Abstract

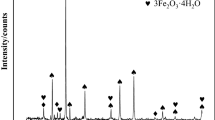

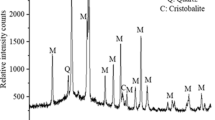

Hardening behaviour of multimetallic magnetite ore (MMO) bonded with three different organic binders: corn starch, carboxymethyl cellulose (CMC), dextrin and one inorganic binder: colemanite, has been investigated. The study aimed to optimize the hardening parameter of MMO with a suitable binder. Four separate green mixtures with doses (0.5, 1, 1.5, 2) wt% were made for each binder. The pellets were fired at four different temperatures (1273 K, 1373 K, 1473 K, 1523 K) for 2 h, and porosity was measured. HR-XRD and SEM techniques were used to analyse the hardened pellets. Pellets bonded with organic binders showed sufficient green strength and dry strength, but failed at higher temperature except for CMC bonded pellets which gave better cold crushing strength (140 kg/pellet) compared to dextrin (21.6 kg/pellet) or corn starch (24.3 kg/pellet) bonded ones. Pellets bonded with 1.5 wt% colemanite gave optimum properties of cold crushing strength (294 kg/pellet) and porosity (25 volume%).

Similar content being viewed by others

References

Indian Minerals Yearbook, 2018, Part III, Government of India, Ministry of Mines, Indian Bureau of Mines.

Mohapatra B K, Rath P C, and Sahoo R K, Current Science 68 (1995) 1036.

Nayak B, Vaish A K, Singh S D, and Bhattacharyya K K, Memoir Geological Society of India 75 (2010) 341.

Vaish A K, Nayak B, Goswami M C, Singh S D, Singh D P and Gupta R C, in Proc Symp The XI International Seminar on Mineral Processing Technology (eds) Singh R, Das A, Banerjee P K, Bhattacharyya K K and Goswami N G, National Metallurgical Laboratory, Jamshedpur (2010), p 1064.

Vaish A K, Singh S D, Minj R K and Gupta R C, Transactions of Indian Institute of Metals, 66 (2013) 491.

Gupta R C, Theory and Laboratory Experiments in Ferrous Metallurgy, PHI Publication, New Delhi (2010).

Sivrikaya O, and Arol A I, The Open Mineral Processing Journal, 3 (2010) 25.

Sivrikaya O and Arol A I, Powder Technology 210 (2011) 23.

Sivrikaya O, and Arol A I, Holos 3 (2014) 94.

Sivrikaya O, and Arol A I, Holos 3 (2014) 104.

Keskinkilic E, Pournaderi S, Geveci A, and Topkaya Y A, Journal Of Mining and Metallurgy Section B – Metallurgy 55 (2019) 1.

Rusen A, Revista Romana de Materiale/Romanian Journal of Materials 48 (2018) 245

Sivrikaya O and Arol A I, IV International boron symposium, (2009), 251.

Qiu G, Jiang T, Li H, and Wang D, Colloids and Surfaces A: Physicochemical and Engineering Aspects 224 (2003) 11.

Sivrikaya O, Arol A I, Timothy E, and Kawatra S K, Mineral Processing & Extractive Metallurgy Review, 34 (2013) 210.

Srivastava U, Kawatra S K, and Eisele T C, Metallurgical and Materials Transactions B, 44b (2013) 1000.

Kumar T K S, Investigation of Sintering Kinetics of Magnetite Pellets during Induration, Ph D Thesis, Luleå University of Technology, Sweden (2015).

Yang L X, ISIJ International, 45 (2005) 469.

Li G, Jiang T, Zhang Y and Tang Z, Recrystallization of Fe2O3 During the Induration of Iron Ore Oxidation Pellets, Recrystallization, Krzysztof Sztwiertnia, (Intech Open, 2012), https://www.intechopen.com/books/recrystallization/recrystallization-of-fe2o3-during-the-induration-of-iron-oreoxidized-pellets. Accessed 7 Mar 2012.

Yang L X, and Matthew E, ISIJ International, 37 (1997) 854.

Ptáček P, Šoukal F, Opravil T, Havlica J, and Brandštetr J, Powder Technology, 208 (2011) 20.

Levin E M, Robbins C R, and McMurdie H F, Phase Diagrams for Ceramists, 2nd ed., American Ceramic Society, Columbus (1969).

De Moraes SL, José De Lima JSB, Ribeiro TR, Iron Ore Agglomeration Technologies. Intechopen, London (2017) https://doi.org/10.5772/intechopen.73164

Forsmo S P E, Forsmo S E, Samskog P O, and Bjorkman B M T, Powder Technology, 183 (2008) 247.

Kotta A B, Karak S K, and Kumar M, IOP Conf. Ser. Mater. Sci. Eng., 178 (2017) 012003.

Haas L A, Aldinger J A, and Zahl R K, Effectiveness of Organic Binders for Iron Ore Pelletisation, Report of Investigations RI-9230, United States Department of the Interior, Bureau of Mines, USA (1989).

Acknowledgements

We are profoundly grateful to M/s National Metallurgical Laboratory, Jamshedpur, India, for supplying magnetite ore for the present study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mishra, B., Dishwar, R.K., Omar, R.j. et al. Hardening Behaviour of Pellets Prepared from a Novel Combination of Rare Multimetallic Magnetite Ore and Binder. Trans Indian Inst Met 74, 2049–2055 (2021). https://doi.org/10.1007/s12666-021-02302-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02302-w