Abstract

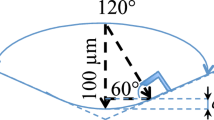

Microscratch test with a spherical indenter was carried out on copper under different tilt conditions and applied loads. Influence of surface slope and applied load on scratch responses such as friction coefficient, residual groove width, penetration depth was quantified by simple (e.g., linear, quadratic, and power-law) expressions. Apparent friction coefficient for non-tilt condition can be obtained by correcting the results measured for a prior known surface slope. Contact area is believed to be confined in the front side of the indenter with pile-up of material contributing to the horizontally projected area and a minor segment for the vertically projected area. The radius of spherical indenter can be calibrated on a reference material from residual groove width and penetration depth data.

Similar content being viewed by others

Data Availability

The data and material are available from the corresponding author on request via email: mingliuUK@gmail.com or mingliu@fzu.edu.cn.

References

Menezes, P.L., Kailas, S.V.: Effect of roughness parameter and grinding angle on coefficient of friction when sliding of Al–Mg alloy over EN8 steel. J. Tribol. 128, 10–14 (2006)

Zhang, X., Li, Z., Wang, J.: Friction prediction of rolling-sliding contact in mixed EHL. Measurement 100, 262–269 (2017)

Sabat, R.K., SuryaPavan, M.V., Aakash, D.S., Kumar, M., Sahoo, S.K.: Mechanism of texture and microstructure evolution during warm rolling of Ti–6Al–4V alloy. Philos. Mag. 98, 2562–2581 (2018)

Liu, C.S., Zheng, Z.Y., Wu, D.W., Ye, M.S., Gao, P., Peng, Y.G., et al.: Sliding friction and wear properties of CN X /TiN composite films. Tribol. Int. 37, 721–725 (2004)

Iliuc, I.: Wear and micropitting of steel ball sliding against TiN coated steel plate in dry and lubricated conditions. Tribol. Int. 39, 607–615 (2006)

Ceschini, L., Palombarini, G., Sambogna, G., Firrao, D., Scavino, G., Ubertalli, G.: Friction and wear behaviour of sintered steels submitted to sliding and abrasion tests. Tribol. Int. 39, 748–755 (2006)

Jianxin, D., Jianhua, L., Jinlong, Z., Wenlong, S., Ming, N.: Friction and wear behaviors of the PVD ZrN coated carbide in sliding wear tests and in machining processes. Wear 264, 298–307 (2008)

Archard, J.F.: Elastic deformation and the laws of friction. Procrsoclonda 24, 190–205 (1957)

Menezes, P.L., Kailas, S.V.: Effect of surface topography on friction and transfer layer during sliding. Tribology 3, 25–30 (2008)

Moore, M.A., King, F.S.: Abrasive wear of brittle solids. Wear 60, 123–140 (1980)

Hiratsuka, K., Enomoto, A., Sasada, T.: Friction and wear of Al2O3, ZrO2 and SiO2 rubbed against pure metals. Wear 153, 361–373 (1992)

Mokhtar, M.O.A., Zaki, M., Shawki, G.S.A.: Correlation between the frictional behaviour and the physical properties of metals. Wear 65, 29–34 (1980)

Yoon, E.S., Kong, H., Kwon, O.K., Oh, J.E.: Evaluation of frictional characteristics for a pin-on-disk apparatus with different dynamic parameters. Wear s 203–204, 341–349 (1997)

Liu, Y., Wang, W., Zhang, H., Zhao, Z.: Solution of temperature distribution under frictional heating with consideration of material inhomogeneity. Tribol. Int. 126, 80–96 (2018)

Udaykant Jadav, P., Amali, R., Adetoro, O.B.: Analytical friction model for sliding bodies with coupled longitudinal and transverse vibration. Tribol. Int. 126, 240–248 (2018)

Lafaye, S., Gauthier, C., Schirrer, R.: The ploughing friction: analytical model with elastic recovery for a conical tip with a blunted spherical extremity. Tribol. Lett. 21, 95–99 (2006)

Thakre, A.A., Singh, A.K.: Frictional study of the soft and hard solid interface using response surface methodology. J. Tribol. 140, 1601 (2018)

Zhang, N., Li, C., Lu, A., Chen, X., Liu, D., Zhu, E.: Experimental studies on the basic friction angle of planar rock surfaces by tilt test. J. Testing Eval. 47, 256–283 (2019)

