limit strains at all stress states. In addition, the representative anisotropic FL was proposed and transformed to fracture forming limit curve (FFLC), which was afterwards verified by a cross die forming test and a square cup drawing test. The predicted force-displacement curves, moment of fracture onsets, and fracture sites of samples positioned in different directions were well in accordance with the experimental results. The state of stress and material anisotropy strongly affected the fracture occurrences of tested samples. The representative FFLC by the Lou-Huh model and the Yld2000-2d yield function more accurately described the forming limits of investigated aluminum sheet.

Similar content being viewed by others

Data availability

Not applicable.

References

Sekhar KC, Narayanasamy R, Velmanirajan K (2014) Experimental investigations on microstructure and formability of cryorolled AA 5052 sheets. Mater Des 53:1064–1070. https://doi.org/10.1016/j.matdes.2013.08.008

Keeler SP, Backofen WA (1963) Plastic instability and fracture in sheets stretched over rigid punches. Trans ASM 56:25–48

Goodwin GM (1968) Application of strain analysis to sheet metal forming problems in the press shop. Trans Soc Automotive 25:1413–1424

Bao YB, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J Mech Sci 46:81–98

Børvik T, Hopperstad OS, Pedersen KO (2010) Quasi-brittle fracture during structural impact of AA7075-T651 aluminum plates. Int J Impact Eng 37:537–551

Khan AS, Liu H (2012) A new approach for ductile fracture prediction on Al 2024-T351 alloy. Int J Plast 35:1–12. https://doi.org/10.1016/j.ijplas.2012.01.003

Khan AS, Liu H (2012) Strain rate and temperature dependent fracture criteria for isotropic and anisotropic metals. Int J Plast 37:1–15. https://doi.org/10.1016/j.ijplas.2012.01.012

Lemaitre J (1985) A continuous damage mechanics model for ductile fracture. J Eng Mater Technol 107:83–89

McClintock FA (1968) A criterion for ductile fracture by the growth of holes. ASME J Appl Mech 35:363–371

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields. J Mech Phys Solids 17:201–217

Chu CC, Needleman A (1980) Void nucleation effects in biaxially stretched sheets. J Eng Mater Technol 102:249–256

LeRoy G, Embury J, Edwards G, Ashby MF (1981) A model of ductile fracture based on the nucleation and growth of voids. Acta Metall 29:1509–1522

Cockcroft MG, Latham DJ (1968) Ductility and the workability of metals. J Inst Met 96:33–39

Brozzo P, DeLuca B, Rendina R (1972) A new method for the prediction of the formability limits of metal sheets. In: Proceedings of the 7th Biennial Conference of IDDRG on Sheet Metal Forming and Formability.

Oh SI, Chen CC, Kobayashi S (1979) Ductile fracture in axisymmetric extrusion and drawing: part 2: workability in extrusion and drawing. J Manuf Sci Eng 101(1):36–44. https://doi.org/10.1115/1.3439471

Oyane M, Sato T, Okimoto K, Shima S (1980) Criteria for ductile fracture and their applications. J Mech Work Technol 4:65–81. https://doi.org/10.1016/0378-3804(80)90006-6

Clift SE, Hartley P, Sturgess CEN, Rowe GW (1990) Fracture prediction in plastic deformation processes. Int J Mech Sci 32:1–17. https://doi.org/10.1016/0020-7403(90)90148-C

Ko YK, Lee JS, Huh H, Kim HK, Park SH (2007) Prediction of fracture in hub-hole expanding process using a new ductile fracture criterion. J Mater Process Technol 187:358–362. https://doi.org/10.1016/j.jmatprotec.2006.11.071

Bai Y, Wierzbicki T (2010) Application of extended Mohr-Coulomb criterion to ductile fracture. Int J Fract 161:1–20. https://doi.org/10.1007/s10704-009-9422-8

Lou YS, Huh H, Lim SJ, Pack KH (2012) New ductile fracture criterion for pre- diction of fracture forming limit diagrams of sheet metals. Int J Solids Struct 49:3605–3615. https://doi.org/10.1016/j.ijsolstr.2012.02.016

