Abstract

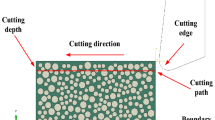

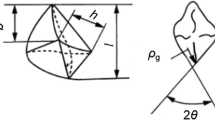

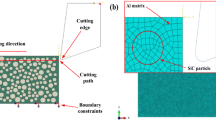

In recent years, SiCp/Al metal matrix composites (MMCs) have attracted increasing attention from academia and industry. The size and distribution of particles in this material have an important effect on its actual performance. First, the geometric analysis of milling is performed. A two-dimensional micro finite element model consisting of hard SiC particles and a soft aluminum matrix is established to study the milling of SiCp/Al composites. In this paper, the cutting mechanism of SiCp/Al MMCs reinforced by a uniform distribution of particles of the same size and random distribution of non-equal size particles at the micron level was compared by using the finite element method and finite element model with a zero-thickness cohesive layer. The simulation results show that same-size particles are evenly distributed in the matrix, and good stress distribution and chip morphology can be obtained. In addition, the cutting force fluctuation is small, and the machining surface quality is good. The properties of Al-based SiC composites can be improved by evenly distributing same-size particles. Considering the particle size and distribution, the random model can more accurately simulate the chip, cutting force fluctuation of the workpiece, and workpiece surface damage than the uniform model. A good correlation between the research results and experimental results is shown in the literature.

Similar content being viewed by others

References

Miller WS, Humphreys FJ (1991) Strengthening mechanisms in particulate metal matrix composites. Scr Metall Mater 25:33–38

Wang Z, Chen T-K, Lloyd DJ (1993) Stress distribution in particulate-reinforced metal-matrix composites subjected to external load. Metall Trans A 24:197–207

Kapoor R, Vecchio KS (1995) Deformation behavior and failure mechanisms in particulate reinforced 6061 Al metal-matrix composites. Mater Sci Eng A 202:63–75

Monaghan J, Brazil D (1997) Modeling the sub-surface damage associated with the machining of a particle reinforced MMC. Comput Mater Sci 9:99–107

Ramesh MV, Chan KC, Lee WB (2001) Cheung CF (2001) Finite-element analysis of diamond turning of aluminium matrix composites. Compos Sci Technol 61:1449–1456

Zhu Y, Kishawy HA (2005) Influence of alumina particles on the mechanics of machining metal matrix composites. Int J Mach Tools Manuf 45(4-5):389–398

Zong BY, Zhang F, Wang G, Zuo L (2007) Strengthening mechanism of load sharing of particulate reinforcements in a metal matrix composite. J Mater Sci 42(12):4215–4226

Ozben T, Kilickap E, Çakır O (2008) Investigation of mechanical and machinability properties of SiC particle reinforced Al-MMC. J Mater Process Technol 198(1-3):220–225

Pramanik A, Zhang LC, Arsecularatne JA (2007) An FEM investigation into the behavior of metal matrix composites: tool–particle interaction during orthogonal cutting. Int J Mach Tools Manuf 47(10):1497–1506

Zhou L, Huang ST, Wang D, Yu XL (2010) Finite element and experimental studies of the cutting process of SiCp/Al composites with PCD tools. Int J Adv Manuf Technol 52(5-8):619–626

Mazahery A, Abdizadeh H, Baharvandi HR (2009) Development of high-performance A356/nano-Al2O3 composites. Mater Sci Eng A 518(1-2):61–64

Shiganov IN, Samarin PE (2015) Modelling the process of formation of a composite coating with SiC particles on the surface of aluminium alloys under the effect of powerful laser radiation. Weld Int 30(5):378–382

Dandekar CR, Shin YC (2009) Multi-step 3-D finite element modeling of subsurface damage in machining particulate reinforced metal matrix composites. Compos Part A: Appl Sci Manuf 40(8):1231–1239

Zhou L, Wang Y, Ma ZY, Yu XL (2014) Finite element and experimental studies of the formation mechanism of edge defects during machining of SiCp/Al composites. Int J Mach Tools Manuf 84:9–16

Aghababaei R, Joshi SP (2013) Micromechanics of crystallographic size-effects in metal matrix composites induced by thermo-mechanical loading. Int J Plast 42:65–82

Lai X, Li H, Li C, Lin Z, Ni J (2008) Modelling and analysis of micro scale milling considering size effect, micro cutter edge radius and minimum chip thickness. Int J Mach Tools Manuf 48(1):1–14