Wu, J., Wu, G., Kou, X., Lu, Z., Zhang, G., Wu, Z.: Probing tribological behaviors of Cr-DLC in corrosion solution by tailoring sliding interface. Tribol. Lett. 68, 95 (2020)

Liu, M., Yang, F.: Finite element analysis of the indentation-induced delamination of Bi-layer structures. J. Comput. Theor. Nanosci. 9, 235–238 (2012)

Liu, M., Yang, F.: Three-dimensional finite element simulation of the Berkovich indentation of a transversely isotropic piezoelectric material: effect of material orientation. Modell Simul. Mater. Sci. Eng. 21, 045014 (2013)

Subhash, G., Zhang, W.: Investigation of the overall friction coefficient in single-pass scratch test. Wear 252, 123–134 (2002)

Liu, D., Wang, Q., Zhang, D., Wang, J., Zhang, X.: Torsional friction behavior of contact interface between PEEK and CoCrMo in calf serum. J. Tribol. 141, 011612 (2018)

Shi, H., Atkinson, M.: A friction effect in low-load hardness testing of copper and aluminium. J. Mater. Sci 25, 2111–2114 (1990)

Pelletier, H., Gauthier, C., Schirrer, R.: Influence of the friction coefficient on the contact geometry during scratch onto amorphous polymers. Wear 268, 1157–1169 (2010)

Zhan, J., Fard, M.: Effects of helix angle, mechanical errors, and coefficient of friction on the time-varying tooth-root stress of helical gears. Measurement 118, 135–146 (2018)

Niemczewska-Wójcik, M., Wójcik, A.: The machining process and multi-sensor measurements of the friction components of total hip joint prosthesis. Measurement 116, 56–67 (2018)

Nieminen, I., Andersson, P., Holmberg, K.: Friction measurement by using a scratch test method. Wear 130, 167–178 (1989)

Xie, Y., Hawthorne, H.M.: On the possibility of evaluating the resistance of materials to wear by ploughing using a scratch method. Wear 240, 65–71 (2000)

Jardret, V., Zahouani, H., Loubet, J.L., Mathia, T.G.: Understanding and quantification of elastic and plastic deformation during a scratch test. Wear 218, 8–14 (1998)

Liu, Z., Sun, J., Shen, W.: Study of plowing and friction at the surfaces of plastic deformed metals. Tribol. Int. 35, 511–522 (2002)

Kumar, A., Staedler, T., Jiang, X.: Effect of normal load and roughness on the nanoscale friction coefficient in the elastic and plastic contact regime. Beilstein J. Nanotechnol. 4, 66–71 (2013)

Bhushan, B., Kulkarni, A.V.: Effect of normal load on microscale friction measurements. Thin Solid Films 278, 49–56 (1996)

Dube, N.B., Hutchings, I.M.: Influence of particle fracture in the high-stress and low-stress abrasive wear of steel. Wears 233–235, 246–256 (1999)

Nahvi, S.M., Shipway, P.H., Mccartney, D.G.: Particle motion and modes of wear in the dry sand–rubber wheel abrasion test. Wear 267, 2083–2091 (2009)

Stevenson, A.N.J., Hutchings, I.M.: Development of the dry sand/rubber wheel abrasion test. Wear 195, 232–240 (1996)

Salah, N., Abdel-wahab, M.S., Habib, S.S., Khan, Z.H.: Lubricant additives based on carbon nanotubes produced from carbon-rich fly ash. Tribol. Trans. 60, 166–175 (2017)

Gao, C., Liu, M.: Effects of normal load on the coefficient of friction by microscratch test of copper with a spherical indenter. Tribol. Lett. 67, 8 (2019)

Maegawa, S., Itoigawa, F., Nakamura, T.: Effect of normal load on friction coefficient for sliding contact between rough rubber surface and rigid smooth plane. Tribol. Int. 92, 335–343 (2015)

Ghasemi, R., Johansson, J., Ståhl, J.-E., Jarfors, A.E.W.: Load effect on scratch micro-mechanisms of solution strengthened compacted graphite irons. Tribol. Int. 133, 182–192 (2019)

Riehm, P., Unrau, H.J., Gauterin, F.: A model based method to determine rubber friction data based on rubber sample measurements. Tribol. Int. 127, 37–46 (2018)

