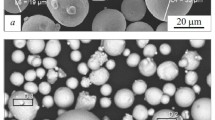

Samples of titanium alloy VT6 obtained by the method of cold gas dynamic spraying (CGDS) and subjected to hot isostatic pressing (HIP) for lowering the porosity and improving the mechanical properties are studied. The HIP is conducted at a temperature of 900°C and a pressure of 110 MPa. This reduces the volume fraction of pores from 8 to 0.5% and raises the ultimate strength of the samples from 70 to 950 MPa and the elongation by 12%.

Similar content being viewed by others

References

A. Papyrin, V. Kosarev, S. Klinkov, et al., Cold Spray Technology, Elsevier Science, Amsterdam (2006), 336 p.

R. G. Maev and V. Leshchynsky, Introduction to Low Pressure Gas Dynamic Spray: Physics and Technology, Wiley-VCH, Weinheim (2008), 234 p.

H. Assadi, F. Gärtner, T. Stotenhoff, and H. Kreye, “Bonding mechanism in cold gas spraying,” Acta Mater., 51(15), 4379 – 4394 (2003).

A. P. Alkhimov, S. V. Klinkov, V. F. Kosarev, and V. M. Fomin, Cold Gas Dynamic Spraying [in Russian], FIZMATLIT, Moscow (2010), 536 p.

I. Yu. Smurov, I. A. Movchan, I. A. Yadroitsev, et al., “Experimental additive direct production with the help of laser,” Vest. MGTU “STANKIN,” No. 2(20), 144 – 146 (2012).

I. Yu. Smurov, S. G. Konov, and D. V. Kotoban “On installation of additive technologies and production into domestic industry,” Novosti Materialoved., Nauka Tekh., No. 2, 11 – 22 (2015).

H. Assadi, F. Gärtner, T. Klassen, and H. Kreye, “Comment of adiabatic shear instability is not necessary for adhesion in cold spray,” Scr. Mater., 162, 512 – 514 (2019).

M. Hassani-Gangaraj, D. Veysset, V. K. Champagne, et al., “Adiabatic shear instability is not necessary for adhesion in cold spray,” Acta Mater., 158, 430 – 439 (2018).

X. T. Luo, Y. K. Wei, Y. Wang, and C. J. Li, “Microstructure and mechanical property of Ti and Ti6Al4V prepared by an in-situ shot peening assisted cold spraying,” Mater. Des., 85, 527 – 533 (2015).

N. W. Khun, A. W. Y. Tan, K. J. W. Bi, and E. Liu, Effects of working gas on wear and corrosion resistances of cold sprayed Ti – 6Al – 4V coatings,” Surf. Coat. Technol., 302, 1 – 12 (2016).

R. E. Blose, B. H. Walker, R. M. Walker, and S. H. Froes, “New opportunities to use cold spray process for applying additive features to titanium alloys,” Metal Powder Rep., 61(9), 30 – 37 (2006).

R. N. Raoelison, C. Verdy, and H. Liao, “Cold gas dynamic spray additive manufacturing today: Deposit possibilities, technological solutions and viable applications,” Mater Des., 133, 266 – 287 (2017).

A. Sova, S. Grigor’ev, A. Okunkova, and I. Smurov, “Potential of cold gas dynamic splay as additive manufacturing technology,” Int. J. Adv. Manuf. Technol., 69(9 – 12), 2269 – 2278 (2013).

H. C. Fngelo and R. Subramanian, Powder Metalurge: Science, Technology and Application, New Dehli (2009), 312 p.

A. V. Voronetskii, V. I. Kolpakov, L. A. Filimonov, and A. A. Khodykin, “Mathematical modeling of the process of formation of coatings under supersonic gas plasma spraying,” Vest. MGTU Im. N. E. Baumana, Ser. Mashinostr., No. 3, 30 – 37 (2011).

P. Petrovskiy, A. Sova, M. Doubenskaia, and I. Smurov, “Influence of not isostatic pressing on structure and properties of titanium cold-spray deposits,” Int. J. Adv. Manuf. Technol., 102(1 – 4), 819 – 827 (2019).

GOST 19807–91. Titanium and Deformable Titanium Alloys (with Alteration No. 1) [in Russian].

GOST 25849–83, Metallic Powders. Methods for Determination of Particle Shape [in Russian].

The study has been financed by the RFBR, project number 19-38-90176\19.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 26 – 29, February, 2021.

Rights and permissions

About this article

Cite this article

Spasenko, A.A., Cheverikin, V.V. & Petrovskii, P.V. Effect of Hot Isostatic Pressing on the Structure and Properties of Articles from Alloy VT6 Obtained by Cold Gas-Dynamic Spraying. Met Sci Heat Treat 63, 86–90 (2021). https://doi.org/10.1007/s11041-021-00651-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-021-00651-3