Abstract

The research and development (R&D) of the scale-up process of third-generation photovoltaics (PVs) can benefit from the emerging trends and technologies related to the Industrial Internet of Things. However, to migrate the small-scale laboratory PVs products to a larger version of the industrial scale, a processing platform is needed to design, fabricate, and test the production line. In this paper, after a brief introduction of the production process of thin-film PVs, specifically dye-sensitized solar cells, the Industrial Internet Reference Architecture (IIRA) has been applied to the R&D scenario for the production of thin-film PVs, in order to synchronize and manage the large amount of data generated by the real, virtual or hybrid production devices and processes. The results of this study suggest that the future implementation of IIRA is a reliable option in a learning factory environment for multidisciplinary collaboration, research training in novel technologies and methods in the Tijuana Institute of Technology. This contribution is in order to optimize and scale-up the production process of a new generation of solar cells.

Similar content being viewed by others

References

Abele, E., Chryssolouris, G., Sihn, W., Metternich, J., ElMaraghy, H., Seliger, G., et al. (2017). Learning factories for future oriented research and education in manufacturing. CIRP Annals, 66(2), 803–826.

Abermann, S. (2013). Non-vacuum processed next generation thin film photovoltaics: Towards marketable efficiency and production of CZTS based solar cells. Solar Energy, 94, 37–70.

Alonso-Perez, J. L., Reynoso-Soto, E. A., Trujillo-Navarrete, B., & Cazarez-Castro, N. R. (2017). Fabricación automatizada de películas delgadas compactas en el desarrollo de celdas solares tipo grätzel (Automated manufacturing of compact thin-films for the development of dye-sensitized solar cells). Revista de Tecnología e Innovación, 4(11), 36–42.

Babiceanu, R. F., & Seker, R. (2016). Big data and virtualization for manufacturing cyber-physical systems: A survey of the current status and future outlook. Computers in Industry, 81, 128–137.

Bartłomiej, M., & Pikoń, K. (2018). The environmental and technological evaluation of dyed DSSC cells production. In K. Mudryk, & S. Werle (Eds.), Renewable energy sources: Engineering, technology, innovation (pp. 309–319). Springer International Publishing.

Boyes, H., Hallaq, B., Cunningham, J., & Watson, T. (2018). The industrial internet of things (IIoT): An analysis framework. Computers in Industry, 101, 1–12.

Braune, A., Diedrich, C., Grüner, S., Huettemann, G., Klein, M., Legat, C., Lieke, M., Löwen, U., Thron, M., Usländer, T., Belyaev, A., Okon, M., Walter, G., & Stephan, G. (2019). Usage view of asset administration shell, brochure, pp. 7–10

Cheng, Y., Zhang, Y., Ji, P., Xu, W., Zhou, Z., & Tao, F. (2018). Cyber-physical integration for moving digital factories forward towards smart manufacturing: A survey. The International Journal of Advanced Manufacturing Technology, 97, 1209–1221.

Diab, W., Harper, K., Lin, D. -W., & Sobel, W. (2017). Industrial analytics: The engine driving the IIoI revolution. IIC technical white paper.

Dumitrascu, A., Nae, L., & Predincea, N. (2014). Virtual commissioning a final step in digital validation on the robotic manufacturing systems. Journal Proceedings in Manufacturing Systems, 9(4), 215–220.

Eriksson, T., Bigi, A., & Bonera, M. (2020). Think with me, or think for me? On the future role of artificial intelligence in marketing strategy formulation. The TQM Journal, 32(4), 795–814.

Fraile, F., Sanchis, R., Poler, R., & Ortiz, A. (2019). Reference models for digital manufacturing platforms. Applied Sciences, 9(20), 4433.

Hoffmann, P., Schumann, R., Maksoud, T. M. A., & Premier, G. C. (2010). Virtual commissioning of manufacturing systems a review and new approaches for simplification. In Proceedings of 24th European conference on modelling and simulation, ECMS 2010 (pp. 175–181).

Hösel, M., Dam, H. F., & Krebs, F. C. (2015). Development of lab-to-fab production equipment across several length scales for printed energy technologies, including solar cells. Energy Technology, 3(4), 293–304.

Huang, S.-H., & Pan, Y.-C. (2015). Automated visual inspection in the semiconductor industry: A survey. Computers in Industry, 66, 1–10.

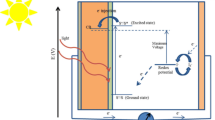

Ito, S., Murakami, T. N., Comte, P., Liska, P., Grätzel, C., Nazeeruddin, M. K., et al. (2008). Fabrication of thin film dye sensitized solar cells with solar to electric power conversion efficiency over 10%. Thin Solid Films, 516(14), 4613–4619.

Lin, S., Durand, B., Bleakley, G., Chigani, A., Martin, R., Murphy, B., & Crawford, M. (2019). The industrial internet of things volume g1: Reference architecture. IIC technical white paper.