Yakup T, Ci H, Ismail Ş, Tayfun F (2011) Study of cutting force and surface roughness in milling of Al/Sic metal matrix composites. Sci Res Essays 6(10):2056–2062

Wang B, Xie L, Chen X, Wang X (2015) The milling simulation and experimental research on high volume fraction of SiCp/Al. Int J Adv Manuf Technol 82(5-8):809–816

Wang T, Xie L, Wang X (2015) Simulation study on defect formation mechanism of the machined surface in milling of high volume fraction SiCp/Al composite. Int J Adv Manuf Technol 79(5-8):1185–1194

Umer U, Ashfaq M, Qudeiri JA, Hussein HMA, Danish SN, Al-Ahmari AR (2015) Modeling machining of particle-reinforced aluminum-based metal matrix composites using cohesive zone elements. Int J Adv Manuf Technol 78(5-8):1171–1179

Ghandehariun A, Kishawy HA, Umer U, Hussein HM (2015) Analysis of tool-particle interactions during cutting process of metal matrix composites. Int J Adv Manuf Technol 82(1-4):143–152

Ghandehariun A, Kishawy HA, Umer U, Hussein HM (2015) On tool–workpiece interactions during machining metal matrix composites: investigation of the effect of cutting speed. Int J Adv Manuf Technol 84(9-12):2423–2435

Dabade UA, Jadhav MR (2016) Experimental study of surface integrity of Al/SiC particulate metal–matrix composites in hot machining. Procedia CIRP 41:914–919

Ghandehariun A, Nazzal M, Kishawy HA, Umer U (2016) On modeling the deformations and tool-workpiece interactions during machining metal matrix composites. Int J Adv Manuf Technol 91(5-8):1507–1516

Teng X, Huo D, Chen W, Wong E, Zheng L, Shyha I (2018) Finite element modelling on cutting mechanism of nano Mg/SiC metal matrix composites considering cutting edge radius. J Manuf Process 32:116–126

Teng X, Chen W, Huo D, Shyha I, Lin C (2018) Comparison of cutting mechanism when machining micro and nano-particles reinforced SiC/Al metal matrix composites. Compos Struct 203:636–647

Zhou L, Cui C, Zhang PF, Ma ZY (2017) Finite element and experimental analysis of machinability during machining of high-volume fraction SiCp/Al composites. Int J Adv Manuf Technol 91:1935–1944

Duan C, Sun W, Fu C (2018) Modeling and simulation of tool-chip interface friction in cutting Al/SiCp composites based on a three-phase friction model. Int J Mech Sci 142:384–396

Unterweger K, Kolednik O (2005) The local deformation behaviour of MMCs—an experimental study. Z Met 96(9):1063–1068

El-Gallab MS, Sklad MP (2005) Machining of aluminum/silicon carbide particulate metal matrix composites Part IV. Residual stresses in the machined workpiece J Mater Process Technol 152:23–34

El-Gallab M, Sklad M (1998) Machining of Al/SiC particulate metal matrix composites Part II:Workpiece surface integrity. J Mater Process Technol 83:277–285

Looney LA, Monaghan JM, O'Reilly P, Taplin DMR (1992) The turning of an A1/SiC metal-matrix composite. J Mater Process Technol 33:453–468

Fathipour M, Zoghipour P, Tarighi J, Yousefi R (2012) Investigation of Reinforced Sic Particles Percentage on Machining Force of Metal Matrix Composite. Mod Appl Sci 6:9–20

Availability of data and materials

The material and data in this paper are obtained by software simulation and quoting other people’s experimental data.

Author information

Authors and Affiliations

Contributions

XZ analyzed and verified the usability and accuracy of the model. YC analyzed comparison of the cutting mechanism of different aluminum-based silicon carbide composites and the effect of silicon carbide particle size and distribution on the machining process. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

The research field of this article is the field of machining and does not involve any ethical issues (not applicable).

Consent to participate and consent for publication

All authors agree to contribute and publish articles. And the data of others in this article have been copyrighted.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Y., Zhang, X. Study on the cutting mechanism of SiCp/Al considering particle size and distribution. Int J Adv Manuf Technol 115, 1211–1225 (2021). https://doi.org/10.1007/s00170-021-07225-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07225-w