Abstract

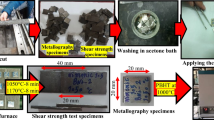

In this paper, dissimilar joining of NbSS/Nb5Si3 composites to GH5188 Co-based superalloy was performed by using two commercial Ni-based brazing filler alloys, BNi-2 and BNi-5 fillers. The interfacial microstructures of the brazed joints were investigated by scanning electron microscope equipped with an X-ray energy dispersive spectrometer. Three-point bending test was also conducted. When brazed with BNi-2 filler alloy at 1020°C for 15 min, typical reaction products across the brazing seam could be identified as NiSS, borides, Ni3Si+Nb3Si, and (Nb,Ti)2Ni phase. Due to the physical and chemical mismatch between the dissimilar base materials, some cracks were observable at the NbSS/Nb5Si3 composites side. The joint strength was only 60 MPa. While brazed with BNi-5 filler alloy at 1160°C for 15 min, the interfacial reaction became more sufficient, and the joints exhibited an average bending strength of 272 MPa.

Similar content being viewed by others

References

Lass EA, Sauza DJ, Dunand DC, Seidman DN (2018) Multicomponent γ’-strengthened Co-based superalloys with increased solvus temperatures and reduced mass densities. Acta Mater 147:284–295

Tytko D, Choi PP, Klöwer J, Kostka A, Inden G, Raabe D (2012) Microstructural evolution of a Ni-based superalloy (617B) at 700 C studied by electron microscopy and atom probe tomography. Acta Mater 60(4):1731–1740

He DG, Lin YC, Chen J, Chen DD, Huang J, Tang Y, Chen MS (2018) Microstructural evolution and support vector regression model for an aged Ni-based superalloy during two-stage hot forming with stepped strain rates. Mater Des 154:51–62

Wen Z, Zhang D, Li S, Yue Z, Gao J (2017) Anisotropic creep damage and fracture mechanism of nickel-base single crystal superalloy under multiaxial stress. J Alloys Compd 692:301–312

Barba D, Alabort E, Pedrazzini S, Collins DM, Wilkinson AJ, Bagot PAJ, Moody MP, Atkinson C, Jérusalem A, Reed RC (2017) On the microtwinning mechanism in a single crystal superalloy. Acta Mater 135:314–329

Bewlay BP, Jackson MR, Subramanian PR, Zhao JC (2003) A review of very-high-temperature Nb-silicide-based composites. Metall Mater Trans A 34(10):2043–2052

Bewlay BP, Jackson MR, Zhao JC, Subramanian PR, Mendiratta MG, Lewandowski JJ (2003) Ultrahigh-temperature Nb-silicide-based composites. MRS Bull 28(9):646–653

Fernandes PB, Coelho GC, Ferreira F, Nunes CA, Sundman B (2002) Thermodynamic modeling of the Nb–Si system. Intermetallics 10(10):993–999

Ma R, Guo X (2020) Effects of V addition on the microstructure and properties of multi-elemental Nb–Si based ultrahigh temperature alloys. J Alloys Compd 845:156254

Shkoda OA, Terekhova OG (2016) SHS in the Nb–Si system: influence of mechanical alloying. Int J Self-Propag High-Temp Synth 25(1):14–16

Fei T, Yu Y, Zhou C, Sha J (2017) The deformation and fracture modes of fine and coarsened NbSS phase in a Nb-20Si-24Ti-2Al-2Cr alloy with a NbSS/Nb5Si3 microstructure. Mater Des 116:92–98

Gang F, Heilmaier M (2014) Influence of directional solidification on the creep properties of a binary NbSi eutectic alloy. JOM 66:1908–1913

Yu CX, Zhao XJ, Xiao LR, Cai ZY, Zhang B, Guo L (2017) Microstructure and mechanical properties of in-situ laminated Nb/Nb5Si3 composites. Mater Lett 209:606–608

Yan Y, Ding H, Kang Y, Song J (2014) Microstructure evolution and mechanical properties of Nb–Si based alloy processed by electromagnetic cold crucible directional solidification. Mater Des 55:450–455

Lin CI, Niuman SJ, Kulkarni AK, King DS, Singh J, Yamamoto N (2020) Sintering and joining of Ni-based superalloys via FAST for turbine disc applications. Metall Mater Trans A 51(3):1353–1366

Ren XY, Ren HS, Kang YW et al (2019) Solid-state diffusion bonding of NbSS/Nb5Si3 composite using Ni/Al and Ti/Al nanolayers. Acta Metall Sin (Engl Lett) 32(9):1142–1150

Ren XY, Xiong HP, Kang YW, Pei C, Chen B, Cheng YY (2019) Microstructure and mechanical properties of vacuum brazed NbSS/Nb5Si3 composite joints using Ni-based filler alloys. Metall Mater Trans A 50(11):5181–5190