Banabic D (2010) Sheet metal forming processes: Constitutive modelling and numerical simulation. Springer, Berlin Heidelberg

Pack K, Roth CC (2016) The second Sandia Fracture Challenge: Blind prediction of dynamic shear localization and full fracture characterization. Int J Fract 198:197–220 http://hdl.handle.net/1721.1/103311

Benzerga AA, Besson J, Pineau A (2004) Anisotropic ductile fracture. Part I: experiments. Acta Mater 52:4623–4638. https://doi.org/10.1016/j.actamat.2004.06.020

Benzerga AA, Besson J, Pineau A (2004) Anisotropic ductile fracture. Part II: theory. Acta Mater 52:4639–4650. https://doi.org/10.1016/j.actamat.2004.06.019

Beese AM, Luo M, Li Y, Bai Y, Wierzbicki T (2008) Partially coupled anisotropic fracture model for aluminum sheets. Eng Fract Mech 77:1128–1152. https://doi.org/10.1016/j.engfracmech.2010.02.024

Luo M, Dunand M, Mohr D (2012) Experiments and modeling of anisotropic aluminum extrusions under multi-axial loading - Part II: Ductile fracture. Int J Plast 32-33:36–58. https://doi.org/10.1016/j.ijplas.2011.11.001

Lou YS, Yoon JW (2015) Anisotropic behavior in plasticity and ductile fracture of an aluminum alloy. Key Eng Mater 651-653:163–168. https://doi.org/10.4028/www.scientific.net/KEM.651-653.163

Park N, Huh H, Lim SJ, Lou YS, Kang YS, Seo MH (2017) Fracture-based forming limit criteria for anisotropic materials in sheet metal forming. Int J Plast 96:1–35. https://doi.org/10.1016/j.ijplas.2016.04.014

Park N, Huh H, Yoon JW (2018) Anisotropic fracture forming limit diagram considering non-directionality of the equi-biaxial fracture strain. Int J Solids Struct 151:181–194. https://doi.org/10.1016/j.ijsolstr.2018.01.009

Lou YS, Yoon JW (2018) Anisotropic yield function based on stress invariants for BCC and FCC metals and its extension to ductile fracture criterion. Int J Plast 101:125–155. https://doi.org/10.1016/j.ijplas.2017.10.012

Li S, He J, Gu B, Zeng D, Xia ZC, Zhao Y, Lin ZQ (2018) Anisotropic fracture of advanced high strength steel sheets: experiment and theory. Int J Plast 103:95–118. https://doi.org/10.1016/j.ijplas.2018.01.003

Young WL (2005) Fracture prediction in metal sheets. PhD Thesis, MIT

Bai Y (2008) Effect of loading history on necking and fracture. PhD Thesis, MIT

Li Y, Luo M, Gerlach J, Wierzbicki T (2010) Prediction of shear-induced fracture in sheet metal forming. J Mater Process Technol 210:1858–1869. https://doi.org/10.1016/j.jmatprotec.2010.06.021

Chen W, Song H, Lazarescu L, Xu Y, Zhang SH, Banabic D (2020) Formability analysis of hot-rolled dual-phase steel during the multistage stamping process of wheel disc. Int J Adv Manuf Technol 110:1563–1573. https://doi.org/10.1007/s00170-020-05963-x

Manopulo N, Peters P, Hora P (2017) Assessment of anisotropic hardening models for conventional deep drawing processes. Int J Mater Form 10:623–631. https://doi.org/10.1007/s12289-016-1306-7

Gorji M, Berisha B, Hora P, Barlat F (2016) Modeling of localization and fracture phenomena in strain and stress space for sheet metal forming. Int J Mater Form 9:573–584. https://doi.org/10.1007/s12289-015-1242-y