Yoshizumi, F., Tani, H., Sanda, S.: Simulation of the friction coefficient of paper-based wet clutch with wavy separators. J. Tribol. 141, 011702-011702–011713 (2018)

Tiwary, C.S., Prakash, J., Chakraborty, S., Mahapatra, D.R., Chattopadhyay, K.: Subsurface deformation studies of aluminium during wear and its theoretical understanding using molecular dynamics. Philos. Mag. 98, 2680–2700 (2018)

Jeon, S., Thundat, T., Braiman, Y.: Effect of normal vibration on friction in the atomic force microscopy experiment. Appl. Phys. Lett. 88, 214102-214102–214103 (2006)

Hu, Z.M., Dean, T.A.: A study of surface topography, friction and lubricants in metalforming. Int. J. Mach. Tools Manuf. 40, 1637–1649 (2000)

Zhang, H., Takeuchi, Y., Chong, W.W.F., Mitsuya, Y., Fukuzawa, K., Itoh, S.: Simultaneous in situ measurements of contact behavior and friction to understand the mechanism of lubrication with nanometer-thick liquid lubricant films. Tribol. Int. 127, 138–146 (2018)

Zhou, C., Hu, B., Qian, X., Han, X.: A novel prediction method for gear friction coefficients based on a computational inverse technique. Tribol. Int. 127, 200–208 (2018)

Wang, J., Ma, L., Li, W., Zhou, Z.: Influence of different lubricating fluids on friction trauma of small intestine during enteroscopy. Tribol. Int. 126, 29–38 (2018)

Chun, L., Zhongyi, M., Fubao, Z., Chen, K., Haiyang, Y.: The wear and friction characters of polycrystalline diamond under wetting conditions. J. Tribol. 141, 021607 (2018)

Alakhramsing, S.S., de Rooij, M.B., Akchurin, A., Schipper, D.J., van Drogen, M.: A mixed-TEHL analysis of cam-roller contacts considering roller slip: on the influence of roller-pin contact friction. J. Tribol. 141, 011503-011503–011515 (2018)

AhmedAli, M.K., Xianjun, H., Essa, F.A., Abdelkareem, M.A.A., Elagouz, A., Sharshir, S.W.: Friction and wear reduction mechanisms of the reciprocating contact interfaces using nanolubricant under different loads and speeds. J. Tribol. 140, 051606-051606–051610 (2018)

Cozza, R.C.: Influence of the normal force, abrasive slurry concentration and abrasive wear modes on the coefficient of friction in ball-cratering wear tests. Tribol. Int. 70, 52–62 (2014)

Li, D., Liu, Y., Deng, Y., Fang, M., Wu, D.: The effect of different temperatures on friction and wear properties of CFRPEEK against AlSi 431 steel under water lubrication. Tribol. Trans. 61, 357–366 (2018)

Kato, K.: Wear in relation to friction—a review. Wear 241, 151–157 (2000)

Rymuza, Z.: Energy concept of the coefficient of friction. Wear 199, 187–196 (1996)

Hartung, F., Kienle, R., Götz, T., Winkler, T., Ressel, W., Eckstein, L., et al.: Numerical determination of hysteresis friction on different length scales and comparison to experiments. Tribol. Int. 127, 165–176 (2018)

Saravanan, P., Selyanchyn, R., Watanabe, M., Fujikawa, S., Tanaka, H., Lyth, S.M., et al.: Ultra-low friction of polyethylenimine/molybdenum disulfide (PEI/MoS2)15 thin films in dry nitrogen atmosphere and the effect of heat treatment. Tribol. Int. 127(255), 263 (2018)

Menezes, P.L., Kishore Kailas, S.V., Bobji, M.S.: Influence of tilt angle of plate on friction and transfer layer—A study of aluminium pin sliding against steel plate. Tribol. Int. 43, 897–905 (2010)

Staph, H.E., Ku, P.M., Carper, H.J.: Effect of surface roughness and surface texture on scuffing. Mech. Mach. Theory 8, 197–208 (1973)

Lakshmipathy, R., Sagar, R.: Effect of die surface topography on die-work interfacial friction in open die forging. Int. J. Mach. Tools Manuf. 32, 685–693 (1992)

Menezes, P.L., KishoreKailas, S.V.: Studies on friction and transfer layer using inclined scratch. Tribol. Int. 39, 175–183 (2006)