Ren XY, Liu W, Ren HS, Jing YJ, Mao W, Xiong HP (2020) Microstructures and joining characteristics of NbSS/Nb5Si3 composite joints by newly-developed Ti66-Ni22-Nb12 filler alloy. J Mater Sci Technol 58:95–99

Yang J, Yu Z, Li Y, Zhang H, Guo W, Zhou N (2018) Influence of alloy elements on microstructure and mechanical properties of Al/steel dissimilar joint by laser welding/brazing. Weld World 62(2):427–433

Ren HS, Wu X, Chen B et al (2017) Microstructures and mechanical properties of Ti3Al/Ni-based superalloy joints diffusion bonded with Ni and TiNiNb foils. Weld World 61(2):375–381

Ren HS, Xiong HP, Chen B, Pang SJ (2015) Vacuum brazing TiAl to Ti3Al using two Ti-based filler metals. Weld World 59(5):639–646

Zhou L, Luo LY, Tan CW, Li ZY, Song XG, Zhao HY, Huang YX, Feng JC (2018) Effect of welding speed on microstructural evolution and mechanical properties of laser welded-brazed Al/brass dissimilar joints. Opt Laser Technol 98:234–246

Chen G, Shu X, Liu J, Zhang B, Zhang B, Feng J (2019) Electron beam hybrid welding-brazing of WC-Co/40Cr dissimilar materials. Ceram Int 45(6):7821–7829

Li WW, Chen B, Xiong HP, Zou WJ (2017) Brazing SiC matrix composites using Co-Ni-Nb-V alloy. Weld World 61(4):839–846

Zhao Y, Yang T, Han B, Luan J, Chen D, Kai W, Liu CT, Kai JJ (2019) Exceptional nanostructure stability and its origins in the CoCrNi-based precipitation-strengthened medium-entropy alloy. Mater Res Lett 7(4):152–158

Niessen AD, De Boer F, Boom R et al (1983) Model predictions for the enthalpy of formation of transition metal alloys II. Calphad 7:51–70

Liu YZ, Zhang LX, Liu CB, Yang ZW, Li HW, Feng JC (2011) Brazing C/SiC composites and Nb with TiNiNb active filler metal. Sci Technol Weld Join 16(2):193–198

Kim WY, Tanaka H, Hanada S (2002) Microstructure and high temperature strength at 1773 K of NbSS/Nb5Si3 composites alloyed with molybdenum. Intermetallics 10(6):625–634

Li WW, Chen B, Xiong Y, Xiong HP, Cheng YY, Zou WJ (2017) Joining of Cf/SiBCN composite with two Ni-based brazing fillers and interfacial reactions. J Mater Sci Technol 33(5):487–491

Guo Y, Jia L, Kong B, Zhang S, Zhang F, Zhang H (2017) Microstructure of rapidly solidified Nb-based pre-alloyed powders for additive manufacturing. Appl Surf Sci 409:367–374

Ghasemi A, Pouranvari M (2019) Intermetallic phase formation during brazing of a nickel alloy using a Ni–Cr–Si–Fe–B quinary filler alloy. Sci Technol Weld Join 24(4):342–351

Song XG, Cao J, Liu YZ, Feng JC (2012) Brazing high Nb containing TiAl alloy using TiNi–Nb eutectic braze alloy. Intermetallics 22:136–141

Cheng Z, Li X, Wang B, Qu S, Li H (2020) M3B2-type borides effect on the wide gap brazing of K417G alloy with mixed powder. J Alloys Compd 821:153431

Liu W, Ren XY, Li N, Gao C, Xiong HP (2021) Rapid directionally solidified microstructure characteristic and fracture behaviour of laser melting deposited Nb–Si–Ti alloy. Prog Nat Sci Mater Int 31(1):113–120

Kang YW, Guo FW, Li M (2019) Effect of chemical composition and heat treatment on microstructure and mechanical properties of Nb-xTi-16Si–3Cr–3Al-2Hf-yZr alloy. Mater Sci Eng A 760:118–124

Li N, Huang S, Zhang GD, Qin RY, Liu W, Xiong HP, Shi GQ, Jon Blackburn (2019) Progress in additive manufacturing on new materials: A review. J Mater Sci Technol 35(2):242–269

Funding

This work was financially supported by the Beijing Municipal Science & Technology Commission (No. Z171100002217048) and the National Natural Science Foundation of China (No. 52005465).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XVII - Brazing, Soldering and Diffusion Bonding

Rights and permissions

About this article

Cite this article

Ren, X., Li, W., Jing, Y. et al. Dissimilar brazing of NbSS/Nb5Si3 composite to GH5188 superalloy using Ni-based filler alloys. Weld World 65, 1767–1775 (2021). https://doi.org/10.1007/s40194-021-01148-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01148-6