Löwen, U., Braune, A., Diesner, M., Huettemann, G., Klein, M., Thron, M., Manger, T., Okon, M., & Kochseder, R. (2017). Exemplification of the industrie 4.0 application scenario value-based service following IIRA structure.

Mariani, P., Vesce, L., & Carlo, A. D. (2015). The role of printing techniques for large-area dye sensitized solar cells. Semiconductor Science and Technology, 30(10), 104003.

Mavrikios, D., Papakostas, N., Mourtzis, D., & Ghryssolouris, G. (2013). On industrial learning and training for the factories of the future: A conceptual, cognitive and technology framework. Journal of Intelligent Manufacturing, 24(3), 473–485.

Milichko, V. A., Shalin, A. S., Mukhin, I. S., Kovrov, A. E., Krasilin, A. A., Vinogradov, A. V., et al. (2016). Solar photovoltaics: Current state and trends. Physics-Uspekhi, 59(8), 727–772.

Nakaruk, A., & Sorrell, C. C. (2010). Conceptual model for spray pyrolysis mechanism: Fabrication and annealing of titania thin films. Journal of Coatings Technology and Research, 7, 665–676.

Nelson, B., Robbins, S., & Sheldon, P. (2005). The NCPV process integration project: Purpose, status, and direction. Conference Record of the Thirty-First IEEE Photovoltaic Specialists Conference, 2005, 243–246.

Okuya, M., Nakade, K., & Kaneko, S. (2002). Porous TiO\(_2\) thin films synthesized by a spray pyrolysis deposition (SPD) technique and their application to dye-sensitized solar cells. Solar Energy Materials and Solar Cells, 70(4), 425–435.

Pedone, G., & Mezgár, I. (2018). Model similarity evidence and interoperability affinity in cloud-ready industry 4.0 technologies. Computers in Industry, 100, 278–286.

Penumuru, D., Mathuswamy, S., & Karumbu, P. (2020). Identification and classification of materials using machine vision and machine learning in the context of industry 4.0. Journal of Intelligent Manufacturing, 31, 1229–1241.

Perednis, D., & Gauckler, L. J. (2005). Thin film deposition using spray pyrolysis. Journal of Electroceramics, 14, 103–111.

Reynoso-Soto, E. A., Alonso-Perez, J. L., Trujillo-Navarrete, B., & Cazarez-Castro, N. R. (2016). Automatización en la deposición de películas delgadas de nanomateriales para la posible utilización en celdas solares (Automatization in the deposition of nanomaterial-based thin-films for the potential use in solar cells). Revista de Tecnología e Innovación, 3(7), 51–59.

Tao, F., Cheng, J., Qi, Q., Zhang, M., Zhang, H., & Sui, F. (2018). Digital twin-driven product design, manufacturing and service with big data. The International Journal of Advanced Manufacturing Technology, 94, 3563–3576.

Vak, D., Hwang, K., Faulks, A., Jung, Y.-S., Clark, N., Kim, D.-Y., et al. (2015). 3d printer based slot-die coater as a lab-to-fab translation tool for solution-processed solar cells. Advanced Energy Materials, 5(4), 1401539.

Velásquez, N., Estevez, E., & Pesado, P. (2018). Cloud computing, big data and the industry 4.0 reference architectures. Journal of Computer Science and Technology, 18(03), e29.

Weyer, S., Meyer, T., Ohmer, M., Gorecky, D., & Zühlke, D. (2016). Future modeling and simulation of CPS-based factories: An example from the automotive industry. IFAC-PapersOnLine, 49(31), 97–102.

Yaho, X., Zhou, J., Lin, Y., Li, Y., Yu, H., & Liu, Y. (2019). Smart manufacturing based on cyber-physical systems and beyond. Journal of Intelligent Manufacturing, 30(8), 2805–20817.

Zaheer, A., & George, K. (2018). Automated dye-sensitized solar cell manufacturing system with IoT monitoring. In 2018 9th IEEE annual ubiquitous computing, electronics mobile communication conference (UEMCON) (pp. 917–921).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This research was partially financed in the framework of the following prejects: (i) Selene L. Cardenas-Maciel, Tecnológico Nacional de México, 11122.21-P; (ii) Nohe R. Cazarez-Castro, Tecnológico Nacional de México, 5564.19-P and 8085.20-P; and (iii) Edgar A. Reynoso-Soto, Consejo Nacional de Ciencia y Tecnología, PN-2015-92. Jorge L. Alonso-Perez would like to thank Consejo Nacional de Ciencia y Tecnología for the doctor of science scholarship.

Rights and permissions

About this article

Cite this article

Alonso-Perez, J.L., Cardenas-Maciel, S.L., Trujillo-Navarrete, B. et al. An approach for designing smart manufacturing for the research and development of dye-sensitize solar cell. J Intell Manuf 33, 2307–2320 (2022). https://doi.org/10.1007/s10845-021-01794-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-021-01794-z