Määttä, A., Vuoristo, P., Mäntylä, T.: Friction and adhesion of stainless steel strip against tool steels in unlubricated sliding with high contact load. Tribol. Int. 34, 779–786 (2001)

Malayappan, S., Narayanasamy, R.: An experimental analysis of upset forging of aluminium cylindrical billets considering the dissimilar frictional conditions at flat die surfaces. Int. J. Adv. Manuf. Technol. 23, 636–643 (2004)

Wakuda, M., Yamauchi, Y., Kanzaki, S., Yasuda, Y.: Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 254, 356–363 (2003)

Tripathi, K., Gyawali, G., Amanov, A., Lee, S.W.: Synergy effect of ultrasonic nanocrystalline surface modification and laser surface texturing on friction and wear behavior of graphite cast iron. Tribol. Trans. 60, 226–237 (2017)

Seo, N.J., Armstrong, T.J.: Friction coefficients in a longitudinal direction between the finger pad and selected materials for different normal forces and curvatures. Ergonomics 52, 609–616 (2009)

Gao, C., Yao, L., Liu, M.: Measurement of sample tilt by residual imprint morphology of Berkovich indenter. J. Testing Eval. 48, 4 (2020)

Sinha, S.K., Lim, D.B.J.: Effects of normal load on single-pass scratching of polymer surfaces. Wear 260, 751–765 (2006)

Feng, B.: Tribology behavior on scratch tests: Effects of yield strength. Friction 5, 108–114 (2017)

Gong, F., Guo, B.: Effects of influencing factors on friction coefficient in microsheet forming. Mater. Res. Innovations 17, 7–11 (2013)

Xu, M., Li, L., Wang, M., Luo, B.: Effects of surface roughness and wood grain on the friction coefficient of wooden materials for wood-wood frictional pair. Tribol. Trans. 57, 871–878 (2014)

Han, L., Zhang, D.-W., Wang, F.-J.: Predicting film parameter and friction coefficient for helical gears considering surface roughness and load variation. Tribol. Trans. 56, 49–57 (2013)

Gao, C., Proudhon, H., Liu, M.: Three-dimensional finite element analysis of shallow indentation of rough strain-hardening surface. Friction 7, 587–602 (2019)

Jiang, H., Browning, R., Fincher, J., Gasbarro, A., Jones, S., Sue, H.-J.: Influence of surface roughness and contact load on friction coefficient and scratch behavior of thermoplastic olefins. Appl. Surf. Sci. 254, 4494–4499 (2008)

Menezes, P.L., Kishore Kailas, S.V.: Studies on friction and transfer layer: role of surface texture. Tribol. Lett. 24, 265–273 (2006)

Torrance, A.A.: Using profilometry for the quantitative assessment of tribological function: PC-based software for friction and wear prediction. Wear 181–183, 397–404 (1995)

Bhushan, B., Nosonovsky, M.: Scale effects in dry and wet friction, wear, and interface temperature. Nanotechnology 15, 749 (2004)

Gao, C., Yao, L., Zheng, R., Liu, M.: Effect of sample tilt on spherical indentation of an elastic solid. J. Test. Eval. 47, 2596–2612 (2019)

Black, A.J., Kopalinsky, E.M., Oxley, P.L.B.: An investigation of the different regimes of deformation which can occur when a hard wedge slides over a soft surface: the influence of wedge angle, lubrication and prior plastic working of the surface. Wear 123, 97–114 (1988)

Pondicherry, K., Rajaraman, D., Galle, T., Hertelé, S., Fauconnier, D., De Baets, P.: Optimization and validation of a load-controlled numerical model for single asperity scratch. Tribol. Lett. 68, 45 (2020)

Maas, P., Mizumoto, Y., Kakinuma, Y., Min, S.: Anisotropic brittle-ductile transition of monocrystalline sapphire during orthogonal cutting and nanoindentation experiments. Nanotechnol. Precis Eng. 1, 157–171 (2018)

Tseng, A.A.: A comparison study of scratch and wear properties using atomic force microscopy. Appl Surf Sci 256, 4246–4252 (2010)

(!!! INVALID CITATION !!! [63–66]).