Pack K, Tancogne-Dejean T, Gorji M, Mohr D (2018) Hosford-Coulomb ductile failure model for shell elements: Experimental identification and validation for DP980 steel and aluminum 6016-T4. Int J Solids Struct 51:214–232. https://doi.org/10.1016/j.ijsolstr.2018.08.006

Talebi-Ghadikolaee H, Naein HM, Naeini HM, Mirzai MA, Alexandrov S, Gorji H (2019) Experimental and numerical investigation of failure during bending of AA6061 aluminum alloy sheet using the modified Mohr-Coulomb fracture criterion. Int J Adv Manuf Technol 105:5217–5237

Panich S, Suranuntchai S, Jirathearanat S, Uthaisangsuk V (2016) A hybrid method for prediction of damage initiation and fracture and its application to forming limit analysis of advanced high strength steel sheet. Eng Fract Mech 166:97–127. https://doi.org/10.1016/j.engfracmech.2016.08.025

Charoensuk K, Panich S, Uthaisangsuk V (2017) Damage initiation and fracture loci for advanced high strength steel sheets taking into account anisotropic behavior. J Mater Process Technol 248:218–235. https://doi.org/10.1016/j.jmatprotec.2017.05.035

Dunand M, Mohr D (2010) Hybrid experimental-numerical analysis of basic ductile fracture experiments for sheet metals. Int J Solids Struct 47:1130–1142. https://doi.org/10.1016/j.ijsolstr.2009.12.011

Butuc MC, Gracio JJ, Da Rocha AB (2006) An experimental and theoretical analysis on the application of stress-based forming limit criterion. Int J Mech Sci 48:414–429. https://doi.org/10.1016/j.ijmecsci.2005.11.007

Stoughton TB (2000) A general forming limit criterion for sheet metal forming. Int J Mech Sci 42:1–17. https://doi.org/10.1016/S0020-7403(98)00113-1

Barlat F, Brem JC, Yoon JW, Chung K, Dick RE, Lege DJ, Pourboghrat F, Choi SH, Chu E (2003) Plane stress yield function for aluminum alloy sheets-part 1: theory. Int J Plast 19:1297–1319. https://doi.org/10.1016/S0749-6419(02)00019-0

Yoon JW, Barlat F, Dick RE, Chung K, Kang TJ (2004) Plane stress yield function for aluminum alloy sheets - part II: FE formulation and its implementation. Int J Plast 20:495–522. https://doi.org/10.1016/S0749-6419(03)00099-8

Basak S, Panda SK (2019) Failure strains of anisotropic thin sheet metals: Experimental evaluation and theoretical prediction. Int J Mech Sci 151:356–374. https://doi.org/10.1016/j.ijmecsci.2018.10.065

Panich S, Liewald M, Uthaisangsuk V (2018) Stress and strain based fracture forming limit curves for advanced high strength steel sheet. Int J Mater Form 11:643–661. https://doi.org/10.1007/s12289-017-1378-z

Alharthi H, Hazra S, Alghamdi A, Banabic D, Dashwood R (2018) Determination of the yield loci of four sheet materials (AA6111-T4, AC600, DX54D+ Z, and H220BD+ Z) by using uniaxial tensile and hydraulic bulge tests. Int J Adv Manuf Technol 98:1307–1319. https://doi.org/10.1007/s00170-018-2339-5

Prakash V, Kumar DR, Horn A, Hagenah H, Merklein M (2020) Modeling material behavior of AA5083 aluminum alloy sheet using biaxial tensile tests and its application in numerical simulation of deep drawing. Int J Adv Manuf Technol 106:1133–1148

Nasser A, Yadav A, Pathak P, Altan T (2010) Determination of the flow stress of five AHSS sheet materials (DP 600, DP 780, DP 780-CR, DP 780-HY and TRIP 780) using the uniaxial tensile and the biaxial viscous pressure bulge (VPB) tests. J Mater Process Technol 210:429–436. https://doi.org/10.1016/j.jmatprotec.2009.10.003