Ranjan, P., Balasubramaniam, R., Jain, V.K.: Investigations into the mechanism of material removal and surface modification at atomic scale on stainless steel using molecular dynamics simulation. Phil. Mag. 98, 1437–1469 (2018)

Liu, M., Li, S., Gao, C.: Fracture toughness measurement by micro-scratch tests with conical indenter. Tribology 39, 556–564 (2019)

Tabor, A.: The physical meaning of indentation and scratch hardness. Br. J. Appl. Phys. 7, 159–166 (1956)

Williams, J.A.: Analytical models of scratch hardness. Tribol. Int. 29, 675–694 (1996)

Huang, L., Xu, K., Lu, J., Guelorget, B., Chen, H.: Nano-scratch and fretting wear study of DLC coatings for biomedical application. Diam. Relat. Mater. 10, 1448–1456 (2001)

Wu, T.W.: Microscratch and load relaxation tests for ultra-thin films. J Mater Res 6, 407–426 (1991)

Venkataraman, S., Kohlstedt, D.L., Gerberich, W.W.: Microscratch analysis of the work of adhesion for Pt thin films on NiO. J. Mater. Res. 7, 1126–1132 (1992)

Li, X., Bhushan, B.: Micro/nanomechanical and tribological characterization of ultrathin amorphous carbon coatings. J. Mater. Res. 14, 2328–2337 (1999)

Yan, J., Lindo, A., Schwaiger, R., Hodge, A.M.: Sliding wear behavior of fully nanotwinned Cu alloys. Friction 7, 260–267 (2018)

Wei, Y., Nixon, W., Shi, Z.: Evaluation of wear resistance of snow plow blade cutting edges using the scratch test method. J. Test. Eval. 26, 527–531 (1998)

Yazdi, R., Ghasemi, H.M., Abedini, M., Wang, C., Neville, A.: Oxygen diffusion layer on Ti–6Al–4V alloy: scratch and dry wear resistance. Tribol. Lett. 67, 101 (2019)

Sakamoto, T., Tsukizoe, T.: Friction and prow formation in a scratch process of copper by a diamond cone. Wear 44, 393–403 (1977)

Zhang, F., Meng, B., Geng, Y., Zhang, Y., Li, Z.: Friction behavior in nanoscratching of reaction bonded silicon carbide ceramic with Berkovich and sphere indenters. Tribol. Int. 97, 21–30 (2016)

Wo, P.C., Ngan, A.H.W.: Incipient plasticity during nano-scratch in Ni3Al. Philos. Mag. 84, 3145–3157 (2004)

Deng, H., Scharf, T.W., Barnard, J.A.: Adhesion assessment of silicon carbide, carbon, and carbon nitride ultrathin overcoats by nanoscratch techniques. J. Appl. Phys. 81, 5396–5398 (1997)

Burnett, P.J., Rickerby, D.S.: The scratch adhesion test: an elastic-plastic indentation analysis. Thin Solid Films 157, 233–254 (1988)

Sekler, J., Steinmann, P.A., Hintermann, H.E.: The scratch test: different critical load determination techniques. Surf. Coat Technol. 36, 519–529 (1988)

Staia, M.H., Puchi, E.S., Schmutz, C.J.: Adhesion of CVD tin on 316l surgical stainless steel obtained in a mass transfer regime. J. Electron. Mater. 26, 980–986 (1997)

Palesch, E., Cech, V.: Characterization of interlayer adhesion on single glass fibers and planar glass using the nanoscratch test technique. Thin Solid Films 636, 353–358 (2017)

Xu, K., Hu, N., He, J.: Evaluation of the bond strength of hard coatings by the contact fatigue test. J. Adhes. Sci. Technol. 12, 1055–1069 (1998)

Fischer-Cripps, A.C.: Nanoindentation. Springer, New York (2004)

Liu, M., Zhu, G., Dong, X., Liao, J., Gao, C.: Effects of sample tilt on vickers indentation hardness. In: Yao, L., Zhong, S., Kukuta, H., Juang, J.G. (eds.) Advanced Mechanical Science and Technology for the Industrial Revolution 40 FZU 2016, pp. 271–283. Springer, New York (2018)

Xu, Z.H., Li, X.: Effect of sample tilt on nanoindentation behaviour of materials. Philos. Mag. 87, 2299–2312 (2007)

Kashani, M.S., Madhavan, V.: Analysis and correction of the effect of sample tilt on results of nanoindentation. Acta Mater. 59, 883–895 (2011)

Huang, H., Zhao, H., Shi, C., Zhang, L.: Using residual indent morphology to measure the tilt between the triangular pyramid indenter and the sample surface. Meas. Sci. Technol. 24, 105602–105607 (2013)

Shi, C., Zhao, H., Huang, H., Xu, L., Ren, L., Bai, M., et al.: Effects of indenter tilt on nanoindentation results of fused silica: an investigation by finite element analysis. Mater. Trans. 54, 958–963 (2013)

Shi, C., Zhao, H., Huang, H., Wan, S., Ma, Z., Geng, C., et al.: Effects of probe tilt on nanoscratch results: an investigation by finite element analysis. Tribol. Int. 60, 64–69 (2013)

Huang, L.Y., Xu, K.W., Lu, J.: Evaluation of scratch resistance of diamond-like carbon films on Ti alloy substrate by nano-scratch technique. Diam. Relat. Mater. 11, 1505–1510 (2002)

Charitidis, C., Logothetidis, S., Gioti, M.: A comparative study of the nanoscratching behavior of amorphous carbon films grown under various deposition conditions. Surf. Coat. Technol. 125, 201–206 (2000)

Zhang, D., Sun, Y., Gao, C., Liu, M.: Measurement of fracture toughness of copper via constant-load microscratch with a spherical indenter. Wear 444–445, 203158 (2020)

Gao, C., Liu, M.: Effect of sample tilt on measurement of friction coefficient by constant-load scratch testing of copper with a spherical indenter. J. Test. Eval. 48, 20180719 (2020)

Liu, M., Wu, J., Cao, C.: Sliding of a diamond sphere on K9 glass under prograssive load. J. Non-Cryst. Solid 526, 119711 (2019)

Akono, A.T., Randall, N.X., Ulm, F.J.: Experimental determination of the fracture toughness via microscratch tests: application to polymers, ceramics, and metals. J. Mater. Res. 27, 485–493 (2012)

Mcadams, S.D., Tsui, T.Y., Oliver, W.C., Pharr, G.M.: Effects of interlayers on the scratch adhesion performance of ultra-thin films of copper and gold on silicon substrates. MRS Online Proc. Library Arch. 356, 1 (1994)

Liu, M., Huang, C., Gao, C.: Effect of sample tilt and normal load on micro-scratch test of copper with a spherical indenter. Tribology 41, 27–37 (2021)

Gao, C., Liu, M.: Effects of normal load on the coefficient of friction by microscratch test of copper with a spherical indenter. Tribol. Lett. 67, 1–12 (2019)

Scharf, T.W., Barnard, J.A.: Nanotribology of ultrathin a:SiC/SiC-N overcoats using a depth sensing nanoindentation multiple sliding technique. Thin Solid Films 308, 340–344 (1997)

Li, K., Yuhong, B., Li, J.: Stick-slip in the scratching of styrene-acrylonitrile copolymer. J. Mater. Res. 11, 1574–1580 (1996)

Byerlee, J.D.: The mechanics of stick-slip. Tectnonophysics 9, 475–486 (1970)

Zhang, J., Wei, Y., Sun, T., Hartmaier, A., Yan, Y., Li, X.: Twin boundary spacing-dependent friction in nanotwinned copper. Phys. Rev. B 85, 054109 (2012)

Wo, P.C., Jones, I.P., Ngan, A.H.W.: TEM study of the deformation structures around nano-scratches. Phil. Mag. 88, 1369–1388 (2008)

Li, K., Shapiro, Y., Li, J.C.M.: Scratch test of soda-lime glass. Acta Mater. 46, 5569–5578 (1998)

Yamaguchi, T., Sugawara, T., Takahashi, M., Shibata, K., Moriyasu, K., Nishiwaki, T., et al.: Dry sliding friction of ethylene vinyl acetate blocks: effect of the porosity. Tribol. Int. 116, 264–271 (2017)

Almotasem, A.T., Bergström, J., Gåård, A., Krakhmalev, P., Holleboom, L.J.: Atomistic insights on the wear/friction behavior of nanocrystalline ferrite during nanoscratching as revealed by molecular dynamics. Tribol. Lett. 65, 101 (2017)

Lafaye, S., Gauthier, C., Schirrer, R.: A surface flow line model of a scratching tip: apparent and true local friction coefficients. Tribol. Int. 38, 113–127 (2005)

Flores, S.E., Pontin, M.G., Zok, F.W.: Scratching of elastic/plastic materials with hard spherical indenters. J. Appl. Mech. 75, 1055–1062 (2008)