Bandstra JP, Koss DA (2004) A simulation of growth and coalescence of voids during ductile fracture. Mater Sci Eng A 387:399–403. https://doi.org/10.1016/j.msea.2004.02.092

Kuwabara T, Hashimoto K, Iizukac E, Yoon JW (2013) Effect of anisotropic yield functions on the accuracy of hole expansion simulations. J Mater Process Technol 211:475–481. https://doi.org/10.1016/j.jmatprotec.2010.10.025

Raghavan KS (1995) A simple technique to generate in-plane forming limit curves and selected applications. Metall Trans A 26:2075–2084. https://doi.org/10.1007/BF02670679

Quaak G (2008) Biaxial Testing of Sheet Metal: An experimental-numerical analysis. Eindhoven University of Technology, Eindhoven, Netherland, Master Thesis

Beese AM, Luo N, Li Y, Bai Y, Wierzbicki T (2010) Partially coupled anisotropic fracture model for aluminum sheets. Eng Fract Mech 77:1128–1152. https://doi.org/10.1016/j.engfracmech.2010.02.024

Khalfallah A, Alves JL, Oliveira MC, Menezes LF (2015) Influence of the characteristics of the experimental data set used to identify. Simul Model Pract Theory 53:15–44. https://doi.org/10.1016/j.simpat.2015.02.007

Manopulo N, Hora P, Peters P, Gorji M (2015) An extended modified maximum force criterion for the prediction of localized necking under non-proportional loading. Int J Plast 75:189–203. https://doi.org/10.1016/j.ijplas.2015.02.003

Gorji M, Berisha B, Manopulo N, Hora P (2016) Effect of through thickness strain distribution on shear fracture hazard and its mitigation by using multilayer aluminum sheets. J Mater Process Technol 232:19–33. https://doi.org/10.1016/j.jmatprotec.2016.01.014

Gorji M, Mohr D (2018) Predicting shear fracture of aluminum 6016-T4 during deep drawing: Combining Yld-2000 plasticity with Hosford–Coulomb fracture model. Int J Mech Sci 137:105–120. https://doi.org/10.1016/j.ijmecsci.2018.01.008

Habibi N, Ramazani A, Sundararaghavan V, Prahl U (2017) Failure predictions of DP600 steel sheets using various uncoupled fracture criteria. Eng Fract Mech 190:367–381. https://doi.org/10.1016/j.engfracmech.2017.12.022

Jang I, Bae G, Song J, Kim H, Park N (2020) Fracture envelopes on the 3D-DIC and hybrid inverse methods considering loading history. Mat Design 194:108934. https://doi.org/10.1016/j.matdes.2020.108934

Carvalho-Resende TC, Balan T, Bouvier S, Meraim FA, Sablin SS (2013) Numerical investigation and experimental validation of a plasticity model for sheet steel forming. Model Simul Mater Sci Eng 21(1):45006011. https://doi.org/10.1088/0965-0393/21/1/015008

Acknowledgements

This research was funded by King Mongkut’s University of Technology North Bangkok (contract no. KMUTNB-62-KNOW-15). The authors also wish to express their appreciation to KMUTNB for allowing the authors to access the FE software license ABAQUS2017. The authors are much obliged to the Department of Mechanical Engineering, KMUTT and Thai German Graduate School of Engineering (TGGS), KMUTNB for the ARAMIS system and AutoGrid, respectively. The authors acknowledge the Department of Production Engineering, Faculty of Engineering, KMUTNB for all other necessary research facilities. In addition, the authors are very grateful to Prof. Jeong Whan Yoon for providing the Yld2000–2d UMAT program.

Code availability

Not applicable.

Funding

This work was supported by King Mongkut’s University of Technology North Bangkok (Grant number (KMUTNB-62-KNOW-15).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chaimongkon, T., Panich, S. & Uthaisangsuk, V. Anisotropic fracture forming limit curve and its applications for sheet metal forming with complex strain paths of aluminum sheet. Int J Adv Manuf Technol 115, 3553–3577 (2021). https://doi.org/10.1007/s00170-021-07357-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07357-z