Zhao, G., Liu, M., An, Z., Ren, Y., Liaw, P.K., Yang, F.: Electromechanical responses of Cu strips. J. Appl. Phys. 113, 183521 (2013)

Bowden, F.P., Tabor, D.: The friction and lubrication of solids. Clarendon (1950)

Xiao, J.-K., Zhang, L., Zhou, K.-C., Wang, X.-P.: Microscratch behavior of copper–graphite composites. Tribol. Int. 57, 38–45 (2013)

Carreon, A.H., Funkenbusch, P.D. Material specific nanoscratch ploughing friction coefficient. Tribol. Int. (2018).

Beegan, D., Chowdhury, S., Laugier, M.T.: Comparison between nanoindentation and scratch test hardness (scratch hardness) values of copper thin films on oxidised silicon substrates. Surf. Coat. Technol. 201, 5804–5808 (2007)

Cheng, Y.-T., Cheng, C.-M.: Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng. R 44, 91–149 (2004)

Vander, V.G.F., Lucas, G.M.: Micro-indentation Hardness Testing. Butterworths Scientific (1956)

Kese, K.O., Li, Z.C., Bergman, B.: Method to account for true contact area in soda-lime glass during nanoindentation with the Berkovich tip. Mater. Sci. Eng. A 404, 1–8 (2005)

Kese, K., Li, Z.C.: Semi-ellipse method for accounting for the pile-up contact area during nanoindentation with the Berkovich indenter. Scr. Mater. 55, 699–702 (2006)

Yan, Y.D., Sun, T., Dong, S.: Study on effects of tip geometry on AFM nanoscratching tests. Wear 262, 477–483 (2007)

Bucaille, J.L., Felder, E., Hochstetter, G.: Mechanical analysis of the scratch test on elastic and perfectly plastic materials with the three-dimensional finite element modeling. Wear 249, 422–432 (2001)

Kareer, A., Hou, X.D., Jennett, N.M., Hainsworth, S.V.: The existence of a lateral size effect and the relationship between indentation and scratch hardness in copper. Philos. Mag. 96, 3396–3413 (2016)

Kareer, A., Hou, X.D., Jennett, N.M., Hainsworth, S.V.: The interaction between Lateral size effect and grain size when scratching polycrystalline copper using a Berkovich indenter. Philos. Mag. 96, 3414–3429 (2016)

Liu, C., Liu, W., Xing, W.: An improved edge-based level set method combining local regional fitting information for noisy image segmentation. Signal Process. 130, 12–21 (2017)

Wu, Y., Song, Y., Zhou, H.: Edge detection of combustion flame images based on anisotropic mathematical morphology. Yi Qi Yi Biao Xue Bao/Chin. J. Sci. Instrum. 34, 1818–1825 (2013)

Liu, H., Zhao, M., Lu, C., Zhang, J.: Characterization on the yield stress and interfacial coefficient of friction of glasses from scratch tests. Ceram. Int. (2019).

Useinov, A.S., Useinov, S.S.: Scratch hardness evaluation with in-situ pile-up effect estimation. Philos. Mag. 92, 3188–3198 (2012)

Acknowledgements

This project is supported by the National Natural Science Foundation of China (Grant No. 51705082), Engineering Research Centre for CAD/CAM of Fujian Provincial Colleges and Universities (Grant No. K201705), Development Center of Scientific and Educational Park of Fuzhou University in the city of Jinjiang (Grant No. 2019-JJFDKY-11), and Fuzhou University Testing Fund of precious apparatus (Grant No. 2020T017).

Funding

National Natural Science Foundation of China (Grant No. 51705082), Engineering Research Centre for CAD/CAM of Fujian Provincial Colleges and Universities (Grant No. K201705), Development Center of Scientific and Educational Park of Fuzhou University in the city of Jinjiang (No. 2019-JJFDKY-11), and Fuzhou University Testing Fund of precious apparatus (Grant No. 2020T017).

Author information

Authors and Affiliations

Contributions

The sole author M.L. carried out all the work.

Corresponding author

Ethics declarations

Conflict of interest

The author declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, M. Influence of Sample Tilt and Applied Load on Microscratch Behavior of Copper Under a Spherical Diamond Indenter. Tribol Lett 69, 88 (2021). https://doi.org/10.1007/s11249-021-01466-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-021-01466-2